Overheated alarm for electrical equipment heating

A technology of electrical equipment and alarms, applied in alarms, instruments, visible signal devices, etc., can solve problems such as enterprise losses, high prices, inaccurate temperature measurement, etc., to reduce power failure accidents or equipment damage accidents, and reduce accidents Incidence, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

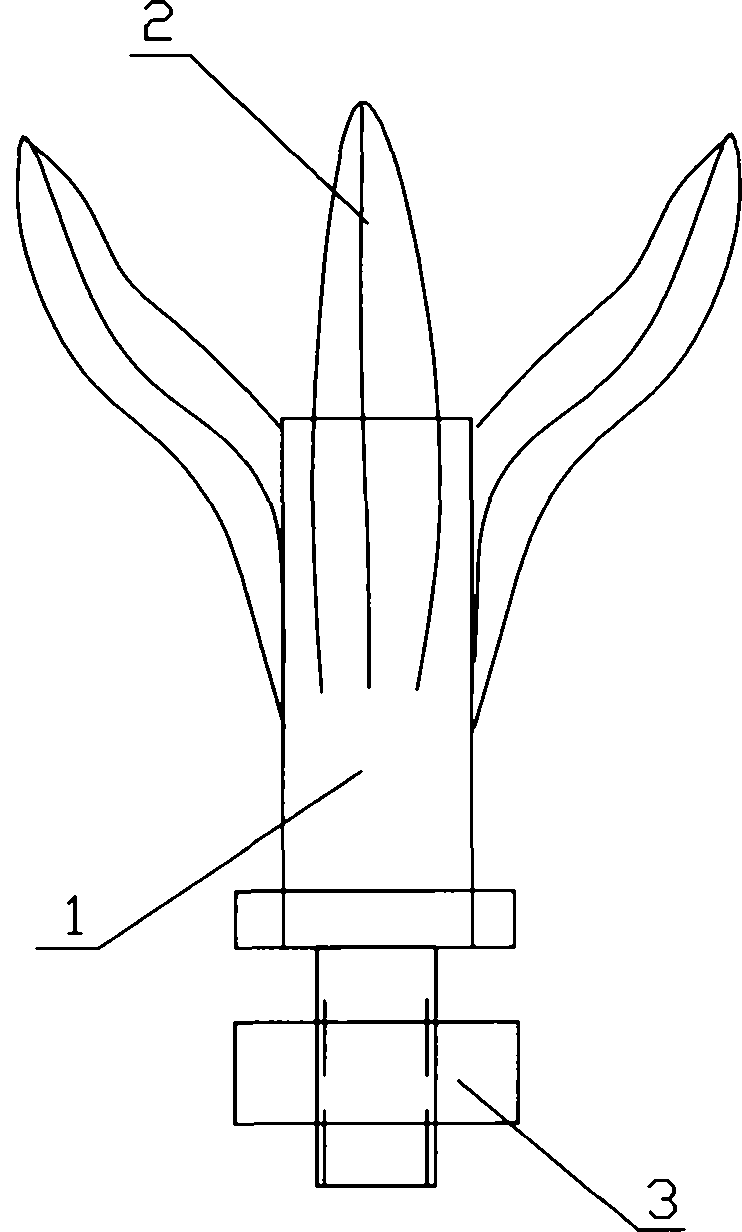

[0010] like figure 1 Shown: an electrical equipment overheating alarm, including a fixed heat-conducting rod 1 with a connecting mechanism, the fixed heat-conducting rod 1 is provided with a polygonal petal-shaped bimetal 2, and the fixed heat-conducting rod 1 is connected to the connecting mechanism 3. on the electrical equipment. The bimetallic sheets include nickel-titanium metal, Cu-Zn, Au-Cu or three-layer metal sheets such as CuZnAL and CuALNi metal materials, which are characterized by large bending amount, high plasticity, and recovery of the previous shape above the memory temperature. The connection mechanism 3 is a bolt connection mechanism. An alarm pigment layer is arranged on the bimetallic sheet 2 . When the electrical setting temperature rises to a certain value, the fixed heat-conducting rod connected to the electrical equipment conducts heat to the bi-metal sheet, the bi-metal sheet deforms from small to large, and the alarm pigment layer is displayed outsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com