System for measuring outer surface temperature of metal shell of air-flow bed reactor

A metal shell, temperature measurement technology, applied in thermometers, measuring devices, measuring heat and other directions, can solve problems such as difficulty in ensuring the safe operation of the entrained fluid bed reactor, inability to continuously detect the entrained fluid bed reactor in real time, and increasing the labor intensity of operators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

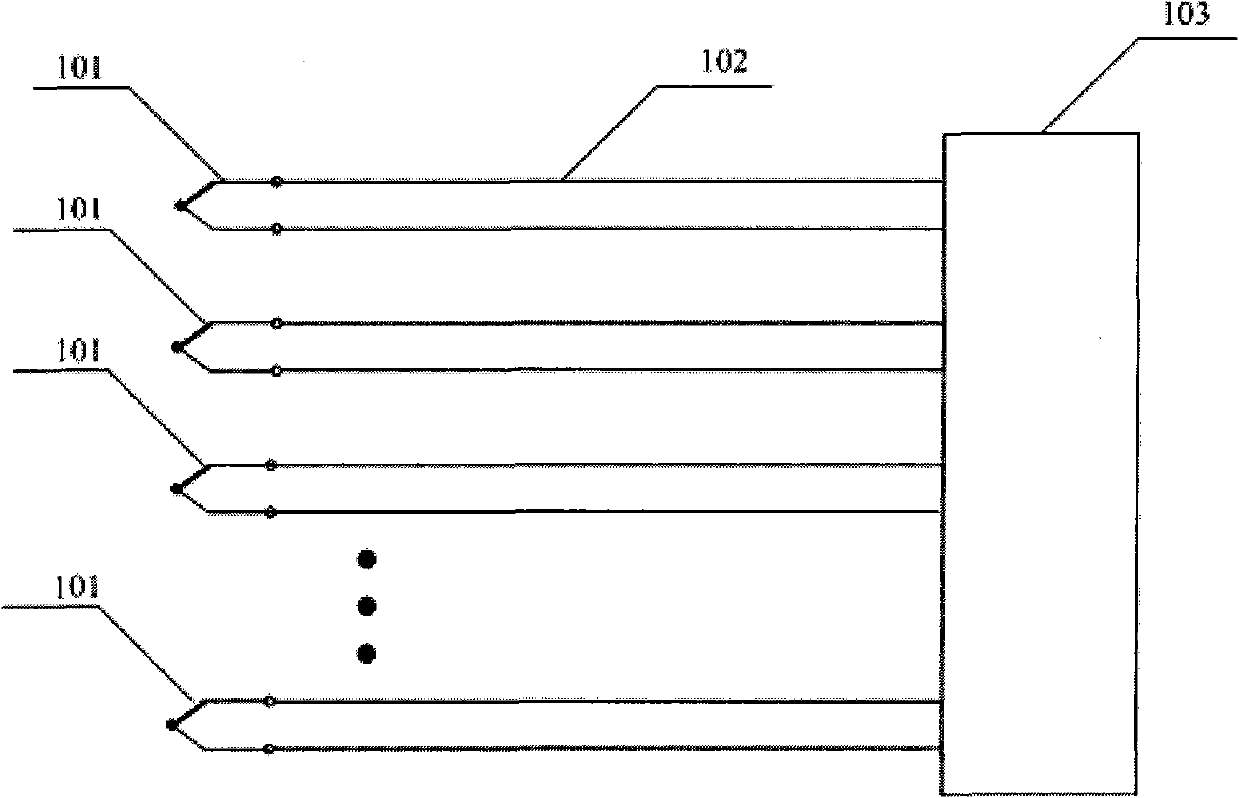

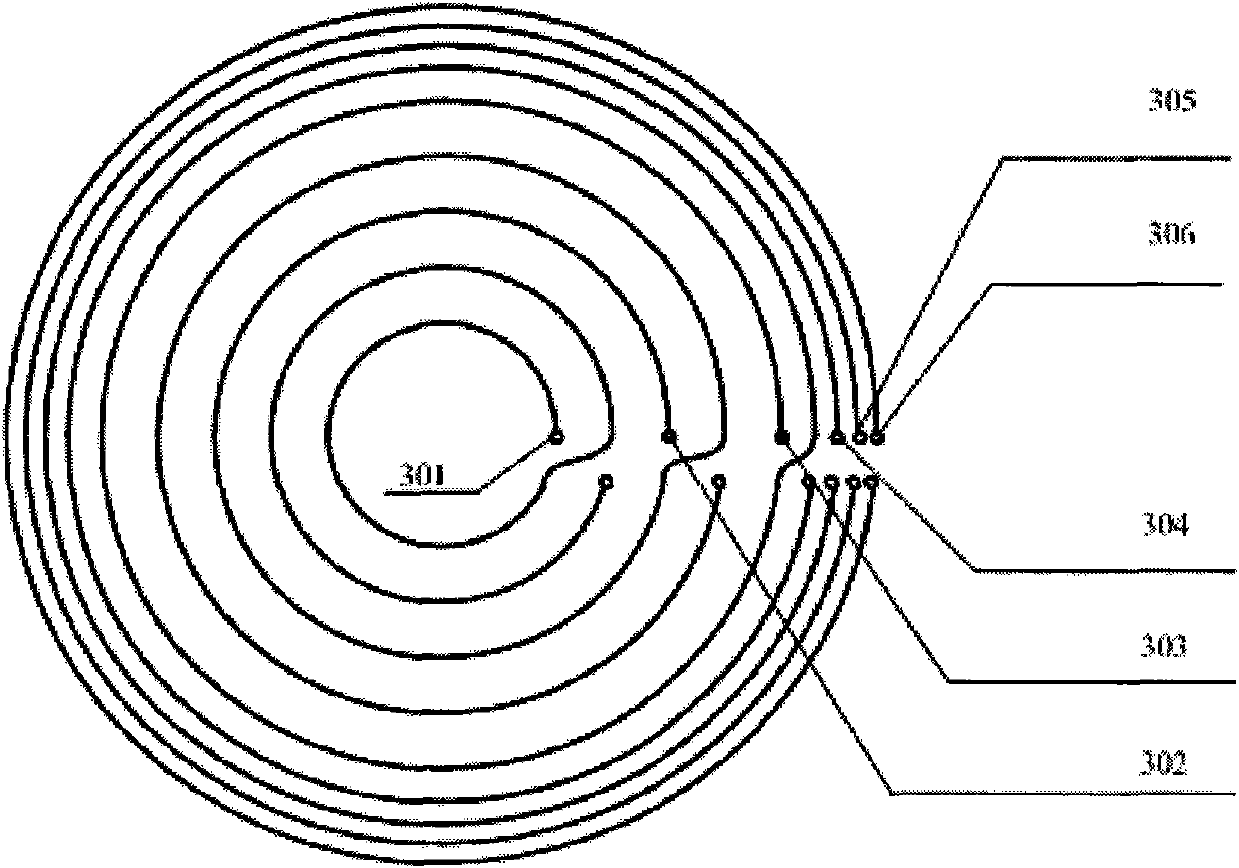

[0054] Using Henan Yima coal as raw material, the entrained bed reactor with a single reactor daily processing capacity of 900 tons of coal has a combustion chamber shell diameter of 2800 mm, an operating pressure of 6.5 MPa, and an operating temperature of 1380 °C. In this embodiment, the temperature measurement system for the outer surface of the metal shell of the entrained bed reactor adopts figure 1 The temperature measurement system is shown. The outer surface of the entrained bed reactor is divided into 22 temperature measurement areas, of which the outer surface of the dome is divided into 6 temperature measurement areas, the outer surface of the upper section of the cylinder is divided into 8 temperature measurement areas, and the outer surface of the lower section of the cylinder is divided into 8 temperature measurement zones. In the temperature measuring area on the outer surface of the dome of the entrained bed reactor, press image 3 Install armored cable therm...

Embodiment 2

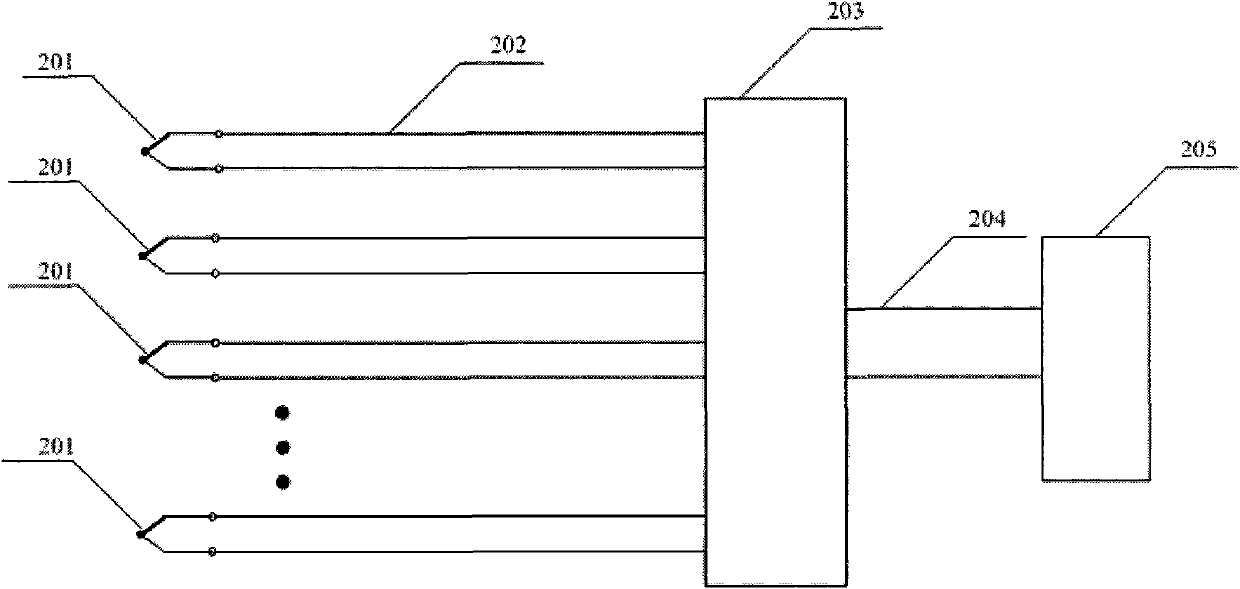

[0069] In a domestic production facility with an annual output of 160,000 tons of synthetic oil, the shell diameter of the entrained bed reactor combustion chamber is 3200 mm, the operating pressure is 4.0 MPa, and the operating temperature is 1340 °C. The outer surface temperature measurement system of the metal shell of the entrained bed reactor adopts figure 2 Shown is the outer surface temperature measurement system of the metal shell of the entrained bed reactor. In this embodiment, the outer surface of the metal casing of the entrained bed reactor combustion chamber is divided into 28 temperature measurement areas, of which the outer surface of the vault is divided into 8 temperature measurement areas, and the outer surface of the upper section of the cylinder is divided into 10 temperature measurement areas. Temperature zone, the outer surface of the lower section of the cylinder is divided into 10 temperature measurement zones. Armored thermocouples are arranged in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com