Patents

Literature

30results about How to "Simple on-site commissioning process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal power generating unit coal feed amount control method based on frequency modulation and peak regulation of power grid

ActiveCN104238494AGuaranteed stabilityMeet the requirements of FM and peak shavingTotal factory controlProgramme total factory controlThermodynamicsControl system

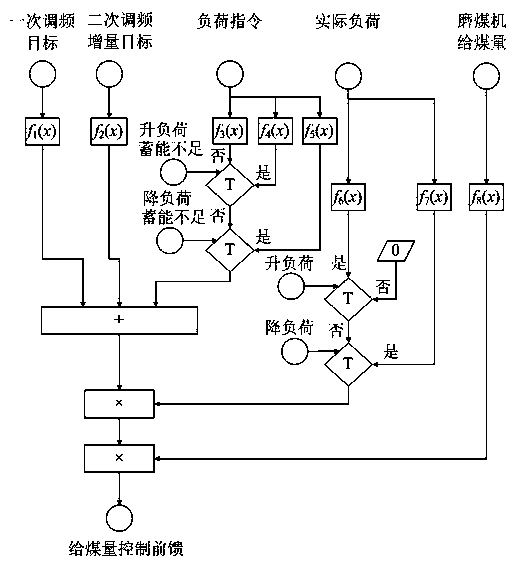

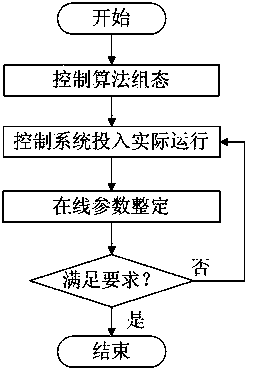

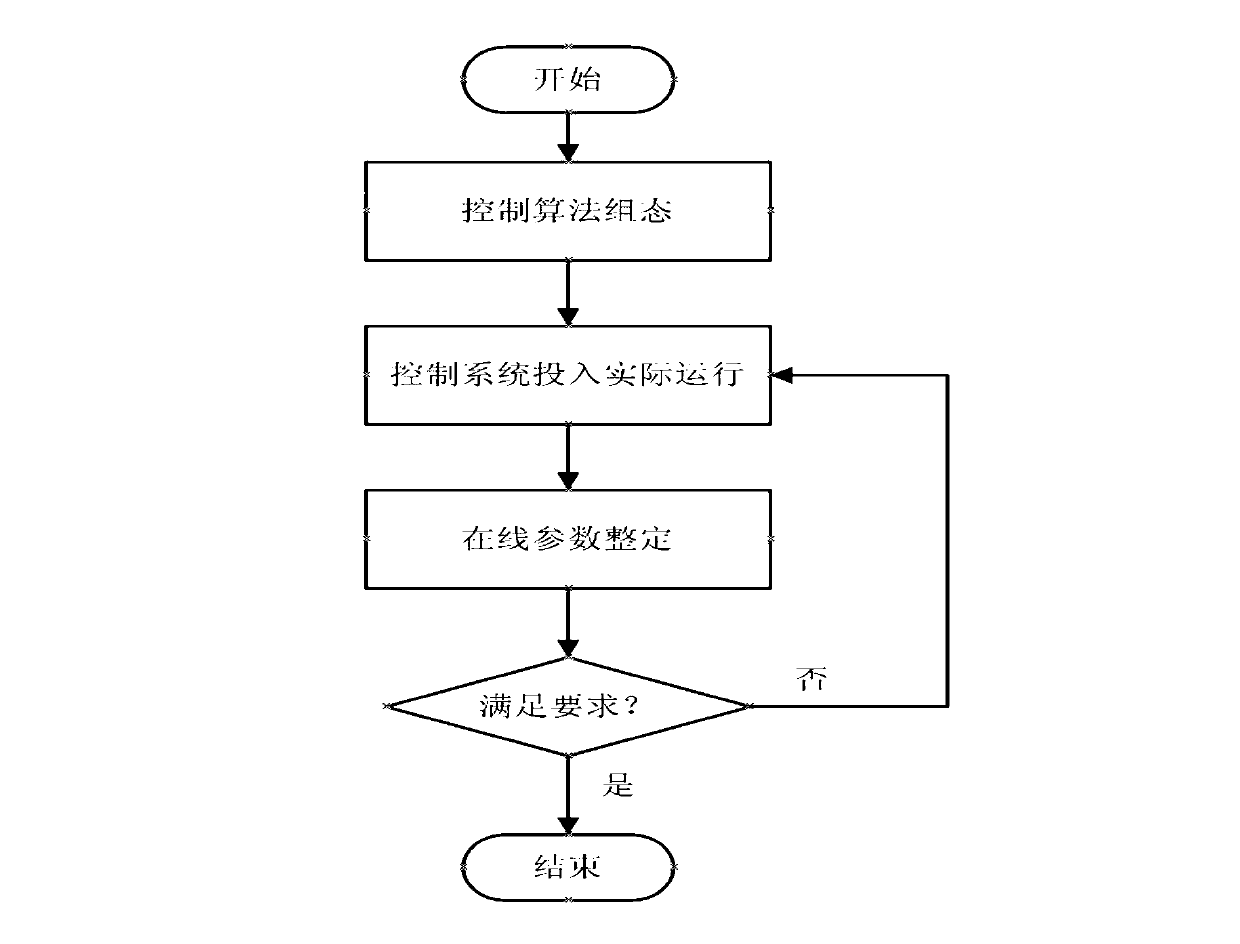

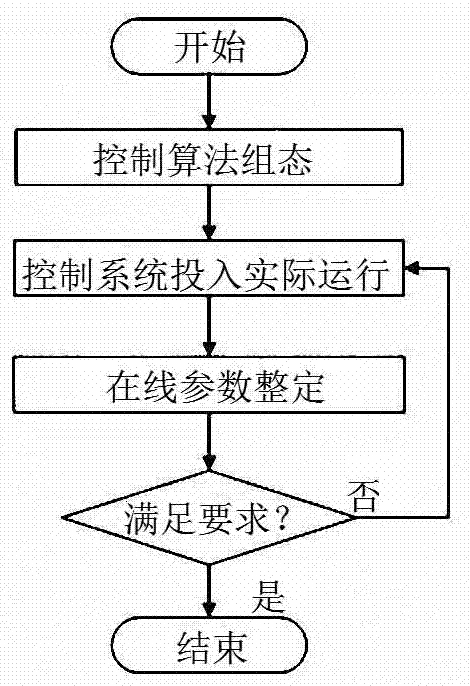

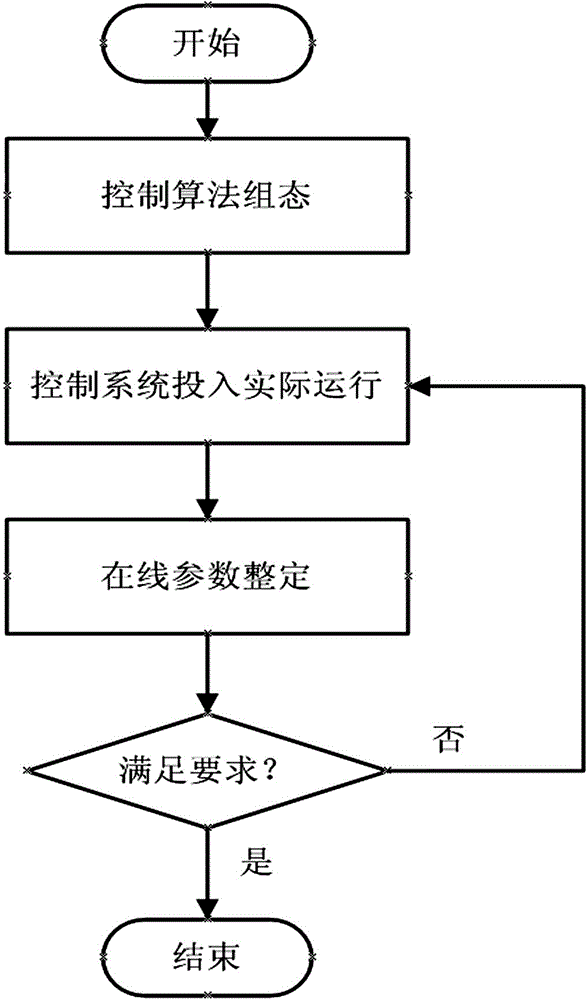

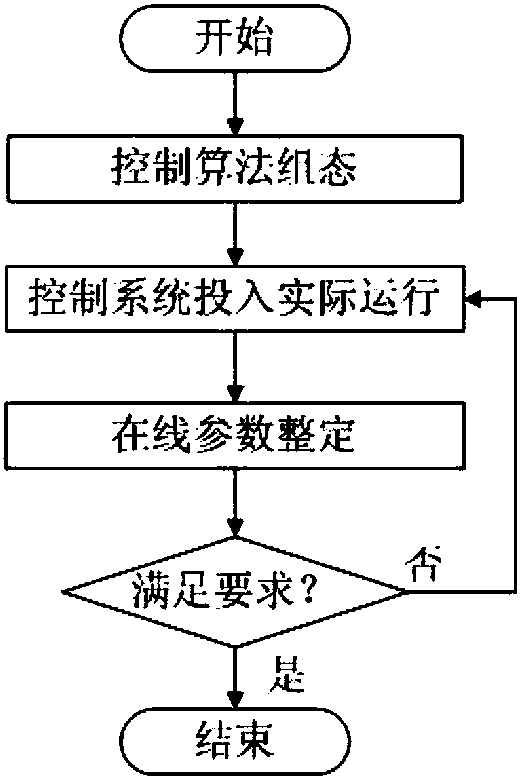

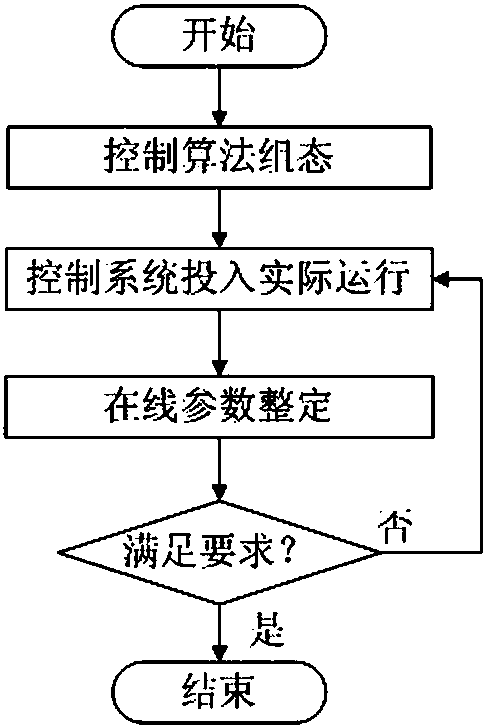

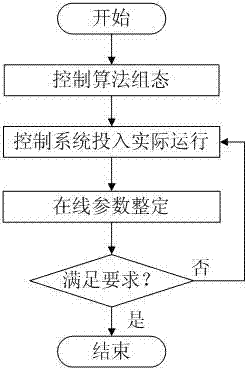

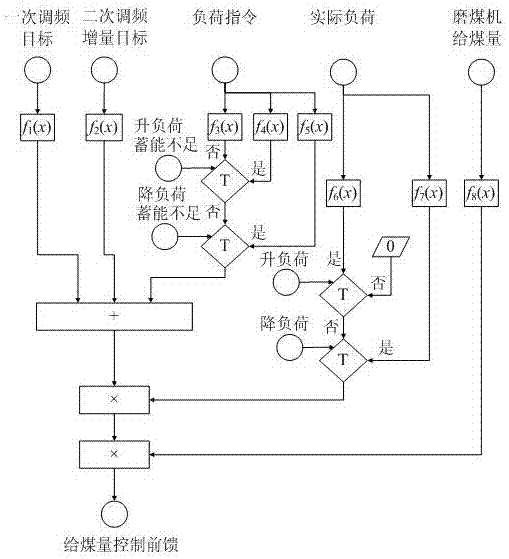

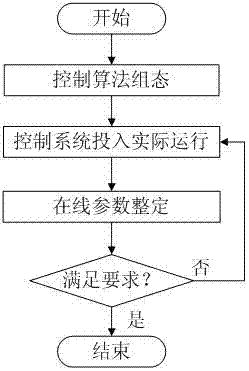

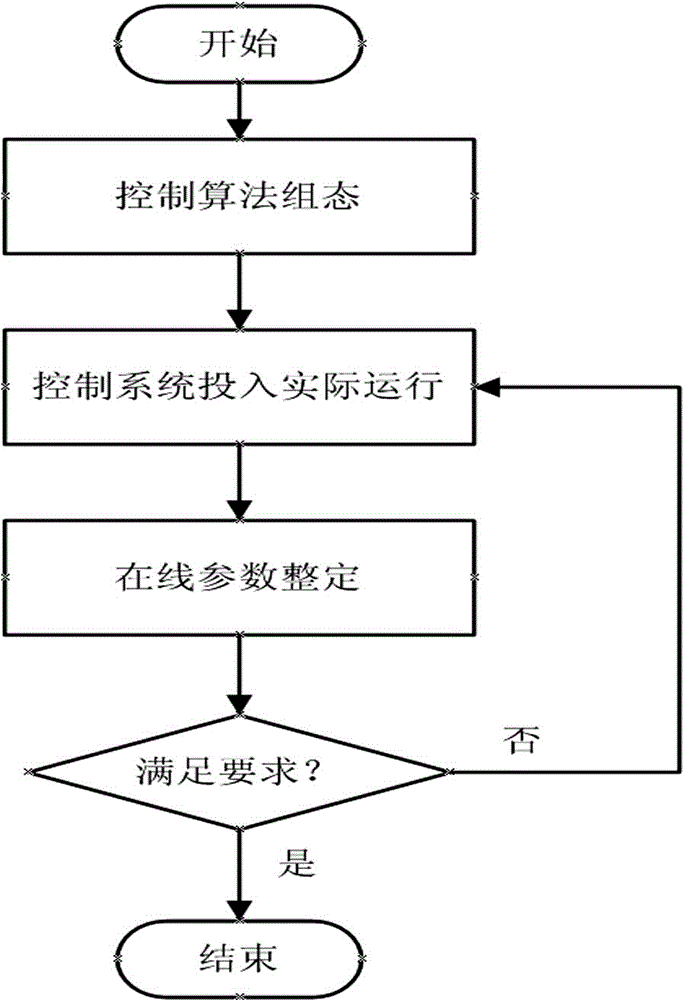

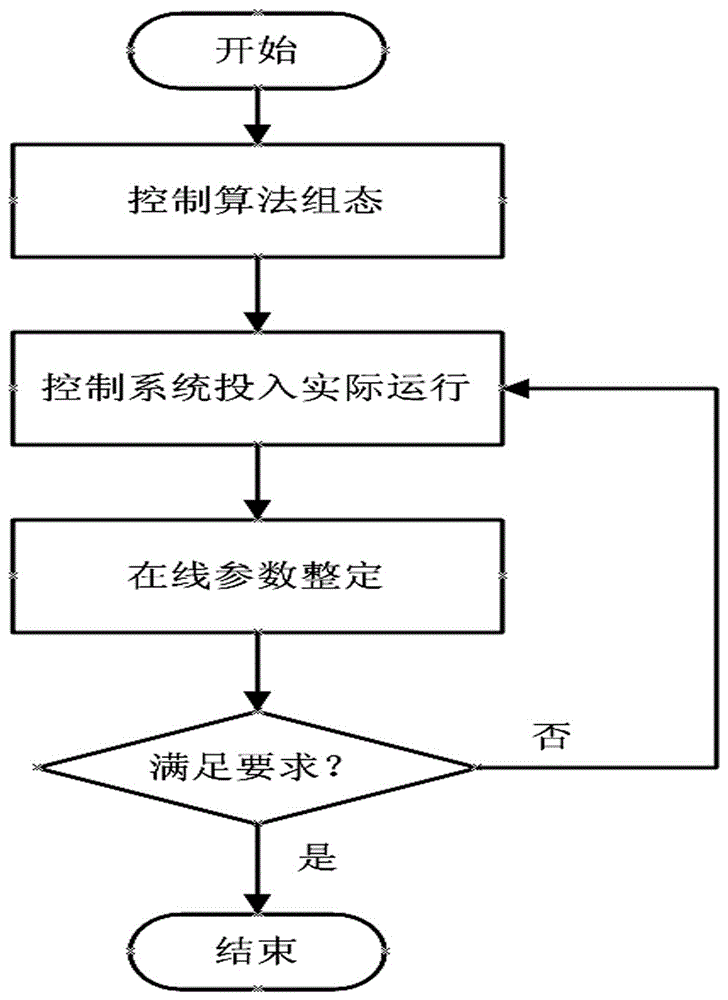

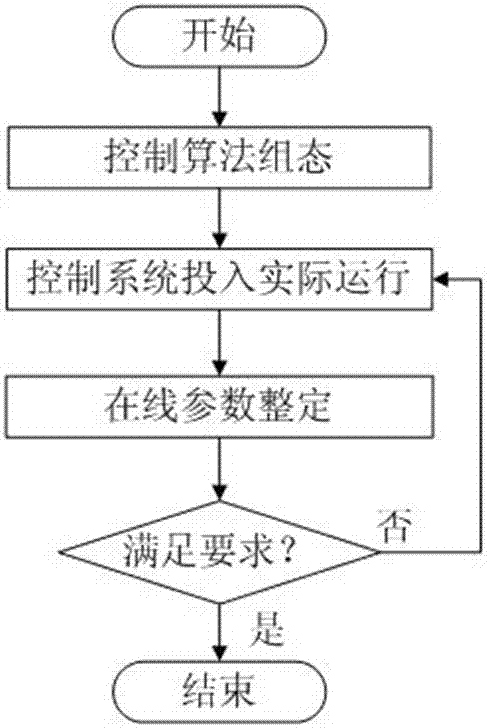

The invention relates to a thermal power generating unit coal feed amount control method based on frequency modulation and peak regulation of a power grid. The method includes the following steps that a thermal power generating unit coal feed amount control loop interface based on frequency modulation and peak regulation of the power grid is added to a logical configuration coal feed amount control loop of an original coordination control system; logical configuration of a thermal power generating unit coal feed amount control loop based on frequency modulation and peak regulation of the power grid is carried out, and output of the logical configuration of the thermal power generating unit coal feed amount control loop based on frequency modulation is introduced to the thermal power generating unit coal feed amount control loop interface based on frequency modulation and peak regulation of the power grid to serve as feedforward signals for controlling the coal feed amount; the control system is put into actual operation, according to the real-time operation curve, relevant parameters of the thermal power generating unit coal feed amount control loop based on frequency modulation and peak regulation of the power grid are set online, and finally the expected control effect is achieved. By means of the existing DCS coordination control system, the real time performance is good, the on-site debugging process is simple, and project realization is facilitated. By judging the operating state of the unit, the coal feed amounts of the unit in different operation states are accurately controlled, fast load response of the unit participating in frequency modulation and peak regulation and the stability of main parameters are guaranteed, the labor intensity of operators is reduced, and the safety and the economical efficiency of operation of the unit are greatly improved.

Owner:STATE GRID CORP OF CHINA +2

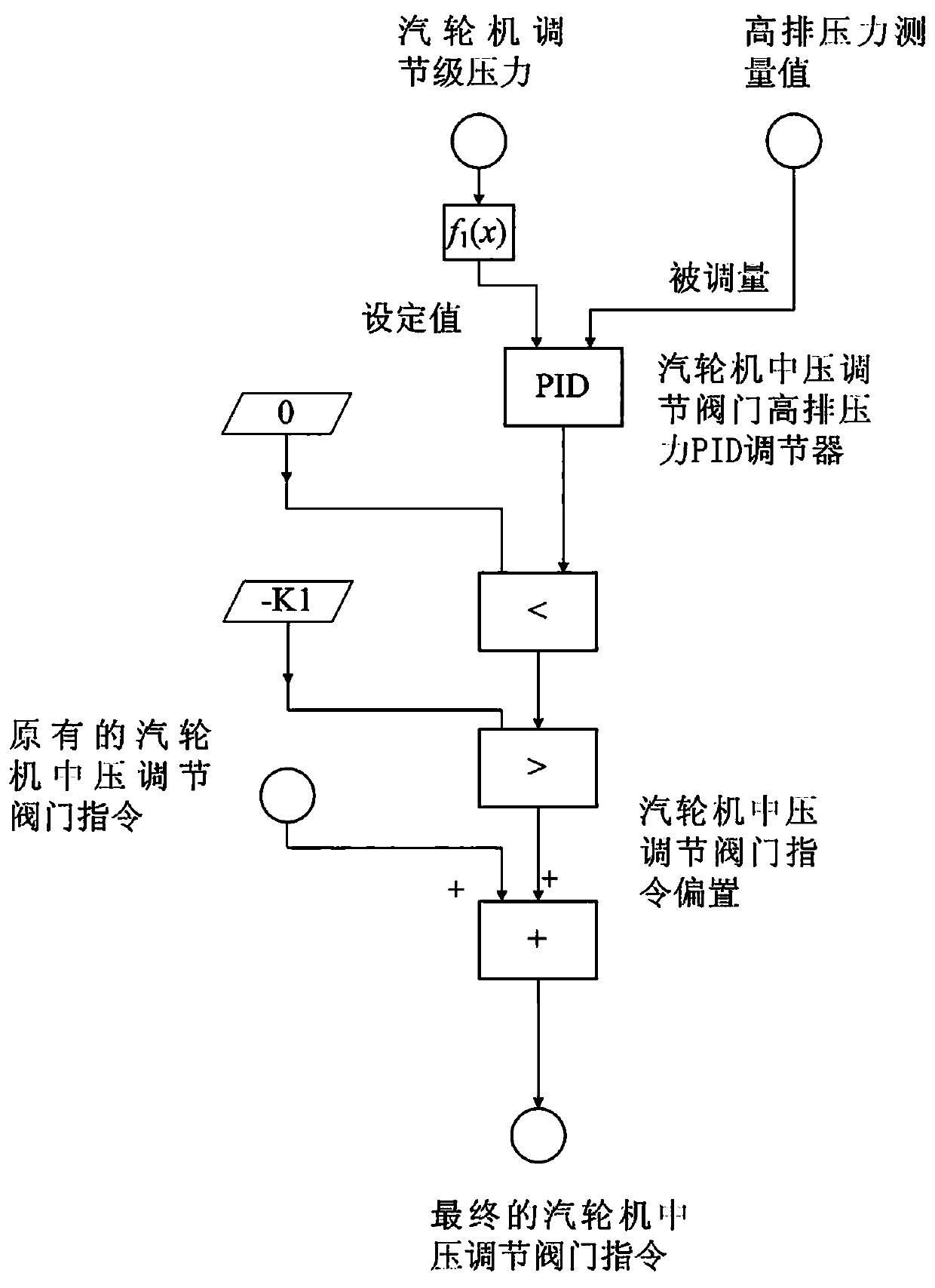

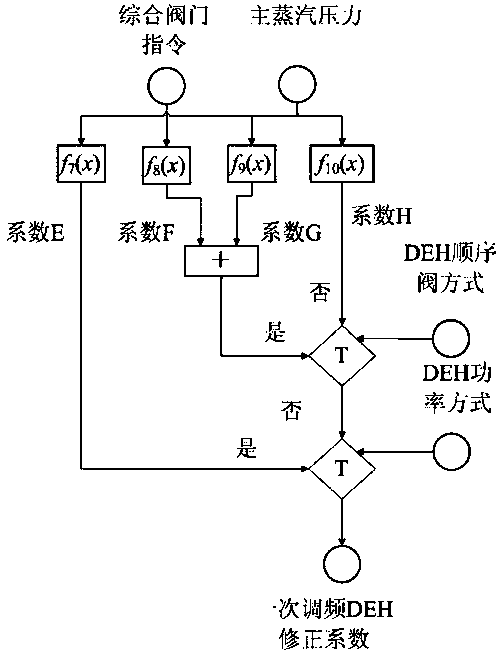

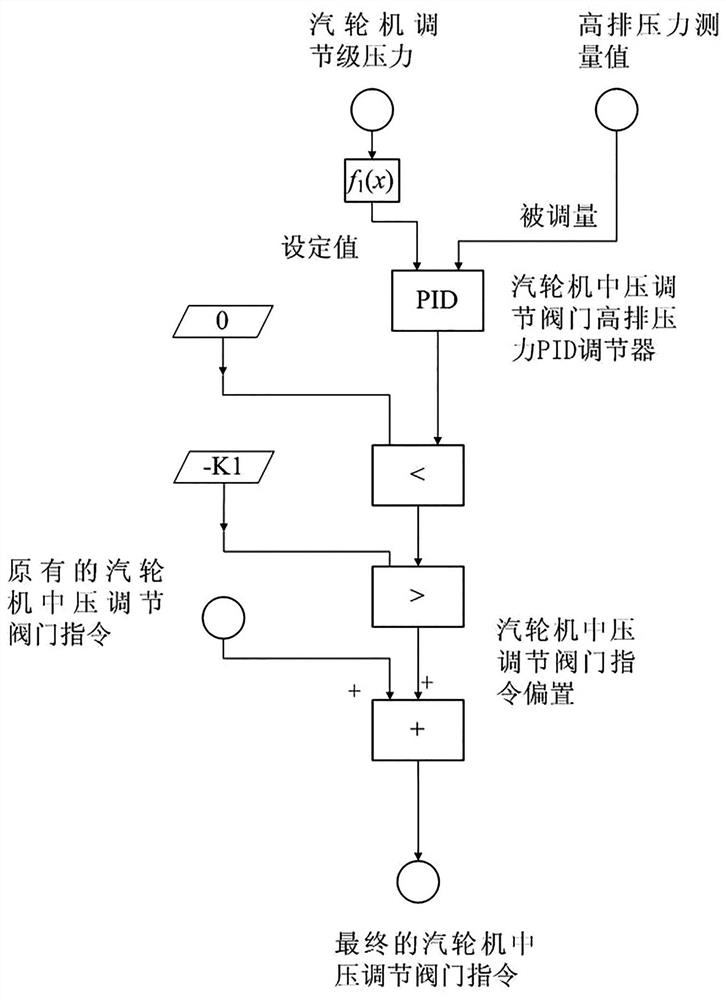

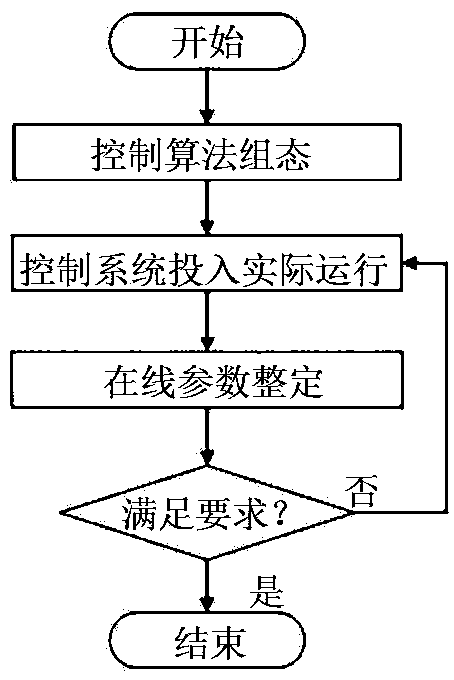

Flow characteristic correction method for steam turbine high pressure control valve of thermal power generating unit

ActiveCN104343475AGuaranteed stabilityMeet the requirements of FM and peak shavingMachines/enginesEngine componentsControl systemPower grid

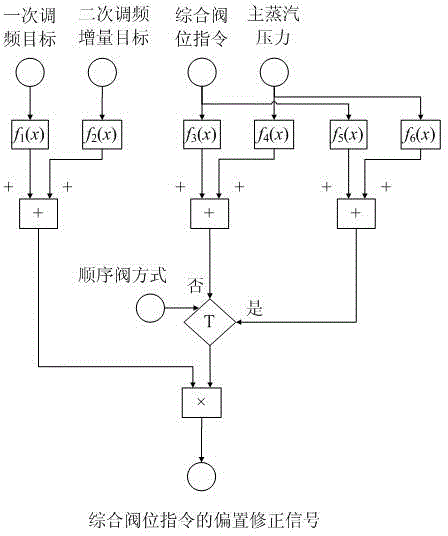

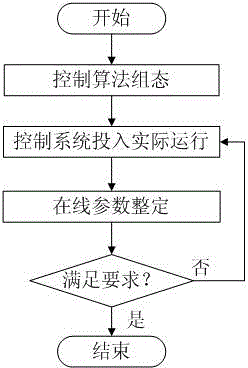

The invention relates to a flow characteristic correction method for a steam turbine high pressure control valve of a thermal power generating unit. The flow characteristic correction method comprises the following steps: additionally arranging a flow characteristic correction control loop interface of the steam turbine high pressure control valve of the thermal power generating unit in the logical configuration comprehensive valve position control loop of an original steam turbine digital electric hydraulic control system; carrying out the logical configuration of a flow characteristic correction control loop of the steam turbine high pressure control valve of the thermal power generating unit, and outputting and introducing the logical configuration into the flow characteristic correction loop interface of the steam turbine high pressure control valve of the thermal power generating unit as the offset correction signal of a comprehensive valve position command; putting a control system into actual operation, setting relevant parameters of the flow characteristic correction control loop of the steam turbine high pressure control valve of the thermal power generating unit on line according to a real-time operation curve, and finally achieving a prospective control effect. The opening of the steam turbine high pressure control valve when the unit participates in frequency modulation and peak modulation corresponds to the linearity of main steam flow, so that the equipment potential is fully developed, and the stability of main parameters is guaranteed while the frequency modulation and peak modulation requirements of a power grid are met.

Owner:STATE GRID CORP OF CHINA +2

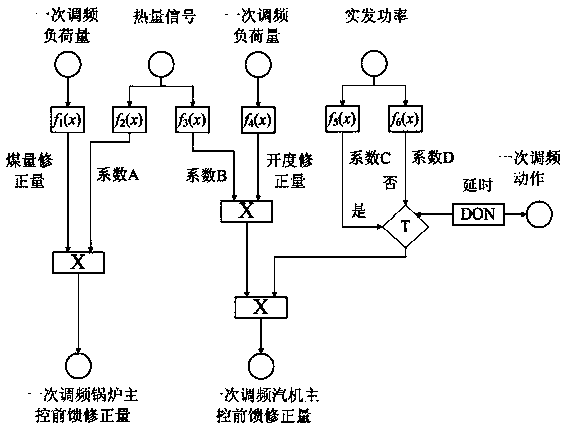

Drum boiler thermal power generator set primary frequency modulation control optimization method

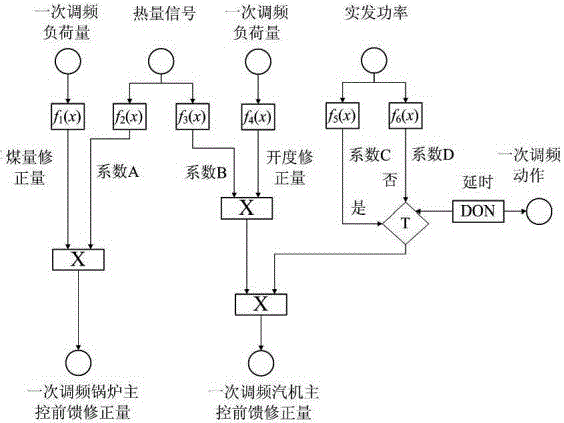

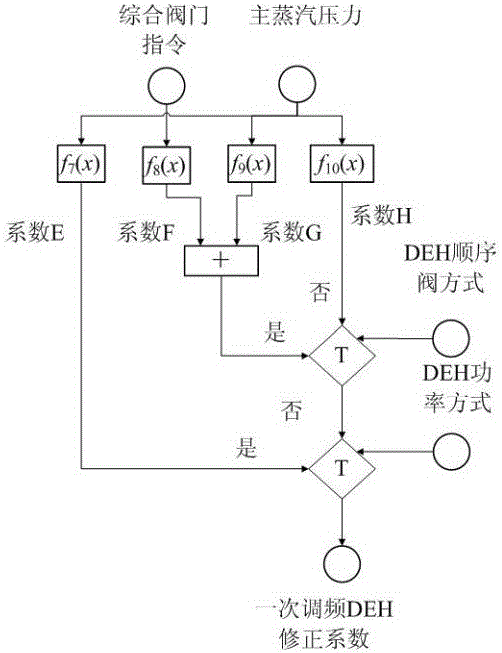

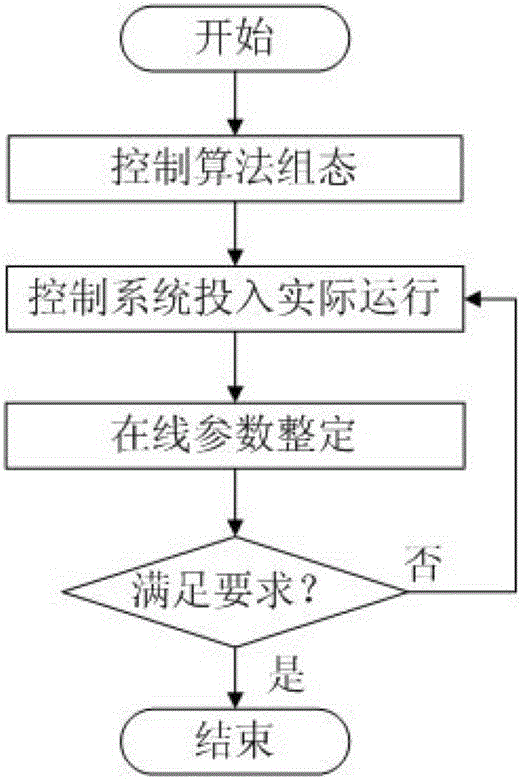

ActiveCN106773681AReduce labor intensityImprove real-time performanceMachines/enginesEngine componentsAutomatic controlDistributed control system

The invention belongs to the technical field of automatic control of a thermal power generator set and especially relates to a drum boiler thermal power generator set primary frequency modulation control optimization method. The method can be used for primary frequency modulation automatic control of the drum boiler thermal power generator set in the actual operation process, thereby ensuring that primary frequency modulation load is controlled within a reasonable range automatically in the operation process of the thermal power generator set. The method comprises adding a primary frequency modulation boiler master control feed-forward correction control logic, a primary frequency modulation turbine master control feed-forward correction control logic, a primary frequency modulation steam turbine digital electric hydraulic control system DEH correction coefficient control logic and a primary frequency modulation turbine extraction steam amount correction control logic to control logic configuration of a drum boiler thermal power generator set distributed control system DCS. The method can reduce labor intensity of personnel, and the control effect is not dependent on technical levels of operation personnel; and through an existing set distributed control system DCS coordinated control system, the method is good in real-time performance, simple in field debugging process and convenient for engineering realization.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +1

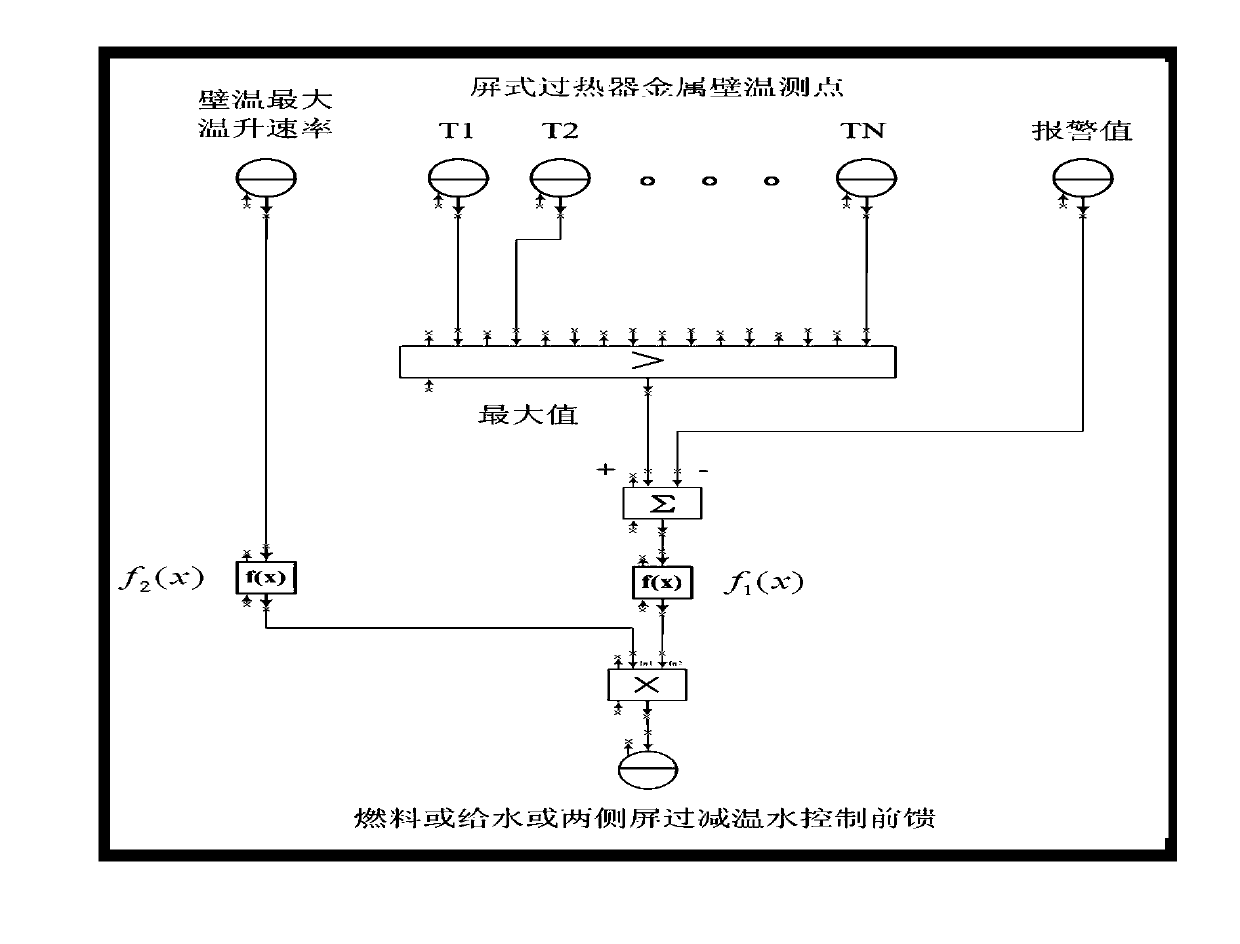

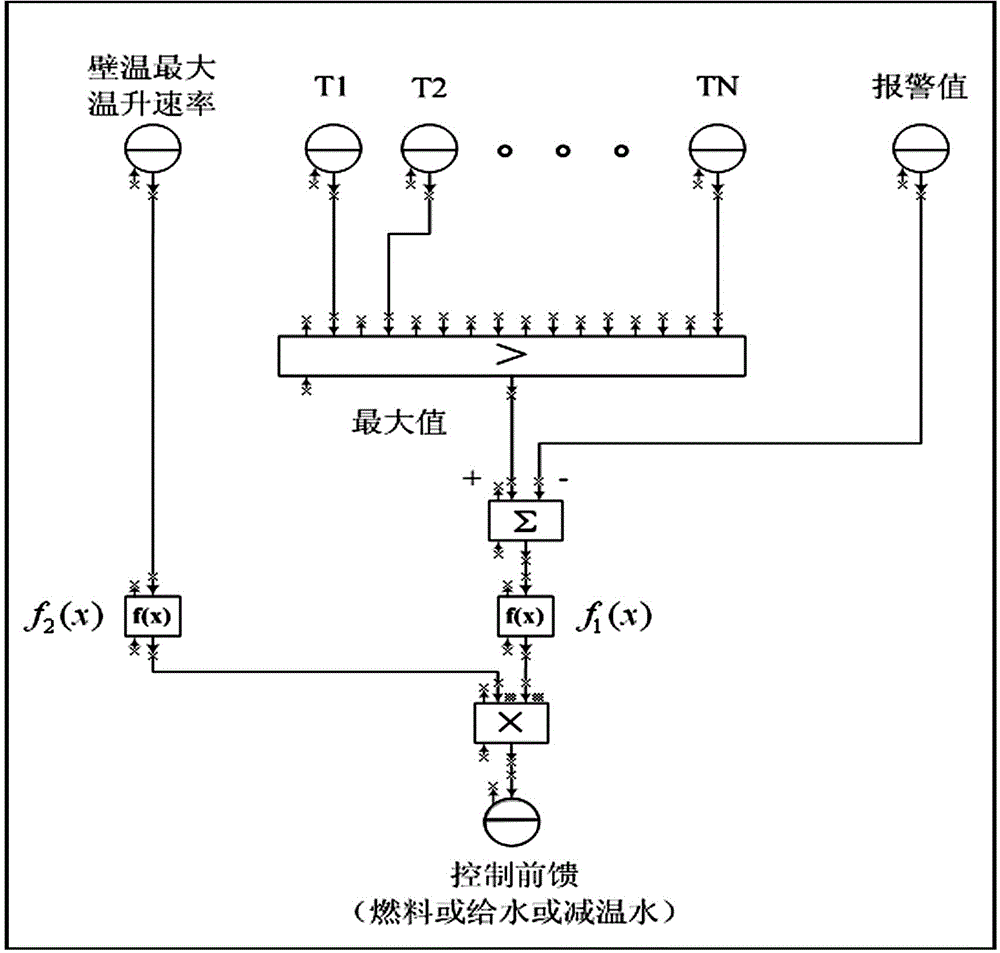

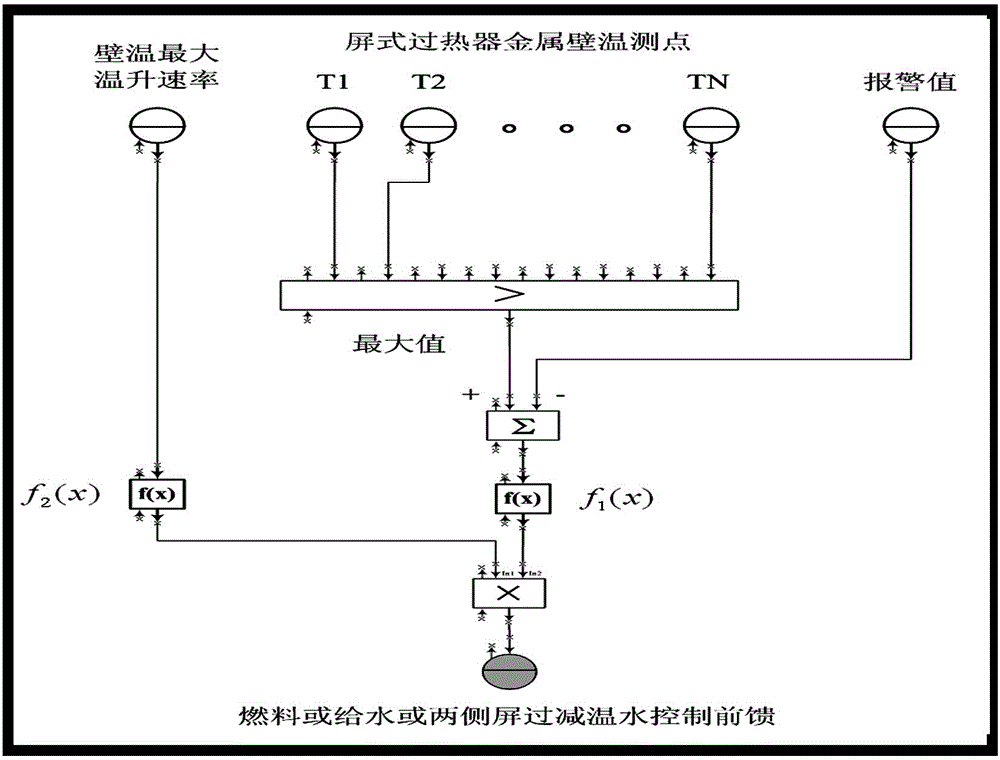

Supercritical coal-fired unit platen superheater metal wall temperature early-warning optimal control method

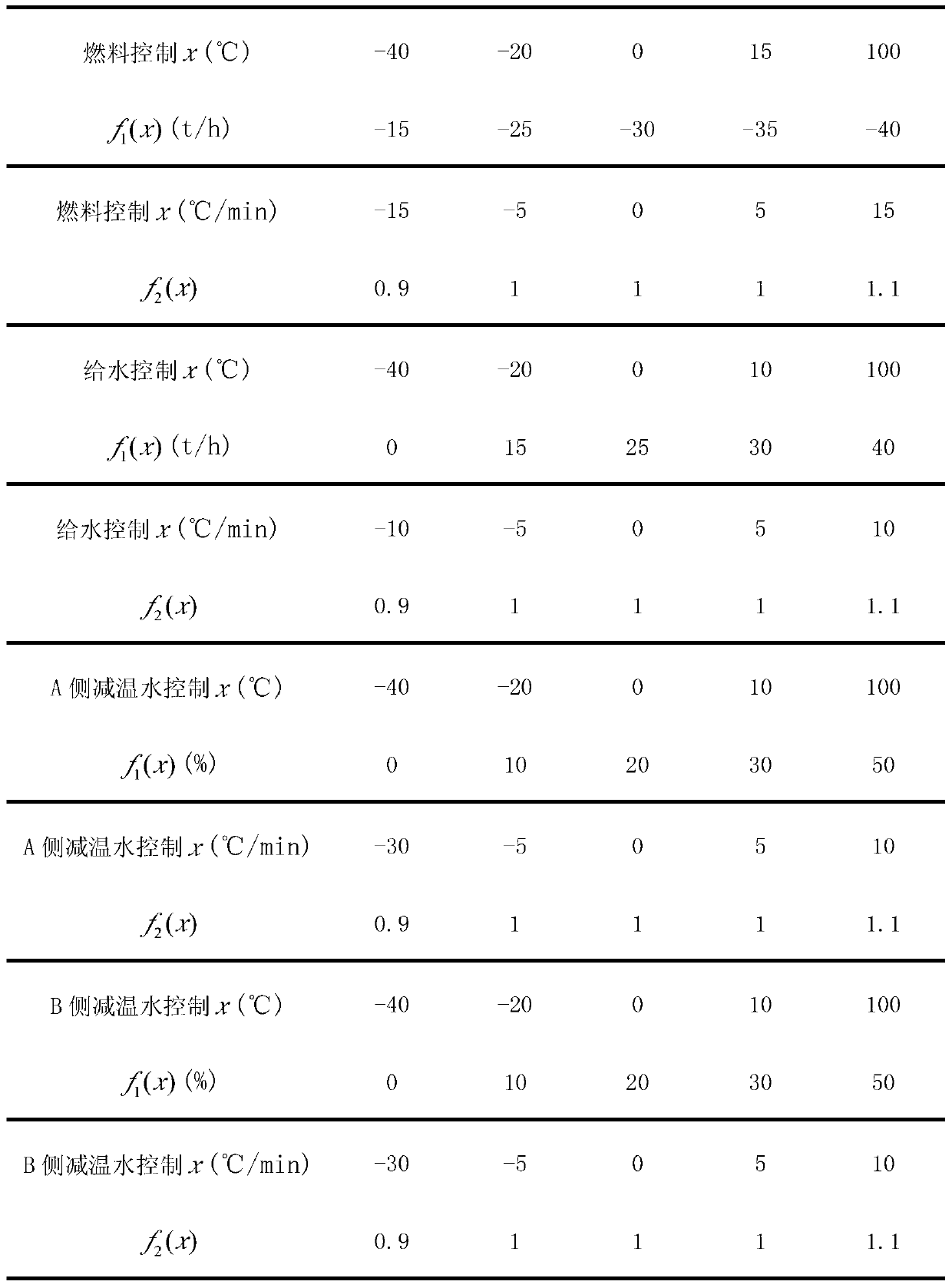

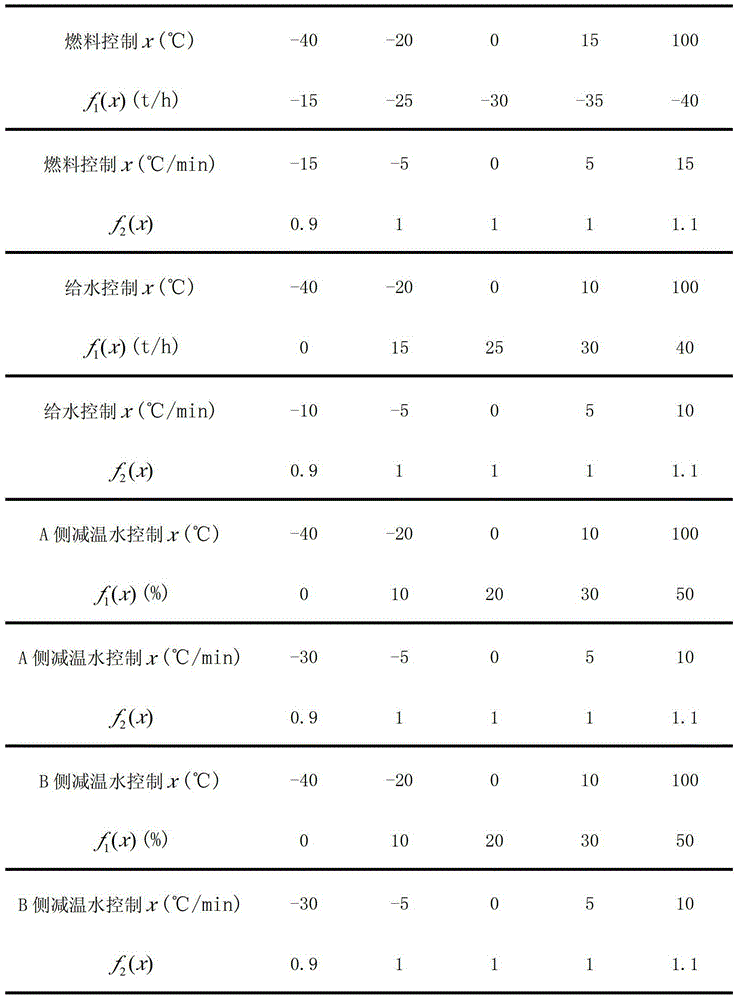

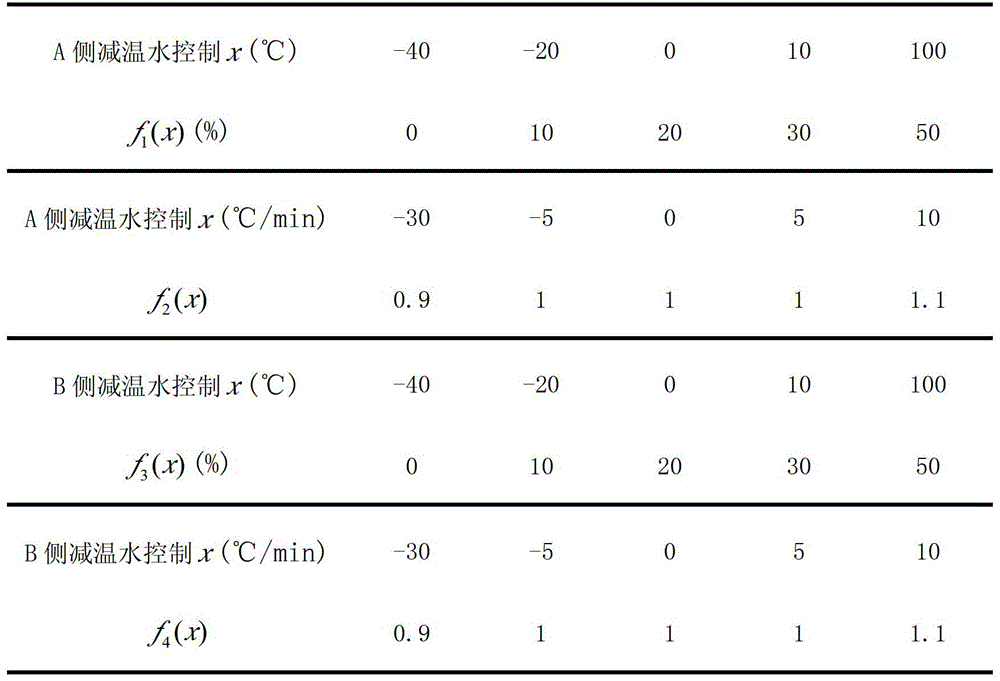

The invention relates to a supercritical coal-fired unit platen superheater metal wall temperature early-warning optimal control method. The method comprises the steps that a platen superheater metal wall temperature control loop connector is added in a logical configuration fuel, water supply and two side platen superheater desuperheating water control loop in an original coordinated control system; platen superheater metal wall temperature control loop logical configuration is conducted and is output and led into the platen superheater metal wall temperature control loop connector to be used as feedforward signals of fuel, water supply and two side platen superheater desuperheating water control; a control system is put into actual operation, platen superheater metal wall temperature control loop parameters are adjusted and set on line according to a real-time operation curve, and the expected effect is finally achieved. According to an existing DCS coordinated control system, the supercritical coal-fired unit platen superheater metal wall temperature early-warning optimal control method is good in real-time performance, and simple in field debugging process, and can achieve engineering realization easily. Both supercritical coal-fired unit major parameters and platen superheater metal wall temperature control are automatically considered, overtemperature pipe explosion accidents of a platen superheater are effectively avoided, labor intensity is reduced, and unit operation safety and economy are improved.

Owner:STATE GRID CORP OF CHINA +2

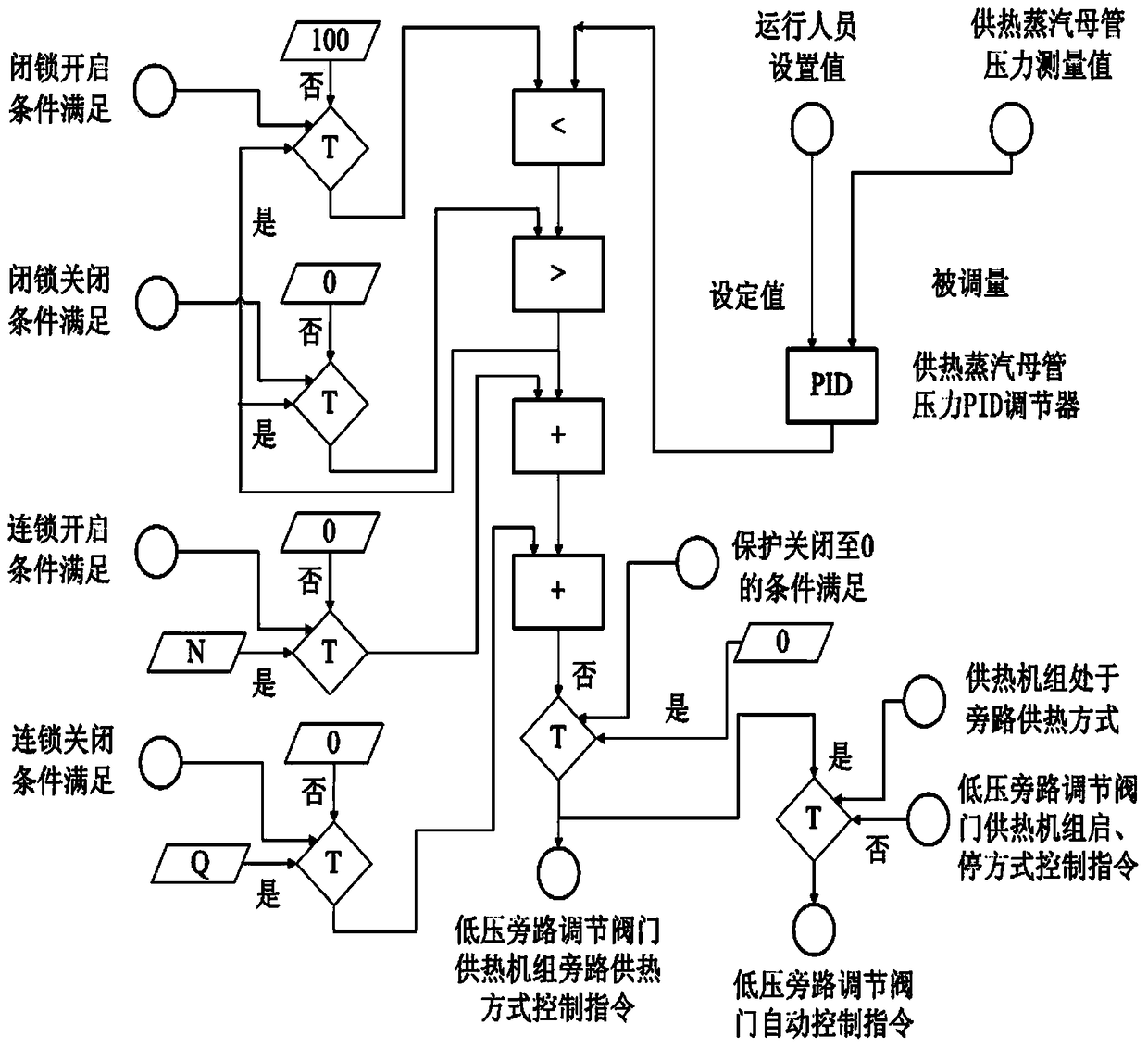

Bypass system comprehensive control method for improving the adjusting capacity of heat supply unit

ActiveCN109442368AEasy to adjustSimple control logicSteam useSteam generation plantsAutomatic controlDistributed control system

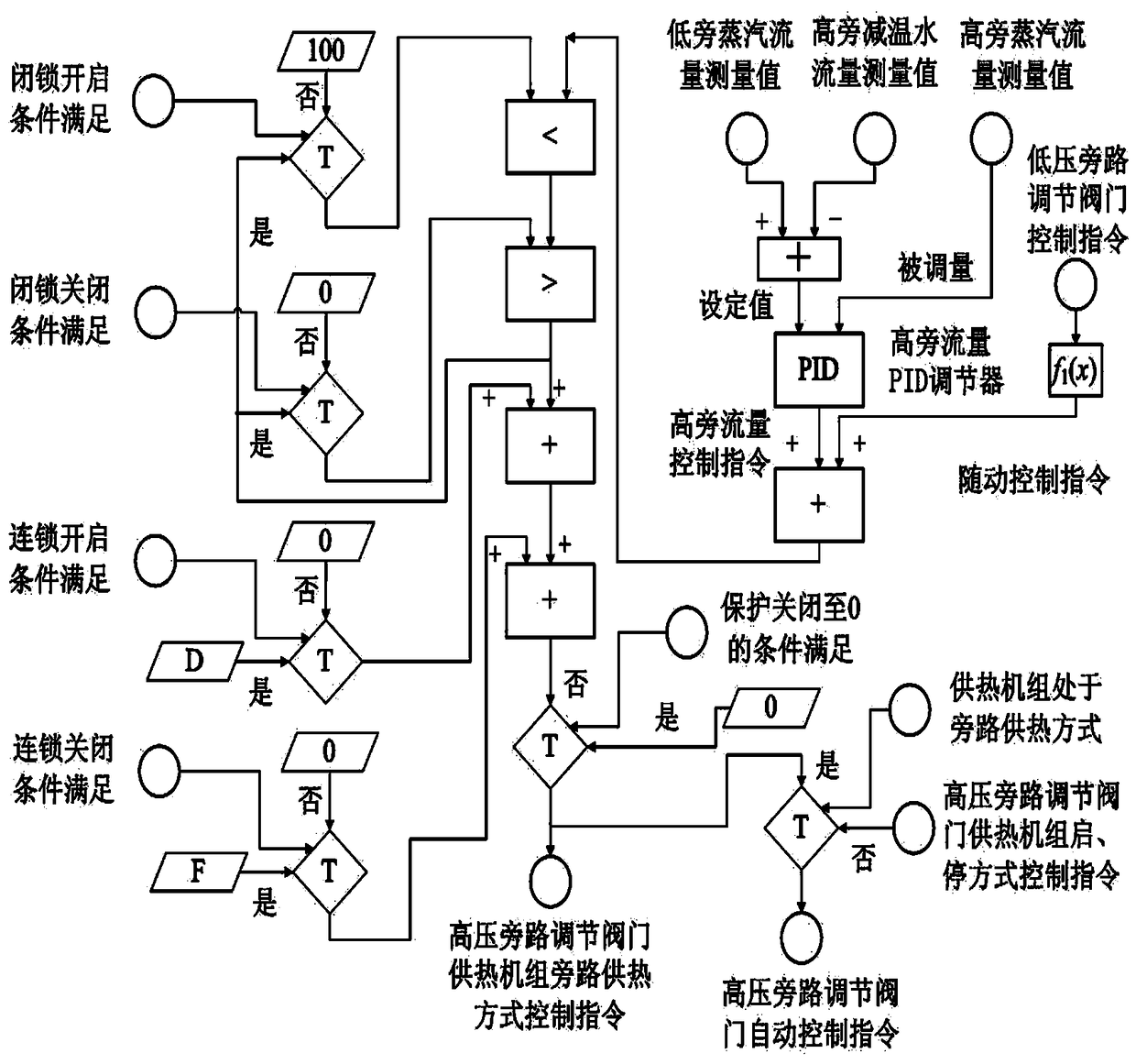

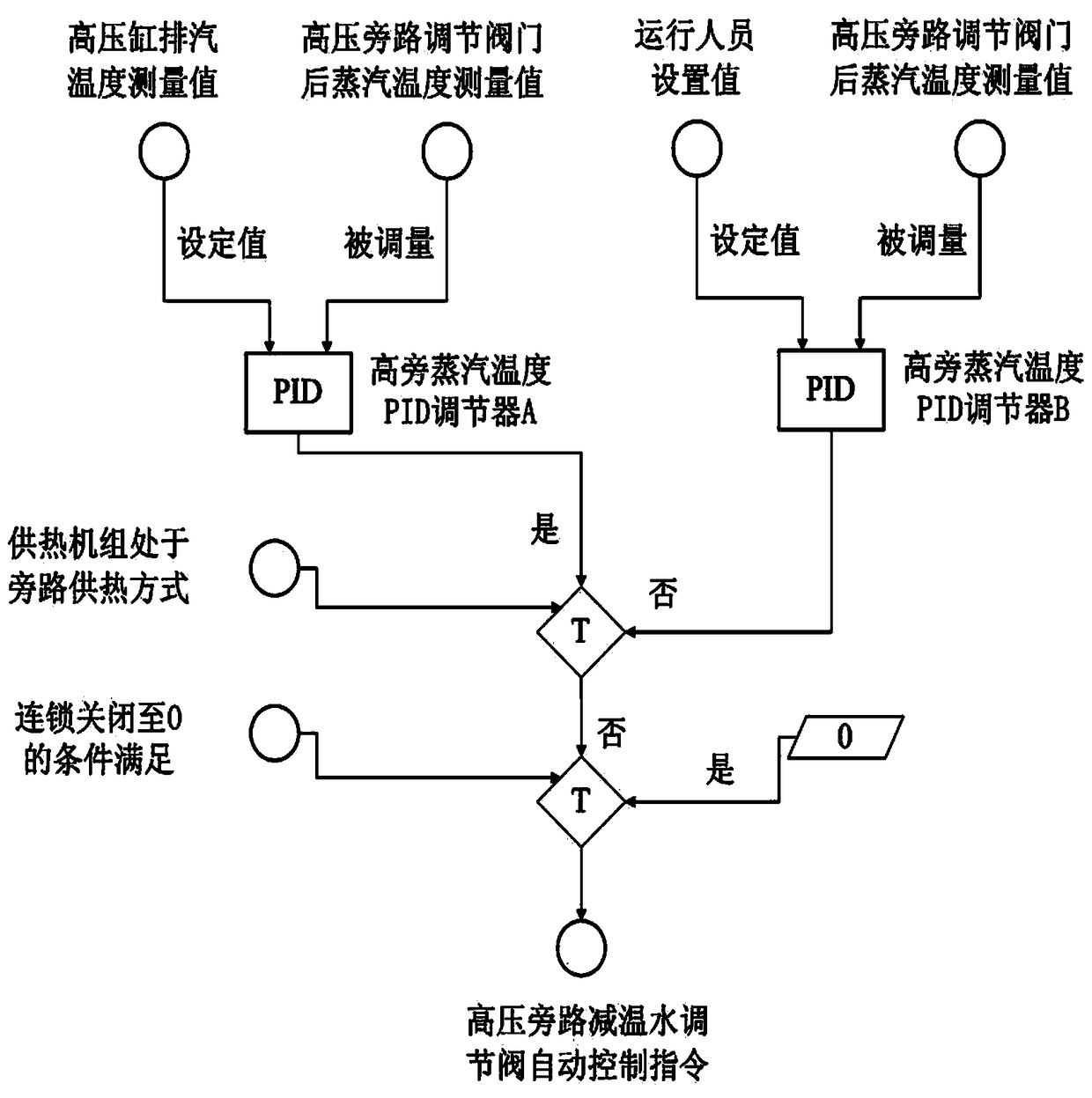

The invention relates to the technical field of automatic control methods, in particular to a bypass system comprehensive control method for improving the adjusting capacity of a heat supply unit. Thebypass system of the heat supply unit is comprehensively controlled, so that the adjusting capacity of the heat supply unit is improved. The control method comprises the following steps that the bypass system comprises a high-pressure bypass system and a low-pressure bypass system; it is judged that the heat supply unit is in a bypass heat supply mode; it is judged that the heat supply unit exitsthe bypass heat supply mode; the control logic of each valve of the high-pressure bypass system is optimized respectively; the control logic of each valve of the low-pressure bypass system is optimized respectively ; control logic configuration is carried out on the DCS of the heat supply unit, the control logic of the DCS of the heat supply unit is optimized and adjusted, and the adjusting capacity of the heat supply unit is improved. According to the bypass control system of an existing unit DCS (distributed control system), the control method is good in real-time performance, simple in field debugging process and convenient for engineering realization.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +1

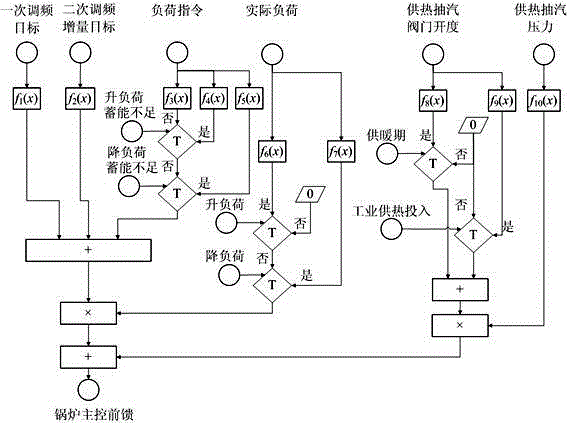

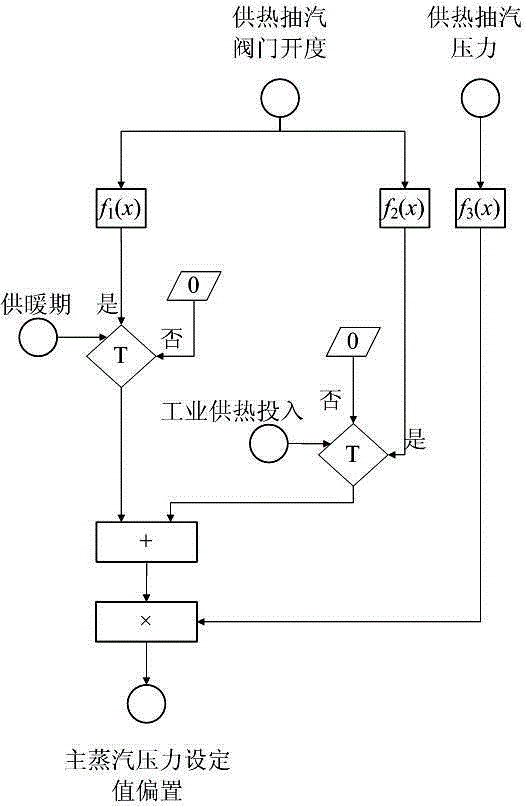

Frequency and peak load modulation all condition coordination control method of heat supply unit

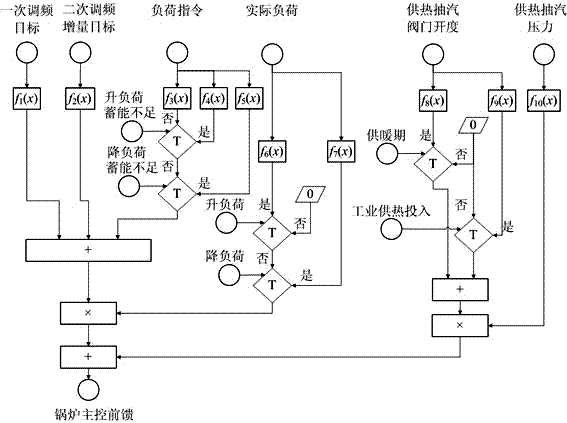

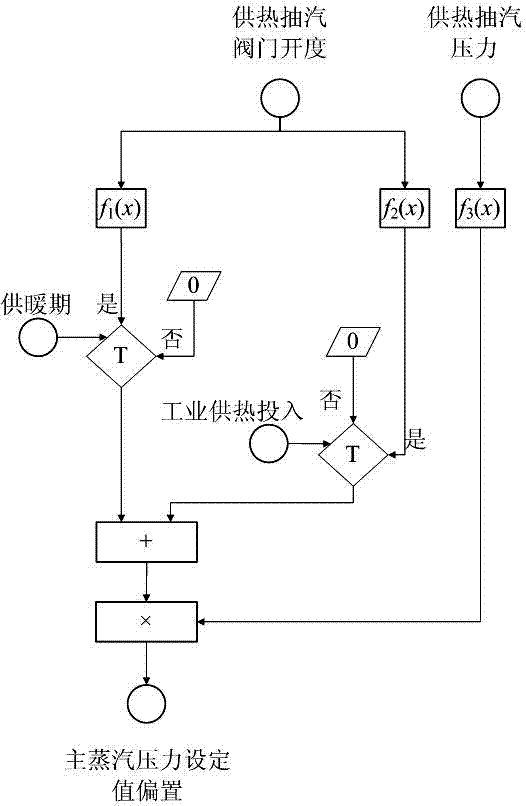

ActiveCN105202519AGuaranteed stabilityGuaranteed accuracyBoiler controlAutomatic controlSteam pressure

The invention belongs to the technical field of automatic control of thermal power generating units, and particular relates to a frequency and peak load modulation all condition coordination control method of heat supply unit. The method is used for automatic control during power grid frequency and peak load modulation under various conditions of the heat supply unit, and main parameters are automatically controlled in a reasonable range while rapid and stable responding of frequency and peak load modulation of the unit is guaranteed. Particularly, the power grid frequency and peak load modulation requirements of the heat supply unit under various conditions are automatically met by optimizing control logic of a DSC (distributed control system) of the heat supply unit. Coordination control stability and accuracy while the unit participates in frequency and peak load modulation and main steam pressure control stability and accuracy under various operation conditions of the heat supply unit are guaranteed, the equipment potential is fully developed, and the stability of main parameters is guaranteed while the power grid frequency and peak load modulation requirements are met. The labor intensity of an operator is reduced effectively, the control effect doesn't rely on the technical level of the operator, the real time performance is good, the site commissioning process is simple, and a project can be realized favorably.

Owner:STATE GRID CORP OF CHINA +2

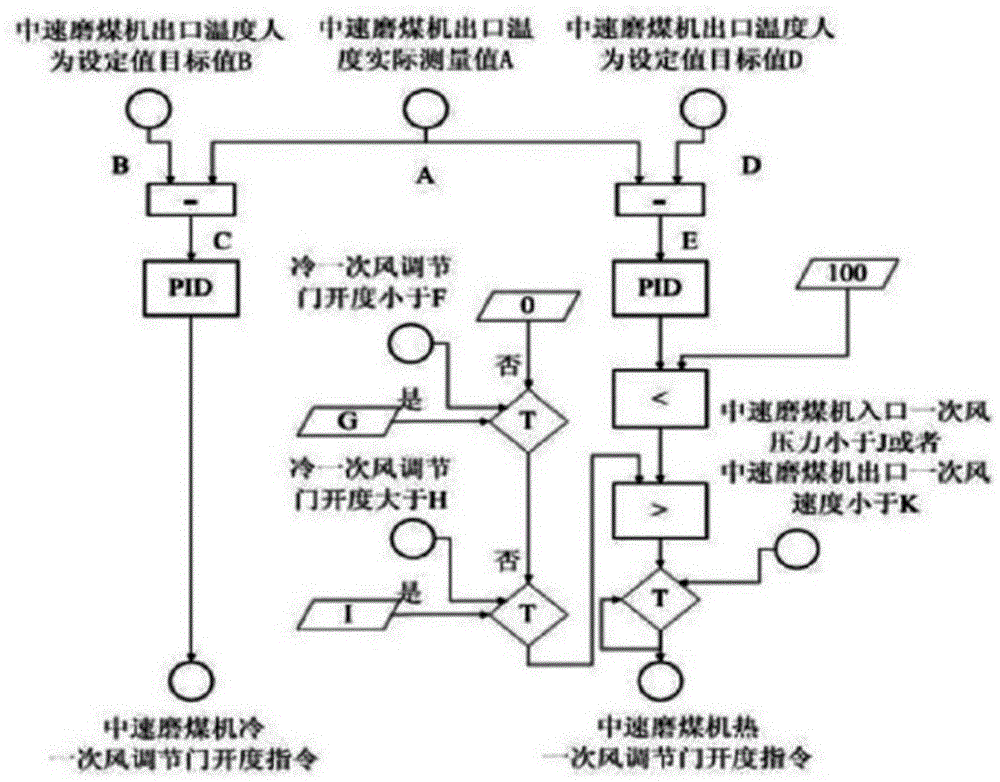

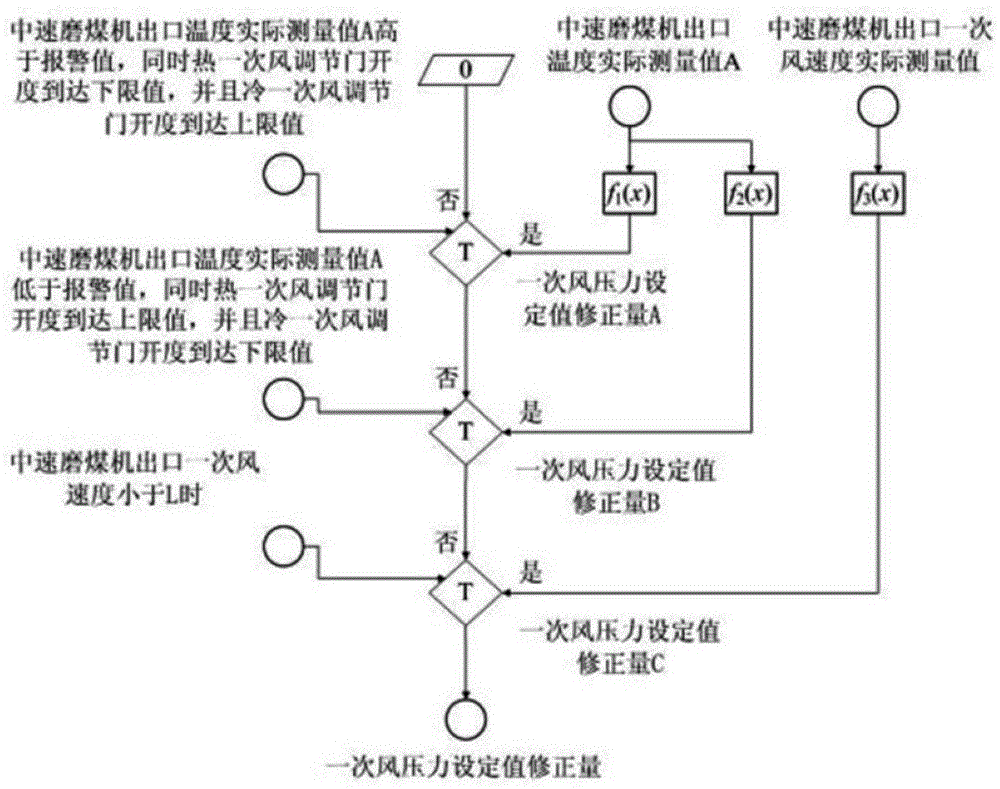

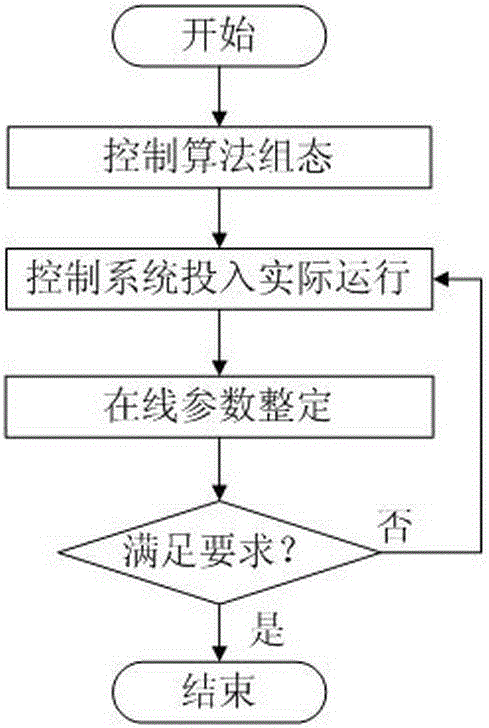

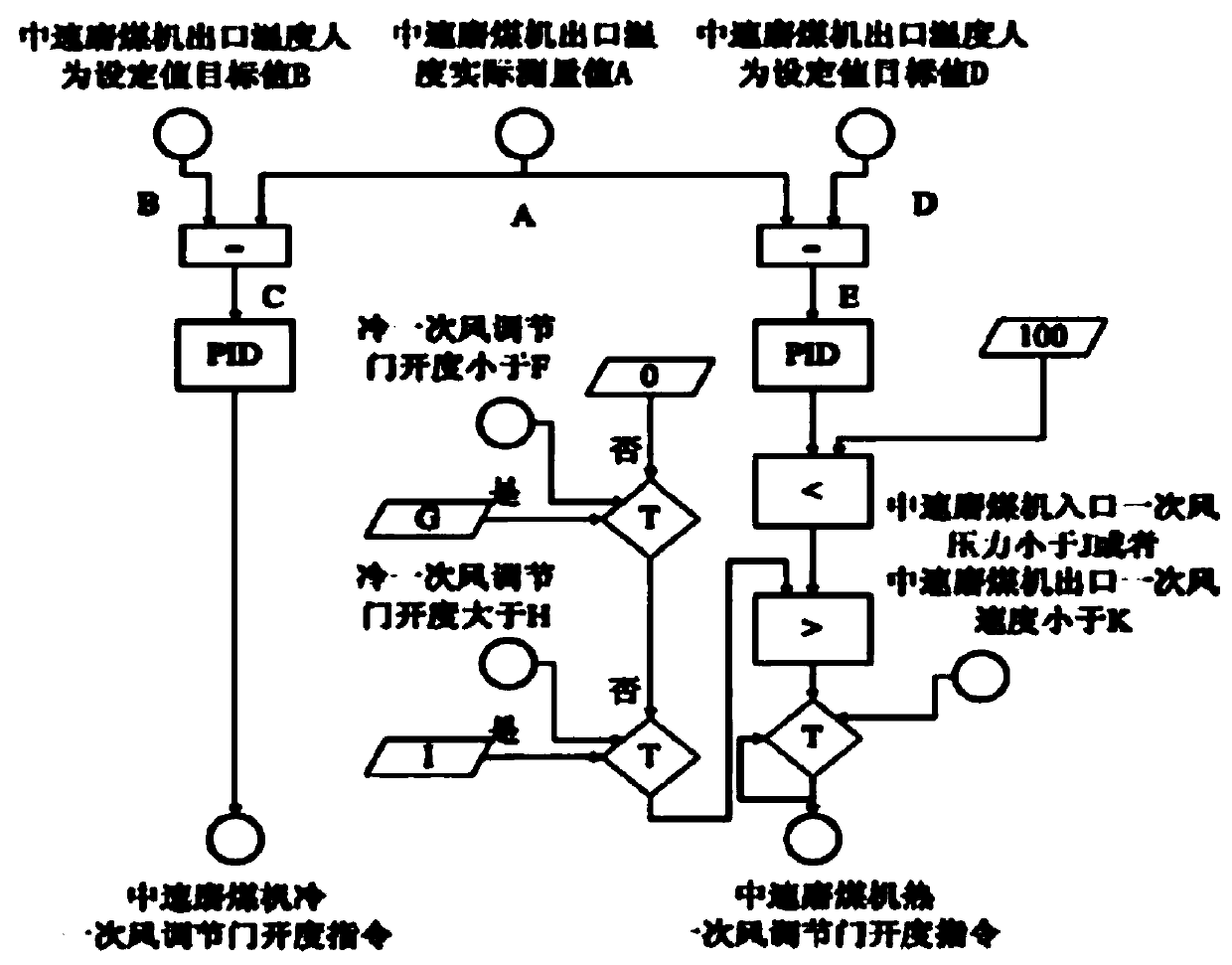

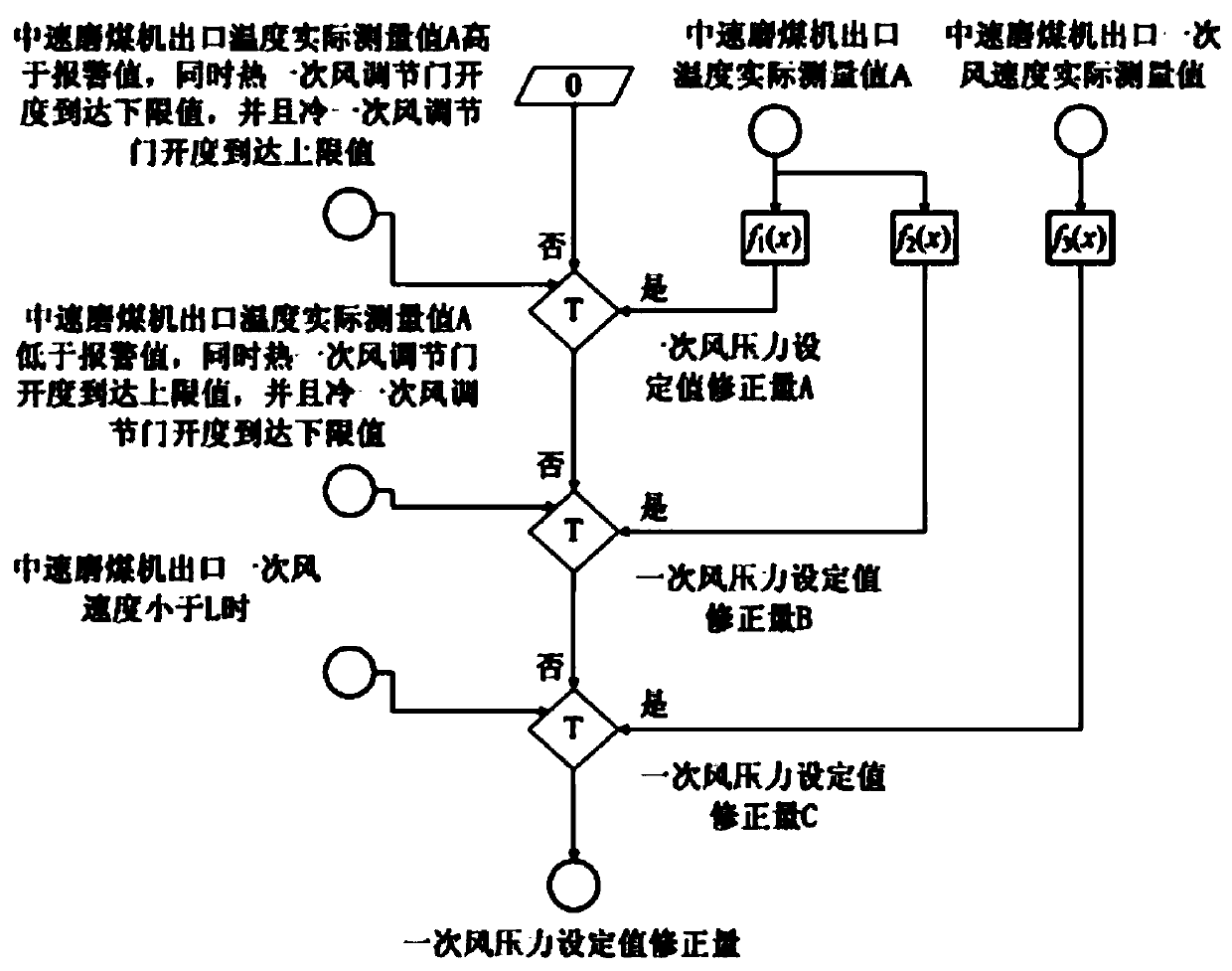

Outlet temperature control optimizing method of medium-speed coal pulverizer of thermal power generating unit

ActiveCN106594793AGuaranteed stabilityFull potentialCombustion regulationTemperature controlProportion integration differentiation

The invention relates to an outlet temperature control optimizing method of a medium-speed coal pulverizer of a thermal power generating unit. The method is characterized in that a PID (Proportion Integration Differentiation) adjuster is additionally arranged in control logic configuration of a DCS (Distributed Control System) of the thermal power generating unit, and linkage control logic is added to the control logic configuration of the DCS of the thermal power generating unit; a primary air pressure setting value correction control loop port based on the outlet temperature control optimization of the medium-speed coal pulverizer is added to primary air pressure control loop configuration of the control logic of the DCS of the thermal power generating unit, and primary air pressure setting value correction linkage control logic output is introduced to the primary air pressure setting value correction control loop port based on the outlet temperature control optimization of the medium-speed coal pulverizer to be used as the primary air pressure control correction; and the DCS is put into actual operation, and the parameters of each control loop in the outlet temperature control of the medium-speed coal pulverizer of the thermal power generating unit are adjusted online, so as to achieve the expected effect. The method is high in real-time performance, simple in on-site debugging process, and conveniently carried out in engineering.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +1

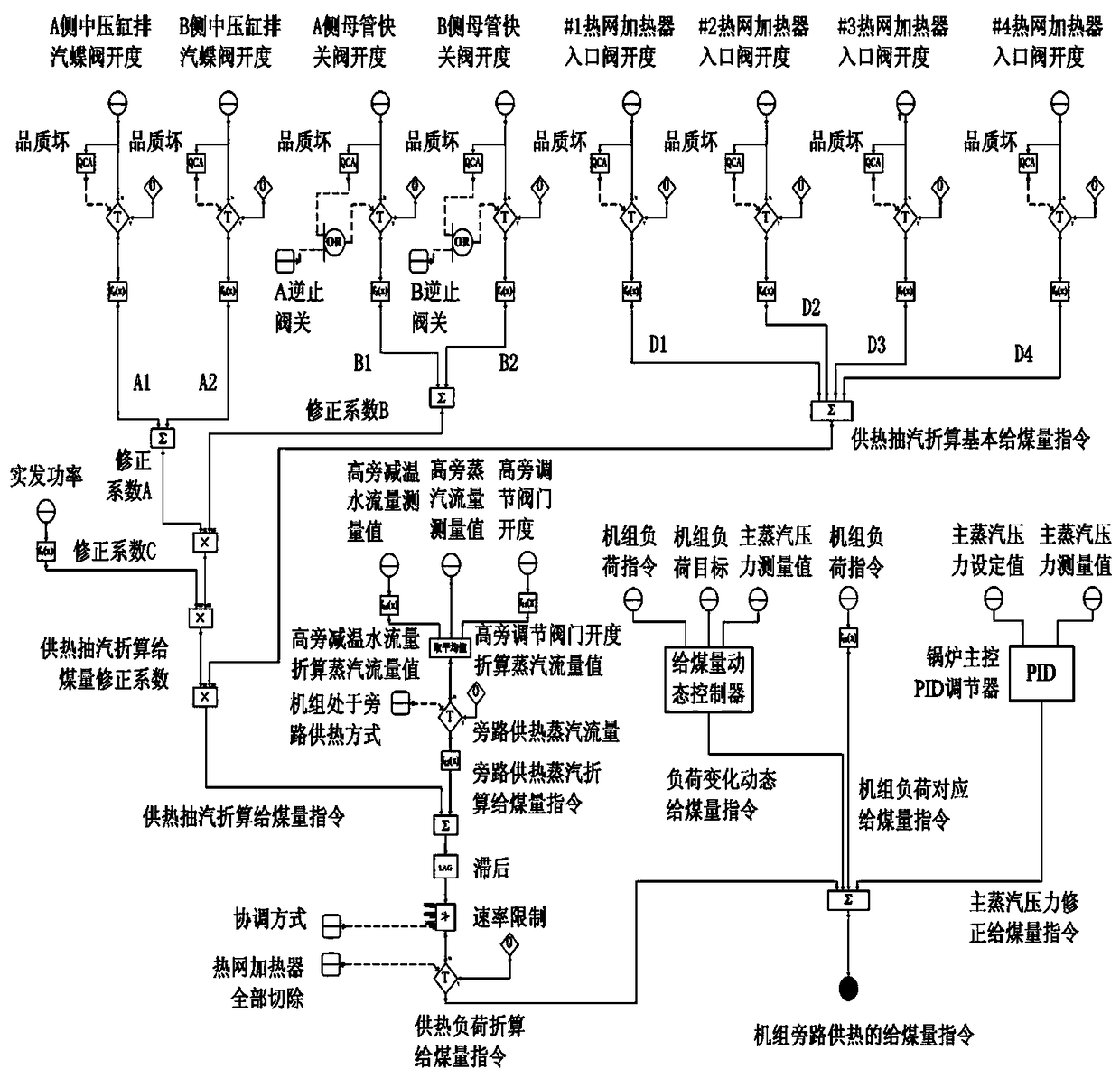

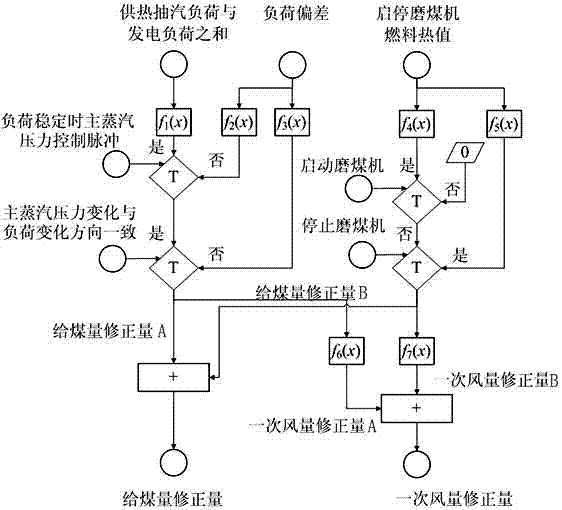

Coal feeding amount optimization control method for unit bypass heat supply

ActiveCN109373347AAutomatically meet the requirements of frequency modulation and peak regulationReduce labor intensityFuel supply regulationSteam pressureAutomatic control

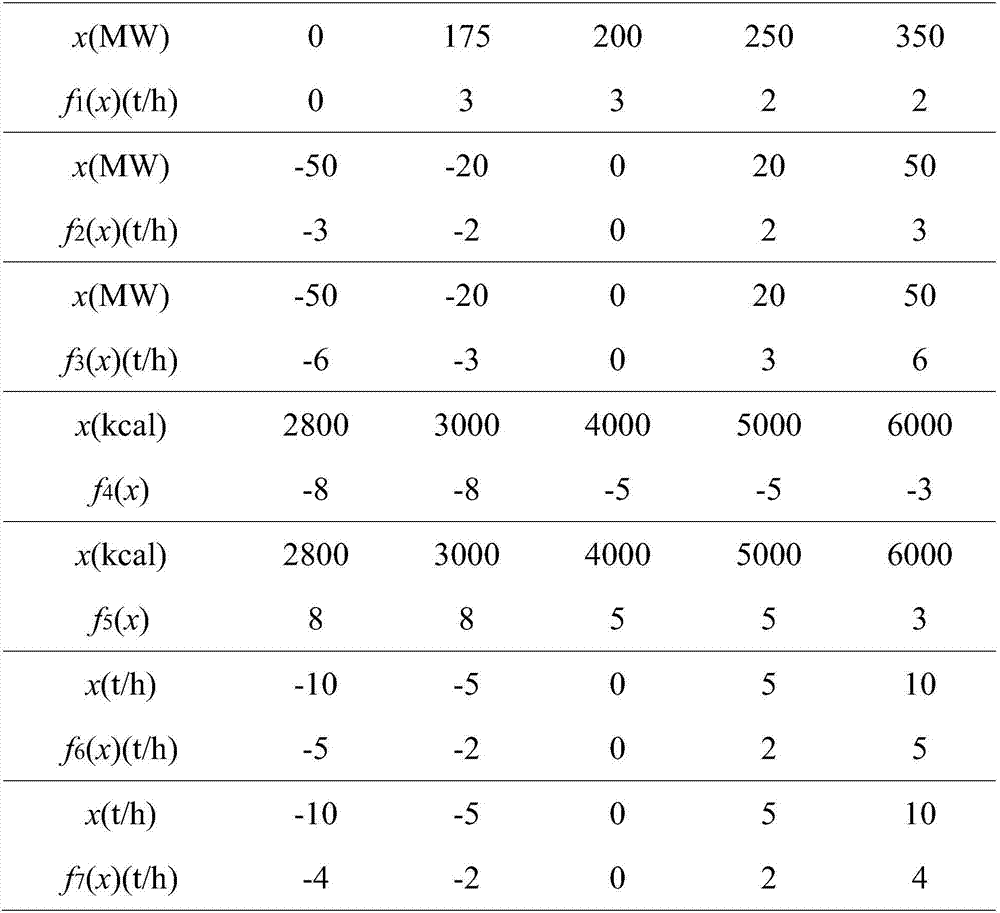

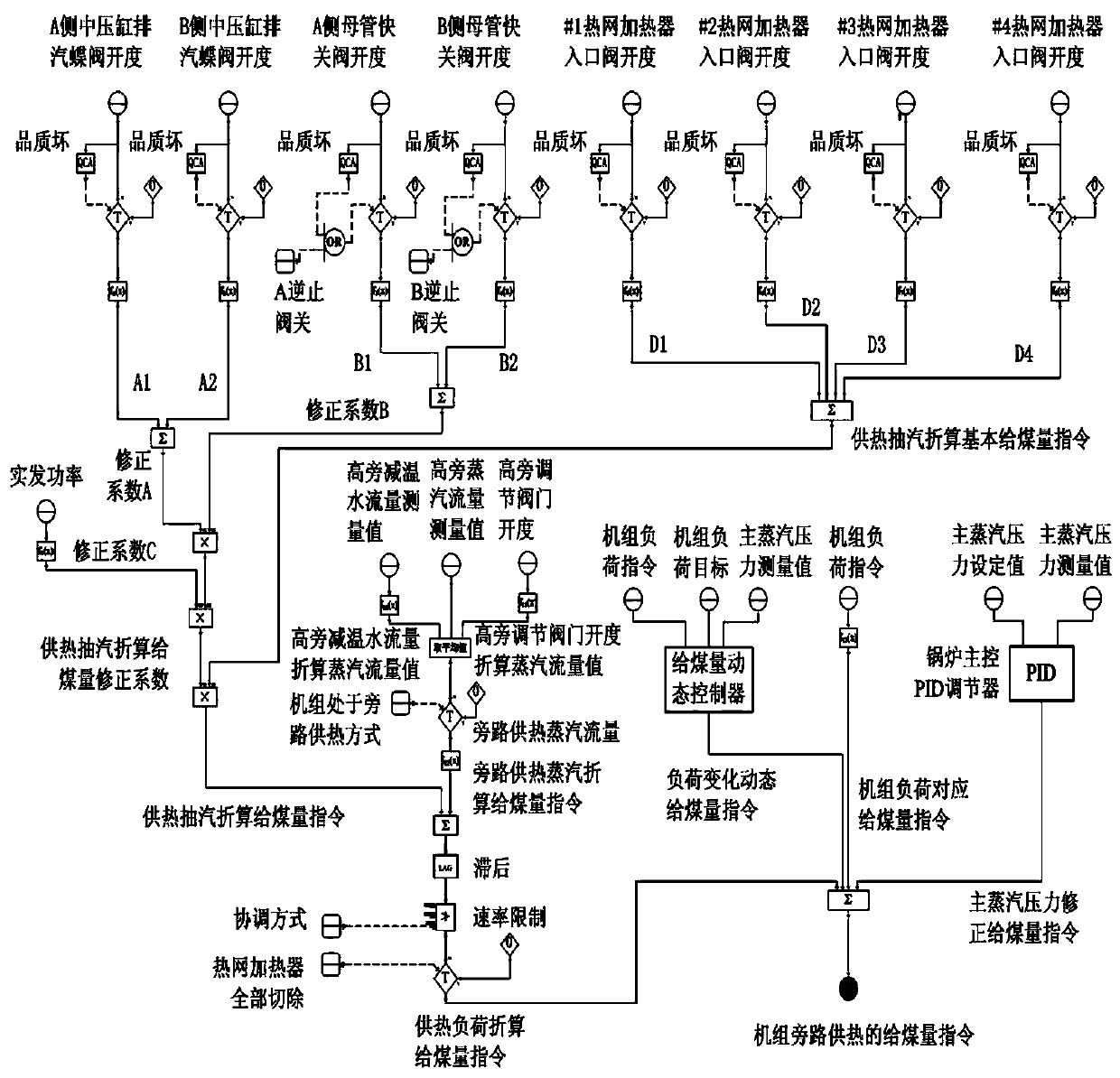

The invention relates to the technical field of automatic control methods, in particular to a coal feeding amount optimization control method for unit bypass heat supply. Through optimizing a coal feeding amount instruction control logic of a heat supply unit dispersion control system (DCS), the heat supply quality of the heat supply unit can be ensured to automatically meet the frequency modulation and peak modulation requirements of a power grid under the bypass heat supply working condition. The method comprises the steps that the coal feeding amount instruction automatic control logic of the unit bypass heat supply is designed; a configuration heat supply load converting coal feeding amount instruction automatic control logic is formed; a configuration unit load corresponding coal feeding amount instruction automatic control logic is formed; a configuration load change dynamic coal feeding amount instruction automatic control logic is formed; a configuration main steam pressure correcting coal feeding amount instruction automatic control logic is formed; and the DCS historical operation data of the unit are inquired. According to the existing unit DCS coal feeding amount control system, the frequency modulation and peak modulation requirements of the power grid can be automatically met by the heat supply unit under the condition that the heat supply quality is ensured; andthe labor intensity of operators is reduced, the real-time performance is good, the field debugging process is simple, and engineering implementation is facilitated.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +1

Optimizing method of air and flue gas system control after desulfurization and denitrification transformation of thermal power generating unit

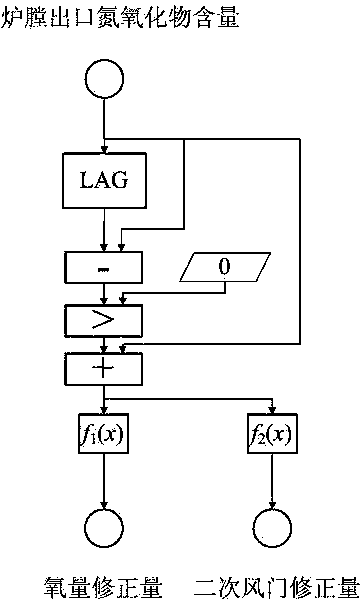

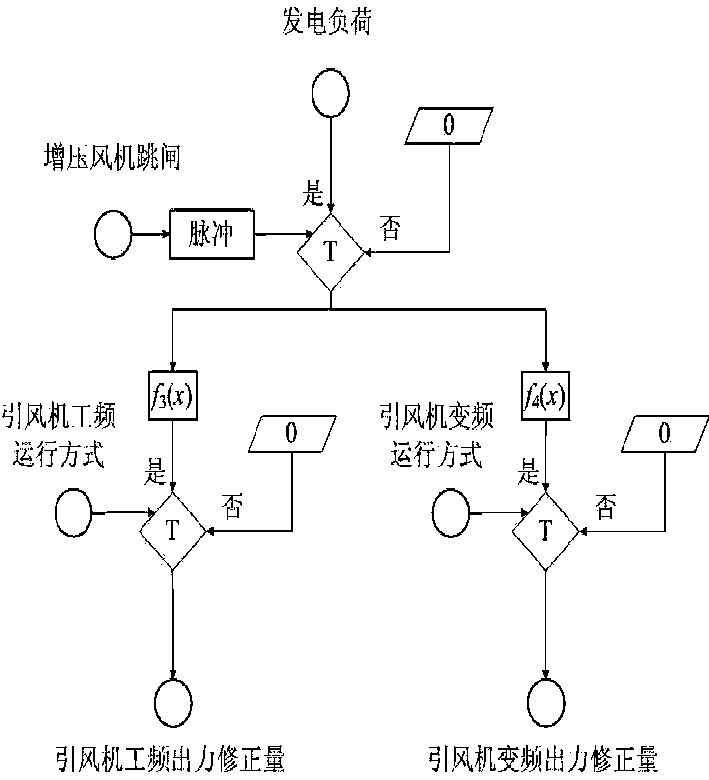

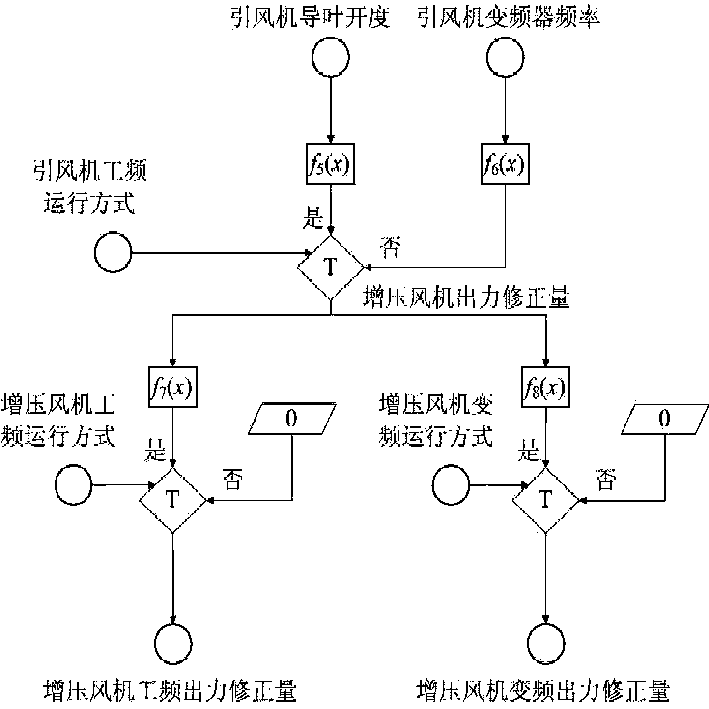

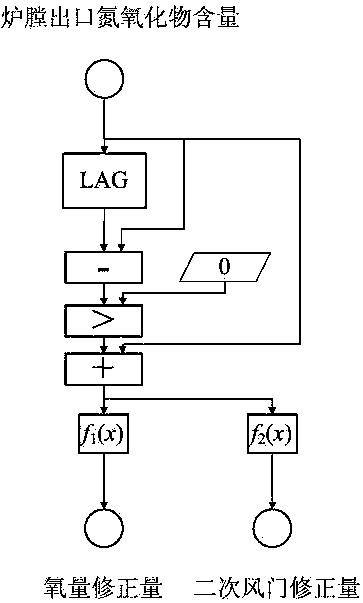

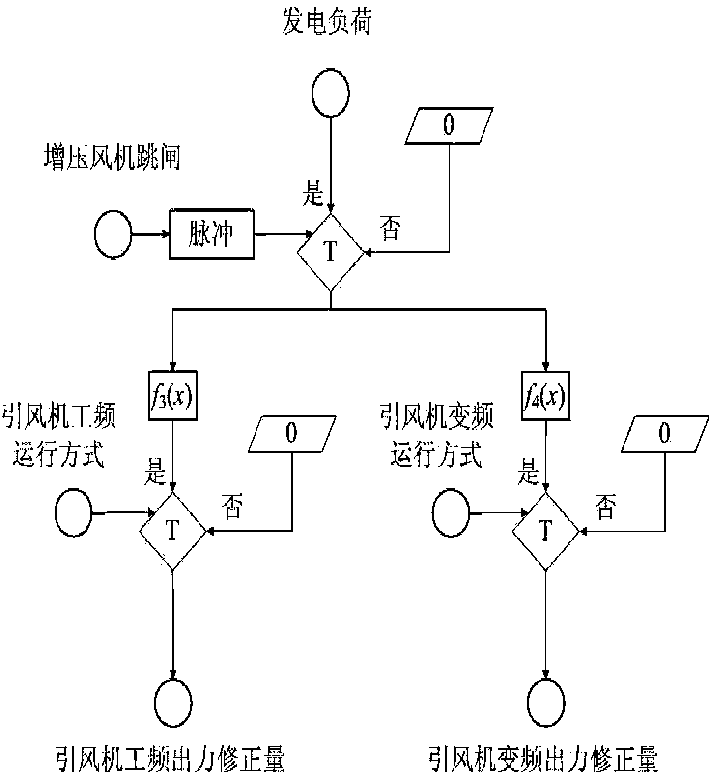

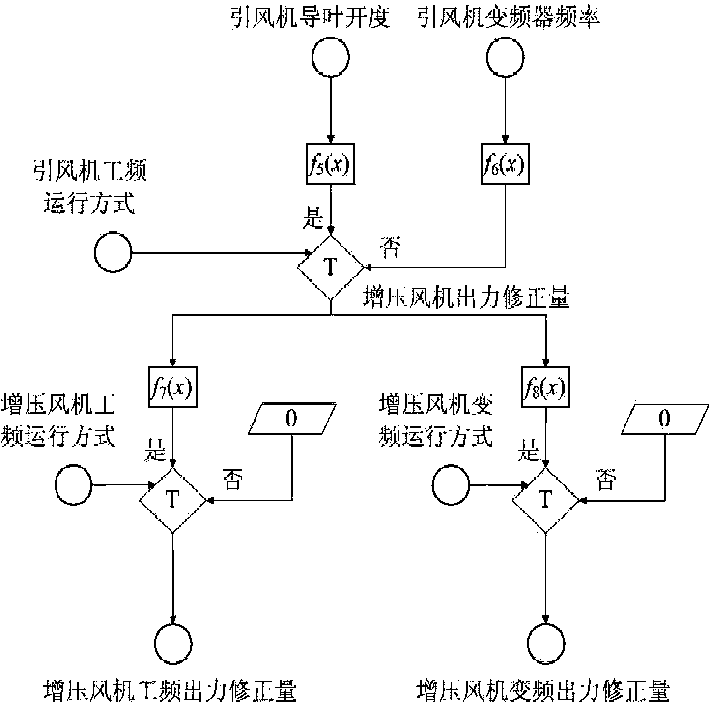

ActiveCN107940501AGuaranteed adjustment qualityFull potentialAir supply regulationAutomatic controlFlue gas

The invention relates to an optimizing method of air and flue gas system control after desulfurization and denitrification transformation of a thermal power generating unit. An oxygen amount allowancecontrol loop after desulfurization and denitrification transformation of the thermal power generating unit and a loop interface, a secondary air valve opening degree allowance control loop after desulfurization and denitrification transformation of the thermal power generating unit and a loop interface, an induced draft fan output allowance control loop after desulfurization and denitrification transformation of the thermal power generating unit and a loop interface as well as a booster fan output allowance control loop after desulfurization and denitrification transformation of the thermal power generating unit and a loop interface are additionally arranged in the control logical configuration of a thermal power generating unit distributed control system (DCS); air blower output interlocking control logic and secondary air valve opening degree interlocking control logic after desulfurization and denitrification transformation of the thermal power generating unit are added in the control logical configuration of the thermal power generating unit DCS; according to the real-time running curve of the control system, related parameters of various control loops for optimization of airand flue gas system control after desulfurization and denitrification transformation of the thermal power generating unit are adjusted online, and the expected control effect is realized finally. Theproblem about automatic air and flue gas system control after desulfurization and denitrification transformation of the thermal power generating unit is solved, the equipment potential is fully played, and the stability of main parameters is guaranteed.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +1

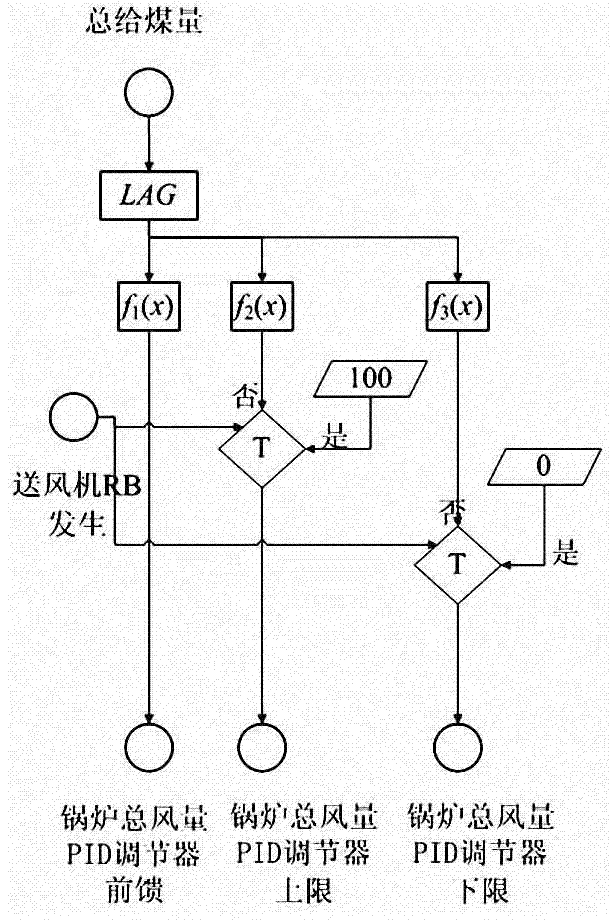

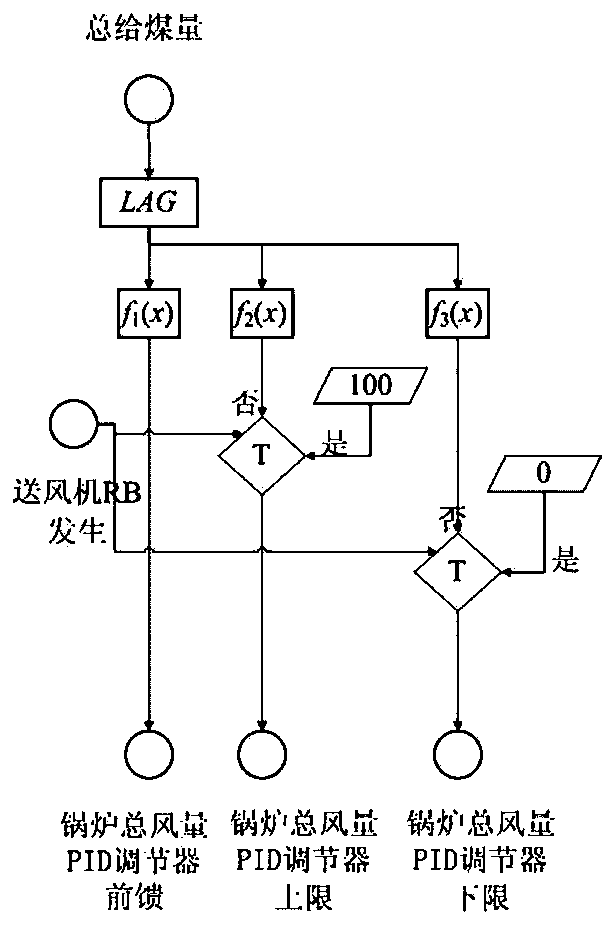

Automatic control optimization method of air feeder of thermal power unit

ActiveCN107166427AReduce labor intensityImprove real-time performanceFuel supply regulationFrequency changerAir volume

The invention relates to an automatic control optimization method of an air feeder of a thermal power unit. The automatic control optimization method comprises the following steps that the feedforward control logic of a boiler total air volume PID adjuster, the upper limit and lower limit control logic of the boiler total air volume PID adjuster, the over-current protection control logic of the air feeder and the anti-stall automatic control logic of the air feeder are designed in the control logical configuration of a distributed control system (DCS) of the thermal power unit; an air feeder guide vane or a frequency converter is controlled to act correctly; the total air volume is automatically controlled within a reasonable range; and the boiler combustion requirement is met. According to the automatic control optimization method, through an existing unit distributed control system (DCS) coordinated control system, the real-time performance is good, the field debugging process is simple, and engineering realization is facilitated.

Owner:LIAONING DONGKE ELECTRIC POWER

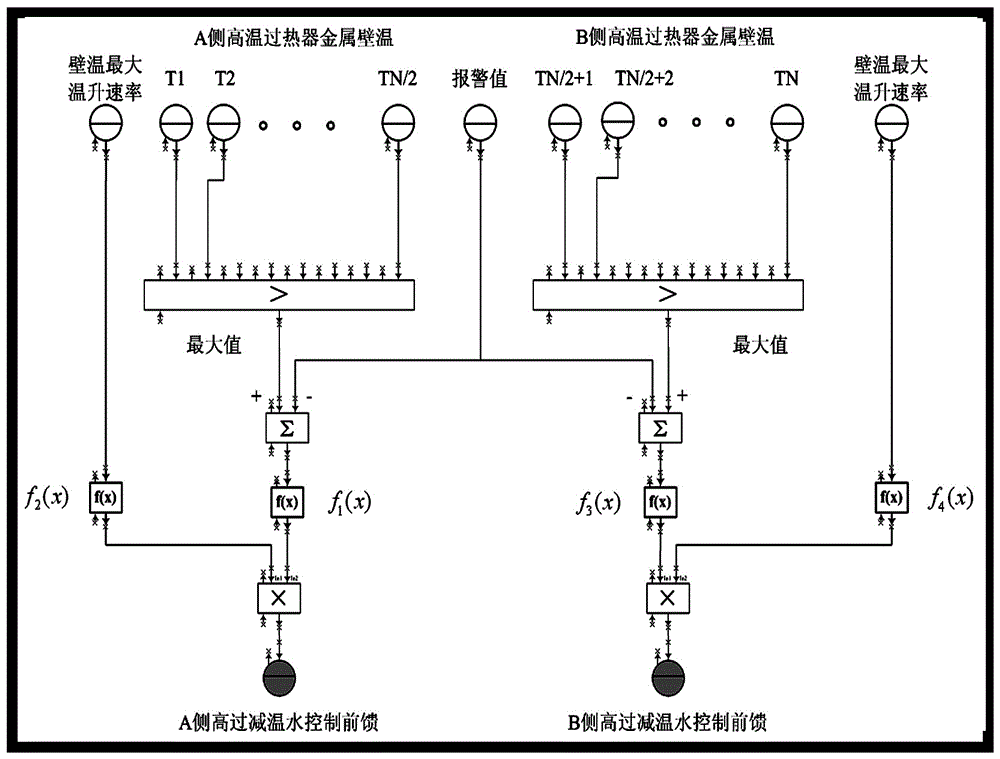

Superheater metal wall temperature control method for thermal power unit

InactiveCN105090932AImprove securityImprove economySuperheating controlTemperature controlPower station

The invention belongs to the technical field of thermal control for power generating unit boiler safety and particularly relates to a superheater metal wall temperature control method for a thermal power unit, and specifically relates to a method for avoiding boiler superheater overheating and tube rupture in a power station. The method comprises the steps that superheater metal wall temperature control loop interfaces are added to control loops of logic configuration fuels of a coordinated control system, water supplying and platen superheater attemperation water on two sides and high-temperature superheater attemperation water on two sides; logic configuration of a superheater metal wall temperature control loop is conducted and output and introduced to the superheater metal wall temperature control loop interfaces, and the logic configuration is taken as a feedforward signal of control over the fuels, water supplying and platen superheater attemperation water on two sides and high-temperature superheater attemperation water on two sides; a control system is placed in actual operation, and superheater metal wall temperature control loop parameters are adjusted and set online according to a real-time operation curve; quick and stable responses of main parameters of the unit are guaranteed, and the superheater metal wall temperature is controlled in a reasonable range at the same time. Superheater overheating and tube rupture accidences are avoided effectively; the labor intensity is reduced; the operation safety and economy of the unit are improved.

Owner:LIAONING DONGKE ELECTRIC POWER

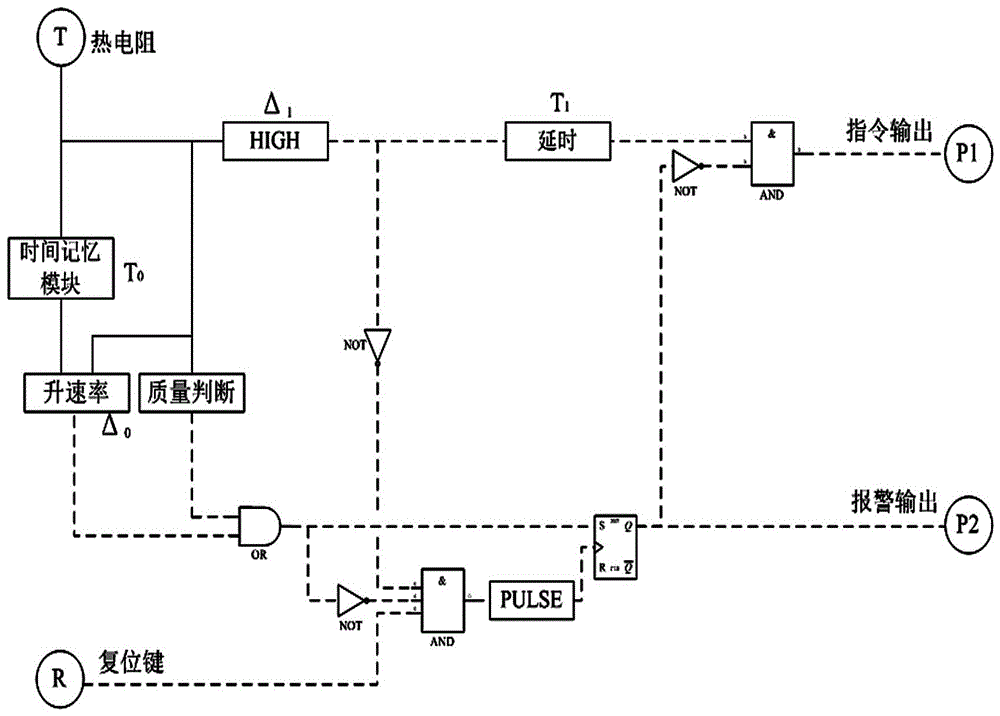

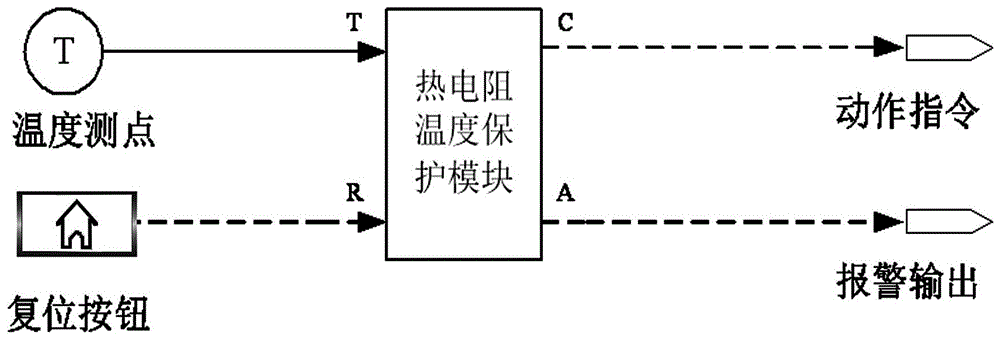

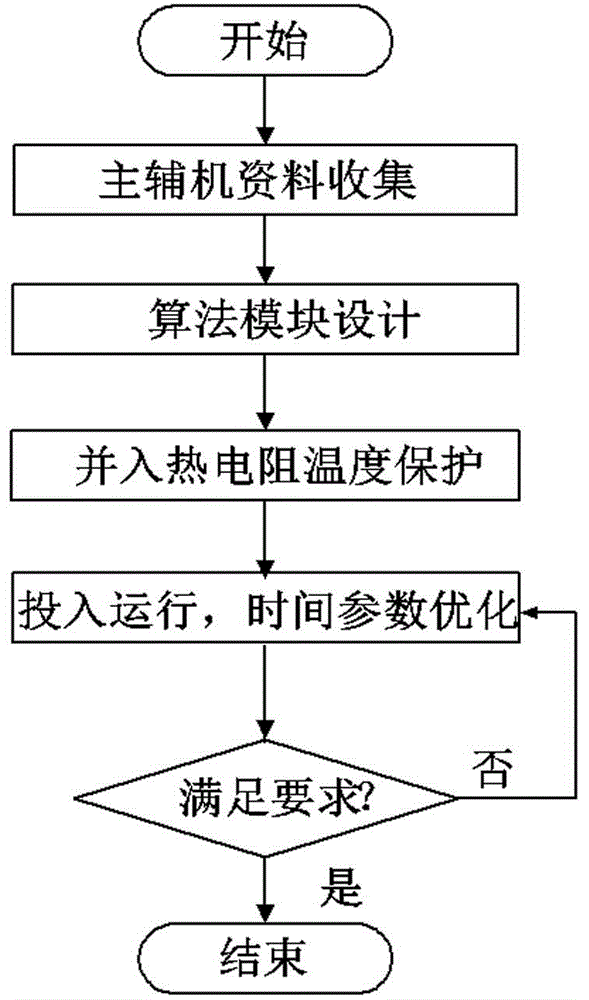

Method for preventing thermal resistor protection failure of thermal power plant DCS

InactiveCN106502229AWith a clear purposePerfect process method systemTotal factory controlProgramme total factory controlAutomatic controlEngineering

The invention belongs to the technical field of thermal generator unit automatic control, especially relates to a method for preventing thermal resistor protection failure of a thermal power plant DCS (Distributed Control System), and specifically relates to a method for preventing thermal resistor temperature protection failure of a thermal generator set. The method can be used to reform a thermal generator unit thermal resistor temperature protection system so as to improve the ability of the unit thermal process protection system to prevent misoperation. A thermal resistor temperature protection system of main and auxiliary equipment of a thermal power plant is taken as an optimized design object, false signals produced due to open circuit or virtual connection of a thermal resistor signal line are shielded, and the phenomenon that the temperature signal of the thermal resistor rises too fast and causes equipment mis-tripping is prevented. The method has the distinctive characteristics of simple field debugging process and easy project implementation. The reliability of the unit DCS thermal process protection system is improved effectively. The occurrence probability of misoperation events is reduced. The occurrence of unit tripping and equipment damage accidents is reduced. The number of non-stop times of the unit is reduced. The cost is lowered. The profit margin is improved. The method is of importance significance to improving the operation safety and economy of thermal generator units.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +1

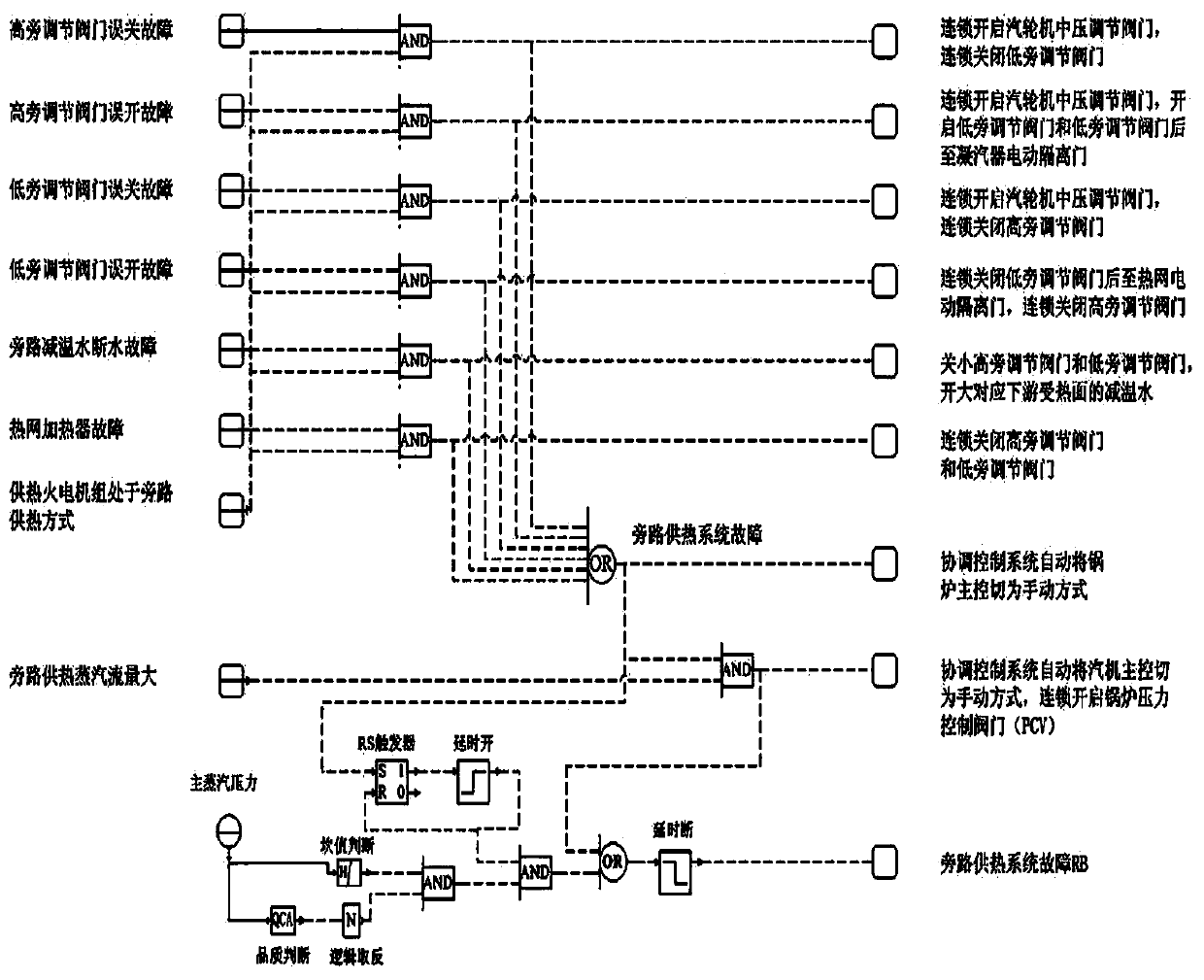

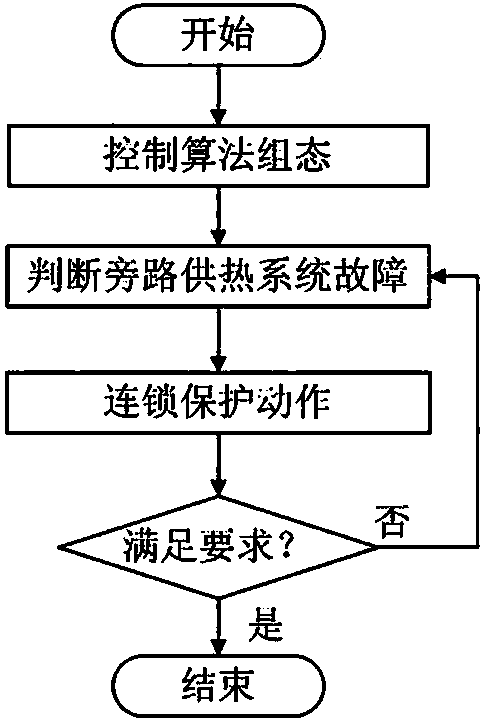

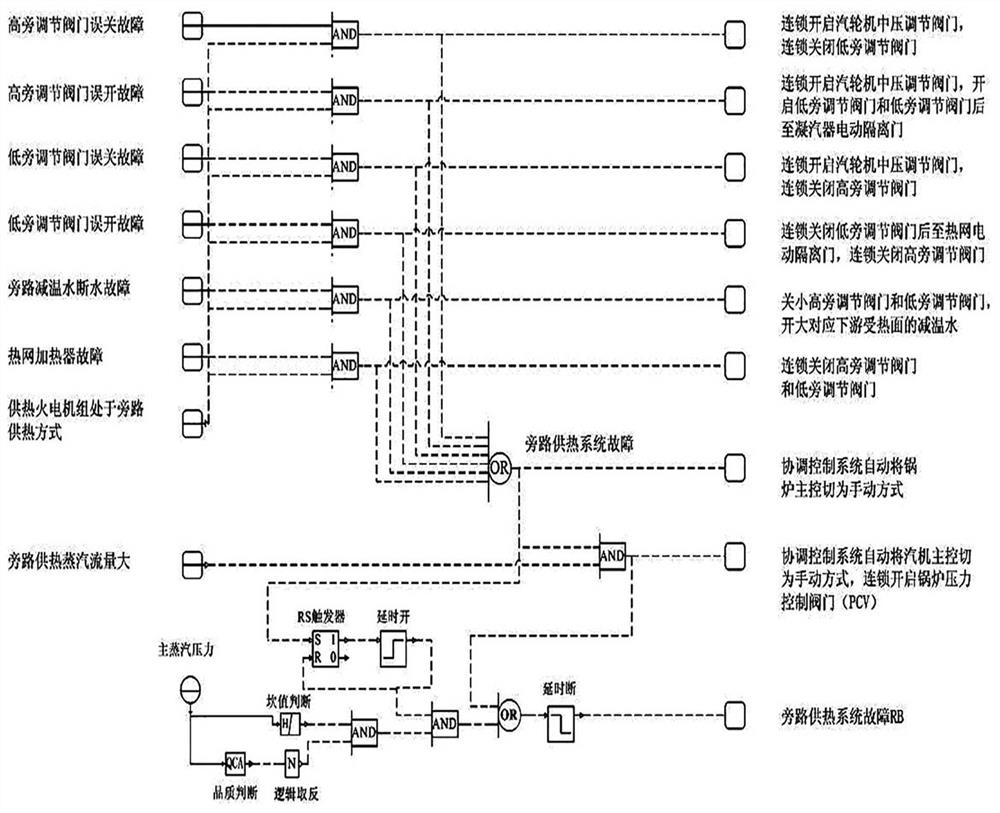

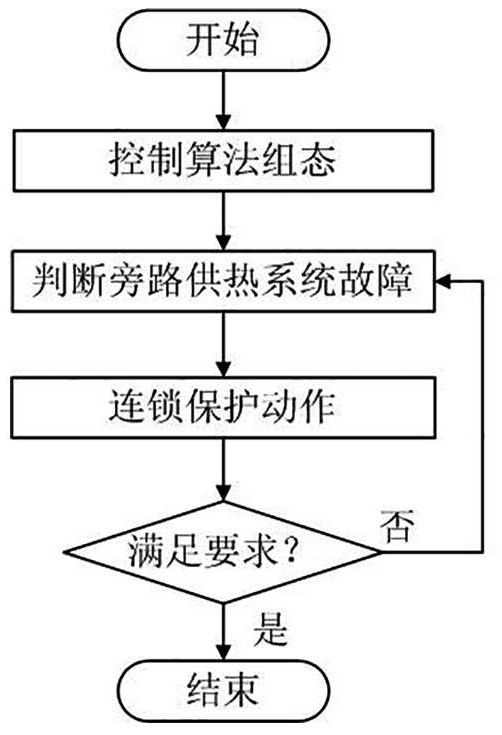

Optimization control method for improving reliability of unit bypass heat supply operation

ActiveCN110500645ASafe and stable operationSafe and Stable Operating ParametersLighting and heating apparatusSpace heating and ventilation detailsAutomatic controlSystem failure

The invention relates to the technical field of automatic control of thermal power units, in particular to an optimization control method for improving the reliability of unit bypass heat supply operation. The method comprises the following steps that when a heat supply thermal power generating unit is in a bypass heat supply mode, the fault of the unit bypass heat supply system is judged throughconfiguration of a control logic of a DCS of the heat supply thermal power generating unit; the size of bypass heat supply steam flow is judged, and interlocking protection action is performed in combination with fault of unit bypass heat supply system, so that the safety and stable operation of the unit is ensured; an automatic control logic is added, and the stability of operation parameters ofthe unit bypass heat supply system is controlled; and historical operation data and design data of the DCS of the heat supply thermal power generating unit are inquired, and all automatic control logic parameters are set. According to the method, the safety of equipment can be guaranteed under the working condition that the heat supply quality is ensured by the heat supply unit, the labor intensity of operators is effectively reduced, the control effect is not dependent on the technical level of operators, the real-time performance is good, the field debugging process is simple, and the engineering is convenient to realize.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +1

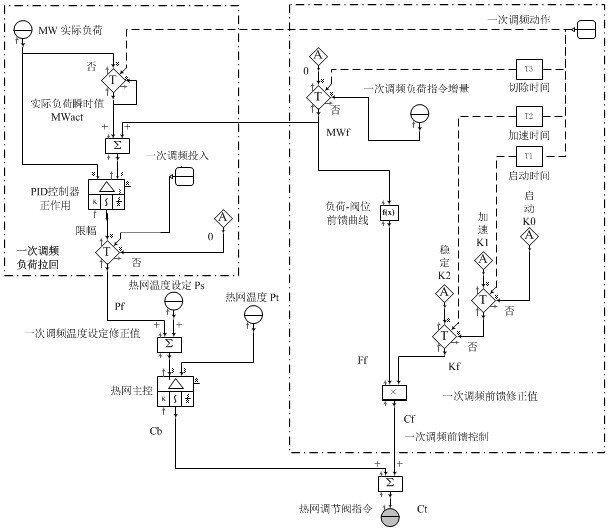

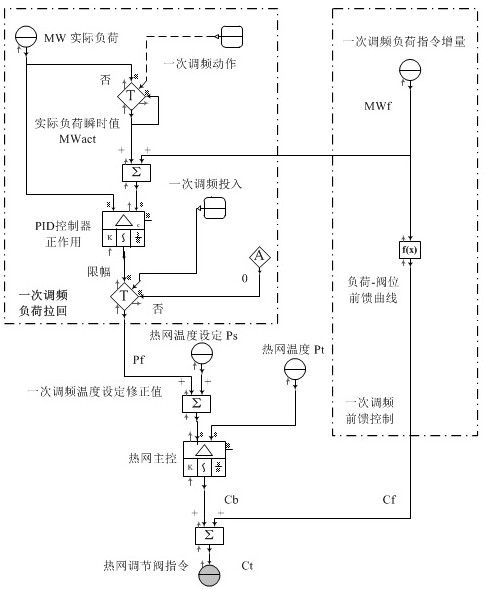

Combined cycle unit steam turbine primary frequency modulation control method

ActiveCN113110316ARealize a frequency modulation functionMeet the assessment requirementsTotal factory controlProgramme total factory controlAutomatic controlLoop control

The invention discloses a combined cycle unit steam turbine primary frequency modulation control method, which can be used for primary frequency modulation automatic control in an actual operation process of a combined cycle unit steam turbine. According to the method, by using a closed-loop control mode, a heat supply network temperature set value is dynamically corrected in real time according to network frequency deviation, so that reverse modulation of heat supply network temperature closed-loop control on primary frequency modulation is effectively avoided, and it is ensured that the primary frequency modulation performance of a unit in the mode is also rapid and accurate; and by comprehensively considering the primary frequency modulation control performance of the unit, primary frequency modulation process dynamic feedforward control is adopted, the control performance and the control target of the primary frequency modulation action process are integrally optimized, and the network-related assessment rule requirements are met in a targeted manner. According to the invention, the labor intensity of operators can be effectively reduced, the control effect does not depend on the technical level of the operators, the real-time performance is good, the field debugging process is simple, and engineering implementation is facilitated.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

An optimization method for primary frequency modulation control of steam drum boiler thermal power unit

ActiveCN106773681BReduce labor intensityImprove real-time performanceMachines/enginesEngine componentsAutomatic controlControl engineering

The invention belongs to the technical field of automatic control of a thermal power generator set and especially relates to a drum boiler thermal power generator set primary frequency modulation control optimization method. The method can be used for primary frequency modulation automatic control of the drum boiler thermal power generator set in the actual operation process, thereby ensuring that primary frequency modulation load is controlled within a reasonable range automatically in the operation process of the thermal power generator set. The method comprises adding a primary frequency modulation boiler master control feed-forward correction control logic, a primary frequency modulation turbine master control feed-forward correction control logic, a primary frequency modulation steam turbine digital electric hydraulic control system DEH correction coefficient control logic and a primary frequency modulation turbine extraction steam amount correction control logic to control logic configuration of a drum boiler thermal power generator set distributed control system DCS. The method can reduce labor intensity of personnel, and the control effect is not dependent on technical levels of operation personnel; and through an existing set distributed control system DCS coordinated control system, the method is good in real-time performance, simple in field debugging process and convenient for engineering realization.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +1

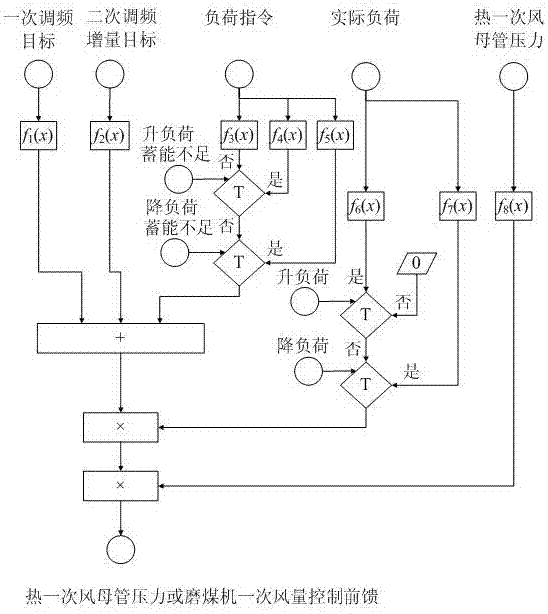

Control method of primary air volume of thermal power unit based on power grid frequency modulation and peak regulation

ActiveCN105318349BGuaranteed stabilityMeet the requirements of FM and peak shavingAir supply regulationAir volumeControl system

The invention relates to a method for controlling the primary air volume of a thermal power unit based on power grid frequency modulation and peak regulation. The steps are as follows: in the logic configuration of the original coordinated control system, increase Thermal power unit primary air volume control loop interface based on power grid frequency and peak regulation; carry out logical configuration of thermal power unit primary air volume control loop based on grid frequency and peak regulation, and introduce its output to the thermal power unit primary air volume control circuit interface based on power grid frequency and peak regulation It is used as the feed-forward signal of the hot primary air main pipe pressure at the outlet of the primary fan and the primary air volume control of a single coal mill; the control system is put into actual operation, and according to the real-time operation curve, the primary air volume control loop of the thermal power unit based on frequency modulation and peak shaving of the power grid is adjusted online Relevant parameters, and finally achieve the expected effect of the control line. Through the existing DCS coordination control system, the present invention has good real-time performance, simple on-site debugging process, and is convenient for engineering realization.

Owner:STATE GRID CORP OF CHINA +2

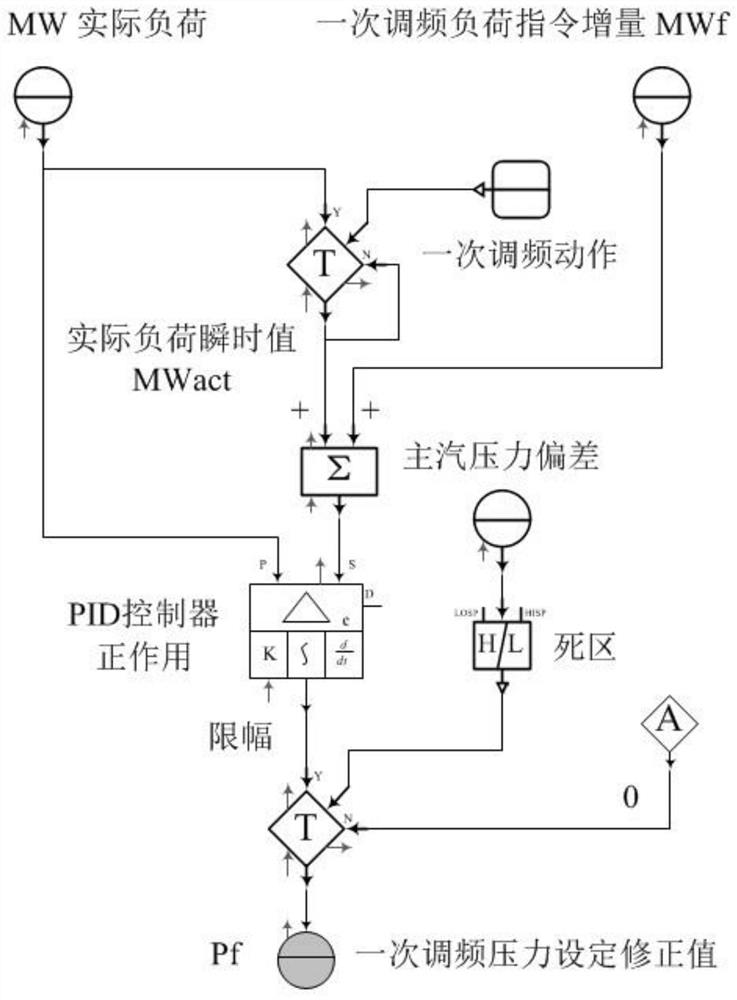

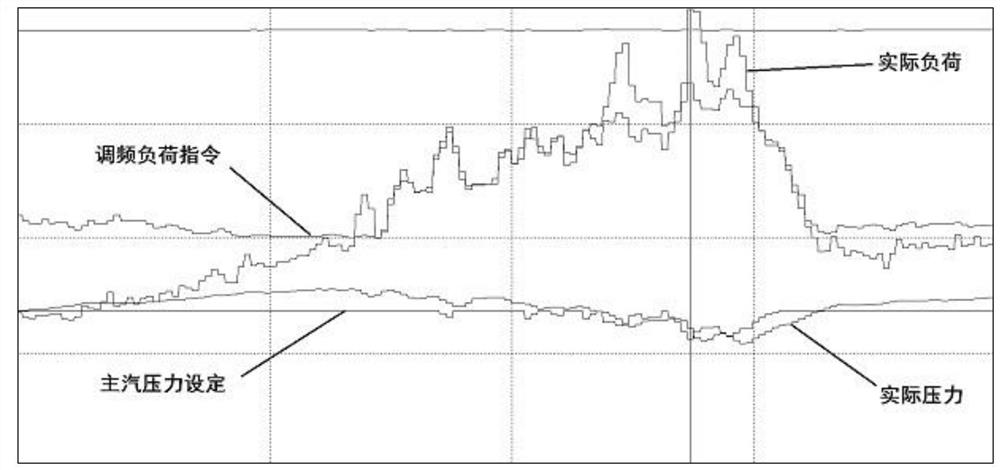

A primary frequency regulation control method for coal-fired units in the turbine following mode

ActiveCN111399448BMeet the assessment requirementsAvoid counter-tuneProgramme total factory controlAutomatic controlSteam pressure

The invention discloses a primary frequency modulation control method of a coal-fired unit in a steam turbine following mode, which belongs to the technical field of automatic control of the coal-fired unit and can be used for the automatic control of primary frequency modulation during the actual operation of the coal-fired unit. By adding the primary frequency modulation load pull-back control logic and adopting the closed-loop control method, the set value of the main steam pressure can be dynamically corrected in real time, which can effectively avoid the reverse adjustment of the primary frequency regulation in the steam turbine following mode, and ensure that the primary frequency regulation performance of the unit in this mode is also excellent. Rapidity and accuracy, to meet the grid assessment requirements.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Optimal method for outlet temperature control of medium-speed pulverizers in thermal power units

ActiveCN106594793BGuaranteed stabilityFull potentialCombustion regulationTemperature controlProportion integration differentiation

The invention relates to an outlet temperature control optimizing method of a medium-speed coal pulverizer of a thermal power generating unit. The method is characterized in that a PID (Proportion Integration Differentiation) adjuster is additionally arranged in control logic configuration of a DCS (Distributed Control System) of the thermal power generating unit, and linkage control logic is added to the control logic configuration of the DCS of the thermal power generating unit; a primary air pressure setting value correction control loop port based on the outlet temperature control optimization of the medium-speed coal pulverizer is added to primary air pressure control loop configuration of the control logic of the DCS of the thermal power generating unit, and primary air pressure setting value correction linkage control logic output is introduced to the primary air pressure setting value correction control loop port based on the outlet temperature control optimization of the medium-speed coal pulverizer to be used as the primary air pressure control correction; and the DCS is put into actual operation, and the parameters of each control loop in the outlet temperature control of the medium-speed coal pulverizer of the thermal power generating unit are adjusted online, so as to achieve the expected effect. The method is high in real-time performance, simple in on-site debugging process, and conveniently carried out in engineering.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +1

Checking method to prevent failure of thermal protection system for thermal power generating units

ActiveCN105332744BVerification steps are concise and clearEasy to operateMachines/enginesSafety/regulatory devicesAutomatic controlEngineering

Owner:STATE GRID CORP OF CHINA +1

Coordinated control method for frequency modulation and peak regulation of heating units in all working conditions

ActiveCN105202519BGuaranteed stabilityGuaranteed accuracyBoiler controlSteam pressureAutomatic control

The invention belongs to the technical field of automatic control of thermal power generating units, and in particular relates to a coordinated control method for frequency modulation and peak regulation of heating units in all working conditions. It is used for the automatic control of the heating unit participating in frequency regulation and peak regulation of the power grid under various working conditions, ensuring that the unit can automatically control the main parameters within a reasonable range while responding quickly and stably to frequency regulation and peak regulation. Specifically, by optimizing the control logic of the distributed control system (DCS) of the heating unit, the heating unit can automatically meet the requirements of frequency regulation and peak regulation of the power grid under various working conditions. Ensure the stability and accuracy of the coordinated control of the unit when participating in frequency regulation and peak regulation and the stability and accuracy of the main steam pressure control of the heating unit under different operating conditions, give full play to the potential of the equipment, and meet the requirements of power grid frequency regulation and peak regulation at the same time , to ensure the stability of the main parameters. It effectively reduces the labor intensity of the operators, and the control effect does not depend on the technical level of the operators. It has good real-time performance, and the on-site debugging process is simple, which is convenient for engineering realization.

Owner:STATE GRID CORP OF CHINA +2

Control method of coal supply for thermal power units based on power grid frequency regulation and peak regulation

ActiveCN104238494BGuaranteed stabilityMeet the requirements of FM and peak shavingTotal factory controlProgramme total factory controlUnit operationEngineering

The present invention relates to a thermal power unit coal supply control method based on power grid frequency modulation and peak regulation. The steps are as follows: adding a thermal power unit coal supply control circuit based on power grid frequency modulation and peak regulation to the logic configuration coal supply control loop of the original coordination control system Interface; carry out logic configuration of the thermal power unit coal supply control loop based on power grid frequency and peak regulation, and introduce its output into the coal supply control loop interface of thermal power unit based on power grid frequency and peak regulation as a feedforward signal for coal supply control ; The control system is put into actual operation, and according to the real-time operation curve, the relevant parameters of the thermal power unit coal supply control loop based on frequency modulation and peak regulation of the power grid are adjusted online, and the expected control effect is finally achieved. Through the existing DCS coordination control system, the present invention has good real-time performance, simple on-site debugging process, and is convenient for engineering realization. By judging the operating status of the unit, accurately control the amount of coal fed to the unit in different operating states, ensure the quick response of the load and the stability of the main parameters when the unit participates in frequency regulation and peak regulation, reduce the labor intensity of the operating personnel, and greatly improve the efficiency of the unit. The safety and economy of unit operation.

Owner:STATE GRID CORP OF CHINA +2

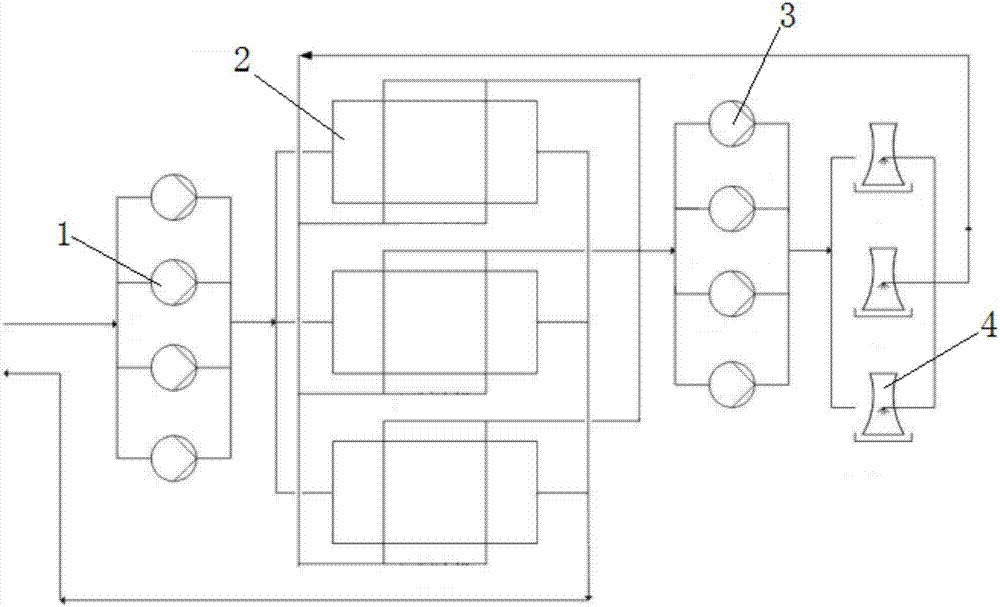

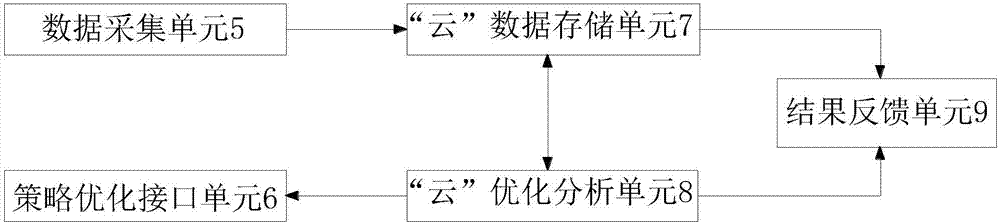

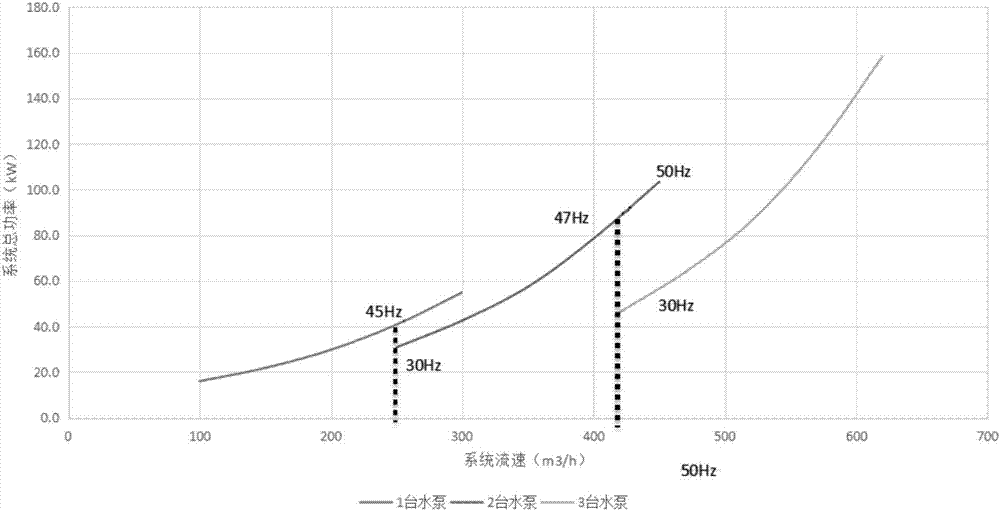

Control system used for achieving operation energy conservation of central air conditioner refrigeration station and control method

InactiveCN107270489AAchieve long-term continuous energy-saving optimizationImprove reliabilitySpace heating and ventilation safety systemsLighting and heating apparatusAutomatic controlControl system

The invention discloses a control system used for achieving operation energy conservation of a central air conditioner refrigeration station and a control method. The control system comprises a data collection unit, a strategy optimization interface unit, a cloud data storage unit, a cloud optimization analysis unit and a result feedback unit. The control method comprises the steps that a refrigeration station system is divided into a plurality of independent subunits; the energy efficiency index and the influence independent variable of each independent subunit are determined; the index and the independent variable of each independent subunit are obtained and recorded; and the relation between the index and the independent variable of each independent subunit is analyzed. Through the control system used for achieving operation energy conservation of the central air conditioner refrigeration station and the control method, the reliability and the usefulness of the automatic control system in actual projects are improved, and thus the risk of being wasted is lowered; and long-time energy conservation optimization of the refrigeration station is achieved, and the debugging process is simplified.

Owner:陈艳婕

Control optimization method of wind and smoke system after desulfurization and denitrification transformation of thermal power units

ActiveCN107940501BGuaranteed adjustment qualityFull potentialAir supply regulationAutomatic controlEngineering

The invention relates to an optimizing method of air and flue gas system control after desulfurization and denitrification transformation of a thermal power generating unit. An oxygen amount allowancecontrol loop after desulfurization and denitrification transformation of the thermal power generating unit and a loop interface, a secondary air valve opening degree allowance control loop after desulfurization and denitrification transformation of the thermal power generating unit and a loop interface, an induced draft fan output allowance control loop after desulfurization and denitrification transformation of the thermal power generating unit and a loop interface as well as a booster fan output allowance control loop after desulfurization and denitrification transformation of the thermal power generating unit and a loop interface are additionally arranged in the control logical configuration of a thermal power generating unit distributed control system (DCS); air blower output interlocking control logic and secondary air valve opening degree interlocking control logic after desulfurization and denitrification transformation of the thermal power generating unit are added in the control logical configuration of the thermal power generating unit DCS; according to the real-time running curve of the control system, related parameters of various control loops for optimization of airand flue gas system control after desulfurization and denitrification transformation of the thermal power generating unit are adjusted online, and the expected control effect is realized finally. Theproblem about automatic air and flue gas system control after desulfurization and denitrification transformation of the thermal power generating unit is solved, the equipment potential is fully played, and the stability of main parameters is guaranteed.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +1

Pre-warning optimization control method for metal wall temperature of panel superheater in supercritical coal-fired unit

The invention relates to a supercritical coal-fired unit platen superheater metal wall temperature early-warning optimal control method. The method comprises the steps that a platen superheater metal wall temperature control loop connector is added in a logical configuration fuel, water supply and two side platen superheater desuperheating water control loop in an original coordinated control system; platen superheater metal wall temperature control loop logical configuration is conducted and is output and led into the platen superheater metal wall temperature control loop connector to be used as feedforward signals of fuel, water supply and two side platen superheater desuperheating water control; a control system is put into actual operation, platen superheater metal wall temperature control loop parameters are adjusted and set on line according to a real-time operation curve, and the expected effect is finally achieved. According to an existing DCS coordinated control system, the supercritical coal-fired unit platen superheater metal wall temperature early-warning optimal control method is good in real-time performance, and simple in field debugging process, and can achieve engineering realization easily. Both supercritical coal-fired unit major parameters and platen superheater metal wall temperature control are automatically considered, overtemperature pipe explosion accidents of a platen superheater are effectively avoided, labor intensity is reduced, and unit operation safety and economy are improved.

Owner:STATE GRID CORP OF CHINA +2

Primary frequency modulation control method for steam turbine generator of double-shaft combined cycle unit

ActiveCN113281988ARealize the function of one frequency modulationMeet the assessment requirementsControllers with particular characteristicsTotal factory controlAutomatic controlLoop control

The invention discloses a primary frequency modulation control method for a steam turbine generator of a double-shaft combined cycle unit. The primary frequency modulation control method can be used for primary frequency modulation automatic control in the actual operation process of a steam turbine of the double-shaft combined cycle unit. On one hand, a closed-loop control mode is adopted, the heat supply network temperature set value is dynamically corrected in real time according to the network frequency deviation, reverse modulation of heat supply network temperature closed-loop control on primary frequency modulation is effectively avoided, thereby ensuring that the primary frequency modulation performance of a unit is accurate in the mode; on the other hand, primary frequency modulation feedforward control is added in heat supply network control logic, it is ensured that the primary frequency modulation performance of the unit is rapid in the mode, and the requirement for network-related assessment rules is integrally met. According to the primary frequency modulation control method, the labor intensity of operators can be effectively reduced, the control effect does not depend on the technical level of the operators, the real-time performance is good, the field debugging process is simple, and engineering implementation is facilitated.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Optimal early warning control method for metal wall temperature of high temperature superheater in supercritical coal-fired unit

ActiveCN103309314BImprove securityImprove economyProgramme total factory controlTemperature controlDistributed control system

The invention relates to a metal wall temperature early warning optimization control method of a high-temperature super-heater of a supercritical coal-fired unit. The metal wall temperature early warning optimization control method comprises the following steps: increasing a metal wall temperature control loop connector of the high-temperature super-heater in a logical configuration excessive desuperheating water control loop of a previous coordinated control system; carrying out logical configuration of a metal wall temperature control loop of the high-temperature super-heater and introducing an output to the metal wall temperature control loop connector of the high-temperature super-heater to be used as a feedforward signal of excessive desuperheating water control; putting a control system into actual operation; and setting relative parameters of the metal wall temperature control loop of the high-temperature super-heater online according to an actual operation curve to finally achieve the predicated control effect. According to the metal wall temperature early warning optimization control method disclosed by the invention, an existing DCS (Distributed Control System) coordinated control system is utilized, so that the instantaneity is good, a field debugging process is simple, and engineering is convenient to realize. Main parameters of the supercritical coal-fired unit and the metal wall temperature control on the high-temperature super-heater are automatically integrated so that an over-temperature pipe explosion accident of the high-temperature super-heater is effectively prevented, the labor intensity of operation personnel is reduced, and the safety and the economical efficiency of the operation of the unit are greatly improved.

Owner:STATE GRID CORP OF CHINA +2

An optimal control method for improving the reliability of the bypass heating operation of the unit

ActiveCN110500645BSafe and stable operationSafe and Stable Operating ParametersLighting and heating apparatusSpace heating and ventilation detailsAutomatic controlSystem failure

The invention relates to the technical field of automatic control of thermal power units, in particular to an optimal control method for improving the reliability of bypass heating operation of the unit, comprising: when the heating thermal power unit is in the bypass heating mode, by configuring the heating thermal power unit The control logic of the decentralized control system DCS judges the failure of the bypass heating system of the unit; judges the size of the bypass heating steam flow, and performs chain protection actions in combination with the failure of the bypass heating system of the unit to ensure the safe and stable operation of the unit; adding automatic control Logic, to control the stability of the operating parameters of the unit bypass heating system; query the historical operating data and design data of the DCS of the decentralized control system of the thermal power unit, and adjust each automatic control logic parameter. The invention can realize the equipment safety of the heating unit under the condition of ensuring the heating quality, effectively reduce the labor intensity of the operating personnel, and the control effect does not depend on the technical level of the operating personnel; the real-time performance is good, the on-site debugging process is simple, and it is convenient for engineering accomplish.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +1

A method for automatic control and optimization of the blower of a thermal power unit

ActiveCN107166427BMeet combustion requirementsReduce labor intensityFuel supply regulationFrequency changerAir volume

The invention relates to an automatic control optimization method of an air feeder of a thermal power unit. The automatic control optimization method comprises the following steps that the feedforward control logic of a boiler total air volume PID adjuster, the upper limit and lower limit control logic of the boiler total air volume PID adjuster, the over-current protection control logic of the air feeder and the anti-stall automatic control logic of the air feeder are designed in the control logical configuration of a distributed control system (DCS) of the thermal power unit; an air feeder guide vane or a frequency converter is controlled to act correctly; the total air volume is automatically controlled within a reasonable range; and the boiler combustion requirement is met. According to the automatic control optimization method, through an existing unit distributed control system (DCS) coordinated control system, the real-time performance is good, the field debugging process is simple, and engineering realization is facilitated.

Owner:LIAONING DONGKE ELECTRIC POWER

Control method for overcoming fluctuations in main steam pressure in multi-coal mixed firing conditions of heating units

The present invention involves a multi -coal -type mixed working condition of heating units to overcome the main steam pressure fluctuation control method. The steps are as follows: Increase the following circuit interface in the control logic configuration of DCS of the heating unit decentralized control systemGive the coal volume control loop interface, overcome the air volume control circuit interface of the main steam pressure fluctuations, overcome the main steam pressure fluctuation of the main steam pressure setting value control loop interface, and overcome the main steam pressure fluctuating steam turbine high -pressure door control loop interface;In the control logic of the control system DCS, the heating unit multi -coal type mixed work conditions overcome the main steam pressure fluctuation logic configuration, and the output is introduced to the main steam pressure fluctuation circuit interface;In real -time running curve, the multi -coal type of the heating units of the heating units is the same as the mixed coal type of the heating unit overcome the relevant parameters of the control circuit of the main steam pressure fluctuations, and finally achieve the expected control effect.The invention coordinate the control system through the existing heating unit DCS DCS. It is good in real -time and the on -site debugging process is simple to facilitate the implementation of the project.

Owner:STATE GRID CORP OF CHINA +2

A Coal Supply Quantity Optimization Control Method for Unit Bypass Heating

ActiveCN109373347BAutomatically meet the requirements of frequency modulation and peak regulationReduce labor intensityFuel supply regulationAutomatic controlSteam pressure

The invention relates to the technical field of automatic control methods, in particular to a coal feeding amount optimization control method for unit bypass heat supply. Through optimizing a coal feeding amount instruction control logic of a heat supply unit dispersion control system (DCS), the heat supply quality of the heat supply unit can be ensured to automatically meet the frequency modulation and peak modulation requirements of a power grid under the bypass heat supply working condition. The method comprises the steps that the coal feeding amount instruction automatic control logic of the unit bypass heat supply is designed; a configuration heat supply load converting coal feeding amount instruction automatic control logic is formed; a configuration unit load corresponding coal feeding amount instruction automatic control logic is formed; a configuration load change dynamic coal feeding amount instruction automatic control logic is formed; a configuration main steam pressure correcting coal feeding amount instruction automatic control logic is formed; and the DCS historical operation data of the unit are inquired. According to the existing unit DCS coal feeding amount control system, the frequency modulation and peak modulation requirements of the power grid can be automatically met by the heat supply unit under the condition that the heat supply quality is ensured; andthe labor intensity of operators is reduced, the real-time performance is good, the field debugging process is simple, and engineering implementation is facilitated.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com