Supercritical coal-fired unit platen superheater metal wall temperature early-warning optimal control method

A screen type superheater, coal-fired unit technology, applied in control systems, lighting and heating equipment, steam generation, etc., can solve problems such as control effects relying on operators, inability to effectively control metal wall temperature, and over-temperature pipe burst accidents. , to achieve the effect of simple on-site debugging process, improving safety and economy, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

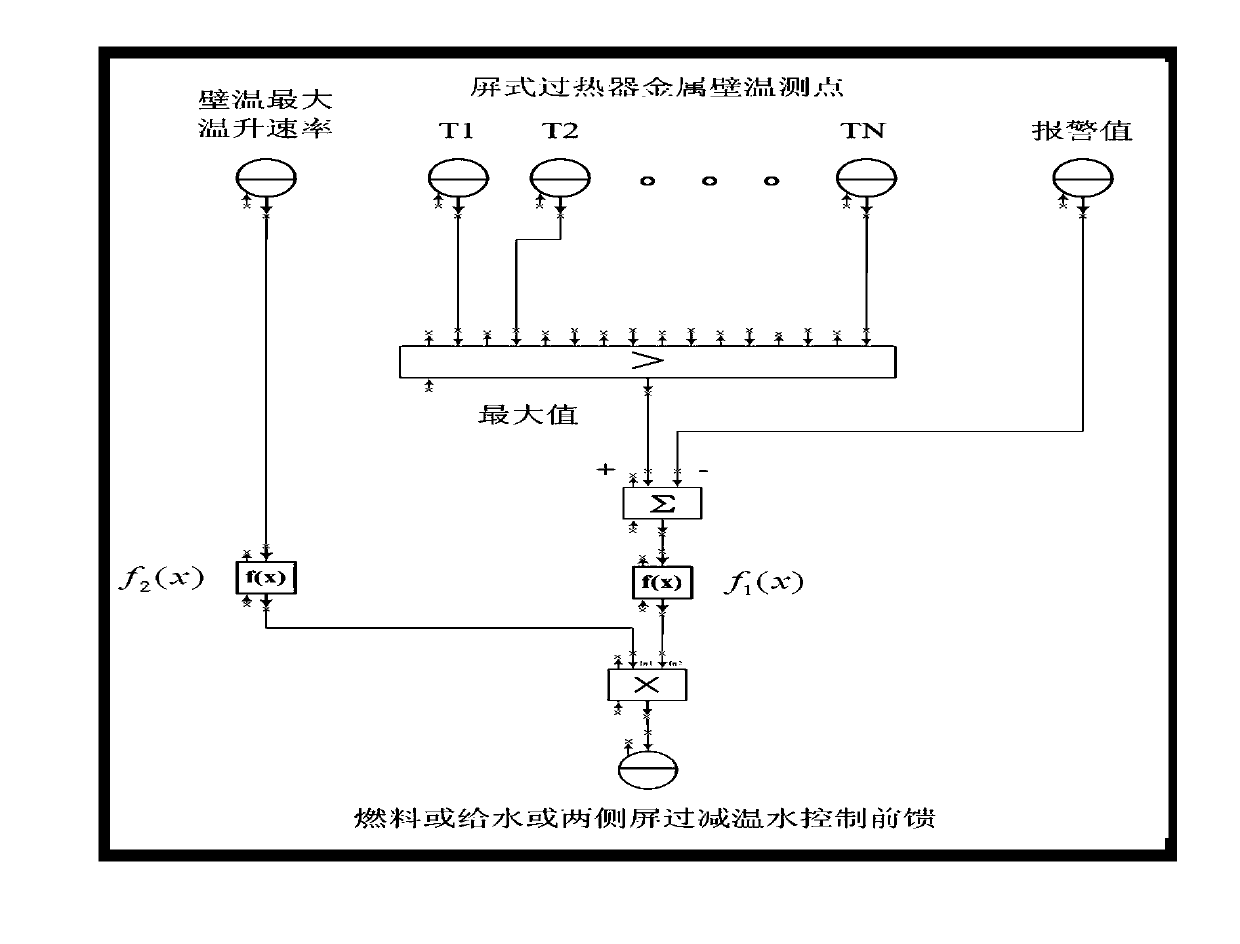

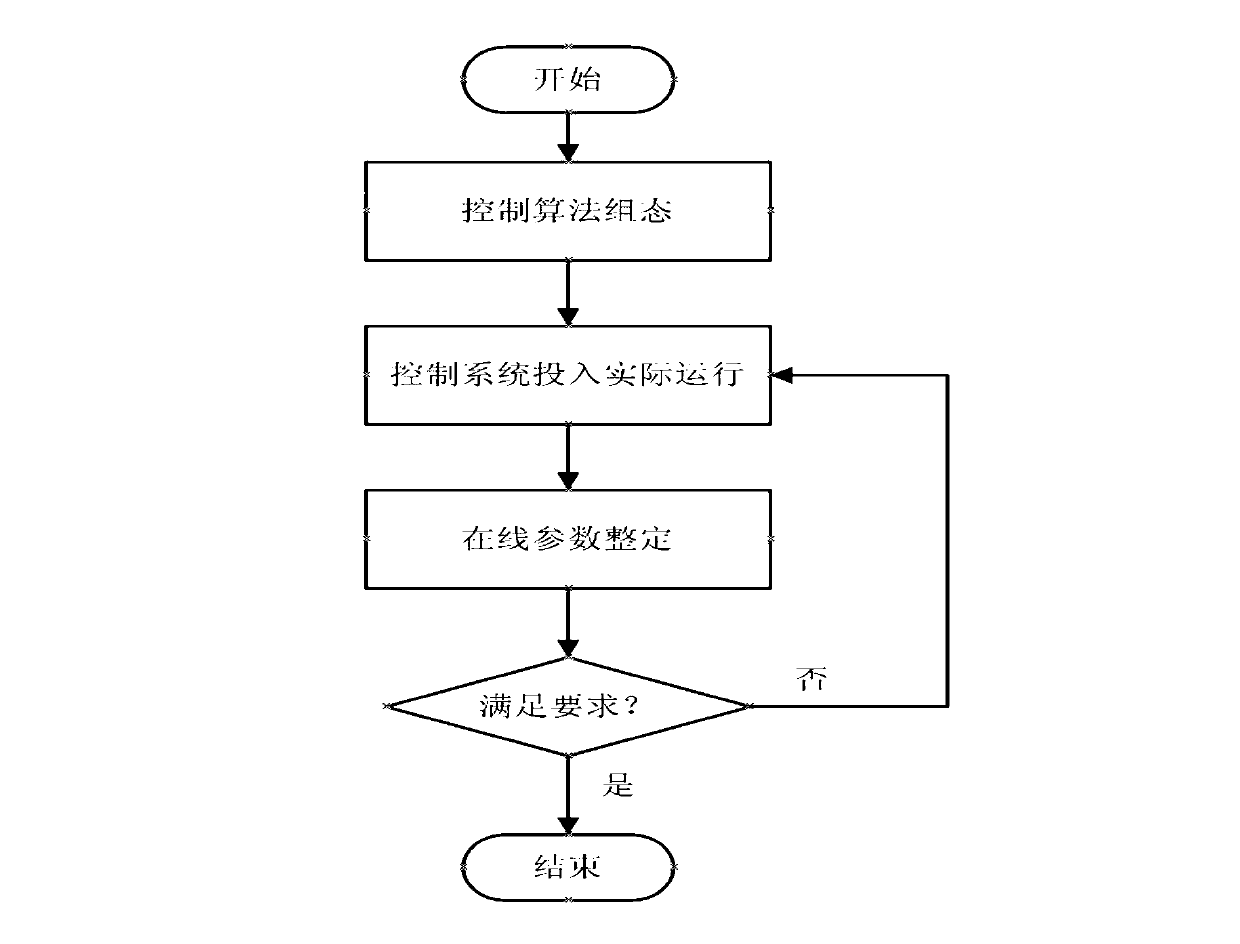

[0022] The present invention is an early warning optimization control method for the metal wall temperature of the panel superheater of a supercritical coal-fired unit, such as figure 2 shown, including the following steps:

[0023] Step 1: Add the metal wall temperature control circuit interface of the panel superheater in the logic configuration fuel, feed water and both sides panel overheating and desuperheating water control circuits of the original coordinated control system;

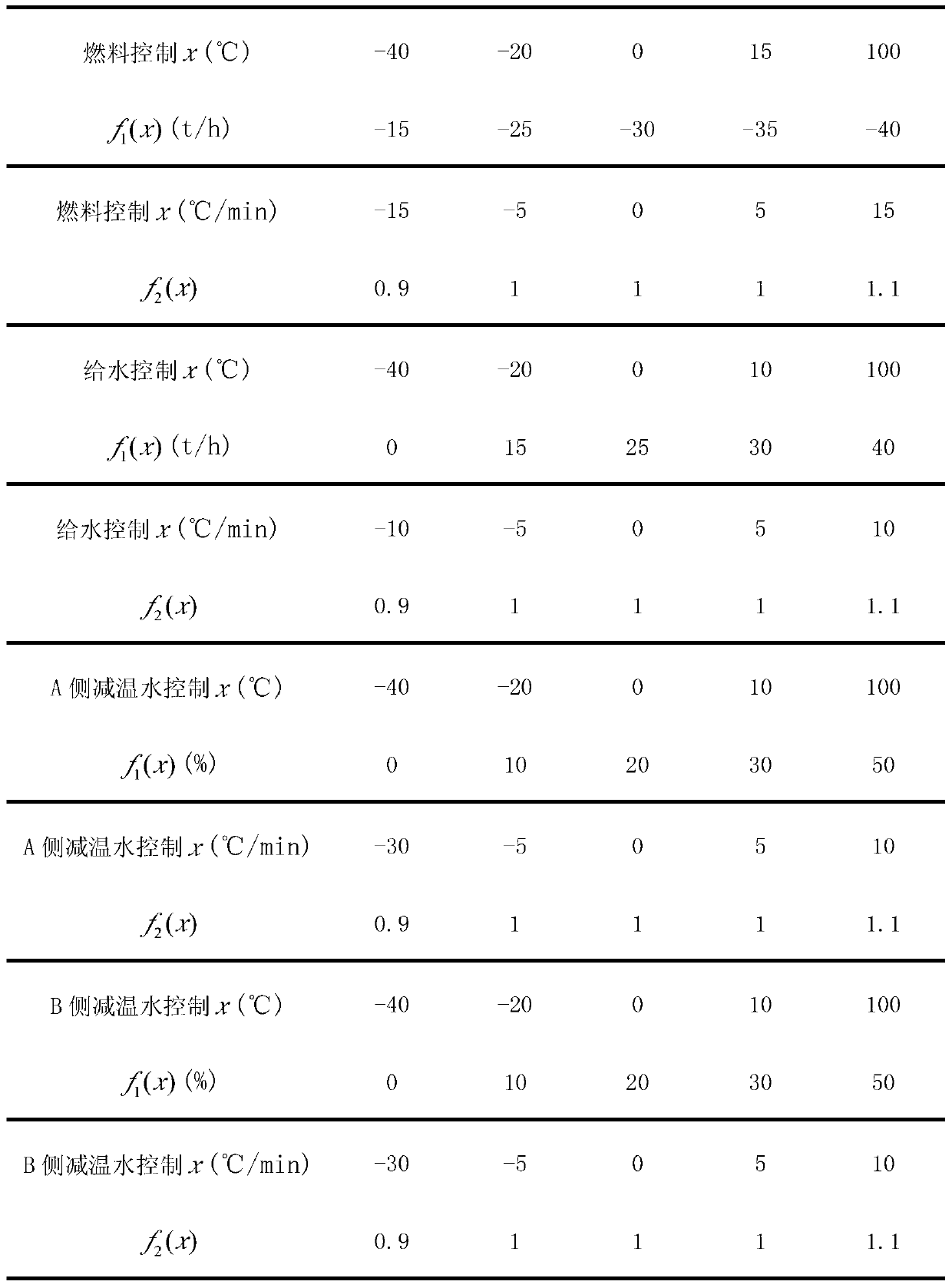

[0024] Step 2: Carry out the logic configuration of the metal wall temperature control loop of the panel superheater, and introduce its output into the interface of the metal wall temperature control circuit of the panel superheater as a feedforward for the control of fuel, feed water, and overheating and desuperheating water on both sides Signal;

[0025] Step 3: The control system is put into actual operation. According to the real-time operation curve, the relevant parameters of the metal wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com