Flow characteristic correction method for steam turbine high pressure control valve of thermal power generating unit

A technology of high-voltage valve control and thermal power units, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., to achieve good real-time performance, reduce labor intensity, and facilitate engineering realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

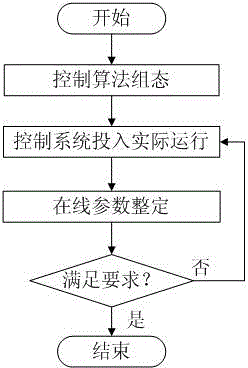

[0026] The present invention is a method for correcting the flow characteristics of a thermal power unit steam turbine with a high pressure valve, such as figure 2 Shown, work flow of the present invention comprises the steps:

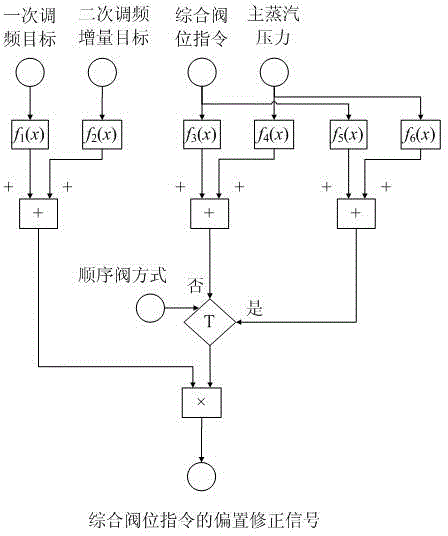

[0027] Step 1: Add the steam turbine high-pressure valve flow characteristic correction control loop interface in the logic configuration comprehensive valve position control loop of the original steam turbine digital electro-hydraulic control system;

[0028] Step 2: Carry out the logic configuration of the high-pressure regulating door flow characteristic correction control loop of the steam turbine of the thermal power unit, and introduce its output into the flow characteristic correction circuit interface of the steam turbine high-pressure regulating valve of the thermal power unit as the bias correction signal of the comprehensive valve position command;

[0029] The third step: the control system is put into actual operation, and according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com