Patents

Literature

37results about How to "Meet the assessment requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Attitude precision estimation method of multiple high-accuracy inertial navigations system

InactiveCN102706361AReduce measurement uncertaintyGuaranteed uptimeMeasurement devicesTransistor–transistor logicEstimation methods

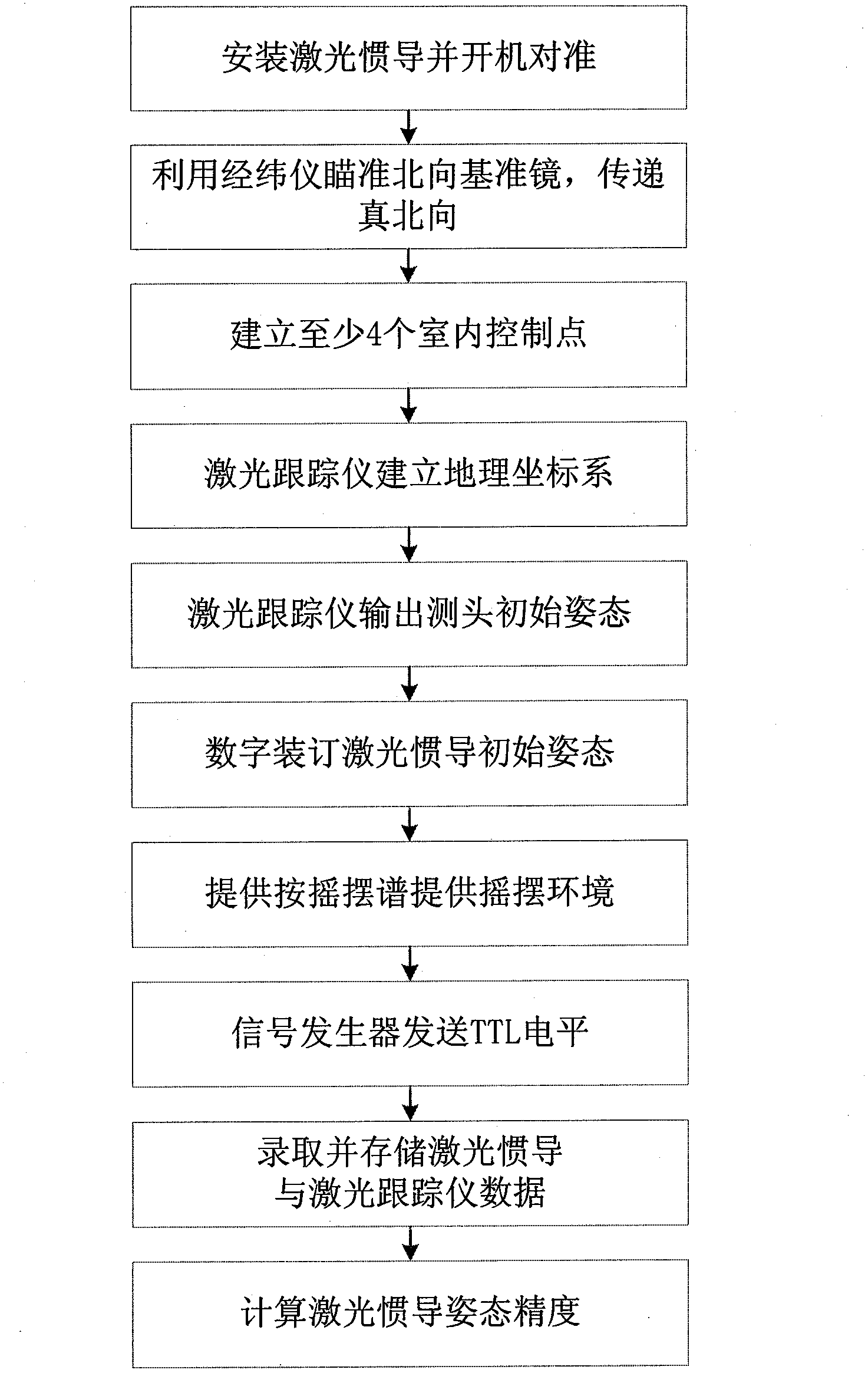

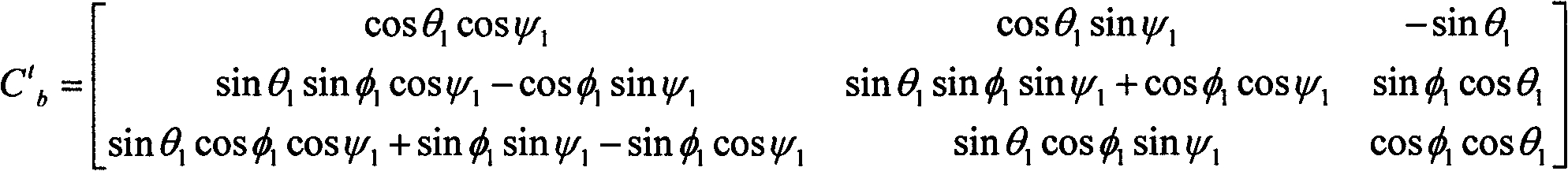

The invention provides an attitude precision estimation method of multiple high-accuracy inertial navigation systems. According to the method, a set of laser tracker, an attitude measuring head, a signal generator, a swing table or turntable, and a data recording device are used to realize the attitude precision estimation of multiple high-accuracy inertial navigation systems at the same time through initial alignment calibration and synchronous data acquisition, wherein the swing table or turntable is used for providing a dynamic swing environment and can realize pitching, horizontal rolling and longitudinal swing according to a given period and amplitude value, the laser tracker and components matched with the laser tracker can measure three attitude angles of the swing table under a geographical system in real time, the signal generator sends TTL (transistor-transistor-logic) synchronizing level to the laser tracker and the laser inertial navigation systems so as to trigger data output, and the data recording device is used for receiving attitude data sent by the laser tracker and the inertial navigation systems in real time and storing the attitude data into lines. The method is quite suitable for the attitude precision estimation of the laser inertial navigation systems and can be used for estimating the attitude precision of multiple high-accuracy laser inertial navigation systems at the same time by using simplest equipment components.

Owner:中国人民解放军92537部队

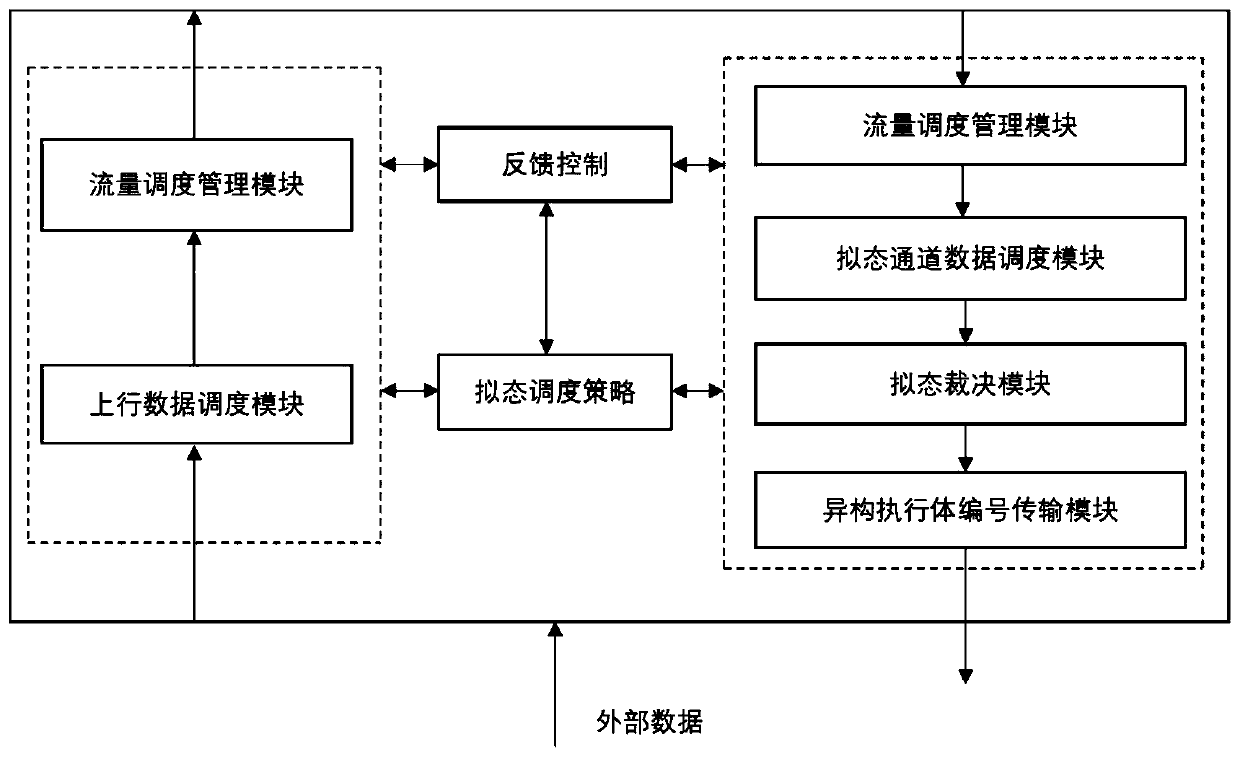

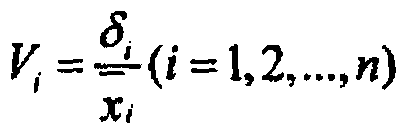

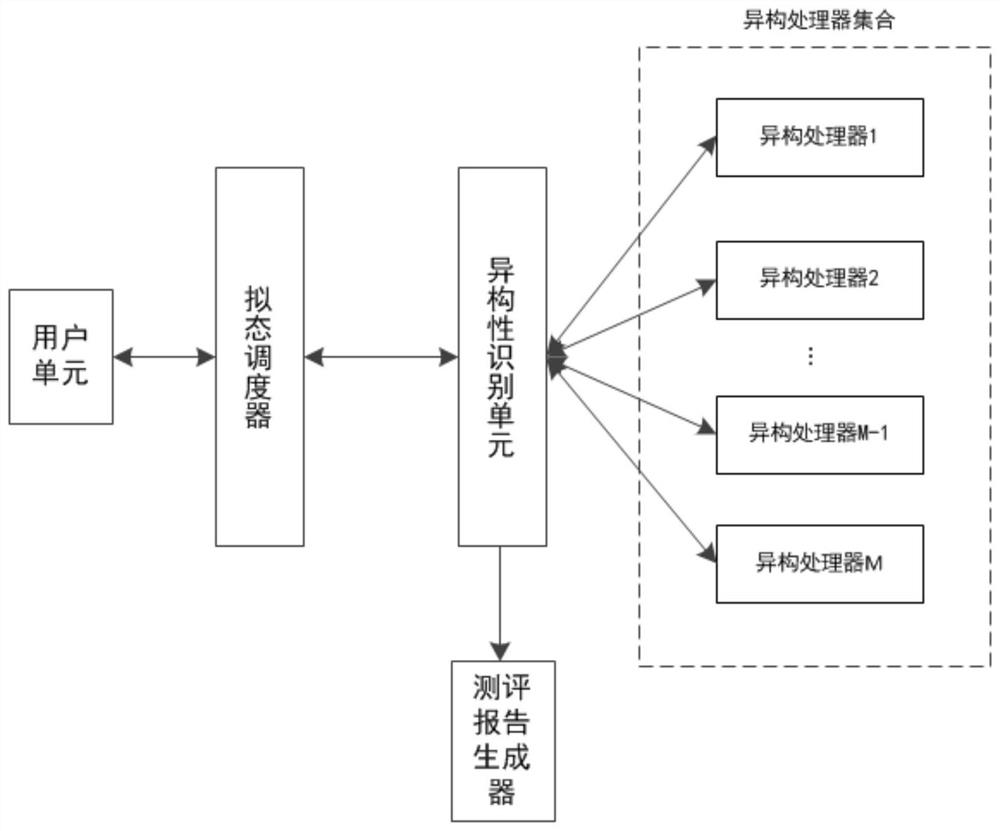

Heterogeneity testing device and method based on a DHR architecture mimicry defense platform

InactiveCN110445787AVerify securityEfficient and stableData switching networksTest fixtureComputer science

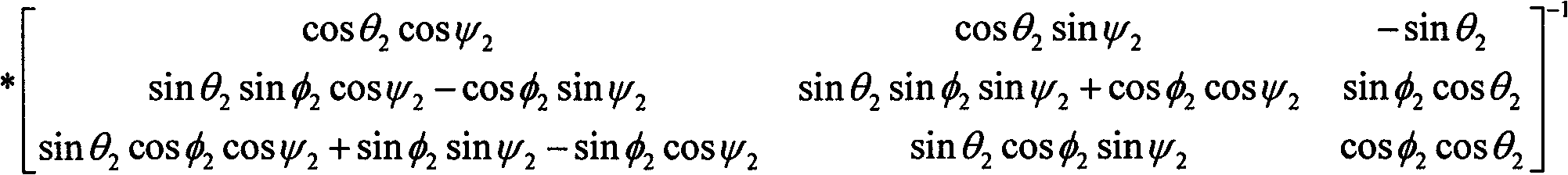

The invention provides a heterogeneity testing device and method based on a DHR architecture mimicry defense platform. The device part comprises a mimicry scheduler, a heterogeneity executor set and aheterogeneity recognizer. The device disclosed by the invention is based on the existing test method for verifying the characteristics of the mimicry system; verification and judgment for the types of the heterogeneous executors are added, the stability, safety and performance rationality of the heterogeneous executors can be verified more efficiently, and a detailed test report is automaticallygenerated, so that the requirement for evaluating the heterogeneity of the mimicry safety information system is met.

Owner:EAST CHINA INST OF COMPUTING TECH

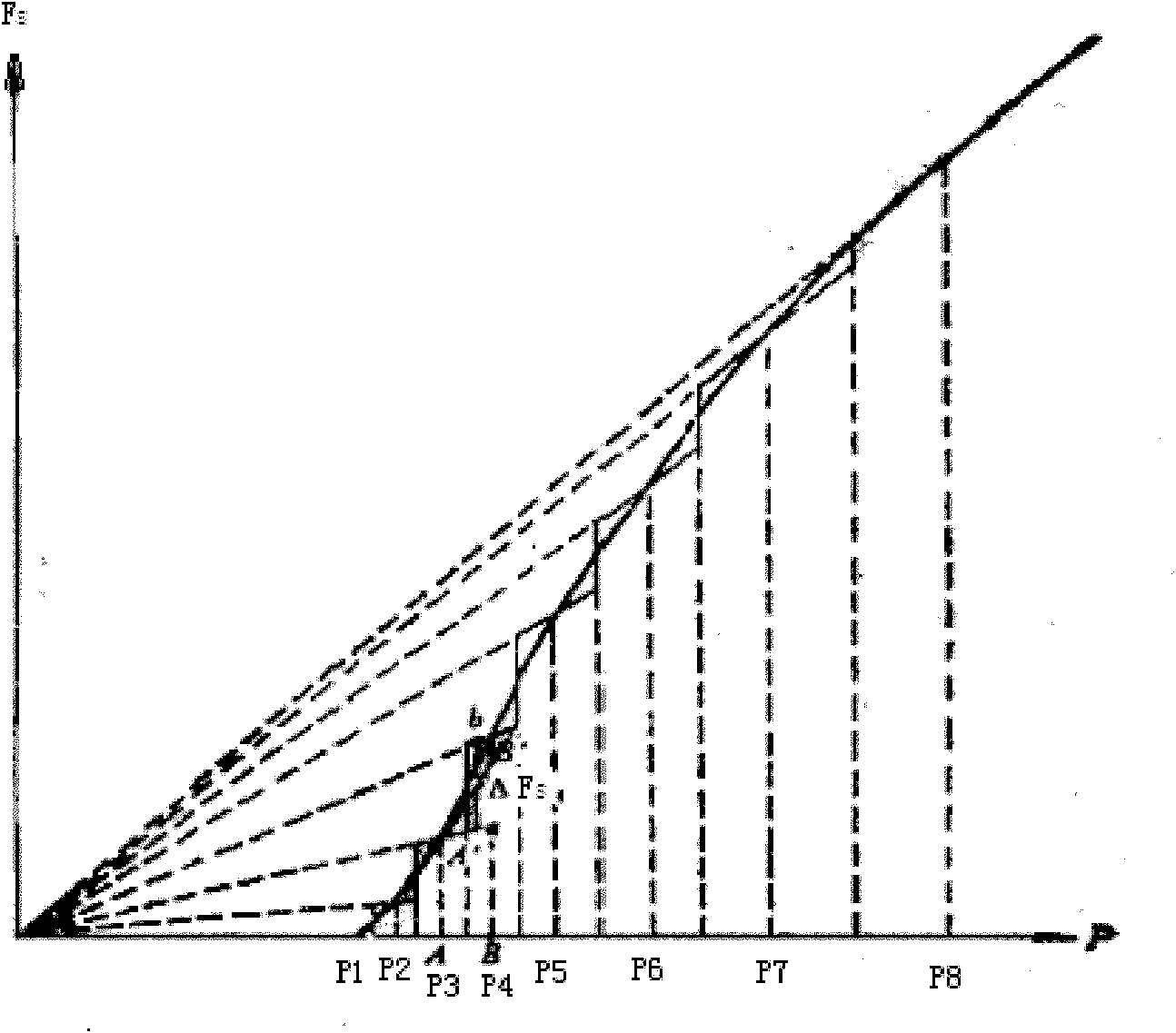

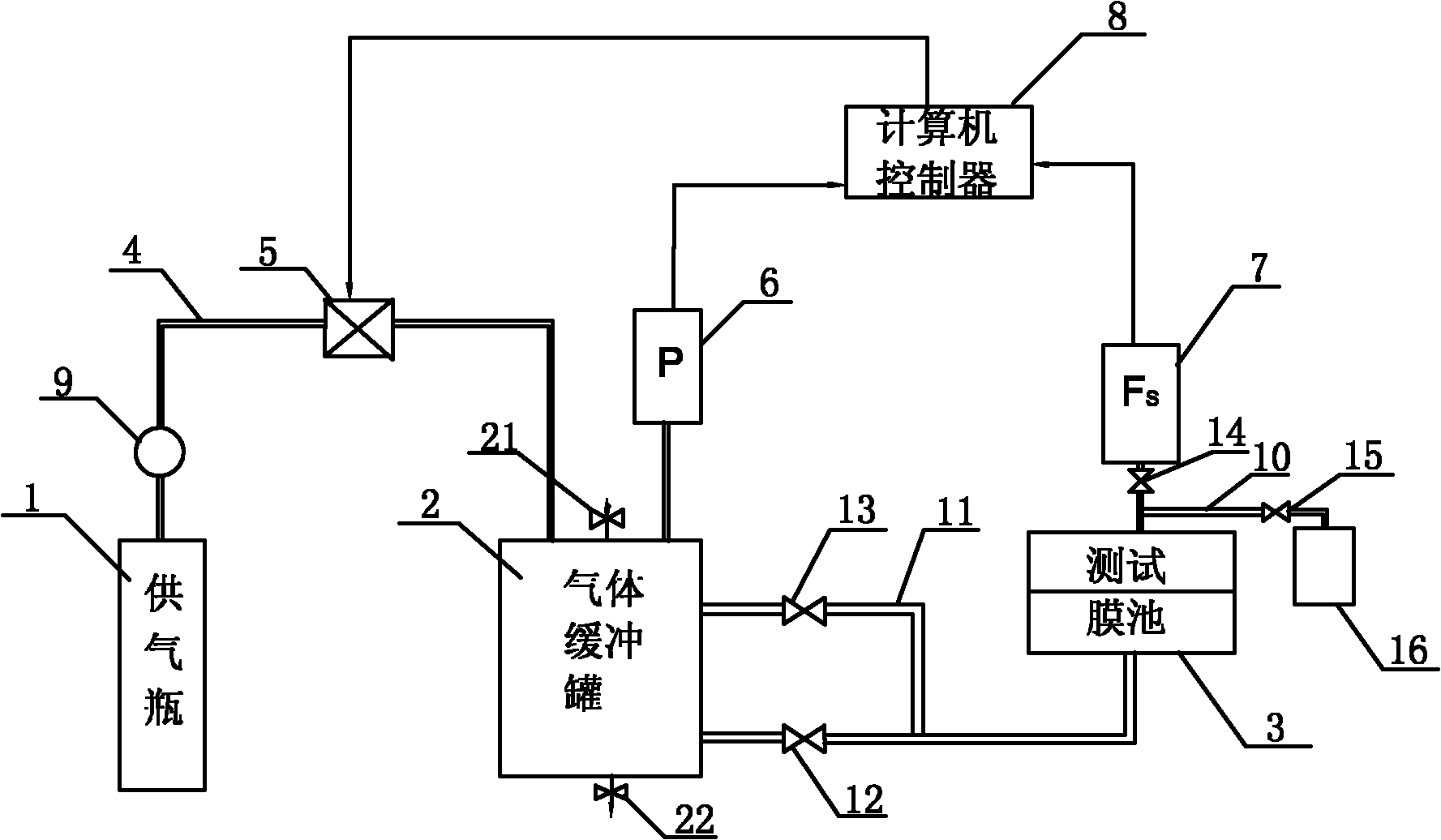

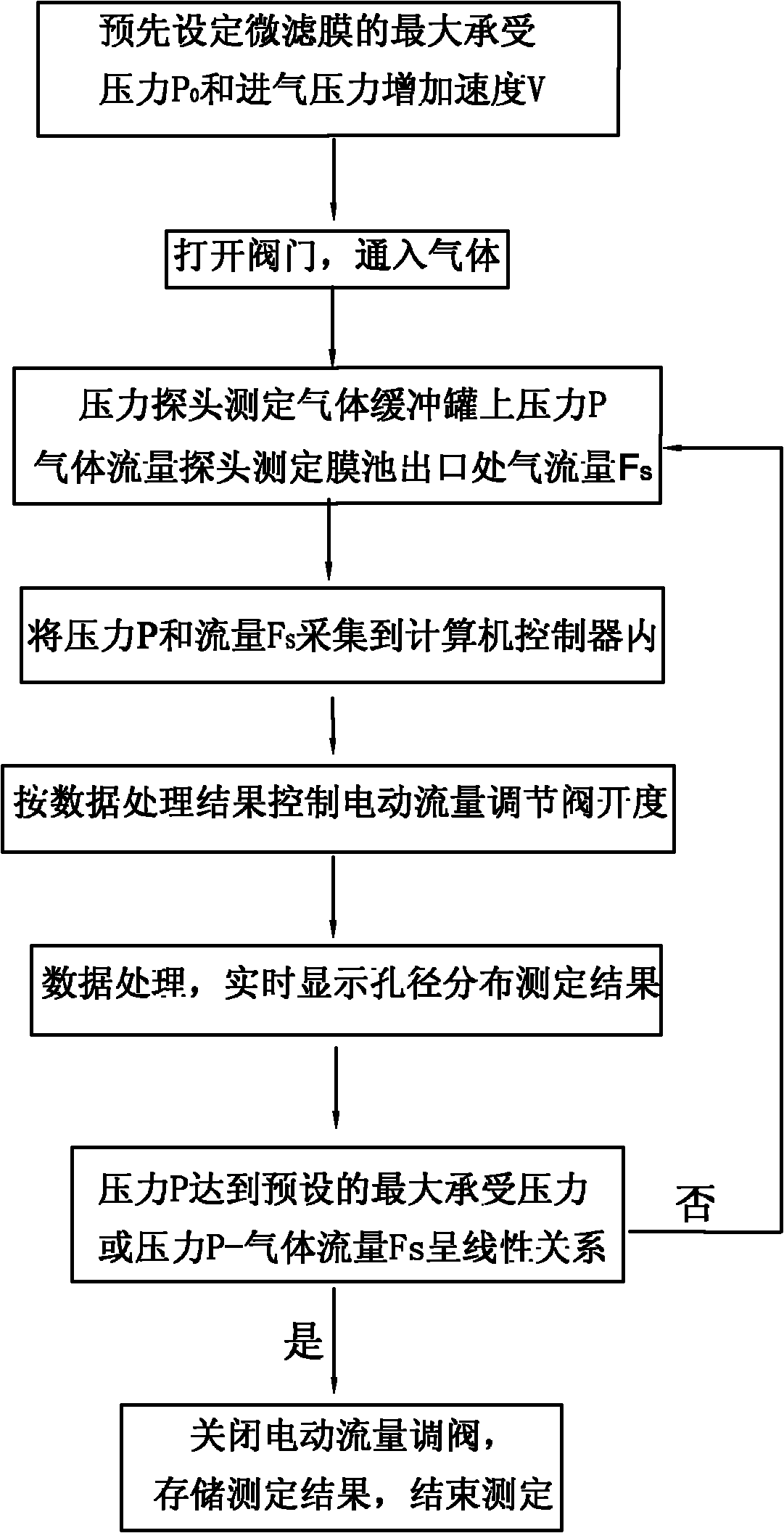

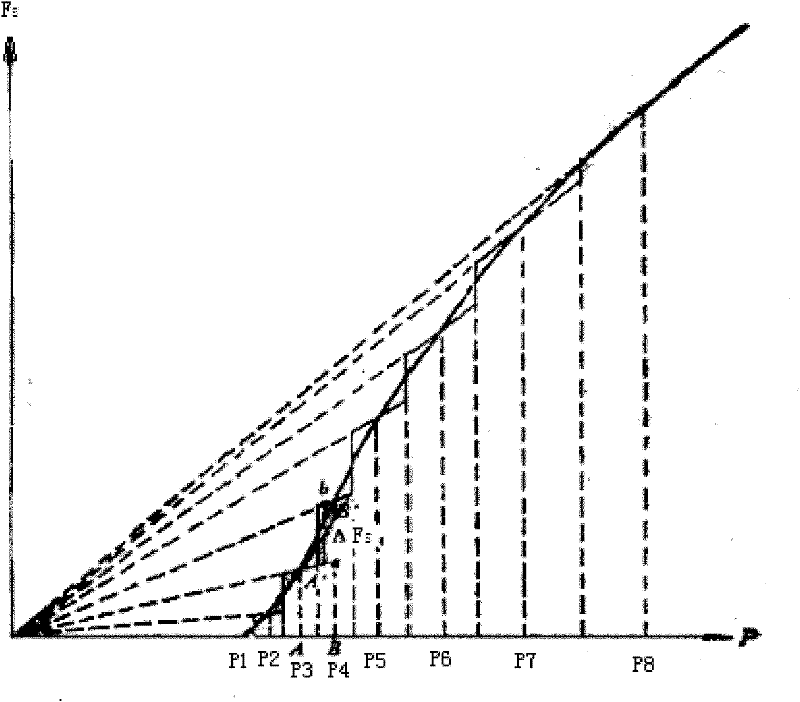

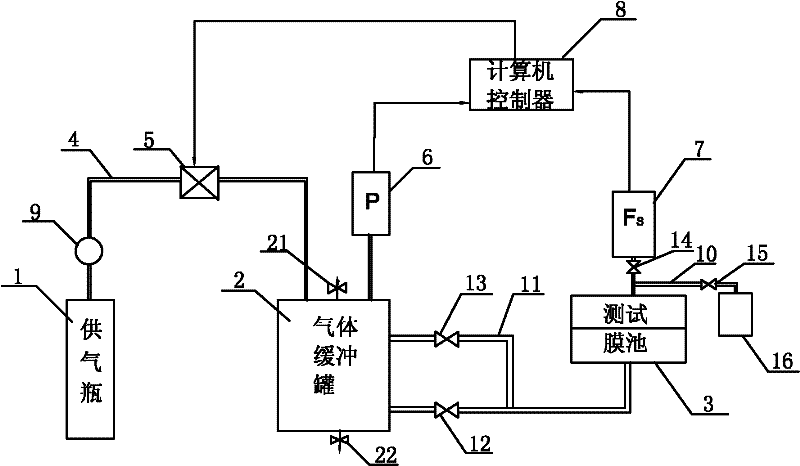

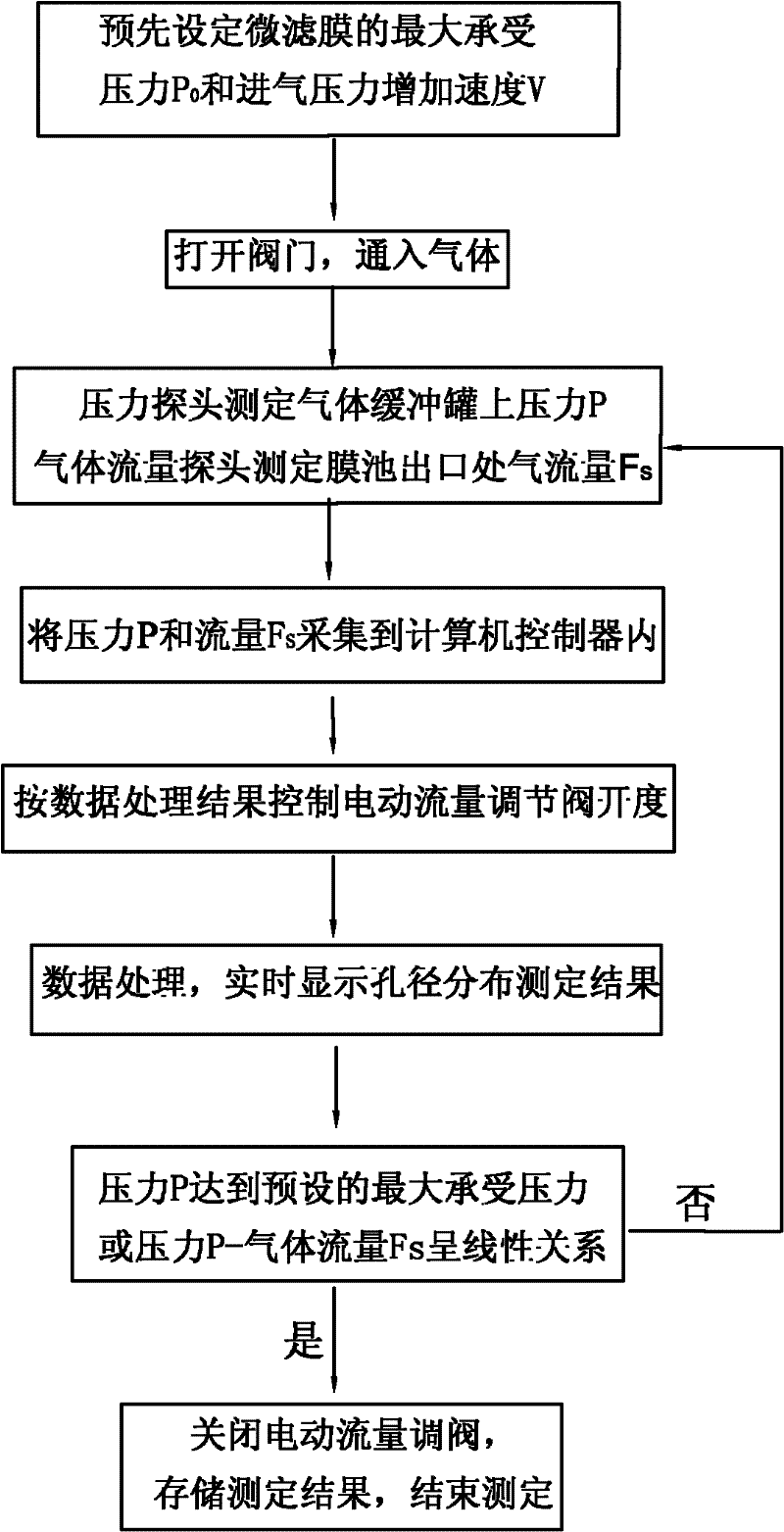

Full-automatic microfiltration membrane aperture distribution tester as well as automatic measuring method and application thereof

InactiveCN102087195AMeet the assessment requirementsImpact performance measurementPermeability/surface area analysisFiltration membraneAutomatic control

The invention discloses a full-automatic microfiltration membrane aperture distribution tester as well as an automatic measuring method and application thereof. The full-automatic microfiltration membrane aperture distribution tester comprises a gas supply cylinder, a gas buffer tank and a test membrane cell for fixing and sealing a microfiltration membrane, wherein the gas supply cylinder, the gas accumulator tank and the test membrane cell are successively connected via a pipeline. The full-automatic microfiltration membrane aperture distribution tester is characterized in that a motor-driven flow regulating valve is arranged between the gas supply cylinder and the gas buffer tank; the gas buffer tank is provided with a pressure probe; an outlet on the microfiltration membrane penetration side of the test membrane cell is provided with a gas flow probe; the signal output end of the pressure probe and the signal output end of the gas flow probe are connected with a data acquisition module for collecting pressure and flow signals in real time; the signals are transmitted by the communication module and a computer controller; the signal output end of the computer controller is connected with the signal input end of the motor-driven flow regulating valve; and the motor-driven flow regulating valve is under real-time feedback control. According to the full-automatic microfiltration membrane aperture distribution tester, the measuring condition can be automatically controlled in real time, measuring data is collected, data is processed in real time, and the assessment requirement on the performance of various sieve-pore filtration membranes can be satisfied.

Owner:NINGBO UNIV

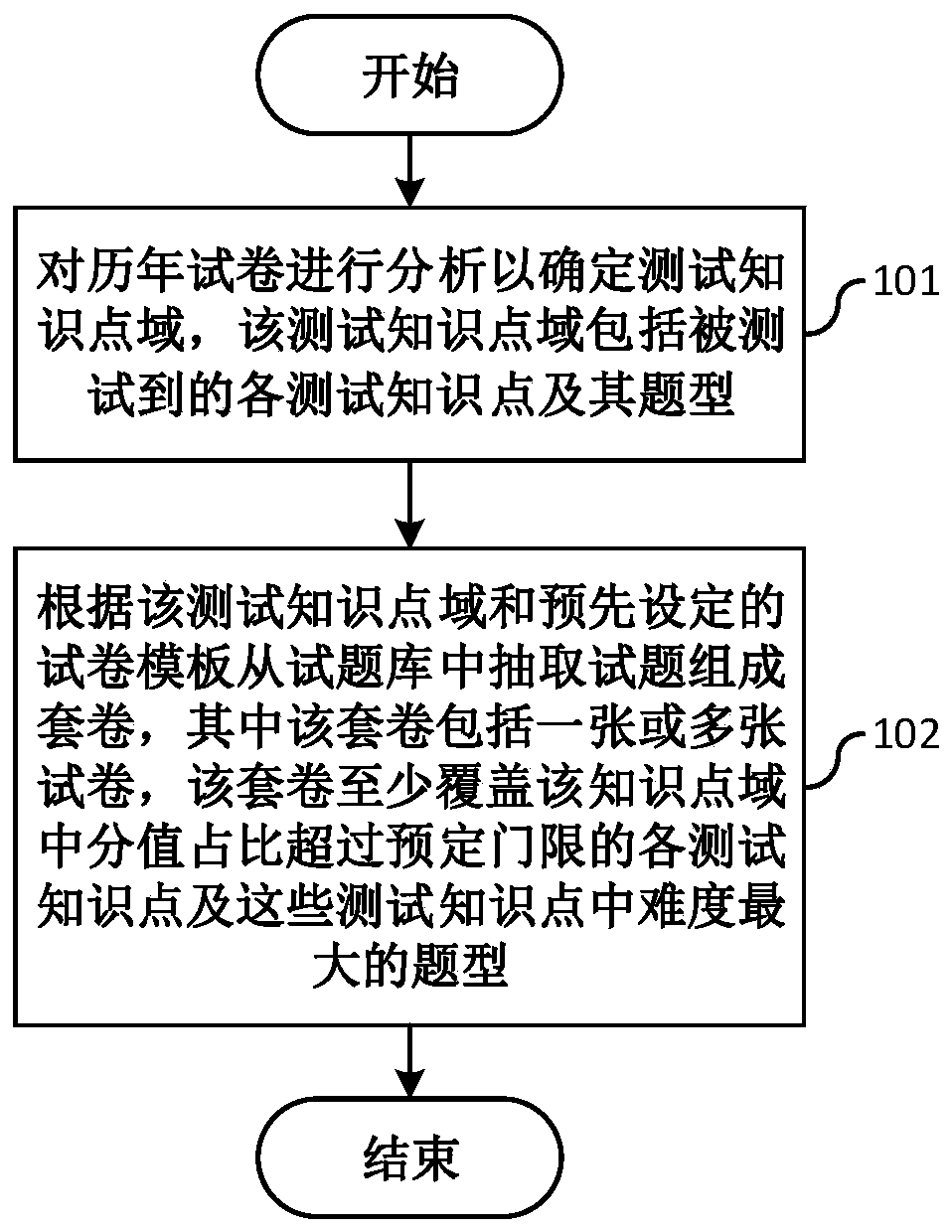

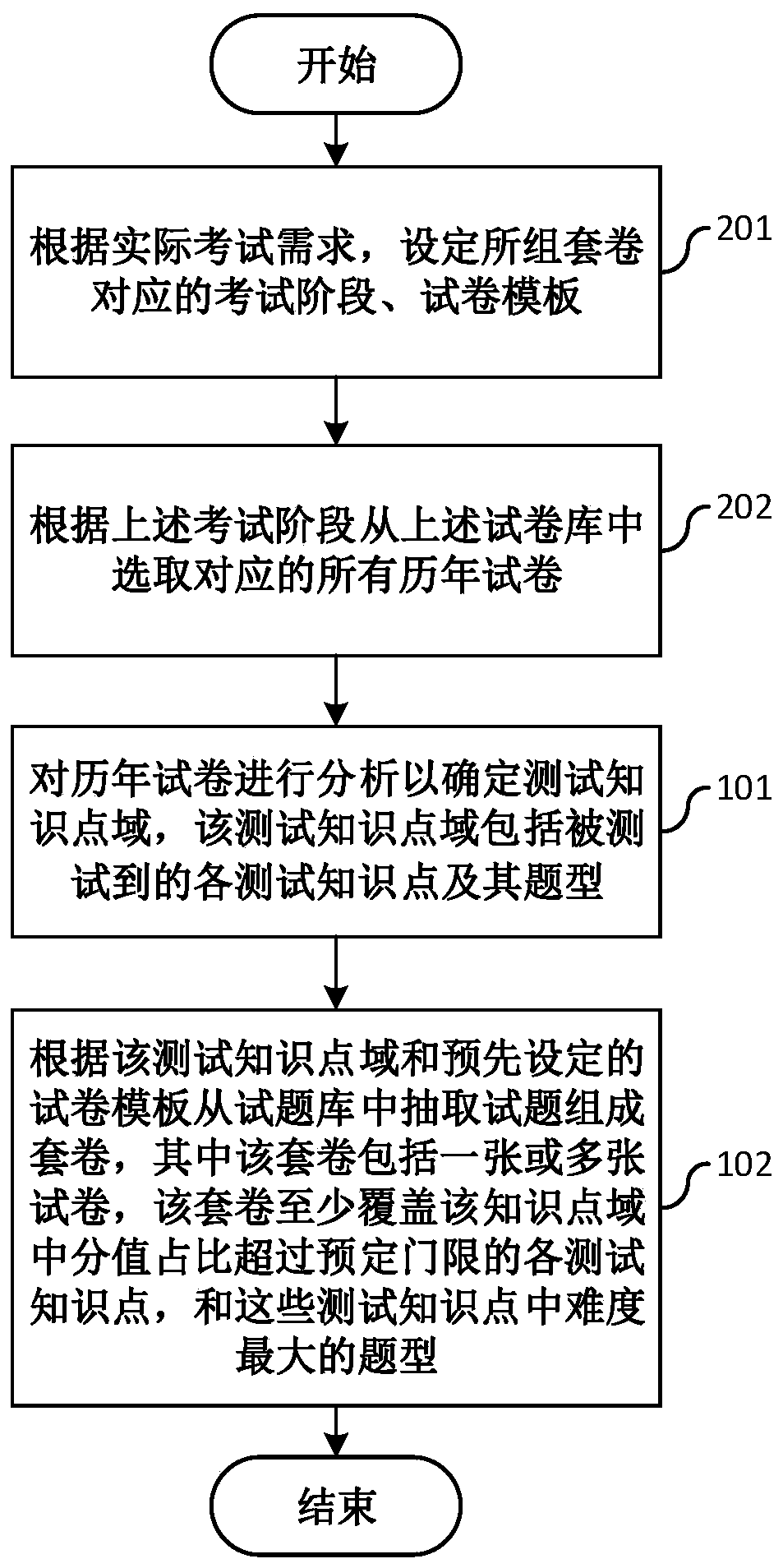

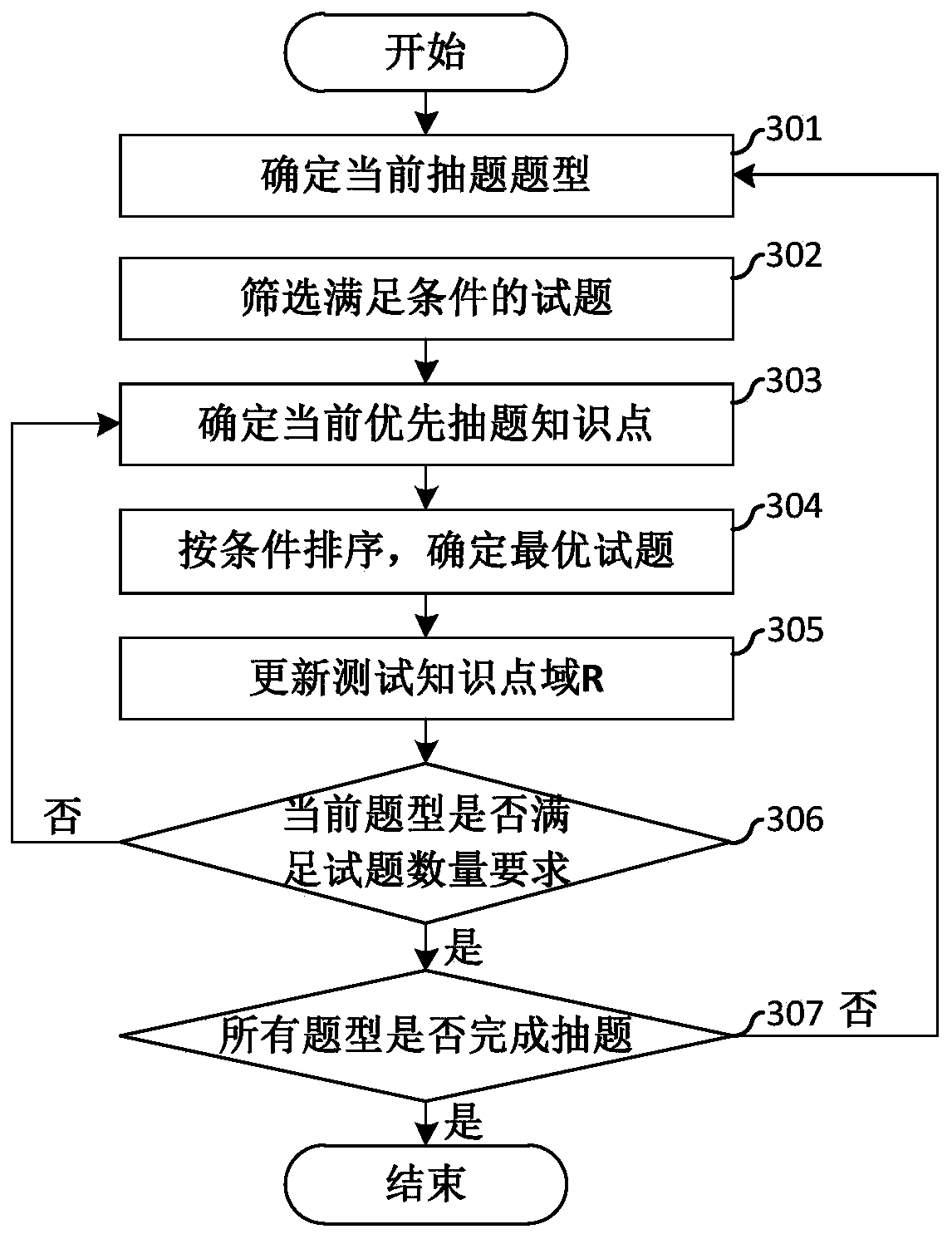

Method and system for automatically generating sets of examination paper by computer

ActiveCN110413973AMeet the scopeMeet the requirementsData processing applicationsText database queryingSoftware engineeringTest question

The invention relates to computer teaching, and discloses a method and a system for automatically generating sets of examination paper by a computer. The method comprises the steps of analyzing examination paper over the years to determine a test knowledge point domain, wherein the test knowledge point domain comprises tested test knowledge points and question types thereof; extracting test questions from a test question bank according to the test knowledge point domain and a preset test paper template to form a test paper set, wherein the test paper set comprises one or more pieces of test paper, and the sets of examination paper at least cover each test knowledge point with the score proportion exceeding a preset threshold in the test knowledge point domain and the question type with thehighest difficulty in the test knowledge points. The sets of examination paper generated by the embodiment of the invention can cover more knowledge points with the minimum number of test papers, thetest knowledge points contained in the examination paper meet the assessment range and requirements, the test key points are prominent, the actual review requirements of students are met, and the review effect is better.

Owner:浙江蓝鸽科技有限公司

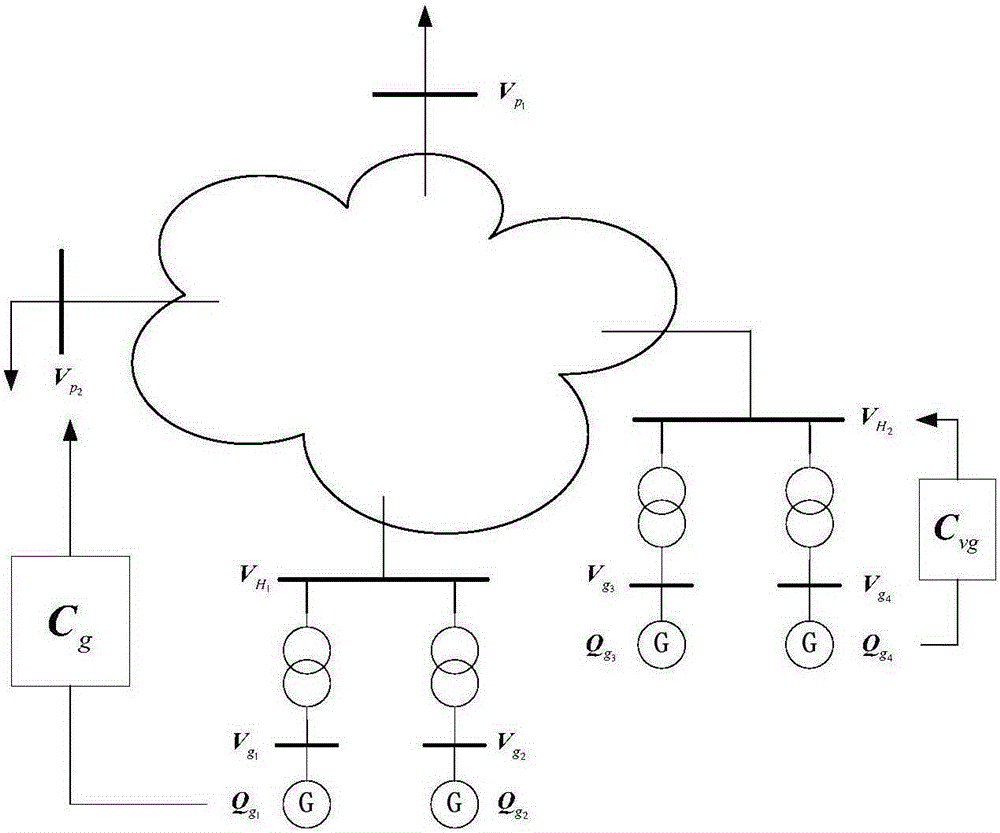

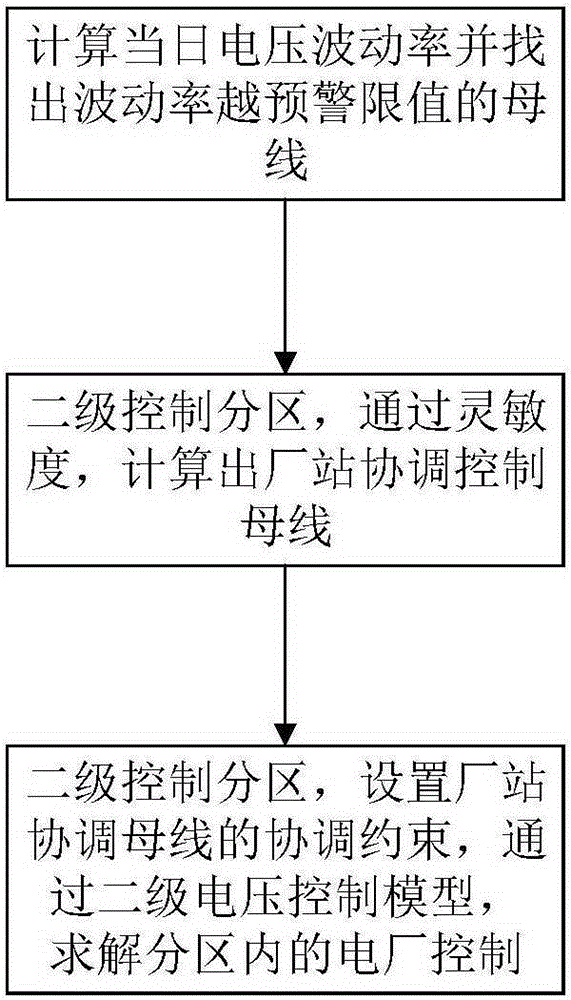

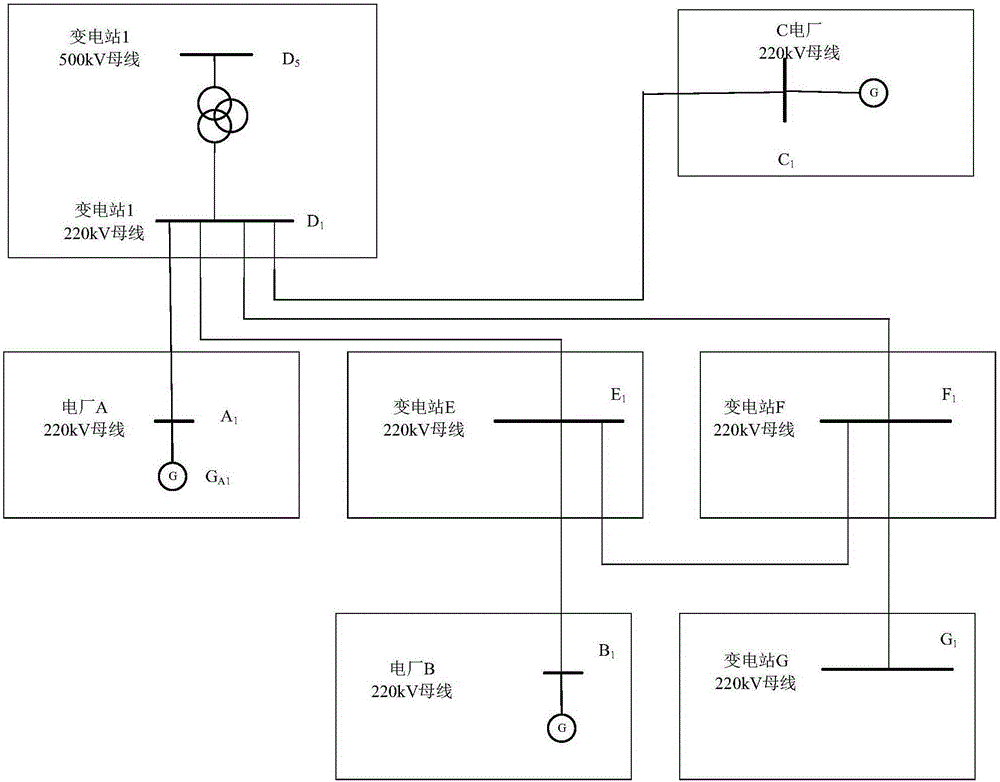

Method for lowering daily volatility of bus voltage through automatic station coordination control

InactiveCN105226665AReduce daily voltage fluctuationsImprove stabilityAc network voltage adjustmentReactive power compensationElectric power systemPower grid

The invention relates to a method for lowering daily volatility of bus voltage through automatic station coordination control in automatic voltage control, and belongs to the technical field of automatic voltage control of power systems. The method comprises the following steps: calculating the voltage fluctuation rate of the day for 220kV buses of all 220kV transformer substations within a provincial power network range, and finding out the buses of which the volatility exceeds an early-warning limit value; for each secondary control sub-region k, selecting a station coordination control bus from the found buses of which the volatility exceeds the early-warning limit value to add to each secondary control sub-region through sensitivity calculation; and for each secondary control sub-region k, determining a power plant control in the sub-region through building a coordinated secondary voltage control model CSVC, so as to achieve a daily volatility limit value control target of the 220kV bus voltage. The method meets the check requirements on the daily volatility of the 220kV bus voltage; and the network voltage stability and the power supply quality are improved.

Owner:STATE GRID CORP OF CHINA +2

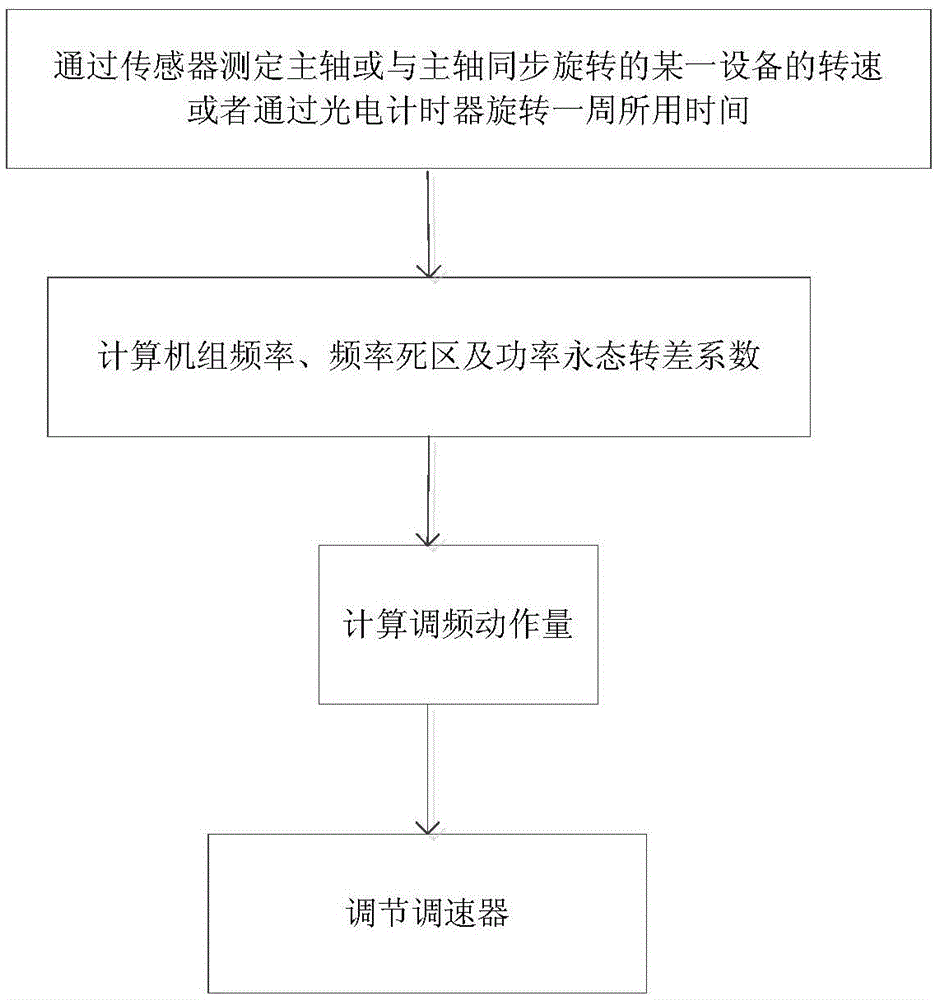

Frequency modulation method for hydraulic power plant

InactiveCN105634009AImproved FM tuning performanceMeet the assessment requirementsData processing applicationsSingle network parallel feeding arrangementsPower modePower grid

The invention discloses a frequency modulation method for a hydraulic power plant. The frequency modulation method comprises the following steps: step 1, a first sensor is arranged on a main shaft or certain equipment synchronously rotating along with the main shaft; the first sensor can measure a rotor winding rotating speed Vg when the unit is running; step 2, the unit frequency Fg when the unit is running is calculated; step 3, a frequency modulation actuating quantity delta p is calculated according to a frequency dead zone fs and a power permanent difference coefficient Ep; whether the absolute value of the delta p is less than a threshold value or not is judged; if the absolute value of the delta p is less than the threshold value, the frequency modulation is stopped; and if the absolute value of the delta p is greater than the threshold value, a step 4 is executed; and step 4, the guide vane opening is adjusted according to the frequency modulation actuating quantity delta p to enable the absolute value of the delta p to be reduced and to execute the step 1. According to the frequency modulation method, when a speed controller works in a power mode, the primary frequency modulation actuating quantity of the hydraulic power plant is converted into the power adjusting quantity for modulation, so that the primary frequency modulation performance of the hydraulic power plant is improved, and the check requirements of the power grid on the primary frequency modulation target value are satisfied.

Owner:CHONGQING DATANG INT WULONG HYDROPOWER DEV

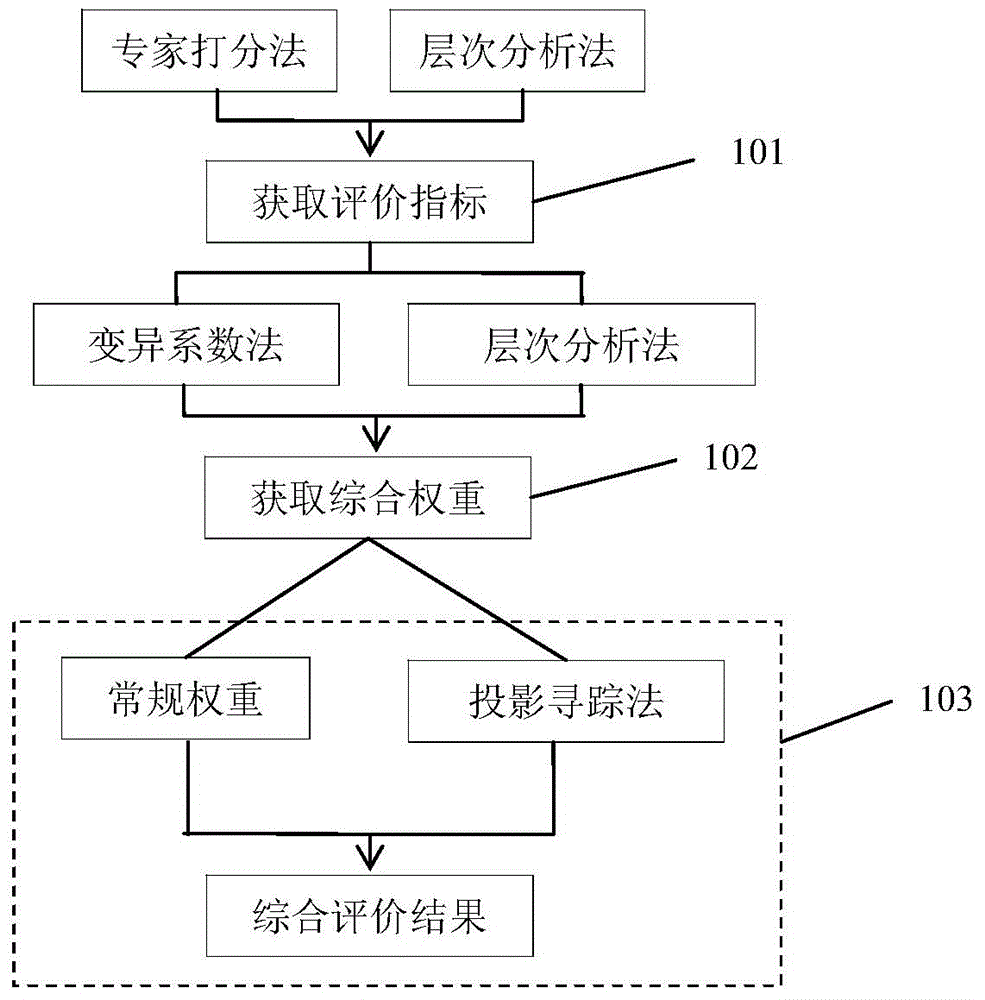

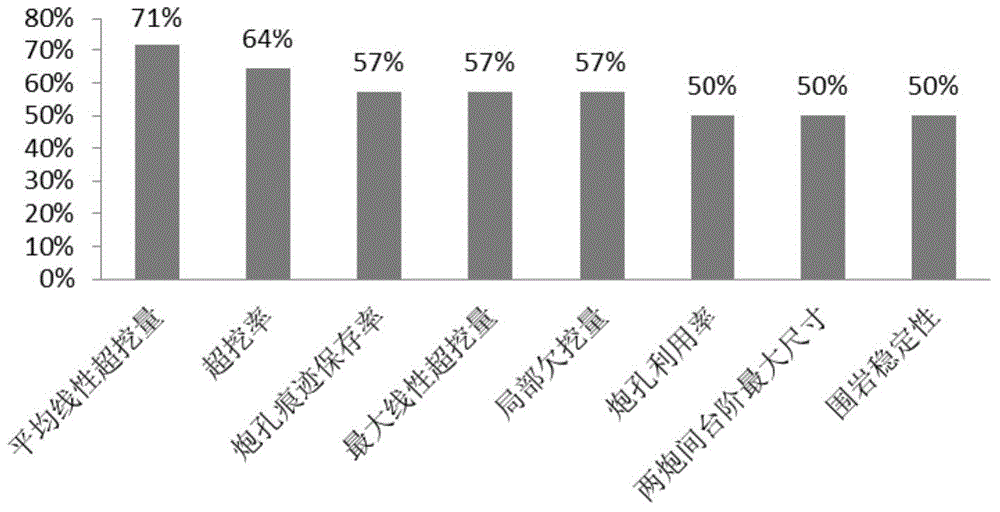

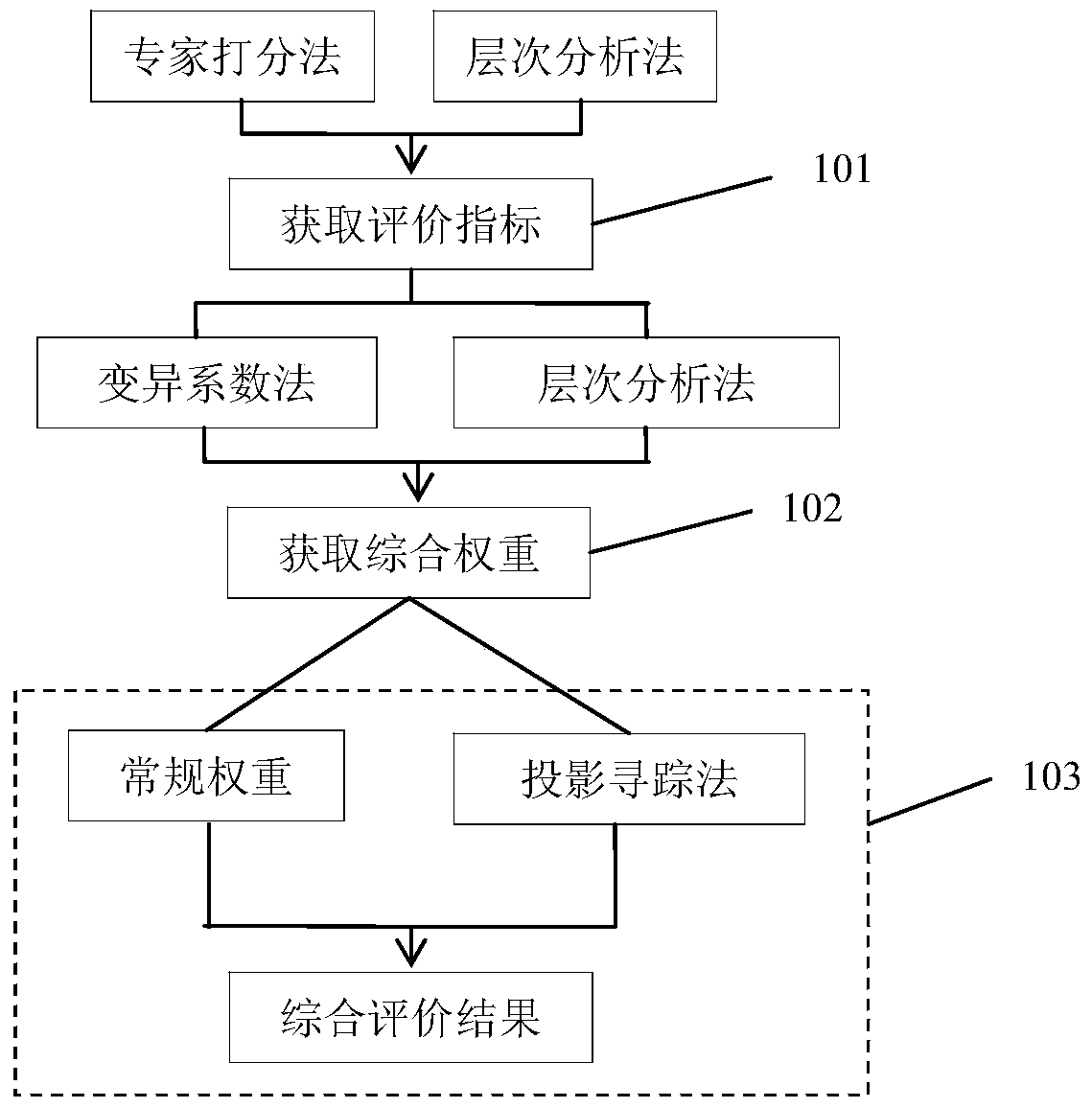

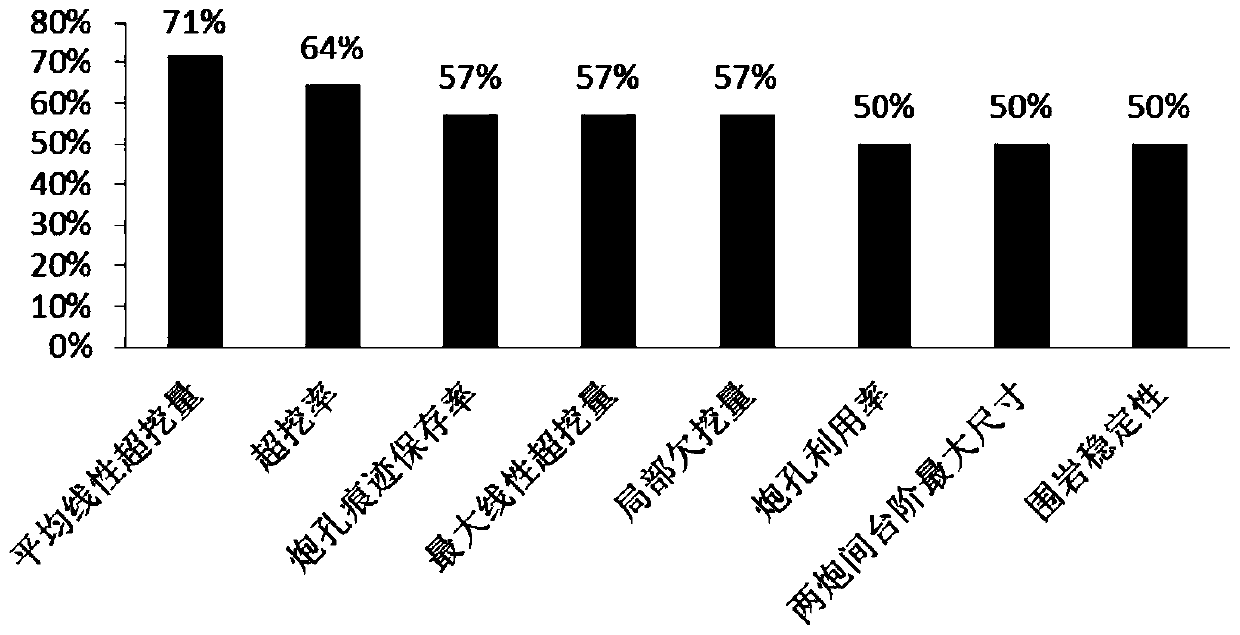

Channel smooth blasting quality evaluation prediction method

ActiveCN104318086AEasy to operateSystematicSpecial data processing applicationsMeasurement evaluationData mining

The invention relates to a channel smooth blasting quality evaluation prediction method, comprising the following steps of 1, obtaining evaluation indexes; 2, obtaining an actual measurement evaluation index value of a section to be evaluated, and adopting a variable coefficient method and an analytic hierarchy process to obtain the comprehensive weight of each evaluation index for the total evaluation; 3, performing evaluation prediction on the smooth blasting quality by respectively using a conventional weighting method and a projection pursuit method and obtaining the comprehensive evaluation result of the smooth blasting quality of the section to be evaluated according to the evaluation prediction result obtained according to each method. Compared with the prior art, the channel smooth blasting quality evaluation prediction method has the advantages of convenience in operation, strong systematization, high practicability and the like.

Owner:TONGJI UNIV

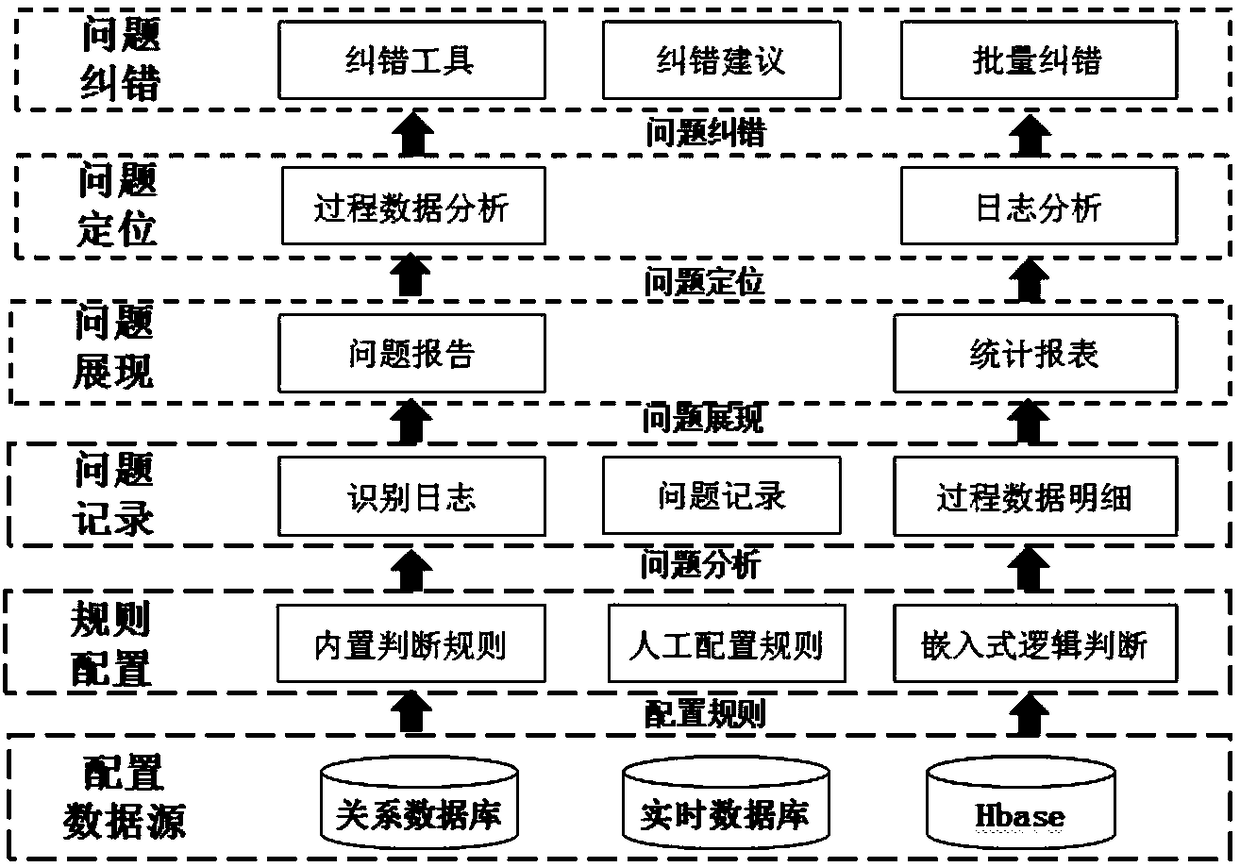

Power grid substation data quality assessment method

InactiveCN108268997AHigh quality and reliable data supportMeet the assessment requirementsResourcesPower gridPower substation

The present invention belongs to the technical field of power grid dispatch automation systems, and discloses a power grid substation data quality assessment method. The method achieves functions of automatic identification of data quality, problem location and problem error correction according to a configuration rule, and helps managers with rapid discovery, determination and solution of qualityproblems in the data. The method provided by the invention can provide data support with high quality and high reliability for the high-grade application of the power grid to meet the assessment requirement of daily key indexes and complete the measurement data quality assessment system.

Owner:STATE GRID SHAANXI ELECTRIC POWER CO ECONOMIC & TECHCAL RES INST +1

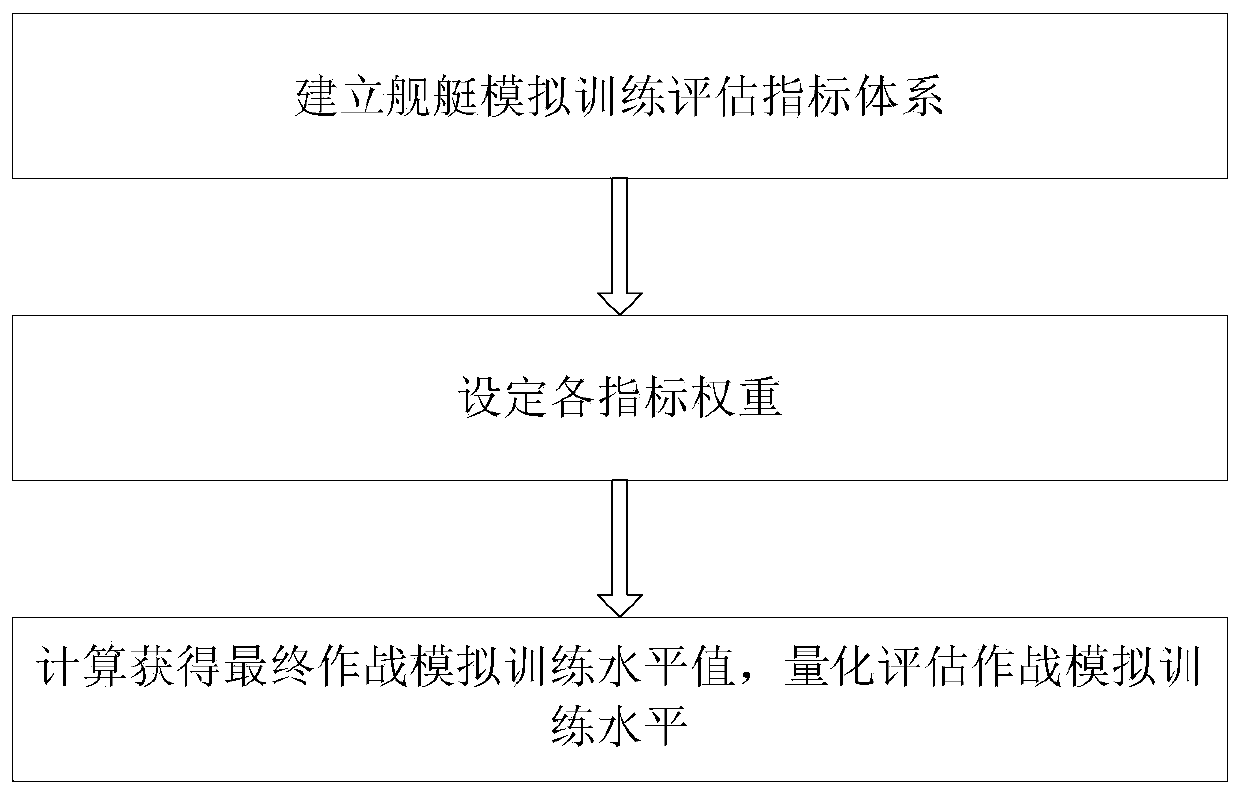

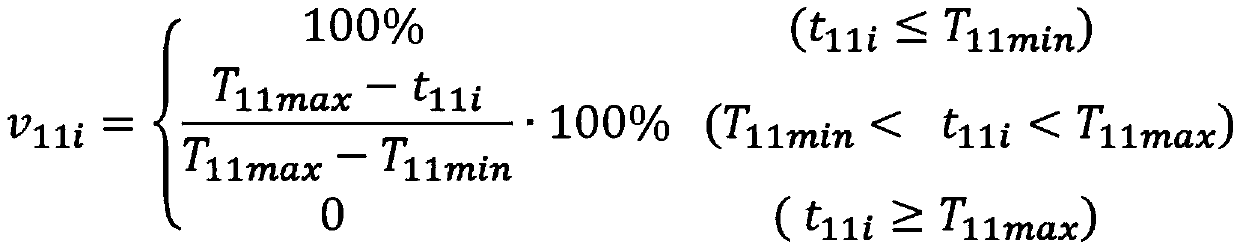

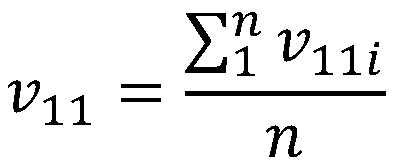

Hierarchical aggregation combat simulation training evaluation method based on multiple dimensions

The invention discloses a hierarchical aggregation combat simulation training evaluation method based on multiple dimensions. The method comprises the following steps: 1) establishing a naval vessel simulation training evaluation index system; wherein a target layer of the naval vessel simulation training evaluation index system is a combat simulation training level; an element layer of the navalvessel simulation training evaluation index system comprises a search detection capability factor, a judgment and identification capability factor, a command and decision capability factor, a weapon use capability factor, a naval vessel maneuvering factor and a combat effect factor; 2) setting the weight of each index; and 3) calculating to obtain a final combat simulation training level value, and quantitatively evaluating the combat simulation training level. According to the method, a naval vessel simulation training evaluation index system is established, the evaluation model establishmentmethod based on multi-dimensional hierarchical aggregation is provided, combat simulation training evaluation is carried out according to the method, objective and fair evaluation is carried out on the training level of a trainee, and evaluation requirements can be better met.

Owner:CHINA SHIP DEV & DESIGN CENT

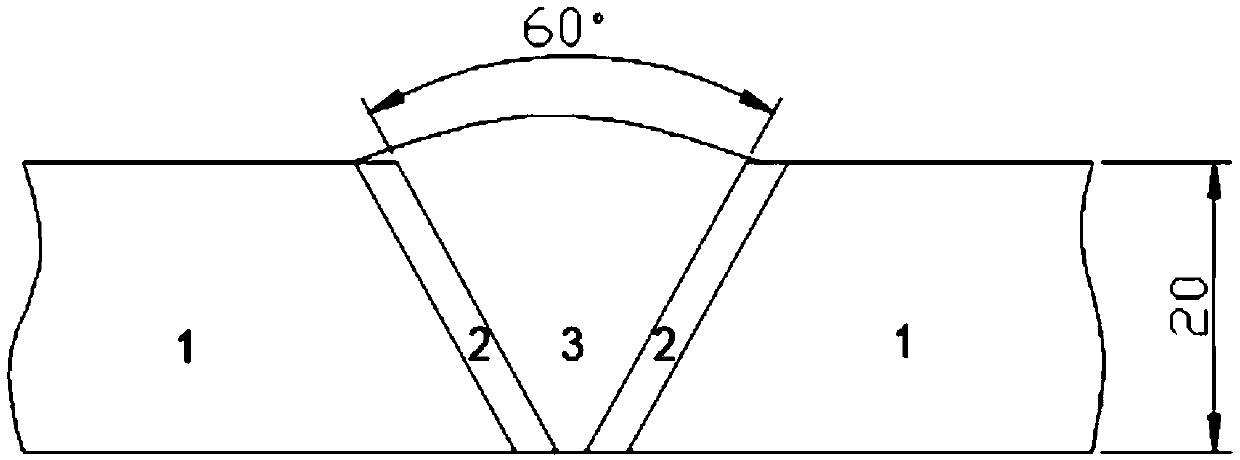

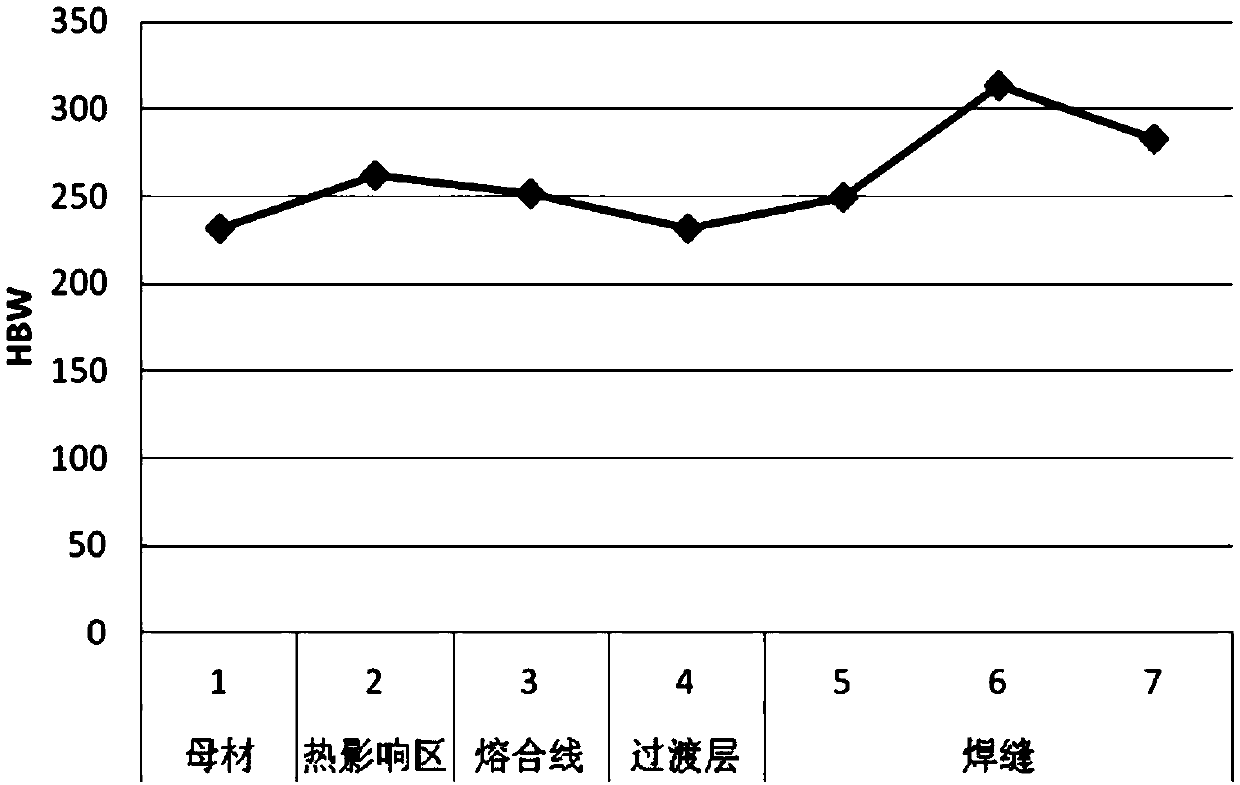

Mn13 high-manganese steel welding technology

InactiveCN110640349AReduce use costGuaranteed performanceArc welding apparatusWelding/cutting media/materialsShielded metal arc weldingManganese

The invention discloses an Mn13 high-manganese steel welding technology, which comprises the following steps that: 1) processing a reasonable welding groove on a butt joint plate material; 2) carryingout transition layer welding, adopting a direct current reverse polarity, immediately carrying out water cooling and hammering after a welding line of which the length is 50-100mm is welded for eachtime, measuring the temperature of a position, which is 10-20mm far away from the groove, of a welded material, cooling to be below 50DEG C, and continuously welding after a surface is cleaned, wherein a welding way is SMAW (Shielded Metal Arc Welding), welding current is 110-130A, electric arc voltage is 35-45V, a welding speed is 150-250mm / min, a cooling way is air cooling, the temperature of alayer channel is less than or equal to 50DEG C, and the thickness of the transition layer is 4-6mm; and 3) welding a filling welding line, adopting argon-rich gas shielded welding for welding, carrying out air cooling to be below 150DEG C after one pass is finished, and carrying out next-pass welding, wherein low-alloy welding wires are adopted as a welding material, welding current is 220-260A, electric arc voltage is 28-31V, a welding speed is 400-450mm / min, a cooling way is air cooling, and the temperature of a layer channel is less than or equal to 150DEG C.

Owner:BAOSHAN IRON & STEEL CO LTD

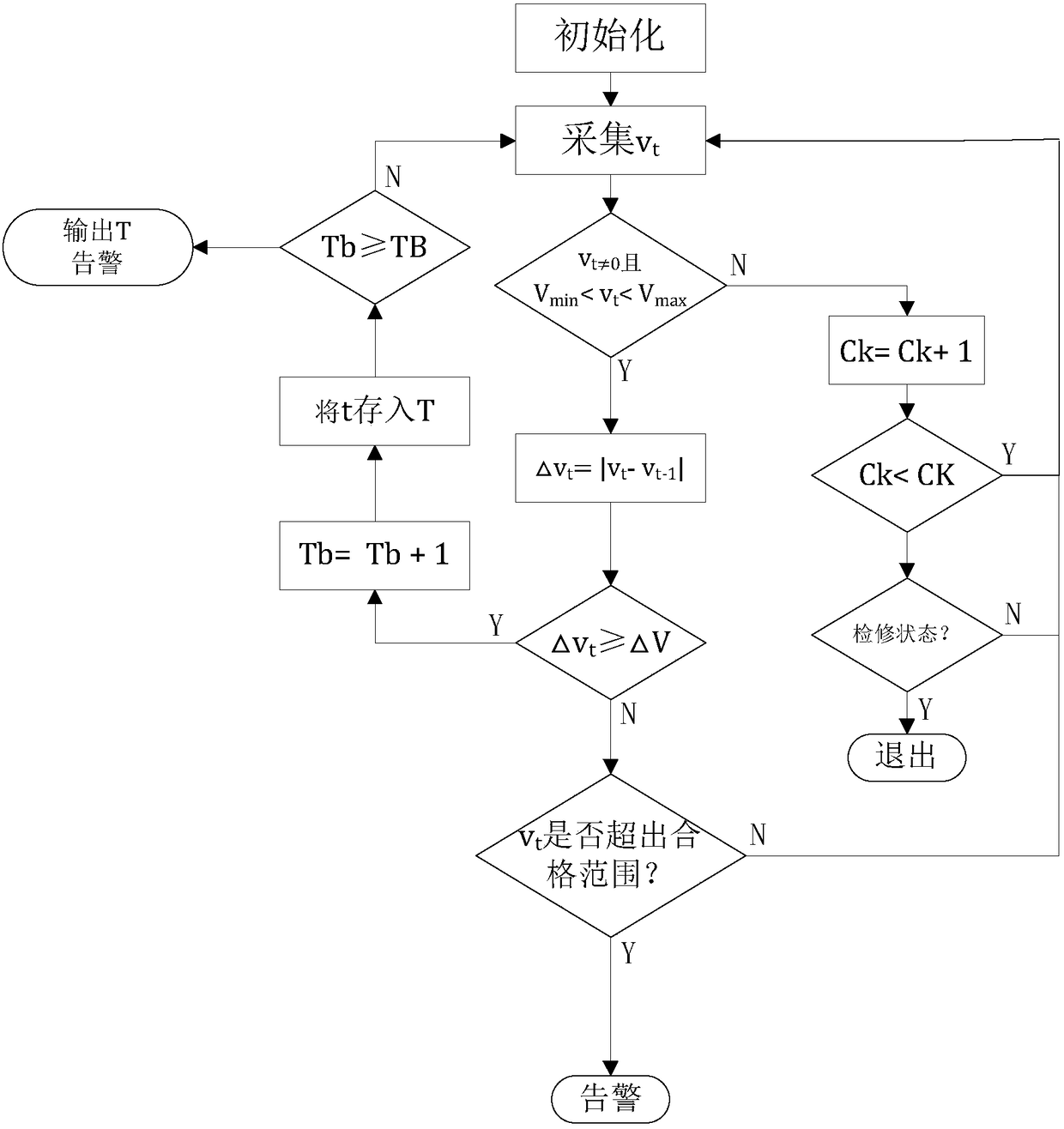

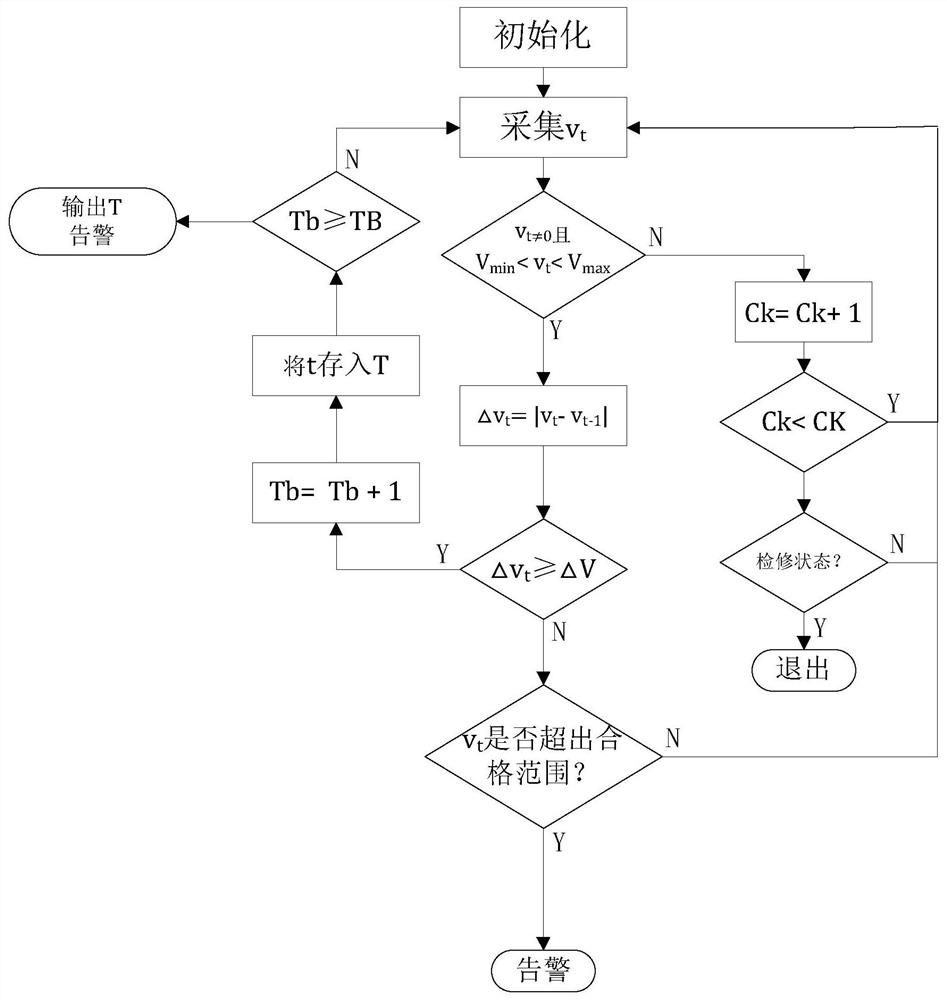

Power substation busbar voltage real-time monitoring method

ActiveCN109459605ARealize real-time monitoringMeet the assessment requirementsCurrent/voltage measurementBusbarSoftware

The invention discloses a power substation busbar voltage real-time monitoring method. The method includes the following steps of dividing the voltages of busbars into N types, and setting different voltage qualified ranges for the voltages of all types of busbars, periodically collecting the voltages of the busbars of a target power substation, and generating corresponding warning according to the collected voltages of the busbars. An existing power substation data collecting and monitoring control system is sufficiently used; on the premise of extremely less increasing hardware devices, thevoltages of the busbars of the power substation are monitored in real time mainly through software, and the assessment requirements of the State Grid Corporation of China for the voltage qualified rate can be met for the power substation at extremely low refitting cost.

Owner:LISHUI POWER SUPPLY COMPANY OF STATE GRID ZHEJIANG ELECTRIC POWER +1

Laser marking method for microelectronic packaging outer shell

InactiveCN106494107AMeet the assessment requirementsFlexible operationDuplicating/marking methodsOptoelectronicsPerformance index

The invention discloses a laser marking method for a microelectronic packaging outer shell. The laser marking method comprises the following steps: (1) editing and storing a laser marking content by adopting Auto CAD or self software of equipment; (2) according to the type of a base material, selecting a proper laser to carry out starting up, equipment calibration and preparation of tool clamp and consumable items; (3) setting technological parameters; (4) adopting laser sent by a laser device to cut the content edited in the step (1) on the base material; (5) plating to form a middle clad layer; (6) assembling the base material to form an outer shell; (7) plating an outer shell clad layer on the outer shell to form a finished product; and (8) carrying out performance index detection on the finished product. The laser marking method has the following beneficial effects: (1) laser marked graphs, characters and bar codes are clear and do not fall off permanently to meet the index assessment requirements including airtightness and salt spray resistance property of the outer shell; and (2) non-contact type automatic processing is carried out and has the advantages of flexible operation, high speed and zero abrasion.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

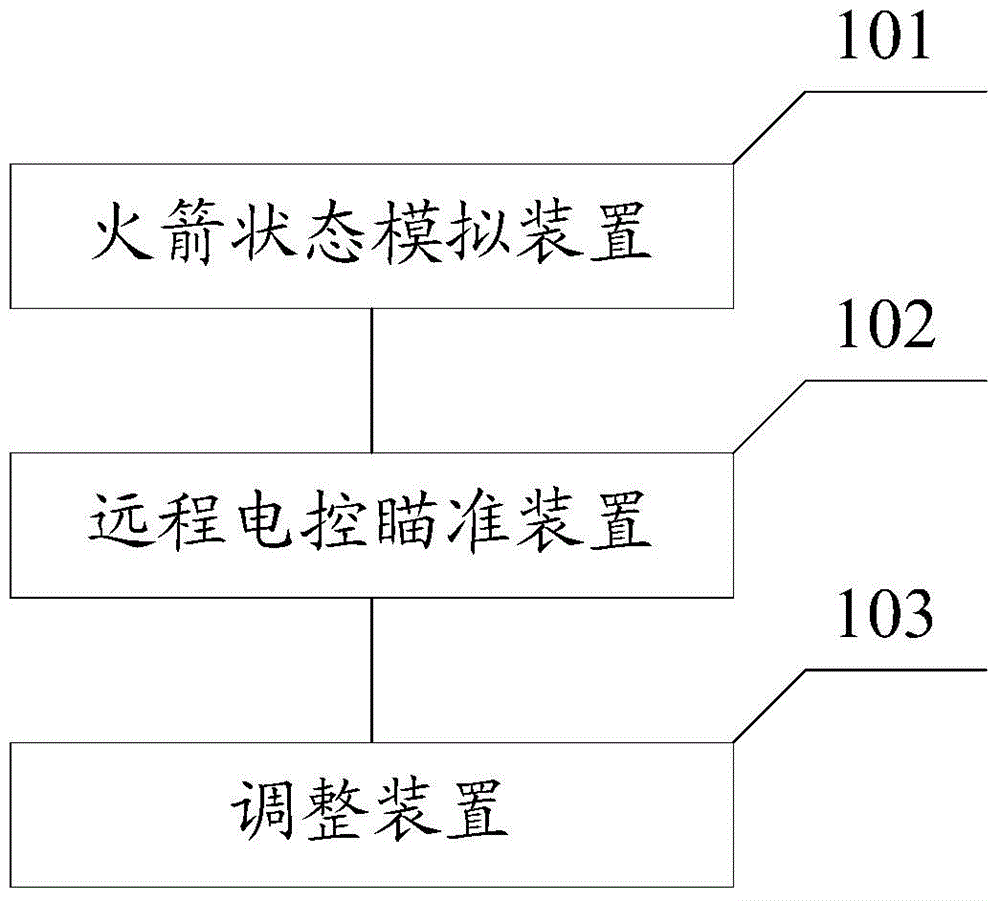

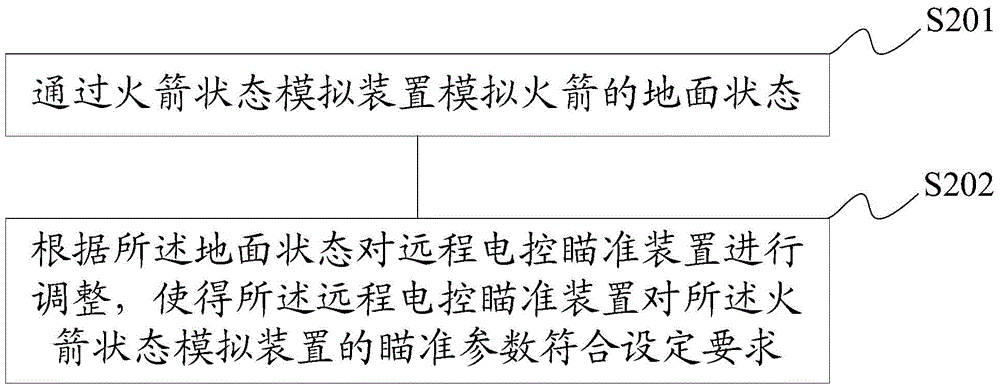

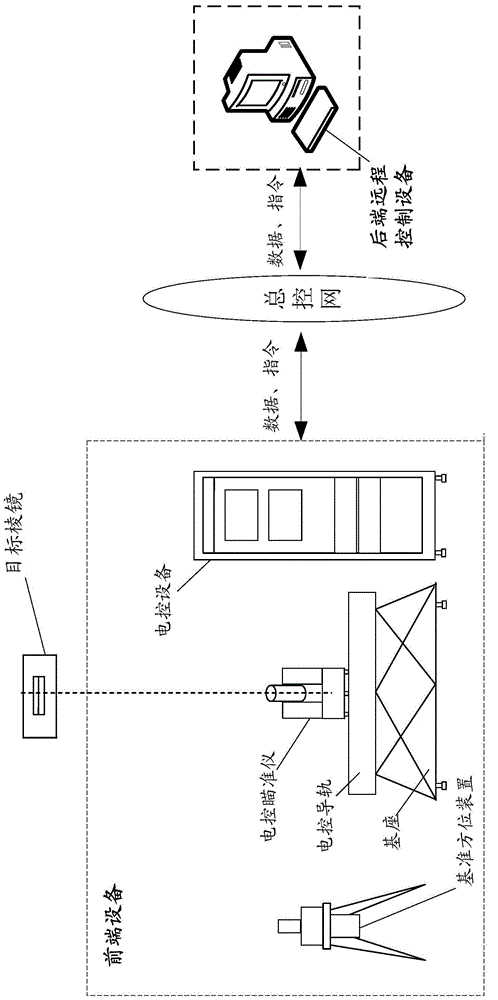

Aiming device checking system and method

The invention provides an aiming device checking system. The aiming device checking system comprises a rocket state simulation device, a remote electronic control aiming device and an adjusting device, wherein the rocket state simulation device is used for simulating the stationary state and the interference state of a rocket, the remote electronic control aiming device is used for aiming at the rocket state simulation device, and the adjusting device is used for adjusting the remote electronic control aiming device based on the stationary state and the interference state so that parameters of aiming conducted by the remote electronic control aiming device on the rocket state simulation device can meet the set requirements. According to the invention, the aiming device can meet the checking requirements by simulating rocket states through the rocket state simulation device and adjusting the remote electronic control aiming device through the adjusting device.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

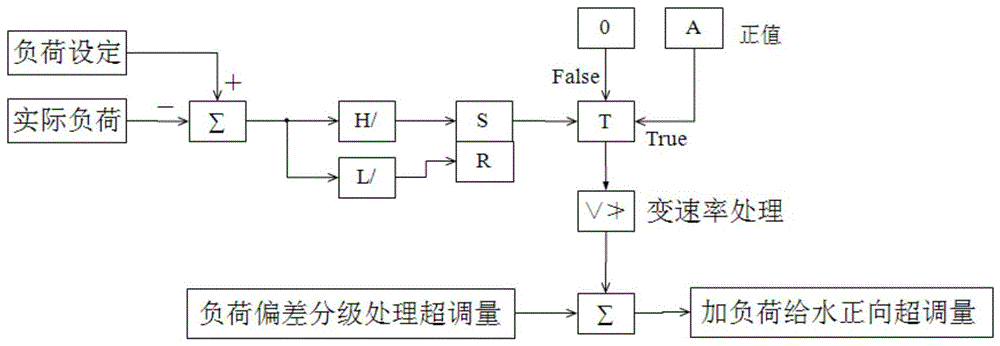

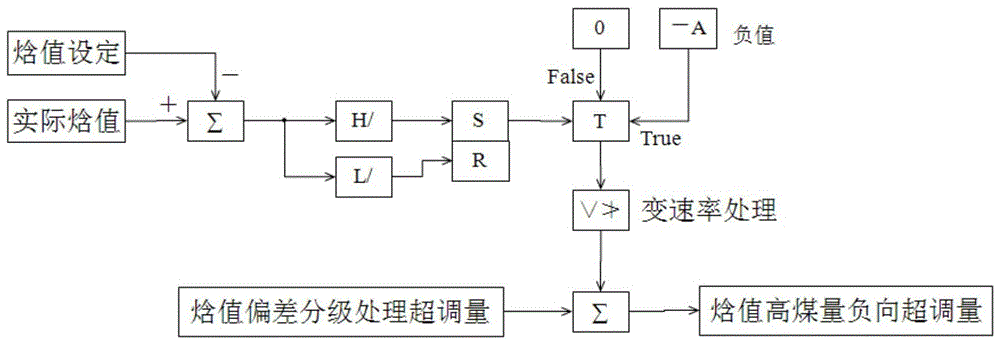

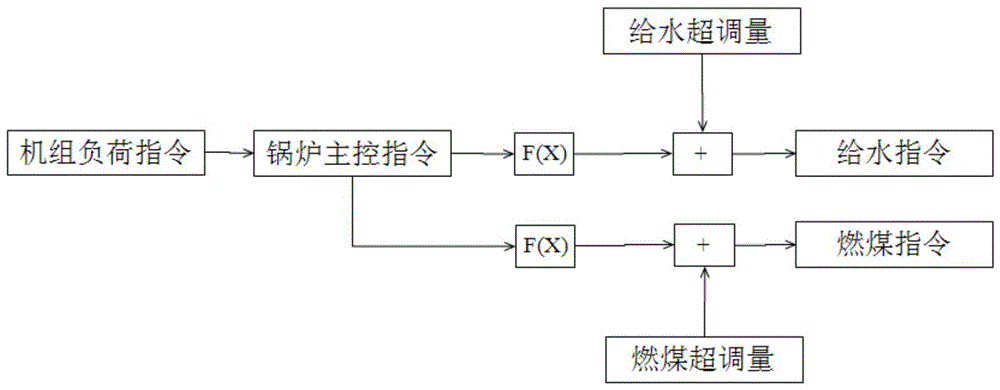

Variable load overshoot control method for supercritical or ultra-supercritical generator sets

The invention relates to a supercritical or ultra-supercritical generating set variable-load overshoot control method. According to the method, water supply overshooting and coal quantity overshooting are conducted separately, and various overshoots are intelligently generated according to a state of the generating set before the load is varied. The control method particularly comprises the following steps that 1, comparison is conducted between a load command and a real load deviation, whether the deviation is larger than a first constant value is judged, if yes, water supply overshooting is triggered, and the overshoot adopts hierarchical control; 2, comparison is conducted between a real intermediate point enthalpy value and a preset value of the enthalpy value, whether the deviation is larger than a second constant value is judged, if yes, the coal quantity overshooting is triggered, and the overshoot adopts the hierarchical control. Compared with the prior art, by means of the supercritical or ultra-supercritical generating set variable-load overshoot control method, the various overshoots are intelligently generated according to the state of the generating set before the load is varied, and load control and steam temperature control of a turbine high-pressure control valve in sliding pressure operation are well achieved.

Owner:SHANGHAI MINGHUA ELECTRIC POWER TECH & ENG +1

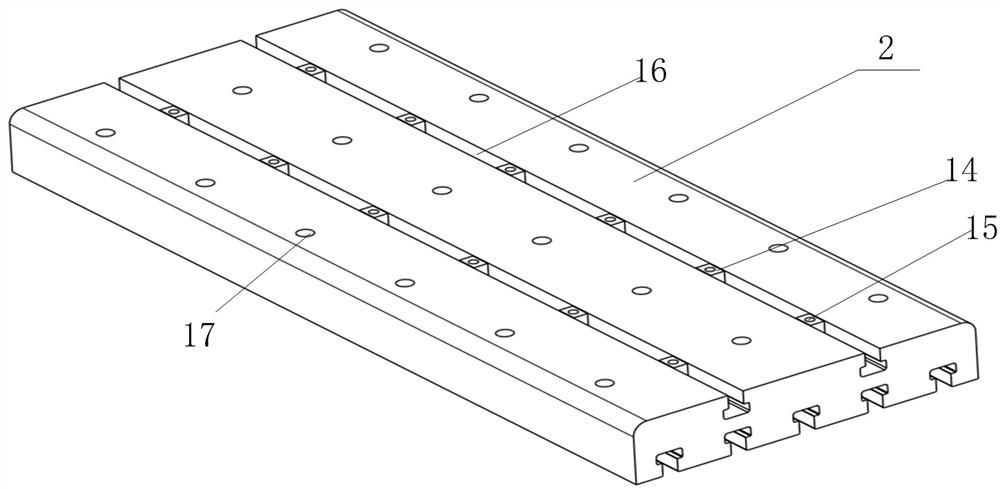

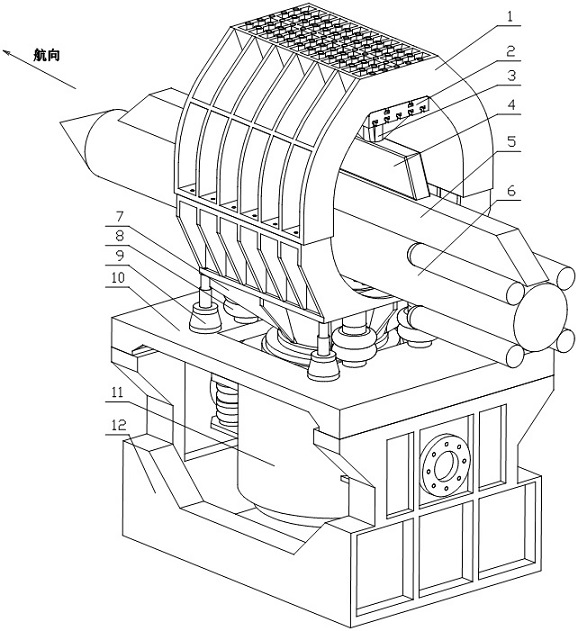

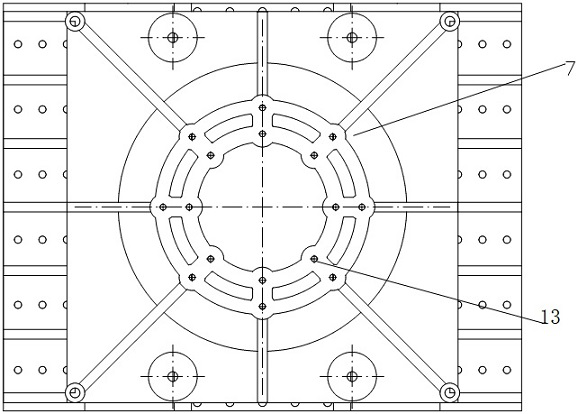

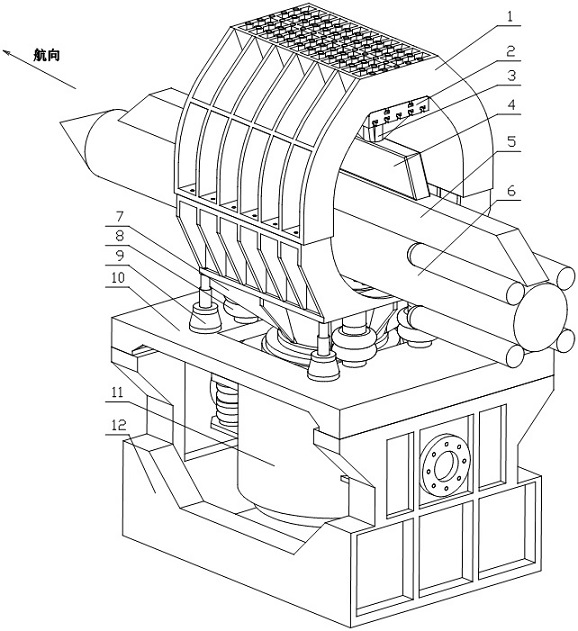

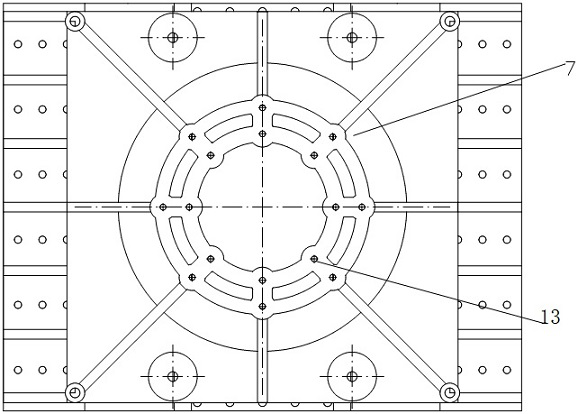

Test device for vibration test of aviation suspension launcher

ActiveCN112393867AImproving the Efficiency of Vibration Test AssessmentImprove transfer characteristicsVibration testingAviationAir spring

The invention discloses a test device for the vibration test of an aviation suspension launcher. The device comprises a vibration table and a vibration test tool disposed at the upper end of the vibration table, wherein the vibration test tool comprises a cage-type tool with a reinforcing rib disposed on the surface, and the cage-type tool comprises a cage-type tool pedestal and a cage-type tool upper cover; the cage type tool base and the cage type tool upper cover are connected through a butt joint face row bolt. Threaded holes are evenly distributed in the top of the plane structure of thecage type tool upper cover in the length direction and the width direction and used for being connected with a suspended launcher transfer platform, and a balancing weight is installed at the top of the cage type tool upper cover. A suspension launching device switching platform connected to the top plane in the cage type tool upper cover is connected with a suspension beam tool of a suspension launching device used for hanging a simulation bomb through bolts. Air springs and linear guide bearings are arranged on the periphery of an upper end of a vibration table expansion table base of the vibration table and used for supporting a vibration test tool. The test device is advantaged in that a purpose of checking accuracy of the vibration test of the suspended launcher can be achieved.

Owner:TIANJIN AEROSPACE RELIA TECH

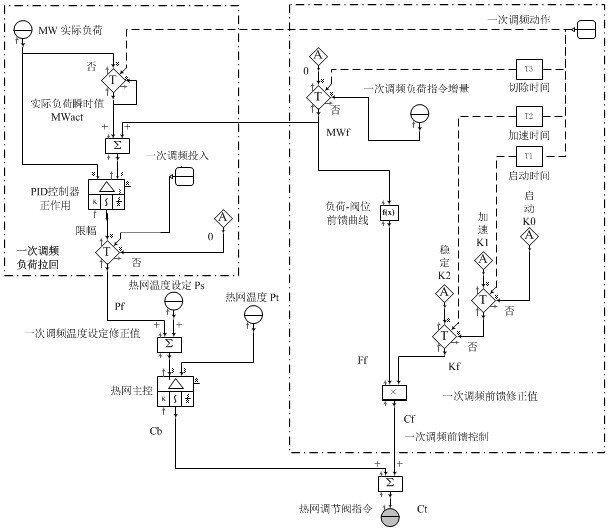

Combined cycle unit steam turbine primary frequency modulation control method

ActiveCN113110316ARealize a frequency modulation functionMeet the assessment requirementsTotal factory controlProgramme total factory controlAutomatic controlLoop control

The invention discloses a combined cycle unit steam turbine primary frequency modulation control method, which can be used for primary frequency modulation automatic control in an actual operation process of a combined cycle unit steam turbine. According to the method, by using a closed-loop control mode, a heat supply network temperature set value is dynamically corrected in real time according to network frequency deviation, so that reverse modulation of heat supply network temperature closed-loop control on primary frequency modulation is effectively avoided, and it is ensured that the primary frequency modulation performance of a unit in the mode is also rapid and accurate; and by comprehensively considering the primary frequency modulation control performance of the unit, primary frequency modulation process dynamic feedforward control is adopted, the control performance and the control target of the primary frequency modulation action process are integrally optimized, and the network-related assessment rule requirements are met in a targeted manner. According to the invention, the labor intensity of operators can be effectively reduced, the control effect does not depend on the technical level of the operators, the real-time performance is good, the field debugging process is simple, and engineering implementation is facilitated.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

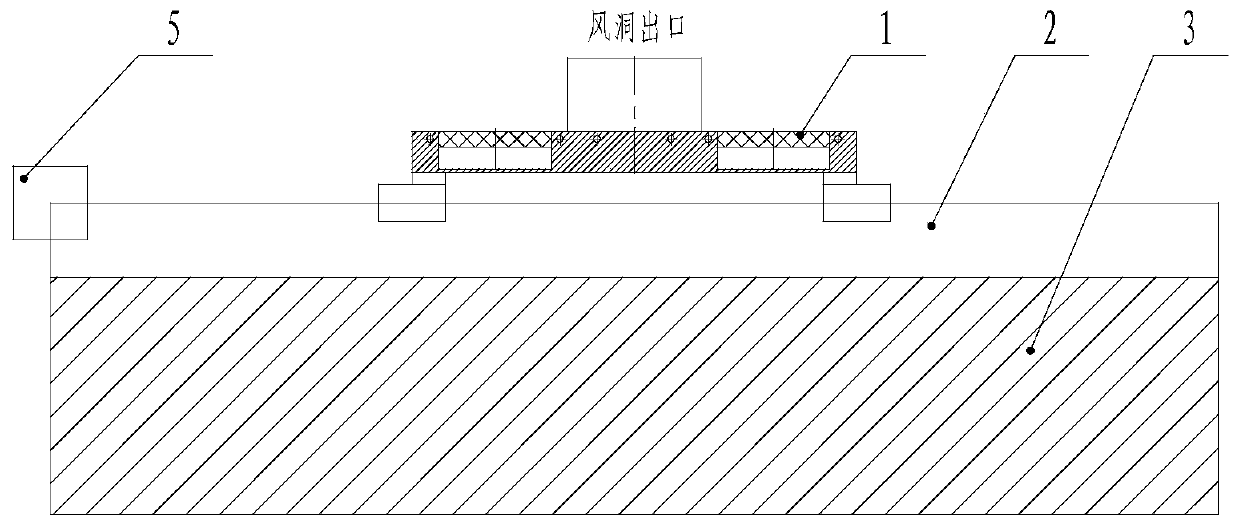

Dual-mode feeding structure and model thermal assessment method based on same

PendingCN111426719AHigh precisionSmooth connectionAerodynamic testingMaterial thermal analysisThermal insulationFlight vehicle

The invention relates to a dual-mode feeding structure and a model thermal assessment method based on the same. The dual-mode feeding structure comprises a guide strip, a dual-mode support, an electric guide rail, a controller and a fixed support. The dual-mode support is a support which is provided with two mounting holes and can be used for cooling water, the bottom end of the dual-mode supportis connected with the electric guide rail, and the dual-mode support can reciprocate under the action of the electric guide rail. The top of the fixed support is connected with the electric guide rail. The controller controls the electric guide rail to move, and manual control and automatic operation according to a preset motion scheme can be carried out. One end of the guide strip is fixed at theoutlet of an arc wind tunnel, and the other end is connected with the dual-mode support through grooves. Based on the structure, the invention further provides a model thermal assessment method. Thedual-mode feeding structure and the model thermal assessment method can be applied to high-precision measurement requirements in aerodynamic heat ground simulation tests of thermal insulation materials of high-speed aircrafts.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

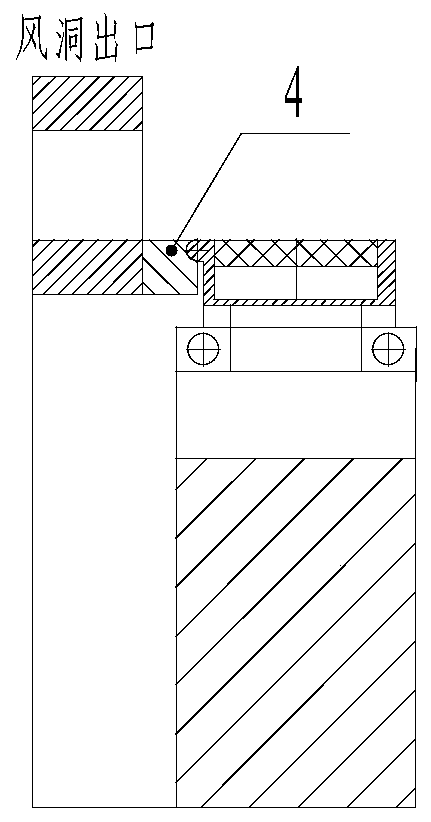

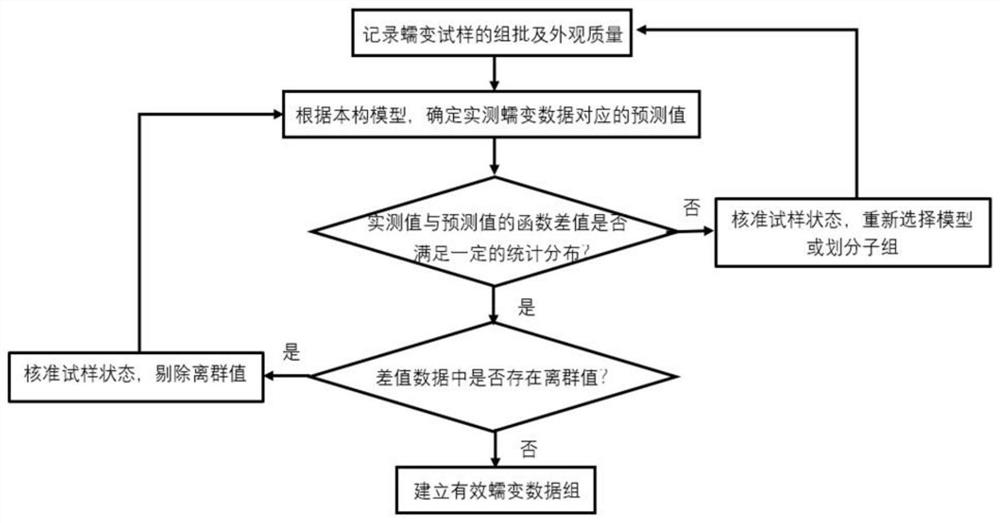

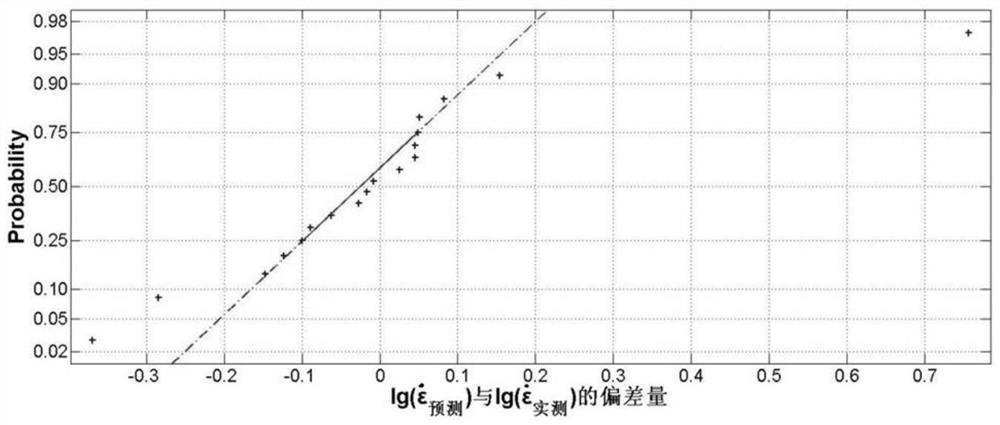

Creep data screening method based on statistical test and state check

ActiveCN113299351ASolve the problem of large dispersionIncrease flexibilityChemical machine learningComputational materials scienceAlgorithmScreening method

The invention discloses a creep data screening method based on statistical test and state inspection, which comprises the following steps: step 1, recording sample state parameters, and carrying out a creep experiment to obtain actually measured creep data; step 2, substituting the creep data into the creep constitutive model, fitting to obtain a creep constitutive equation in a corresponding form, and fitting to obtain a predicted value; step 3, calculating a function difference value [delta]f(x) between the actually measured creep data and a predicted value, and checking a statistical distribution rule of the [delta]f(x); step 4, according to a set saliency level alpha, searching for an outlier in the [delta]f(x) data, marking the actually measured creep data corresponding to the outlier as invalid actually measured creep data, and removing the invalid actually measured creep data; and step 5, repeating the steps 2-4 until all the remaining actually measured creep data do not have the outliers any more. According to the method, the flexibility of data screening is improved, the difficulty of subsequent material creep performance calculation and evaluation work is reduced, and the reliability and accuracy of creep performance prediction are improved.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

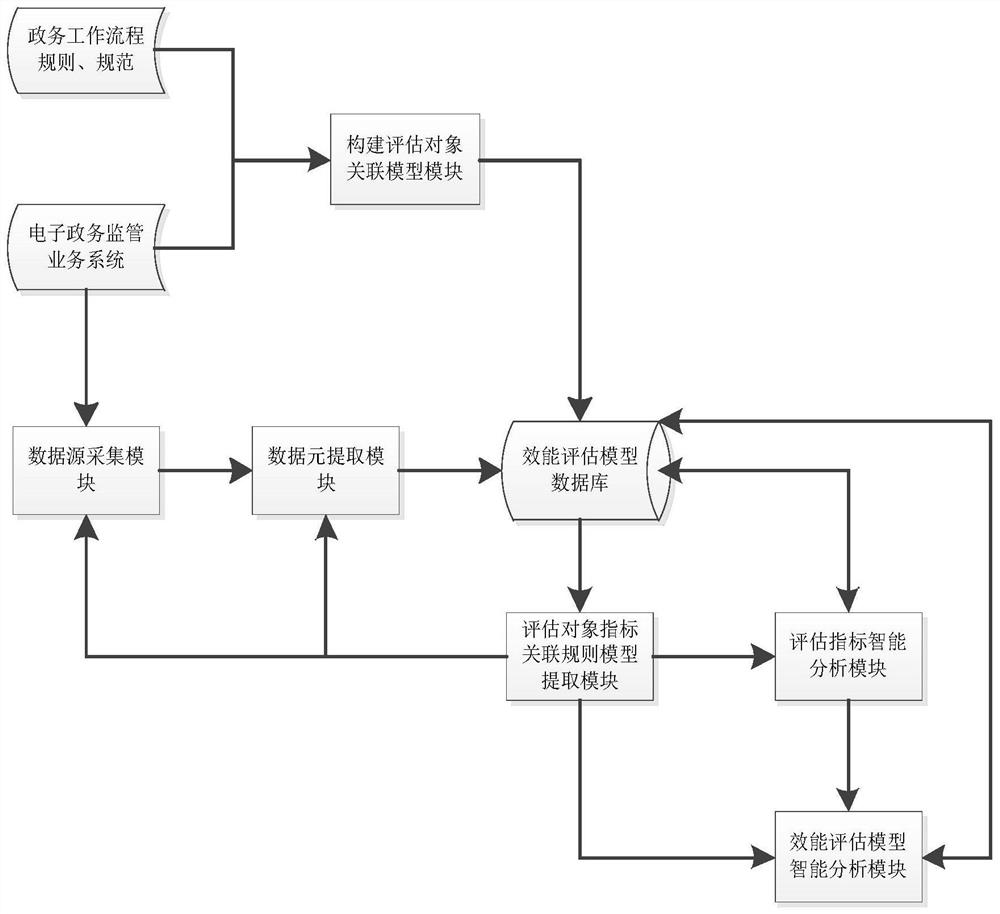

Supervision efficiency evaluation system based on data element index rule model

PendingCN114723298AFlexible weight settingEffective assessmentTechnology managementResourcesEngineeringData science

The invention particularly relates to a supervision efficiency evaluation system based on a data element index rule model. According to the supervision efficiency evaluation system based on the data element index rule model, a centralized deployment mode is adopted to perform unified management on evaluation indexes of all levels, a read-write separation mode is adopted to ensure system performance, and data of an electronic government affair supervision business large-scale system data center is acquired through a POST request interface; comprising an evaluation object association model building module, an efficiency evaluation model database, an evaluation object index association rule model extraction module, a data source collection module, a data element extraction module, an evaluation index intelligent analysis module and an efficiency evaluation model intelligent analysis module function module. According to the supervision efficiency evaluation system based on the data element index rule model, various evaluation requirements of each region on efficiency supervision data collected by each subordinate region and each department are met, and supervision and improvement of government affair efficiency of each department at each level are effectively promoted.

Owner:INSPUR SOFTWARE CO LTD

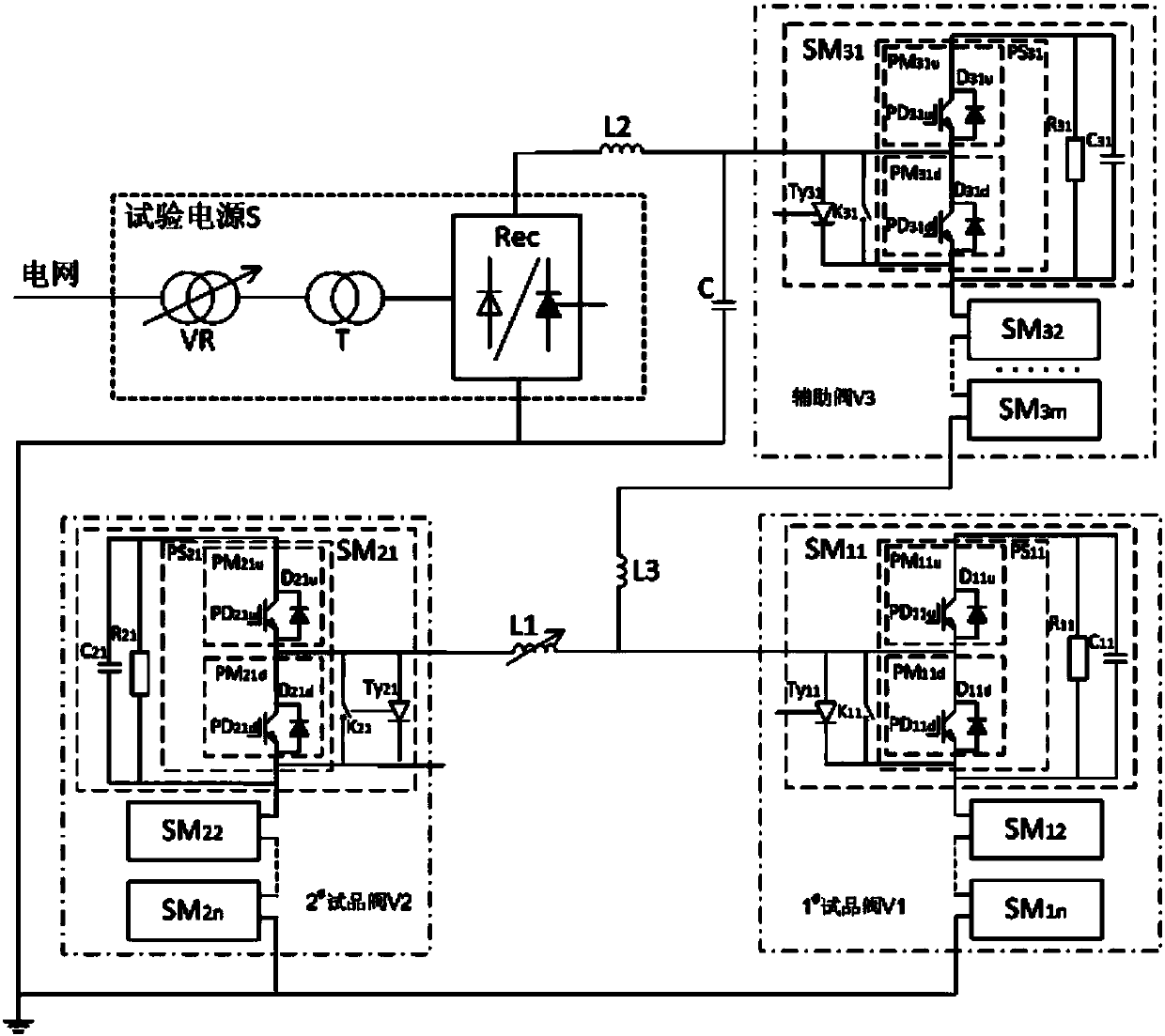

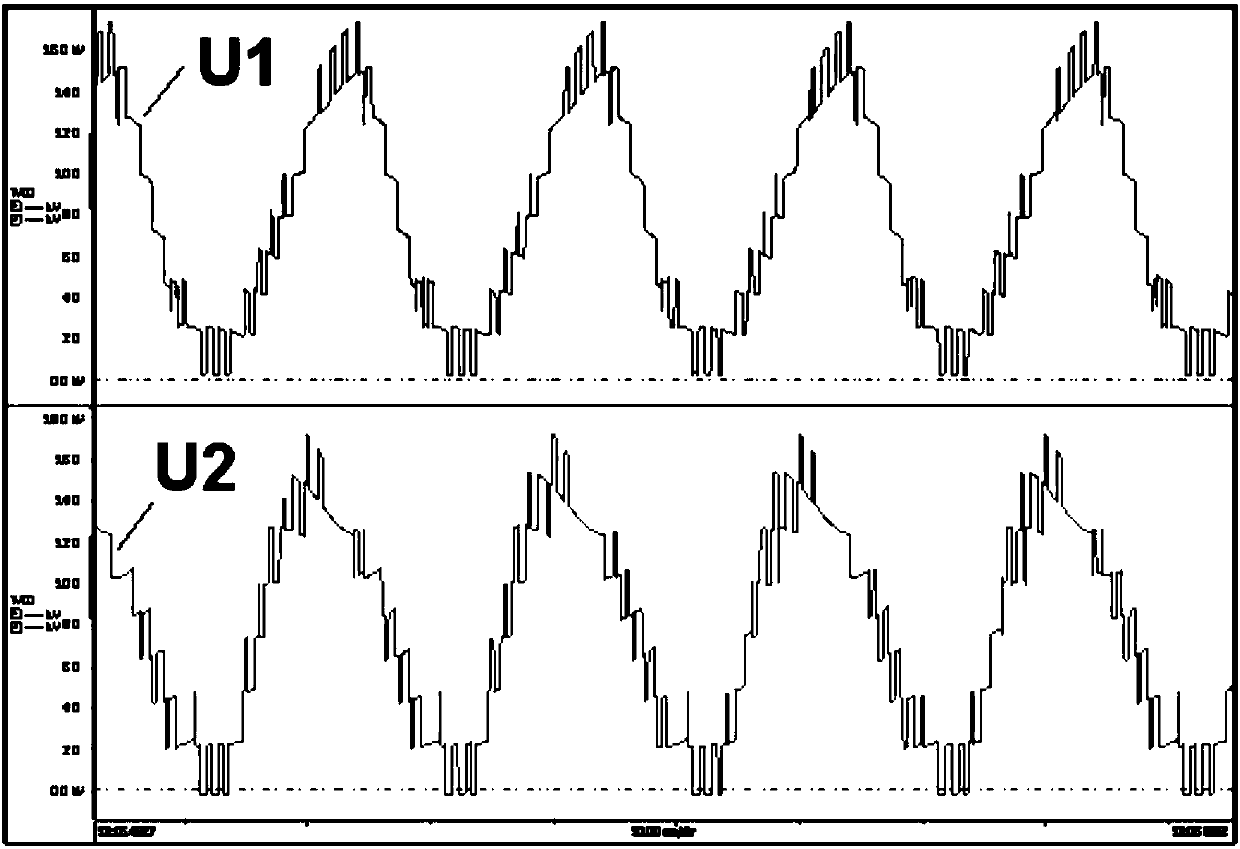

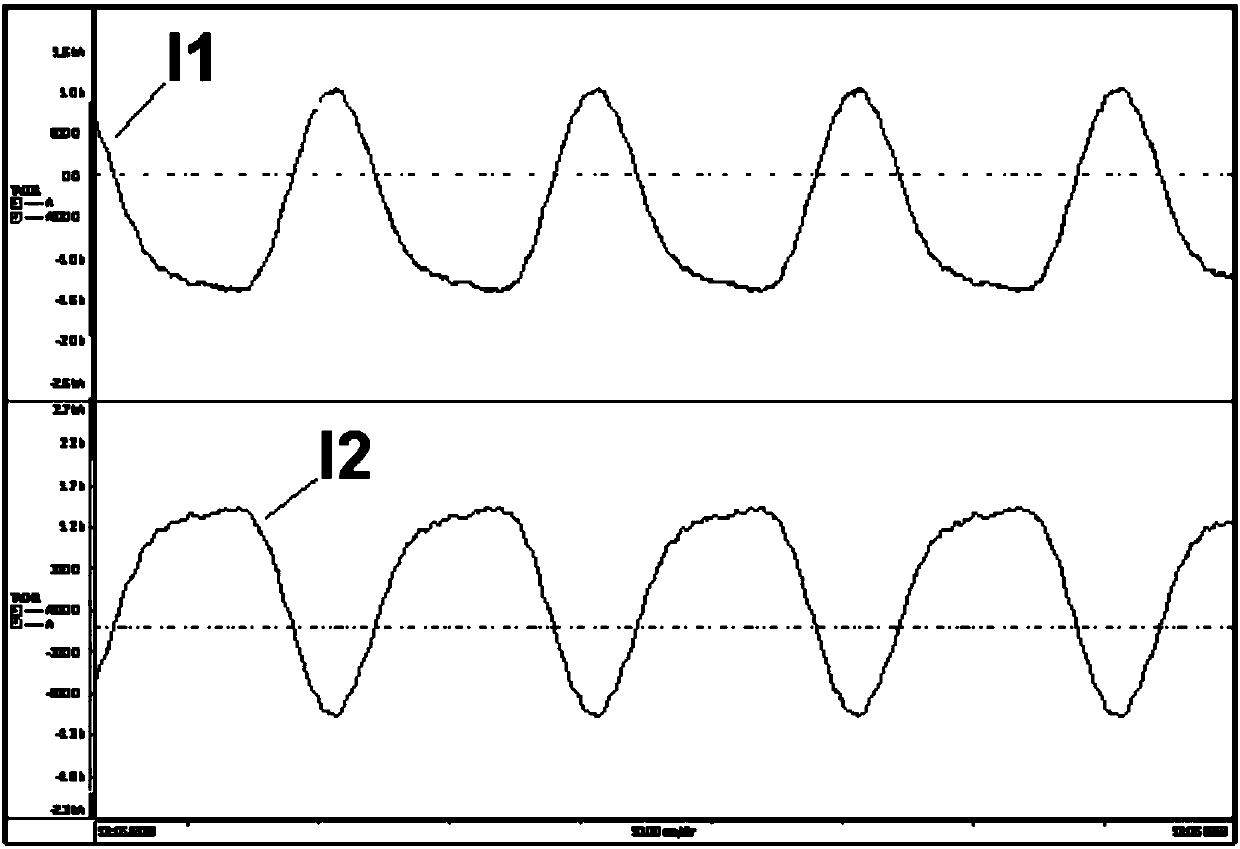

A flexible DC transmission voltage source converter valve operation test device

ActiveCN105372586BReduce power lossMeet the assessment requirementsCircuit interrupters testingTest powerDc current

The invention discloses a flexible DC transmission voltage source converter valve operation test device. The particular technical scheme is as follows: a test power supply is used for charging two sample valve assemblies and an assistant valve group, and a constant DC voltage control strategy is used for enabling voltage of each valve submodule to be distributed uniformly and required test voltage is achieved; a nearest level modulation strategy is adopted to generate test voltage at two ends of the two sample valves, and the two sample valves have the same DC voltage components and AC voltage components with the same amplitudes and different phases; under effects of the test voltage, the two sample valves form a closed-loop power circuit via a test reactor, the test reactor and a sample valve submodule capacitor perform electromagnetic energy exchange in the power closed-loop circuit to obtain test current, and the current contains a power frequency fundamental wave current component, a DC current component and a doubled power frequency loop current component; and the test power supply is used for energy complementation on operation loss of the test circuit, and the assistant valves are used for balancing test voltage fluctuation caused by the power grid.

Owner:XIAN HIGH VOLTAGE APP RES INST CO LTD

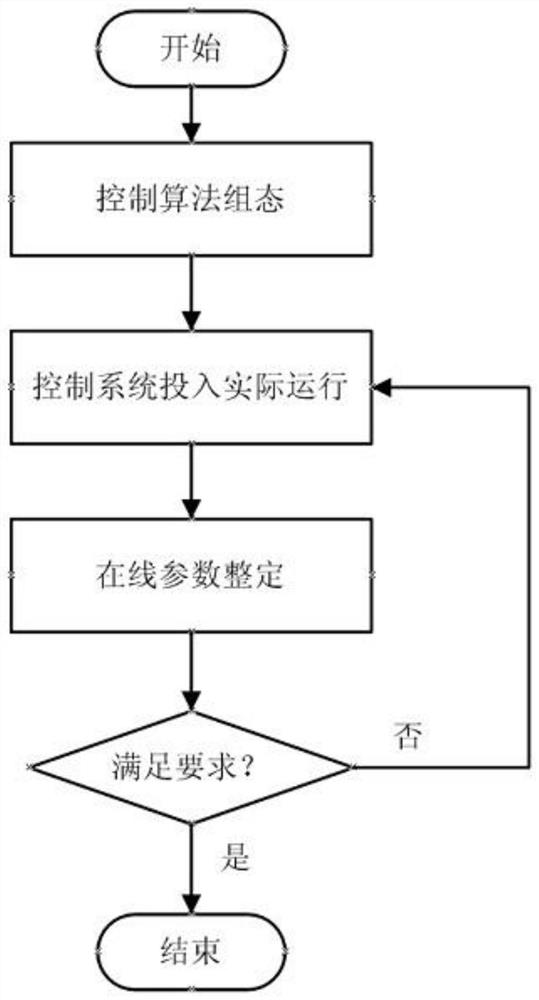

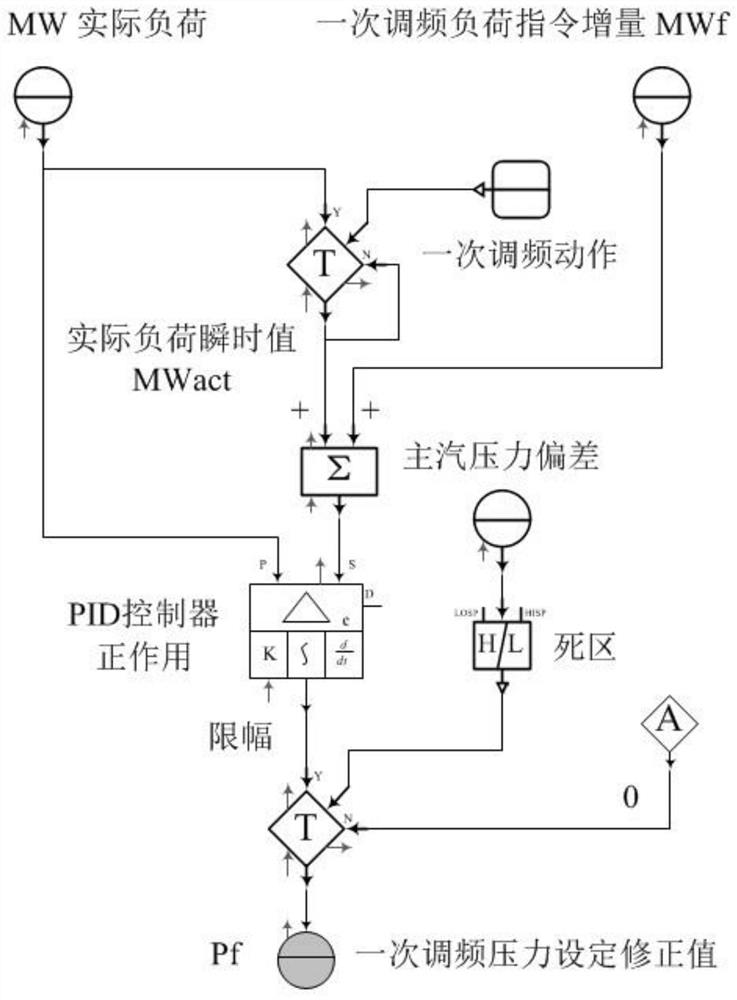

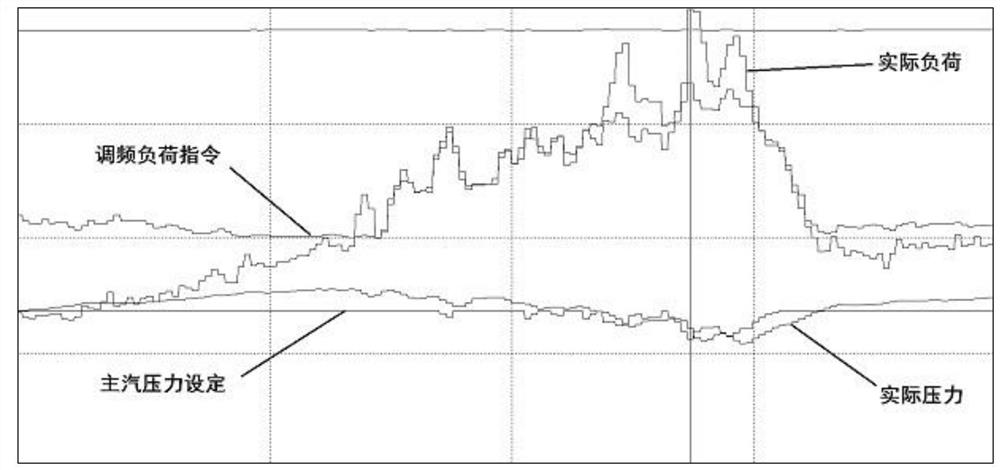

A primary frequency regulation control method for coal-fired units in the turbine following mode

ActiveCN111399448BMeet the assessment requirementsAvoid counter-tuneProgramme total factory controlAutomatic controlSteam pressure

The invention discloses a primary frequency modulation control method of a coal-fired unit in a steam turbine following mode, which belongs to the technical field of automatic control of the coal-fired unit and can be used for the automatic control of primary frequency modulation during the actual operation of the coal-fired unit. By adding the primary frequency modulation load pull-back control logic and adopting the closed-loop control method, the set value of the main steam pressure can be dynamically corrected in real time, which can effectively avoid the reverse adjustment of the primary frequency regulation in the steam turbine following mode, and ensure that the primary frequency regulation performance of the unit in this mode is also excellent. Rapidity and accuracy, to meet the grid assessment requirements.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

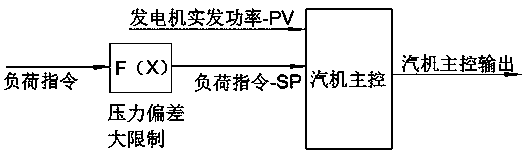

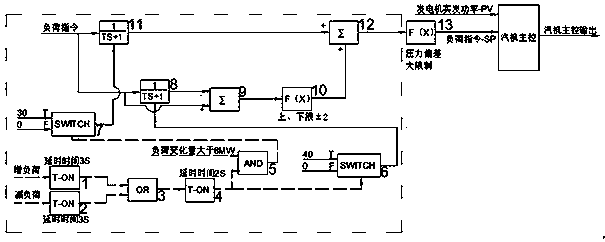

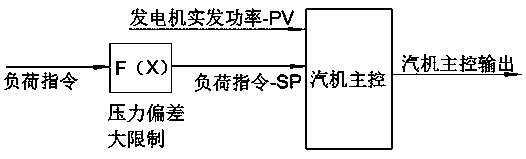

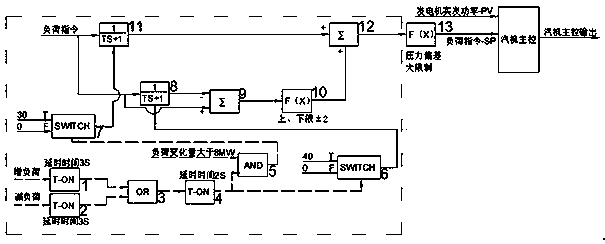

Control method for improving ACE response performance of 300MW coal-fired unit

ActiveCN107605548AMeet the assessment requirementsMachines/enginesEngine componentsLoad instructionComputer module

The invention relates to a control method for improving the area control error (ACE) response performance of a 300MW coal-fired unit. According to the control method for improving the ACE response performance of the 300MW coal-fired unit, a delaying module, an or-gate module, an and-gate module, a selecting module, an inertia link module, an addition module and a function module are included; andby improving forming logic of an load instruction of the main control side of a steam turbine, the unit load can be greater than (when the load is up) or less than (when the load is down) the load target value and can be stabilized at the load target value after two seconds, and ACE assessment requirements are met.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

A control method to improve the ace response performance of 300mw coal-fired unit

ActiveCN107605548BMeet the assessment requirementsMachines/enginesEngine componentsLoad instructionComputer module

The invention relates to a control method for improving the area control error (ACE) response performance of a 300MW coal-fired unit. According to the control method for improving the ACE response performance of the 300MW coal-fired unit, a delaying module, an or-gate module, an and-gate module, a selecting module, an inertia link module, an addition module and a function module are included; andby improving forming logic of an load instruction of the main control side of a steam turbine, the unit load can be greater than (when the load is up) or less than (when the load is down) the load target value and can be stabilized at the load target value after two seconds, and ACE assessment requirements are met.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Full-automatic microfiltration membrane aperture distribution tester as well as automatic measuring method and application thereof

InactiveCN102087195BMeet the assessment requirementsImpact performance measurementPermeability/surface area analysisFiltration membraneAutomatic control

The invention discloses a full-automatic microfiltration membrane aperture distribution tester as well as an automatic measuring method and application thereof. The full-automatic microfiltration membrane aperture distribution tester comprises a gas supply cylinder, a gas buffer tank and a test membrane cell for fixing and sealing a microfiltration membrane, wherein the gas supply cylinder, the gas accumulator tank and the test membrane cell are successively connected via a pipeline. The full-automatic microfiltration membrane aperture distribution tester is characterized in that a motor-driven flow regulating valve is arranged between the gas supply cylinder and the gas buffer tank; the gas buffer tank is provided with a pressure probe; an outlet on the microfiltration membrane penetration side of the test membrane cell is provided with a gas flow probe; the signal output end of the pressure probe and the signal output end of the gas flow probe are connected with a data acquisition module for collecting pressure and flow signals in real time; the signals are transmitted by the communication module and a computer controller; the signal output end of the computer controller is connected with the signal input end of the motor-driven flow regulating valve; and the motor-driven flow regulating valve is under real-time feedback control. According to the full-automatic microfiltration membrane aperture distribution tester, the measuring condition can be automatically controlled in real time, measuring data is collected, data is processed in real time, and the assessment requirement on the performance of various sieve-pore filtration membranes can be satisfied.

Owner:NINGBO UNIV

A Quality Evaluation and Prediction Method of Tunnel Smooth Blasting

ActiveCN104318086BMeet the assessment requirementsEasy to operateSpecial data processing applicationsEvaluation resultMeasurement evaluation

The invention relates to a channel smooth blasting quality evaluation prediction method, comprising the following steps of 1, obtaining evaluation indexes; 2, obtaining an actual measurement evaluation index value of a section to be evaluated, and adopting a variable coefficient method and an analytic hierarchy process to obtain the comprehensive weight of each evaluation index for the total evaluation; 3, performing evaluation prediction on the smooth blasting quality by respectively using a conventional weighting method and a projection pursuit method and obtaining the comprehensive evaluation result of the smooth blasting quality of the section to be evaluated according to the evaluation prediction result obtained according to each method. Compared with the prior art, the channel smooth blasting quality evaluation prediction method has the advantages of convenience in operation, strong systematization, high practicability and the like.

Owner:TONGJI UNIV

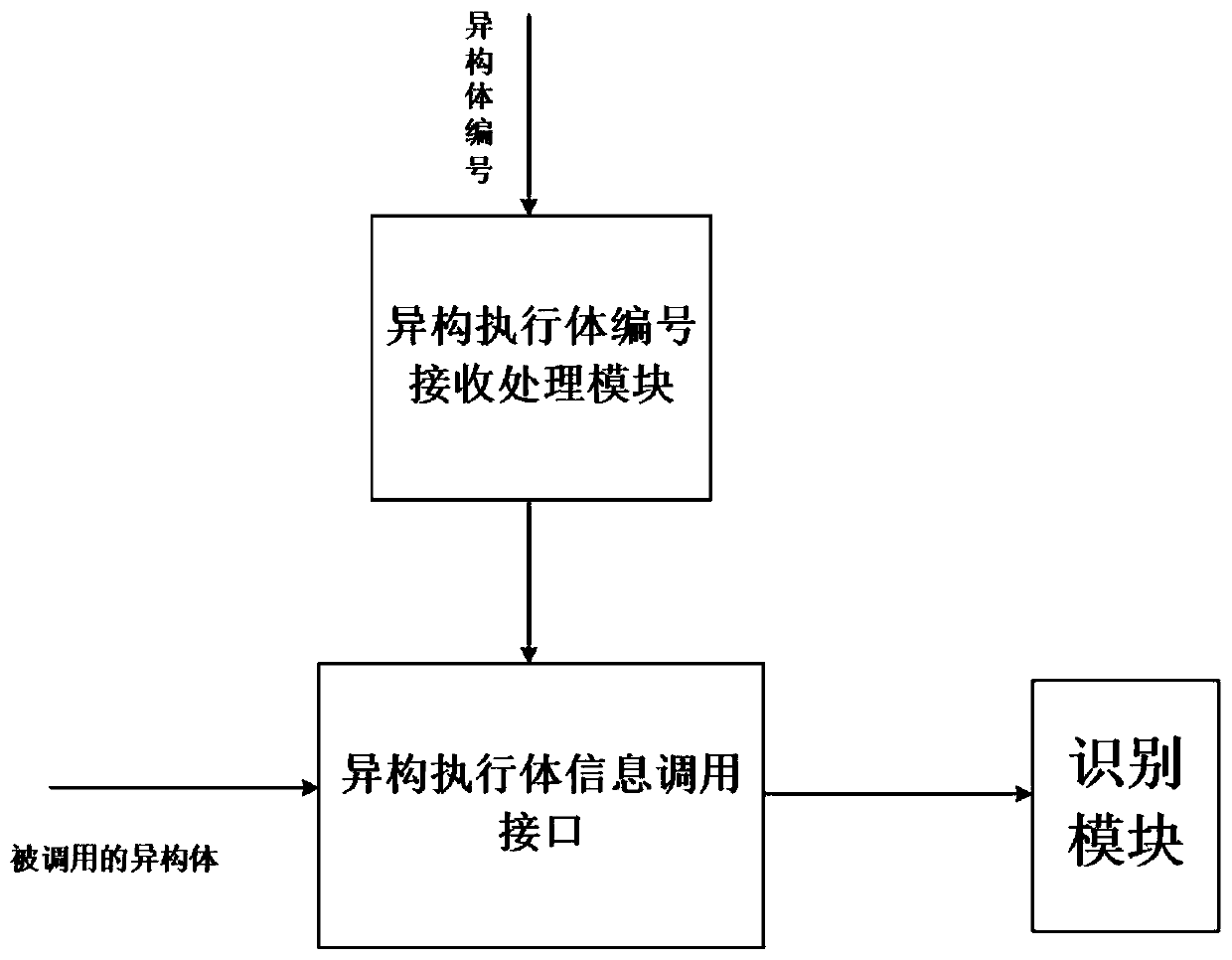

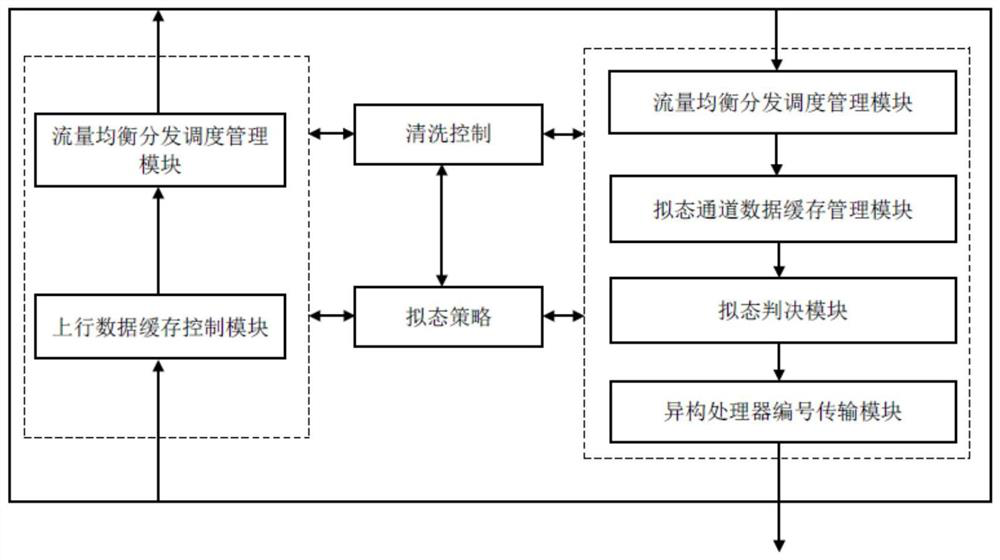

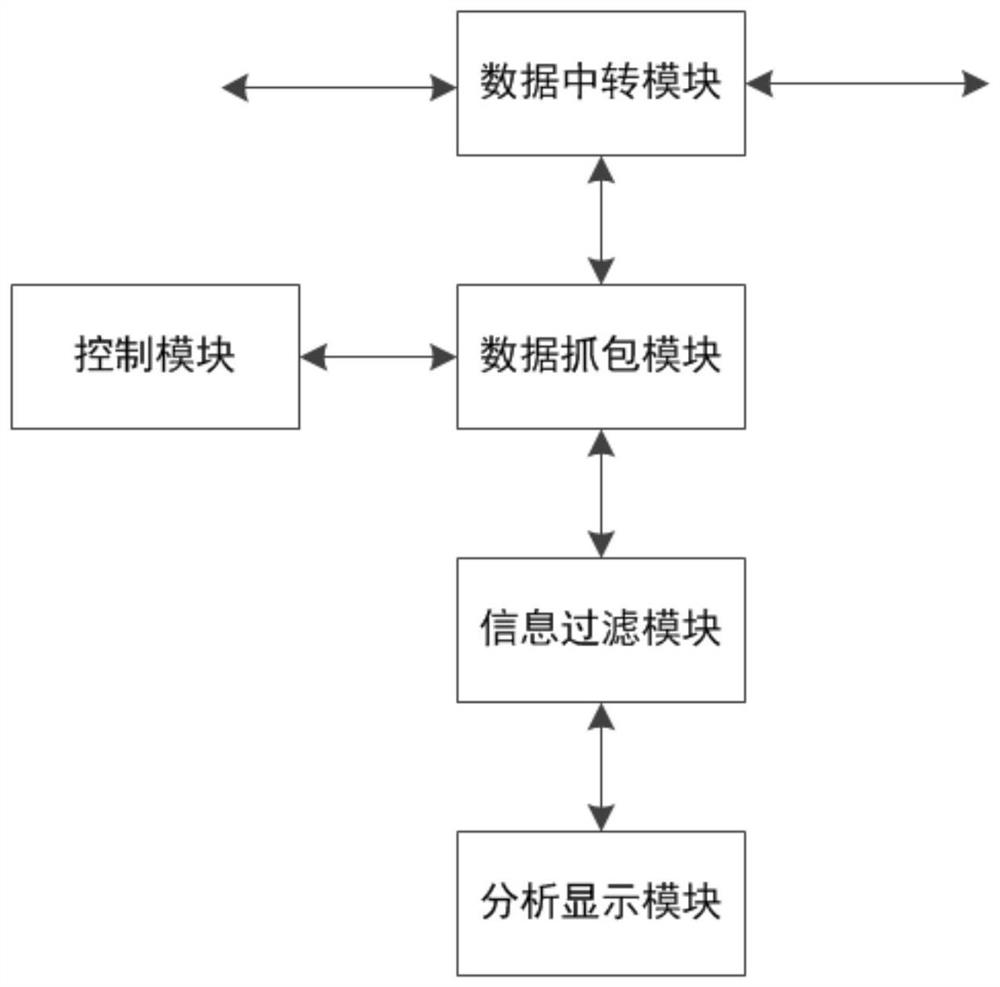

System, method and device for testing heterogeneity of mimic system based on network packet capture

ActiveCN110740077BEnhanced authenticationImprove recognitionData switching networksNetwork packetSecurity information

The present invention provides a method, system and device for testing the heterogeneity of a mimic system based on network packet capture, including: a user unit module: sending data to be tested to a mimic scheduling module; mimic scheduler module: distributing received data to be tested To multiple heterogeneous processors, so that multiple heterogeneous processors perform calculations on the data to be tested separately, obtain the calculation results, perform a mimetic judgment on the calculation results, and output the number sequence of the heterogeneous processors with consistent calculation results to the heterogeneity identification module, and perform cleaning operations on inconsistent heterogeneous processors, and store the operation results. The present invention adds verification and identification functions for heterogeneous processor types, which is beneficial to verify the stability, security and performance rationality of heterogeneous processors more efficiently, conveniently and comprehensively, and automatically generate detailed test reports , in order to meet the evaluation requirements for the heterogeneity of the mimic security information system.

Owner:EAST CHINA INST OF COMPUTING TECH

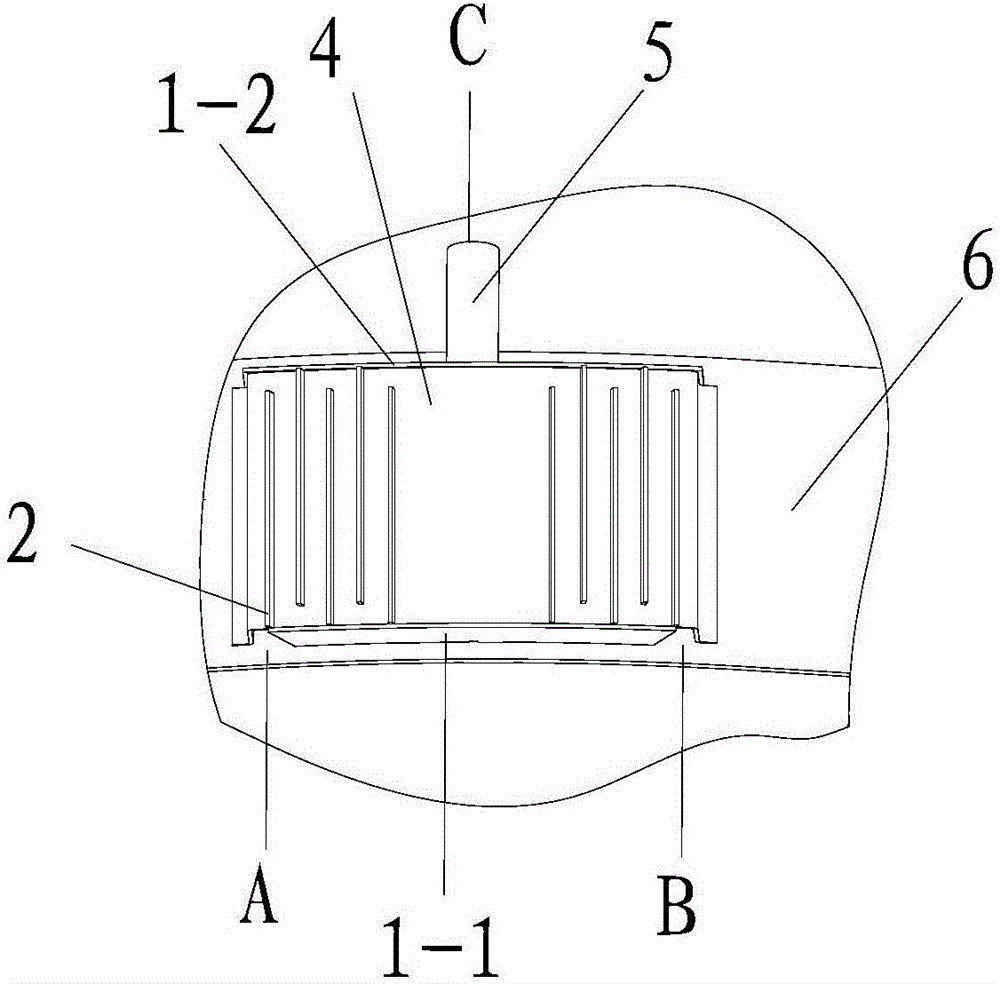

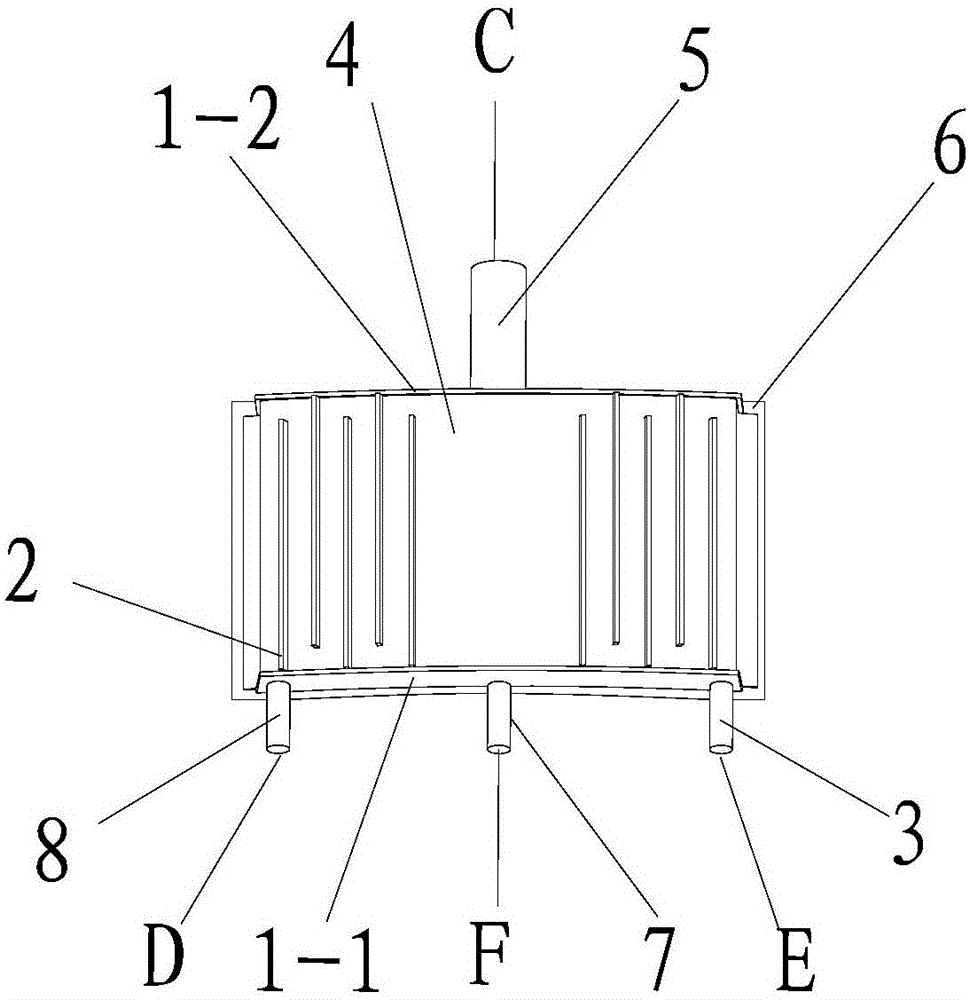

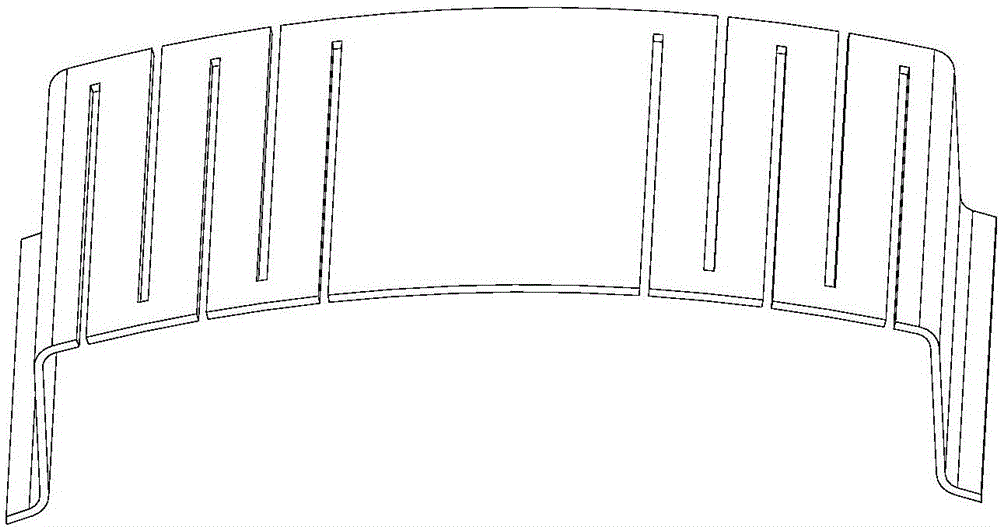

Laminated restrictor

InactiveCN106703998AMeet the assessment requirementsReduce weightTurbine/propulsion lubricationFuel tankEngineering

The invention discloses a laminated restrictor. The laminated restrictor comprises baffle plates (1), oil retaining plates (2), a wall plate (4), a vent pipe (5) and a box inner wall (6). According to the laminated restrictor, the integral structure is simple, manufacturability is good, and cost is relatively low; the laminated restrictor can be properly improved according to different requirements of a ventilating system on the laminated restrictor; and the laminated restrictor can be independently utilized and arranged in a vent pipeline, and can be integrated in other lubricating oil accessories like a lubricating oil tank, so that the laminated restrictor is quite wide in application range and has relatively high utilization value.

Owner:CHINA GAS TURBINE ESTAB

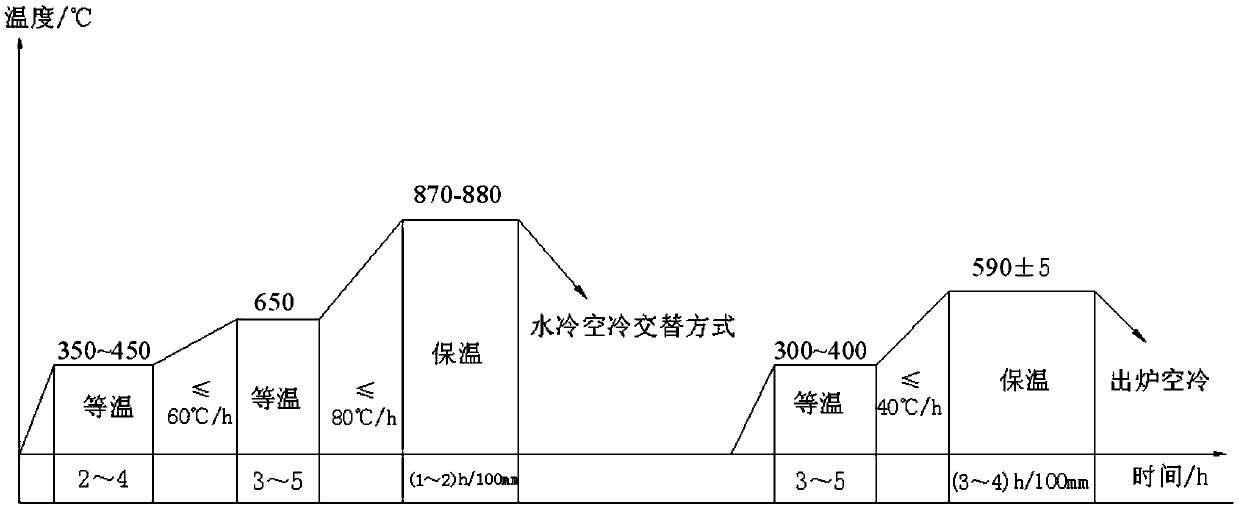

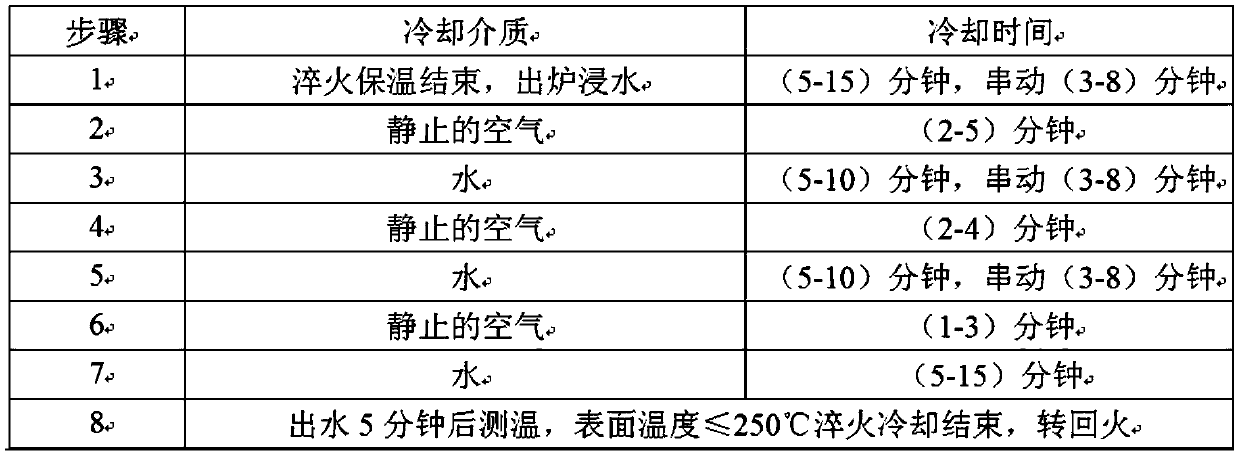

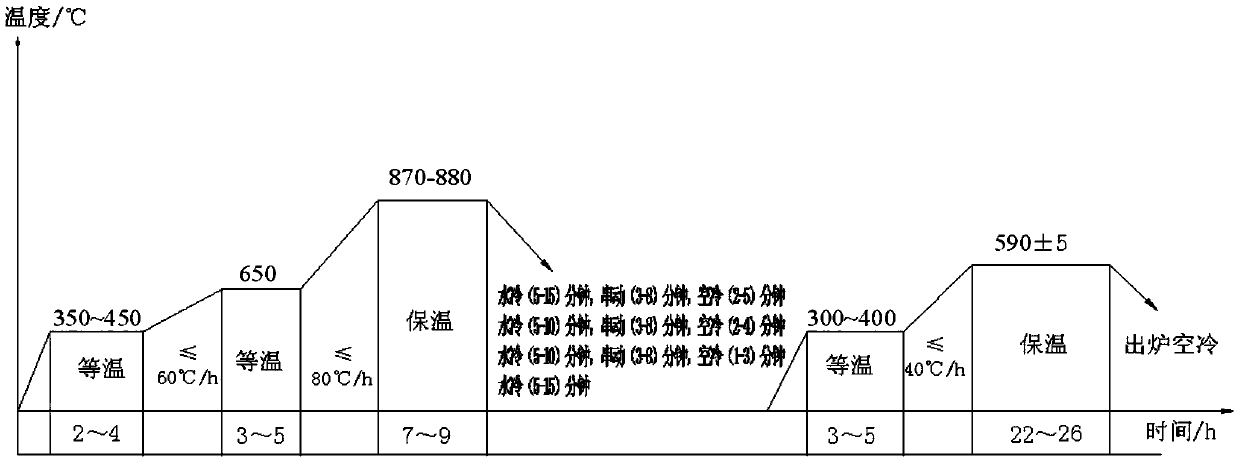

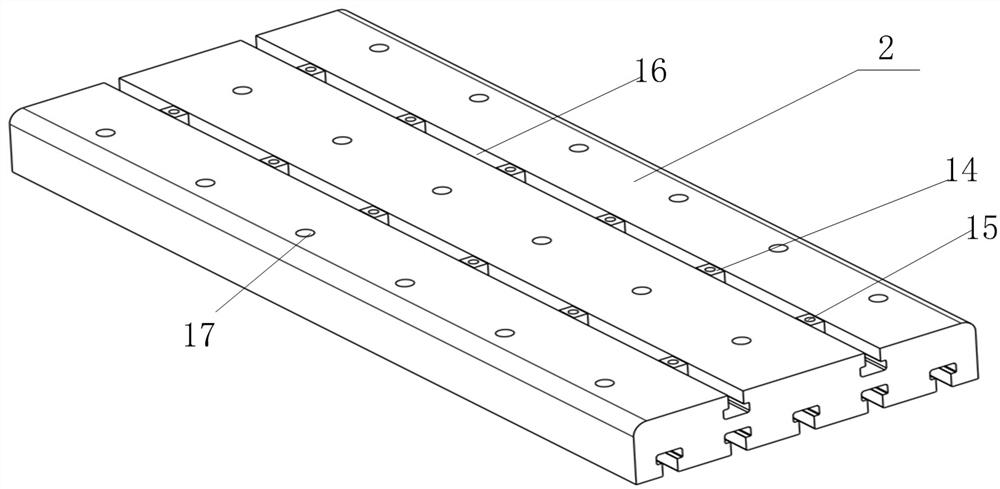

A Quenching and Tempering Treatment Method for Large 34crnimo6 Forgings

ActiveCN106929656BPrevent cooling crackingImprove cooling effectFurnace typesHeat treatment furnacesCombustionWater cooling

Owner:SHANGHAI ELECTRIC SHMP CASTING & FORGING CO LTD

A test device for vibration test of aerial suspension launching device

ActiveCN112393867BImproving the Efficiency of Vibration Test AssessmentImprove transfer characteristicsVibration testingAviationAir spring

Owner:TIANJIN AEROSPACE RELIA TECH

A method for real-time monitoring of bus voltage in substation

ActiveCN109459605BRealize real-time monitoringMeet the assessment requirementsCurrent/voltage measurementControl systemBusbar

Owner:LISHUI POWER SUPPLY COMPANY OF STATE GRID ZHEJIANG ELECTRIC POWER +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com