Laminated restrictor

A laminate restrictor and wall plate technology, which is applied in the lubrication of turbine/propulsion device, engine components, and engine lubrication, etc., can solve the problem of inability to separate oil and gas, and achieve great use value, simple overall structure, and overall weight. light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

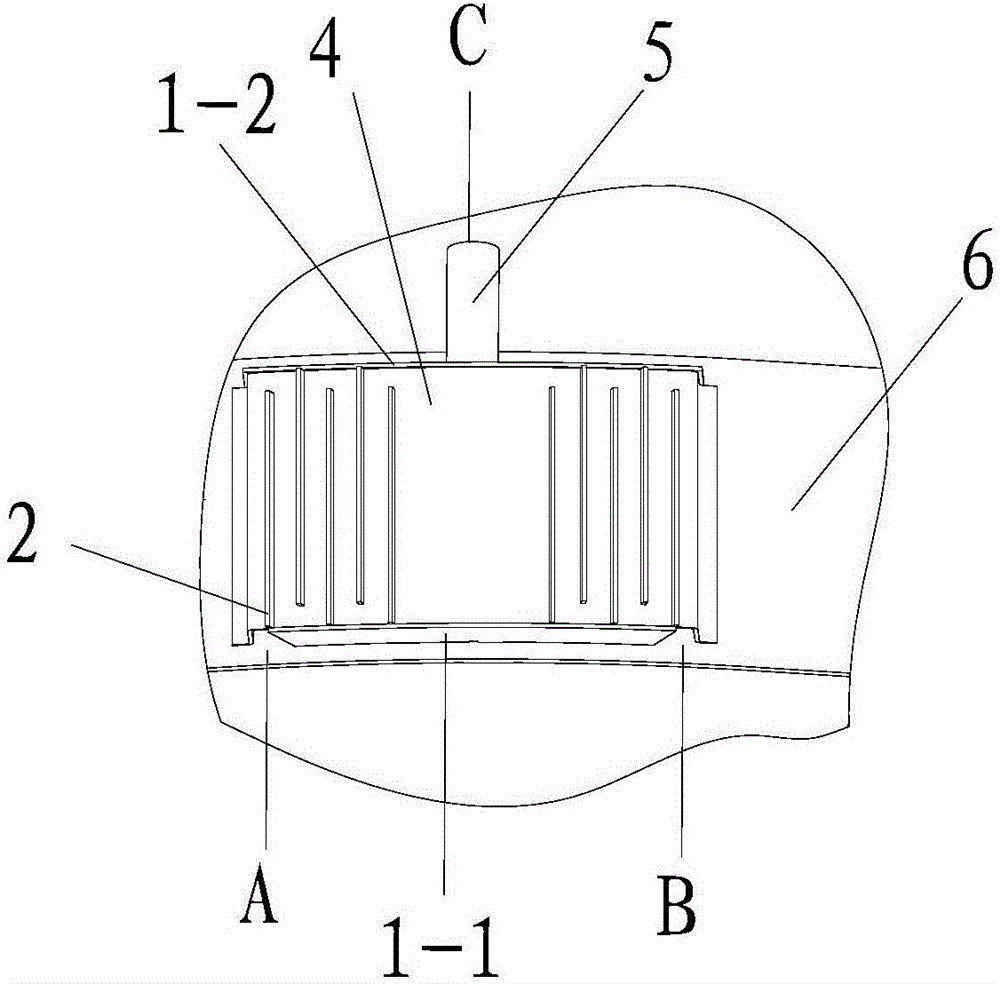

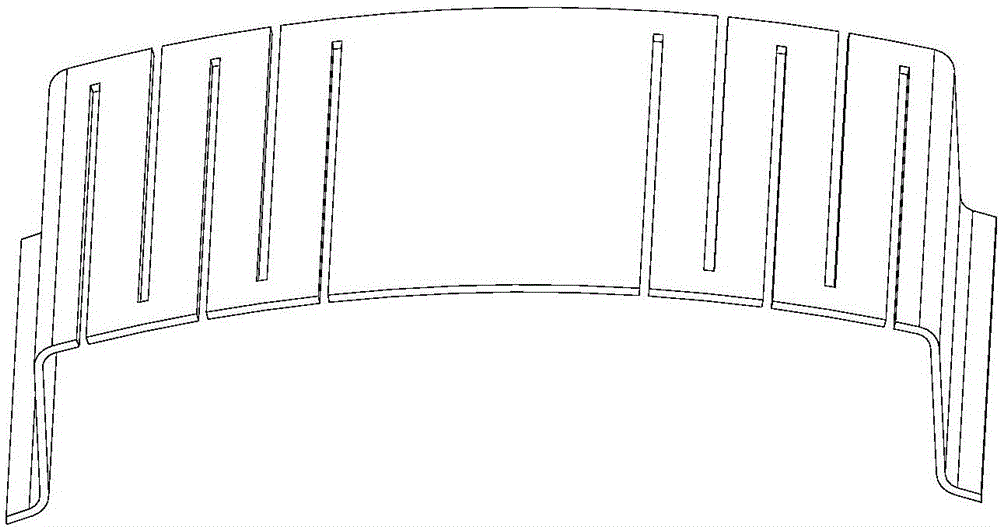

[0019] see figure 1 , image 3 , which is a structural schematic diagram of Embodiment 1 of the floor restrictor of the present invention. In this embodiment, the laminate restrictor is a plate structure, integrated inside the lubricating oil tank cavity, which consists of a front baffle 1-1, an oil retention plate 2, a rear baffle 1-2, a wall plate 4, Ventilation pipe 5 and bottom plate 6 are formed. Wherein, the ventilation pipe 5 is processed from a pipe material, and is fixed at the outlet of the laminate restrictor by welding; The inlet position of the side air inlet A and the right air inlet B has an oil throwing hole, which is located between the front baffle 1-1 and the bottom plate 6; the rear baffle 1-2 is a plate structure, and the installation On the rear end surface of the wall plate 4, there are two oil throwing holes located between the rear baffle plate 1-2 and the bottom plate 6; the bottom plate 6 is located inside the cavity of the integrated lubricating ...

Embodiment approach 2

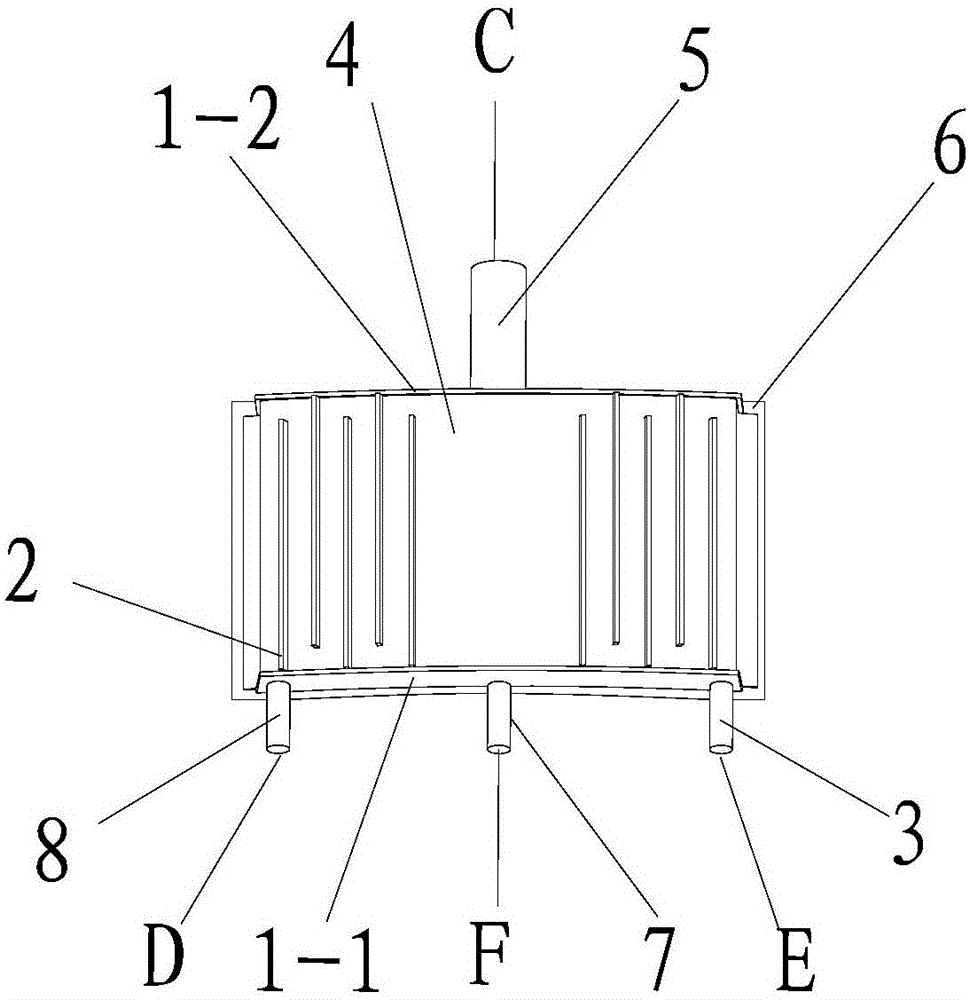

[0022] see figure 2 , image 3 , which is a structural schematic diagram of Embodiment 2 of the floor restrictor of the present invention. In this embodiment, the laminate restrictor is a plate structure, designed as a separate lubricating oil accessory, which consists of a front baffle 1-1, a rear baffle 1-2, an oil retaining plate 2, and a right air inlet Pipe 3 wall plate 4, ventilation pipe 5, bottom plate 6 oil outlet pipe 7 and left side air inlet pipe 8 are formed. Wherein, the ventilation pipe 5 is processed from a pipe material, and is fixed on the outlet of the laminate restrictor by welding; The inlet position of the left air inlet pipe 8 and the right air inlet pipe 3; the rear baffle 1-2 is a plate structure, installed on the rear end surface of the wall plate 4; the bottom plate 6 is located in a thin plate structure, located on the wall The bottom of the plate 4; the oil retaining plate 2 is a rectangular plate structure; the wall plate 4 is processed from a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com