A Quenching and Tempering Treatment Method for Large 34crnimo6 Forgings

A large-scale forging, quenching and tempering treatment technology, applied in the field of heat treatment, can solve the problems of poor oil cooling effect of super-long and super-thick large forgings, inability to ensure stable performance of forgings, hidden dangers of production safety, etc., so as to avoid the phenomenon of quenching oil burning and reduce production Potential safety hazards and the effect of reducing thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be clearly and completely described below with reference to the accompanying drawings. Obviously, the described embodiments are a part of the embodiments of the present invention, but not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work fall within the protection scope of the present invention.

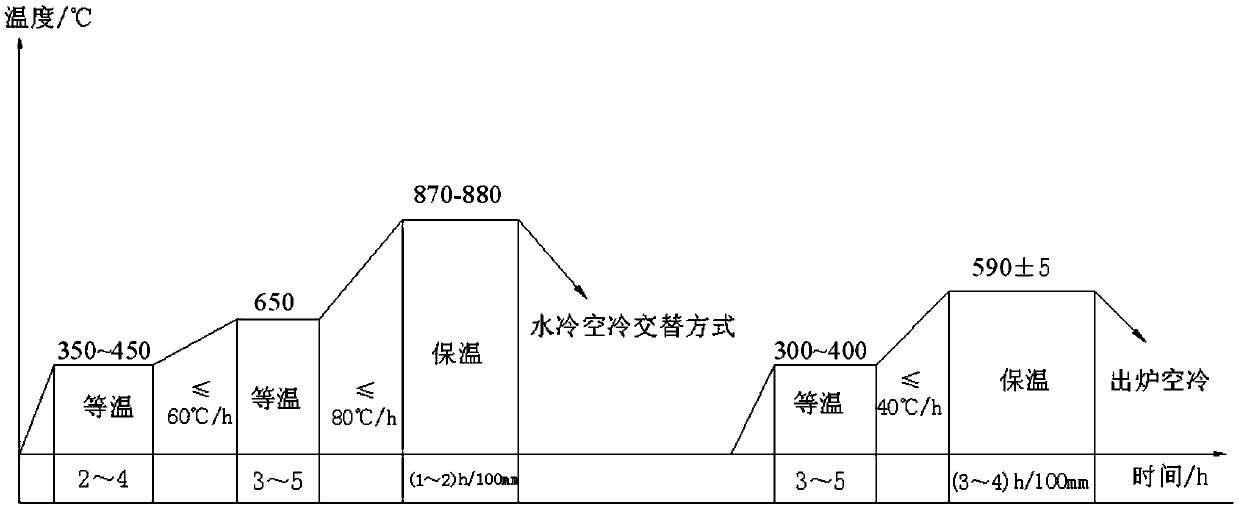

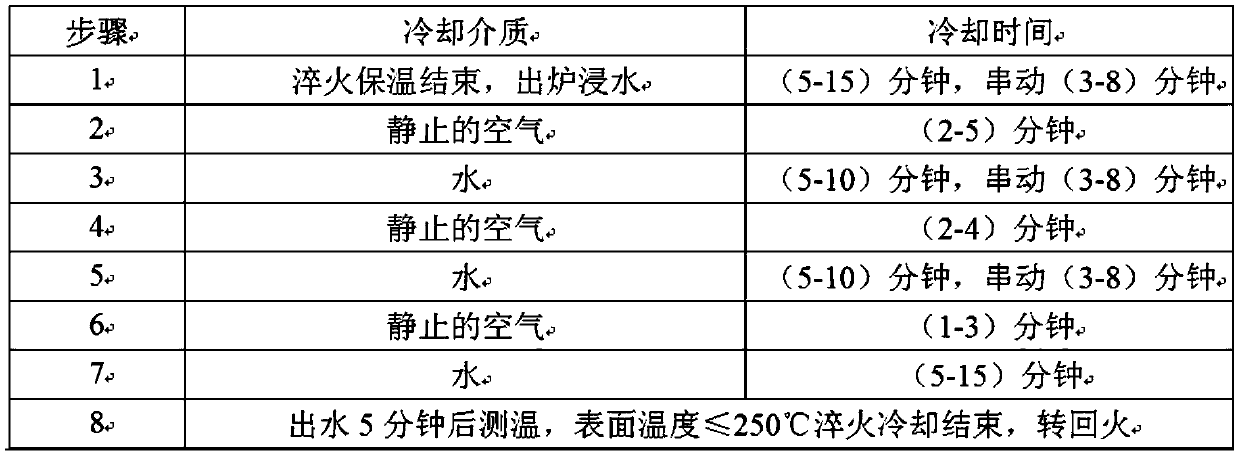

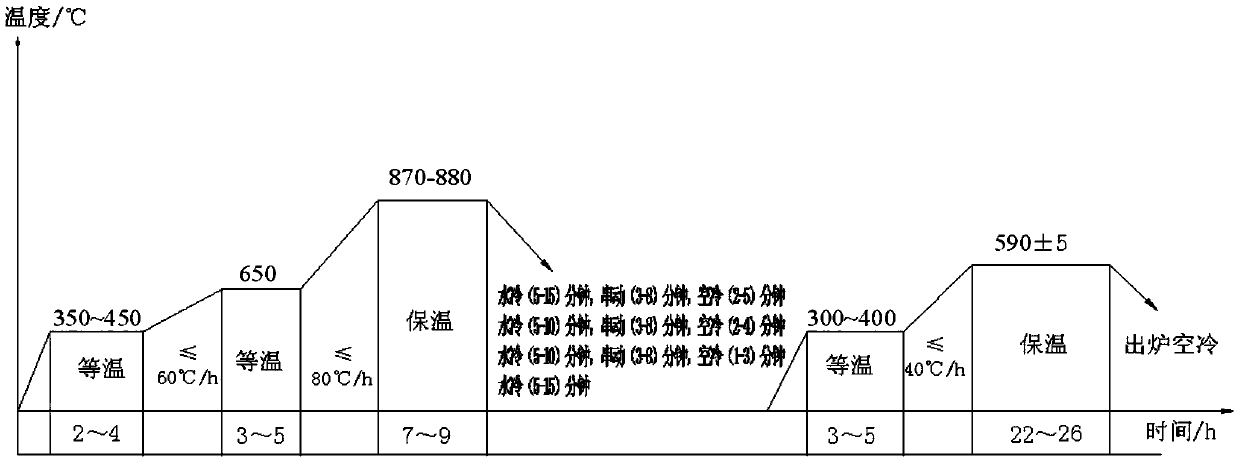

[0031] Taking 140MN free forging hydraulic press tie rod quenching and tempering as an example, the quenching and tempering treatment method of the present invention is specifically described:

[0032] The material of the tie rod of the 140MN free forging hydraulic press is 34CrNiMo6, the size of the part is: Φ600×22940mm, and the net weight is 40650kg; the forgings require Rm: 800MPa~980MPa after quenching and tempering, Re≥650Mpa, A5≥12%, Aku≥28J. The heat treatment size of the forgings is Φ690×23800mm. Its...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com