Creep data screening method based on statistical test and state check

A creep data and screening method technology, applied in chemical statistics, chemical data mining, manufacturing computing systems, etc., can solve the problem of not considering the actual distribution of creep data, and the value range is difficult to meet the evaluation requirements of various engineering materials issues such as improving reliability and accuracy, meeting evaluation requirements, improving screening efficiency and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

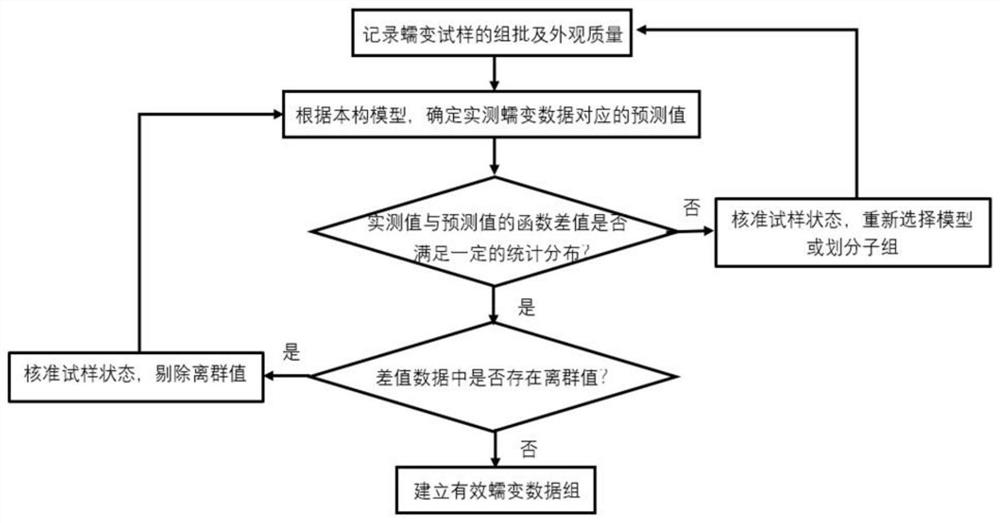

Method used

Image

Examples

Embodiment 1

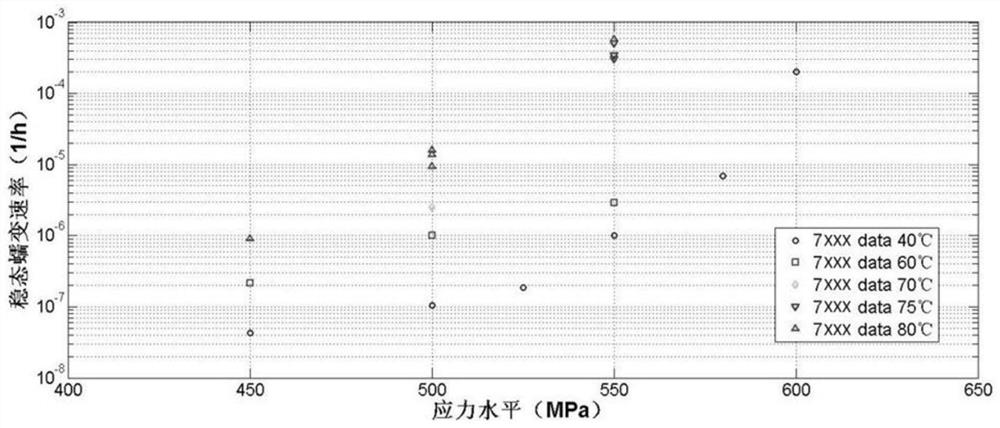

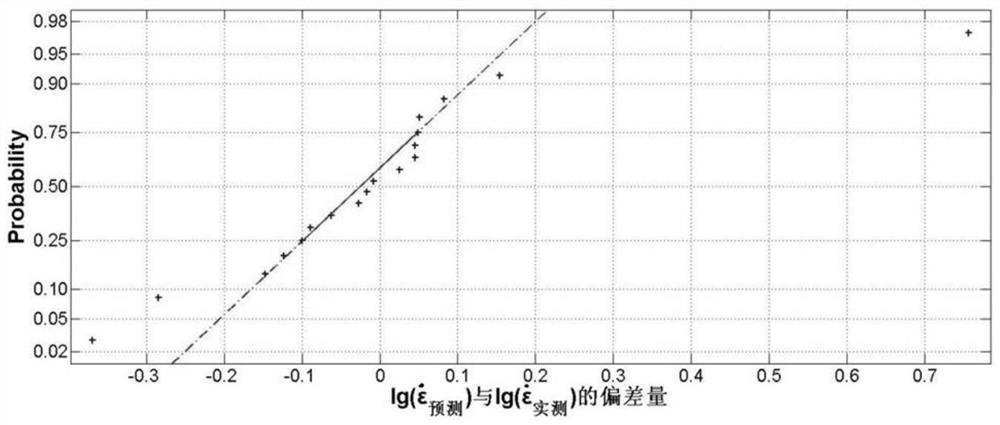

[0040] A 7-series high-strength aluminum alloy pre-forged billet (T6 state) was selected as the research object. The sampling direction of the creep sample was the inner radial direction of the billet (perpendicular to the forging direction of the pre-forged billet). The sample size refers to GB / T 2039-1997 "Metal Tensile Creep and Endurance Test Methods". The experimental temperature levels are 40°C, 60°C, 70°C, 75°C, and 80°C, respectively, and the experimental stress levels are 6.

[0041] (i) Before the creep test, record the state parameters of the sample, such as group batch, surface quality, and processing accuracy: After inspection, it is confirmed that the batch of samples is taken from the same batch of pre-forged blanks, the sampling direction is consistent, and the surface is smooth and not obvious. Defects, machining accuracy meet the requirements of the national standard, after the completion of the creep experiment, a total of 18 original steady-state creep rate...

Embodiment 2

[0047] The 316H stainless steel plate was selected as the research object, and the sampling direction of the creep specimen was the extrusion direction in the plate, and the specimen size was referred to GB / T 2039-1997 "Metal Tensile Creep and Endurance Test Method". The experimental temperature levels were 500°C, 550°C, 600°C, 650°C, 700°C, 750°C, and 800°C, and the experimental stress levels exceeded 10.

[0048] (i) State parameters such as batching, surface quality, and machining accuracy of the samples were recorded before the creep test: after inspection, it was confirmed that the samples of this batch were taken from 3 different batches of extruded plates, the sampling direction was consistent, and the surface was smooth No obvious defects were found, and the processing accuracy met the requirements of the national standard; after the creep test was completed, a total of 63 original creep rupture time data t were obtained 实测 , see the data distribution Figure 5 .

[...

Embodiment 3

[0054] The 316 stainless steel material is selected as the research object, and the sample size refers to GB / T 2039-1997 "Metal Tensile Creep and Endurance Test Methods". The experimental temperature levels are 500°C, 550°C, 600°C, 650°C, 700°C, and 750°C, respectively, and the experimental stress levels exceed 10.

[0055] (i) Before the creep test, record the state parameters of the sample, such as batching, surface quality, and processing accuracy: after inspection, it is confirmed that the batch of samples is taken from two different batches of plates and bars, and the creep samples The sampling direction is the extrusion direction of the plate or bar, the surface is smooth and no obvious defects are found, and the processing accuracy meets the requirements of the national standard. After the creep experiment is completed, a total of 41 original creep data are obtained, which are the creep time t corresponding to 1% of the creep strain 实测 , see the data distribution Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com