A method to eliminate small gap discharge

A small gap and discharge gap technology, applied in electrical components, emergency protection circuit devices for limiting overcurrent/overvoltage, circuit devices, etc. Achieve the effect of improving reliability, eliminating dispersion, avoiding malfunction and transformer damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

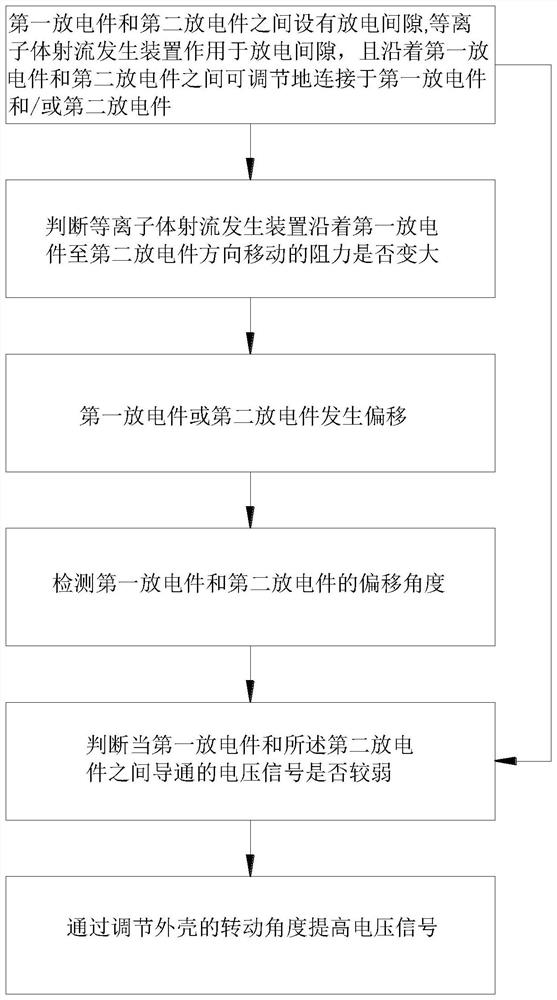

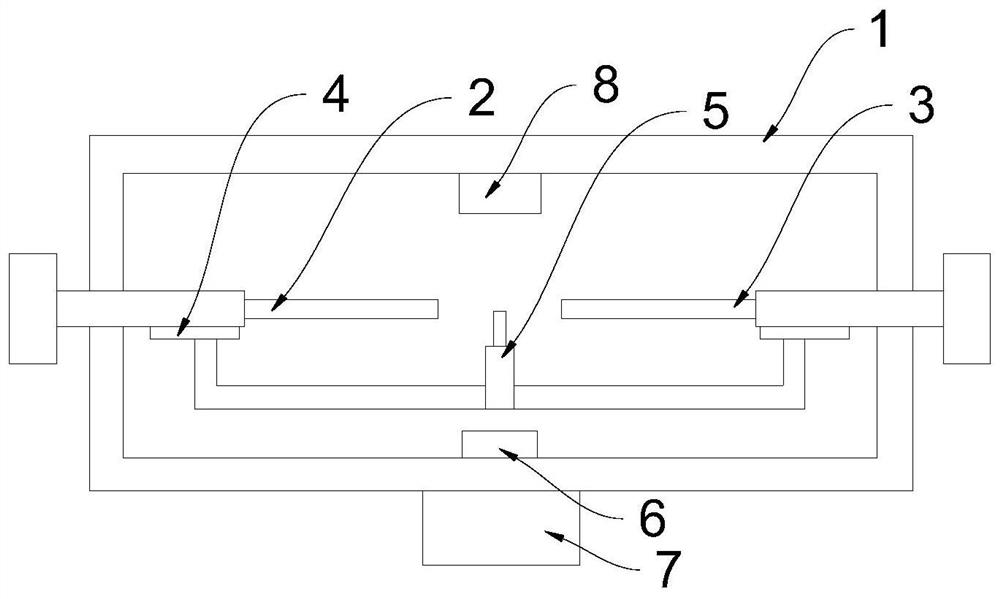

[0028] see Figure 1-Figure 2 , Figure 1-Figure 2 A schematic diagram of the method for eliminating small gap discharge provided by the embodiment of the present application is shown. The method for eliminating small gap discharge includes a first stabilizer, a second stabilizer and a driving mechanism, the first stabilizer is slidably mounted on the first discharge member 2, the second stabilizer is slidably mounted on the second stabilizer, and Both the first stable frame and the second stable frame slide along the direction from the first discharge member 2 to the second discharge member 3, and the plasma jet generator 5 is connected to the first stable frame and the second stable frame Meanwhile, the above-mentioned driving mechanism is used to drive the above-mentioned plasma jet generating device 5 to move along the direction from the above-mentioned first discharge member 2 to the above-mentioned second discharge member 3 .

[0029] In detail, the casing 1 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com