A Method for Eliminating the Errors Introduced by Standard Gears in Measuring Instruments for Double-side Meshing of Gears

A technology of standard gears and measuring instruments, which is applied in the direction of measuring devices, instruments, and optical devices, etc., can solve the problems of eliminating standard gear errors, waste, and short measuring chains, meet the requirements of reducing accuracy, improve manufacturing accuracy, and improve stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

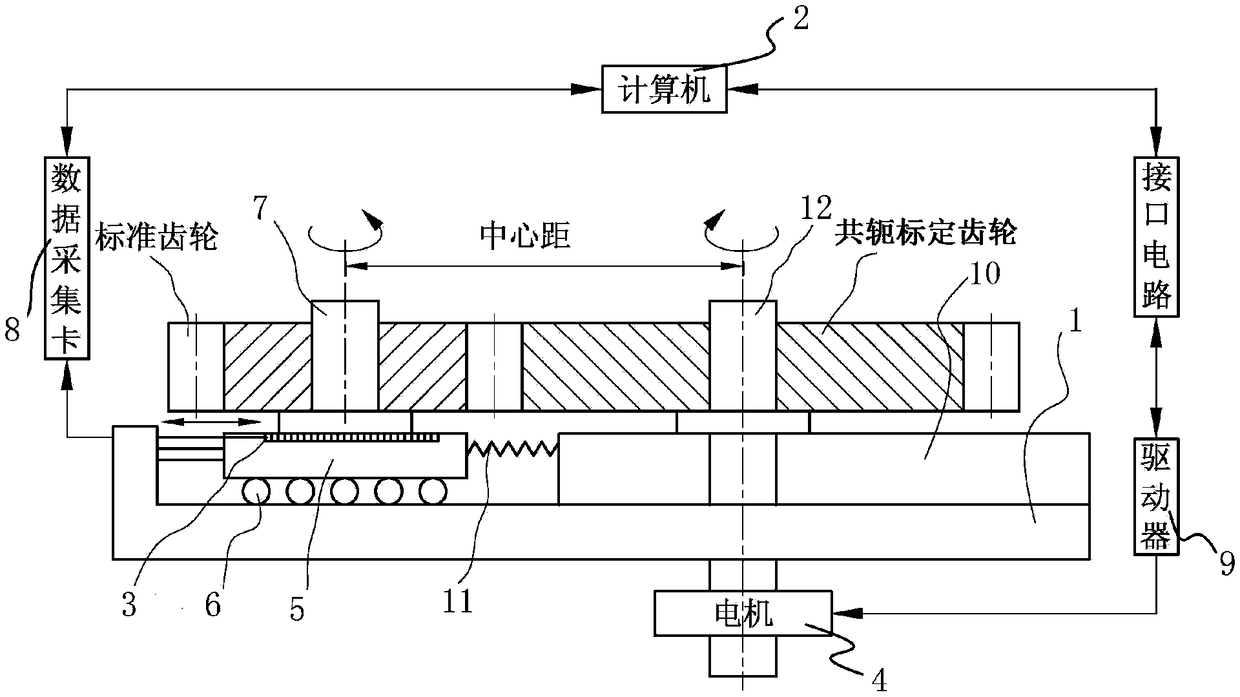

[0025] refer to figure 1 , the gear double-sided meshing measuring instrument of the present invention comprises a base 1, a computer 2, a grating sensor 3, a motor 4 and a slide plate 5, the slide plate 5 is arranged on the base 1 through a guide rail 6, and the top of the slide plate 5 is rotated with a first Positioning shaft 7, the top of slide plate 5 is provided with grating sensor 3 next to first positioning shaft 7, and the output shaft of described motor 4 vertically extends to the top of base 1 and is connected with second positioning shaft 12, and described grating sensor 3 The computer 2 is connected through the data acquisition card 8, and the computer 2 is connected with the motor 4 through the driver 9. The base 1 is provided with a positioning seat 10 over the second positioning shaft 12 , and a connecting spring 11 is provided between the positioning seat 10 and the sliding plate 5 .

[0026] The measuring instrument detects the center distance between the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com