A control method to improve the ace response performance of 300mw coal-fired unit

A 300MW, coal-fired unit technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems that the main control strategy of steam turbines is difficult to meet the assessment requirements, the control logic is difficult to meet the ACE assessment requirements, and it is difficult to meet the power plant assessment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0031] Example.

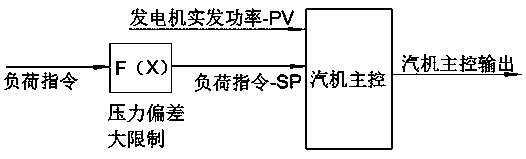

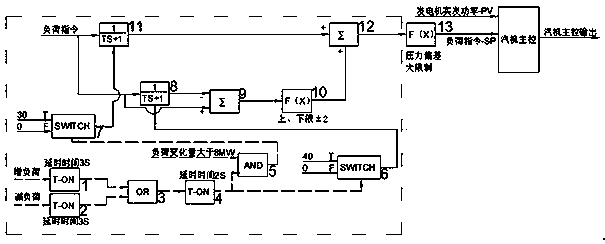

[0032] see figure 2 , a control method for improving the ACE response performance of a 300MW coal-fired unit in this embodiment includes a delay module, an OR module 3, an AND module 5, a selection module, an inertia link module, an addition module and a function module.

[0033] The digital quantity of the load increase in this embodiment is used as the input value of the delay module one 1, and after a delay of 3S, it is output to the OR gate module 3, and the digital quantity of the load reduction is used as the input value of the delay module two 2, and after a delay of 3S , output to the OR gate module 3; the output digital quantity of the delay module 1 and the output digital quantity of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com