Variable load overshoot control method for supercritical or ultra-supercritical generator sets

A technology of ultra-supercritical and generator sets, which is applied in the control system, steam generation, lighting and heating equipment, etc. It can solve the problems that cannot effectively improve the load response capacity of the unit, and achieve the effect of meeting the performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

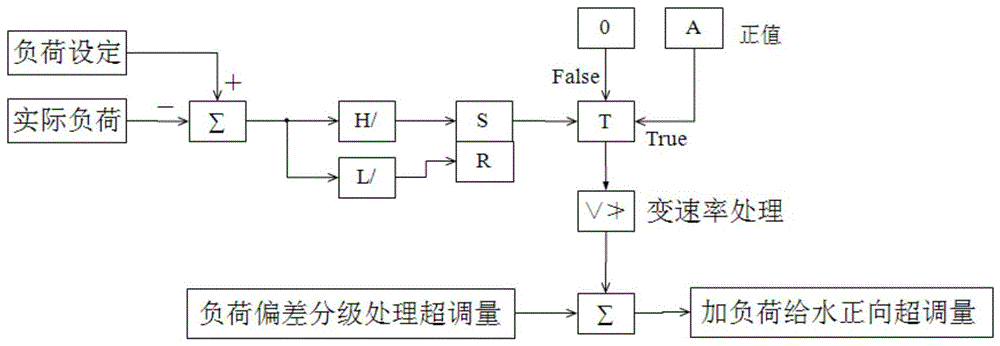

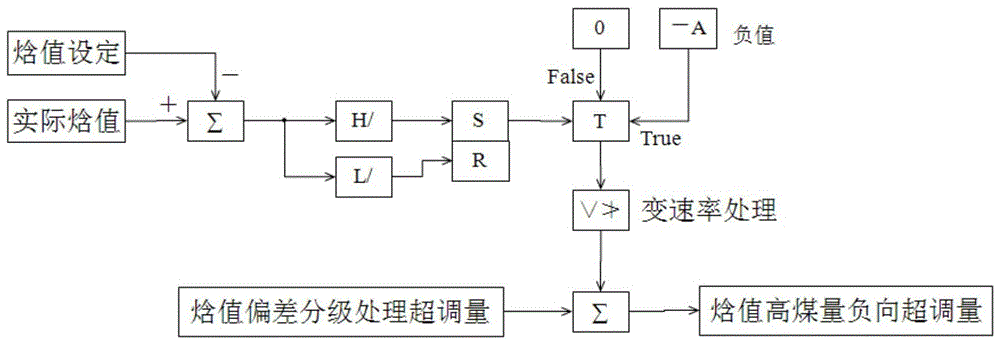

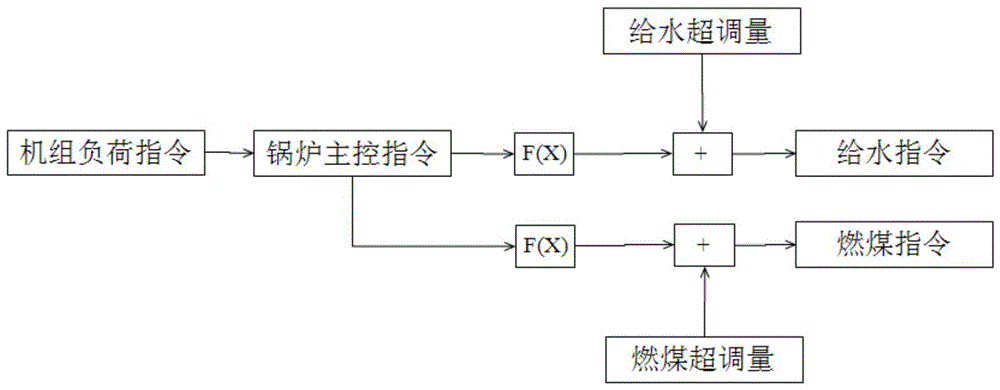

[0028] In order to reduce the throttling loss of the high-pressure valve of the steam turbine and improve the economical operation of the unit, the high-pressure valve of the steam turbine is fully opened and the sliding pressure operation mode is adopted. During the load change process, the valve no longer participates in load regulation or steam pressure control, thus affecting the variable load of the unit. performance. The conventional overshooting method is to increase or decrease the corresponding coal and water volume synchronously with the change of the load command. In the case that the turbine valve does not participate in the adjustment, the load response capability of the unit cannot be effectively improved. For this reason, the present invention provides a new variable load overshoot control method to compensate for the decline in load variation capability due to the full opening of the control door.

[0029] When the supercritical or ultra-supercritical unit ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com