A method for automatic control and optimization of the blower of a thermal power unit

A technology of thermal power unit and optimization method, applied in the direction of controlling combustion, combustion method, adjusting fuel supply, etc., can solve problems such as targeted research, overcurrent of blower, stall of blower, etc., to achieve a simple on-site debugging process and reduce labor Strength, easy engineering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

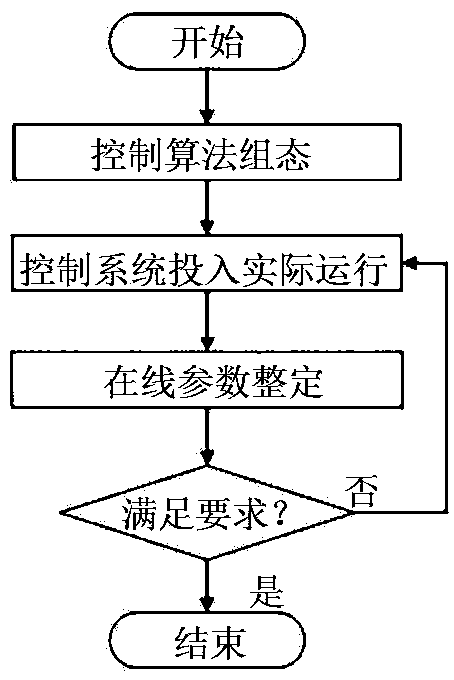

[0031] A thermal power unit blower automatic control optimization method, characterized in that the steps are:

[0032] 1) Detect the total coal supply, the error value D of the guide vane opening of each blower, and the error value I of the inverter frequency of each blower;

[0033] 2) Set the current limit value C, the limit value of the blower outlet pressure drop rate F, the decrease value of the guide vane opening after the blower stalls, the decrease value of the inverter after the blower stalls J;

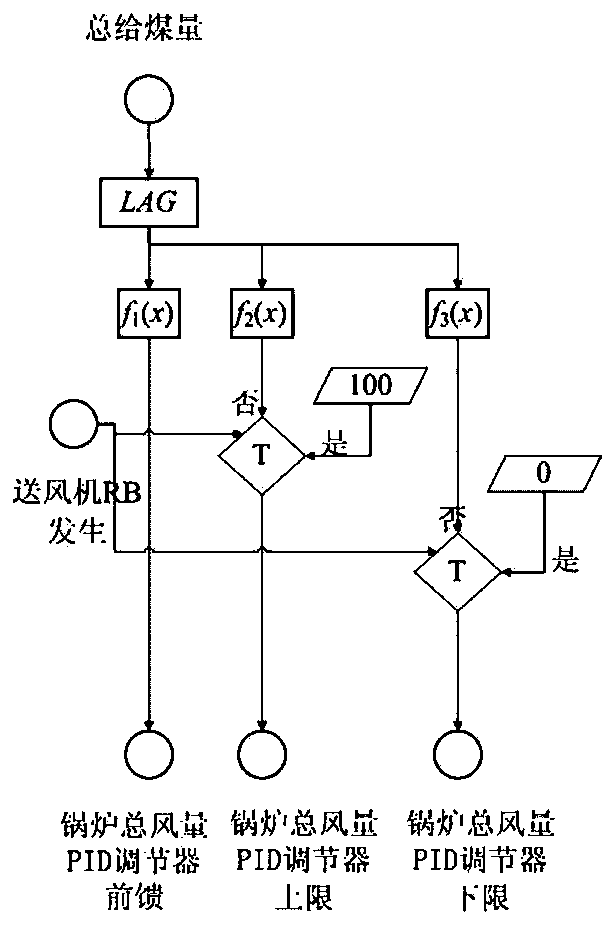

[0034] 3) Optimize the feed-forward control logic of the boiler total air volume PID regulator of the DCS system:

[0035] After the input total coal supply is passed through the first-order inertia link, it is then input to the boiler total air volume PID regulator feedforward broken line function f in the DCS system 1 In (x), the improved boiler total air volume PID regulator feed-forward control logic is obtained;

[0036] 4) Optimize the upper limit value A of the boi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com