Outlet temperature control optimizing method of medium-speed coal pulverizer of thermal power generating unit

A technology of outlet temperature and thermal power unit, which is applied in the direction of controlling combustion, lighting and heating equipment, etc., can solve the problem that the outlet temperature meets the requirements without conducting targeted research, and achieves a simple on-site debugging process, reduces labor intensity, and ensures stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

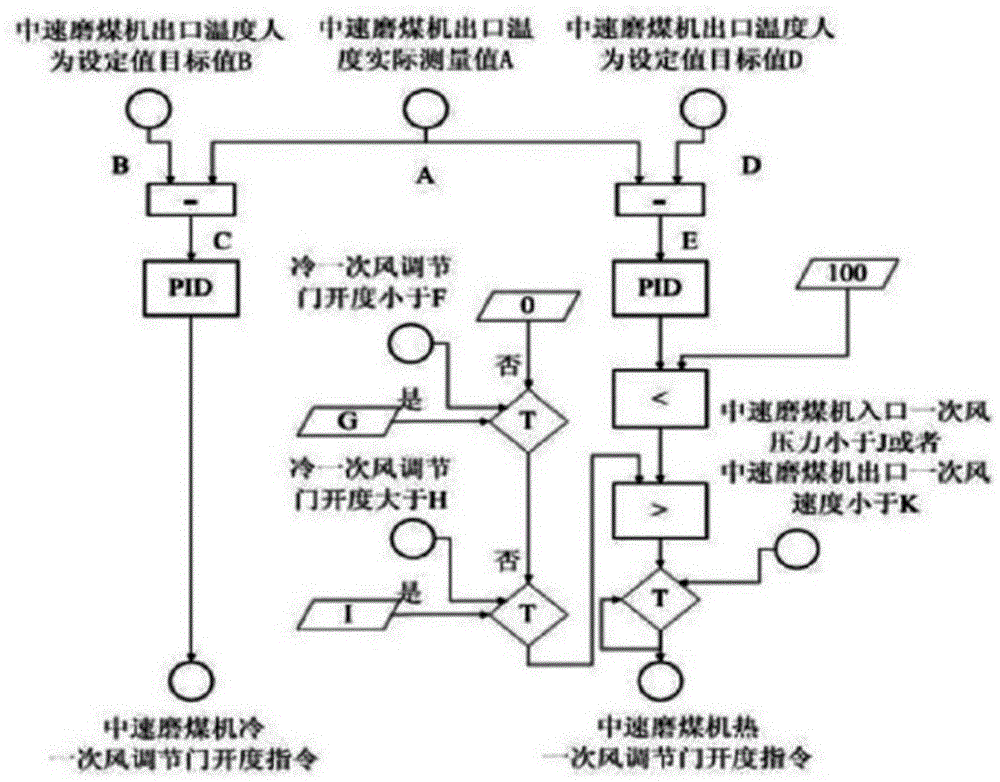

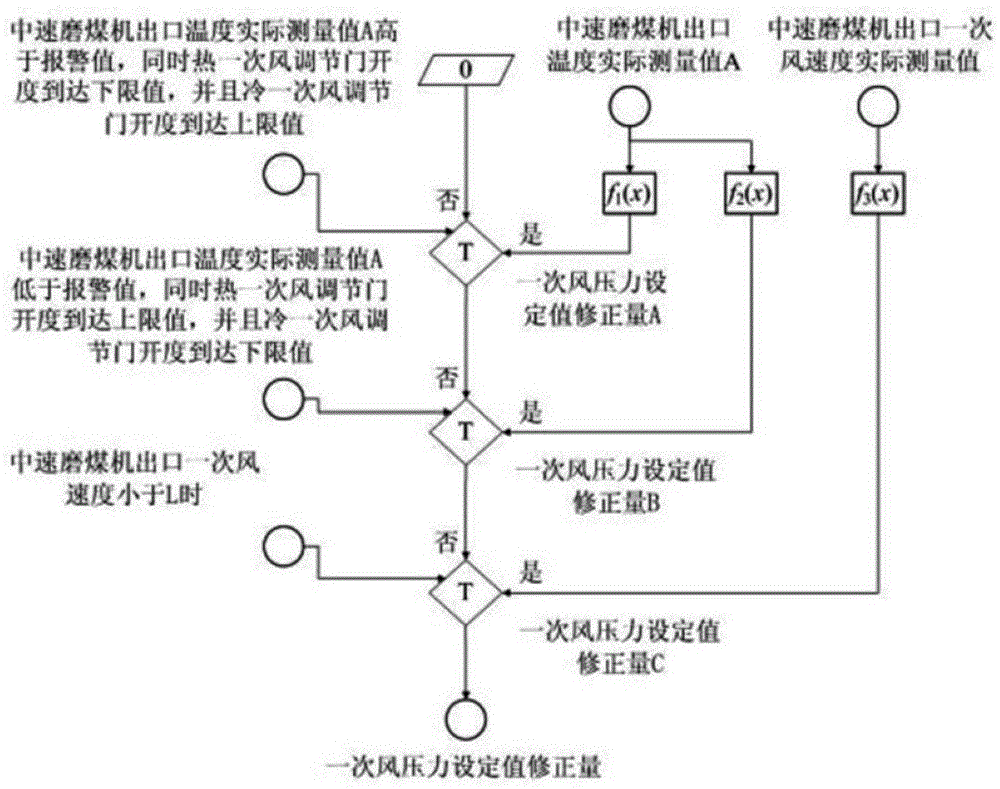

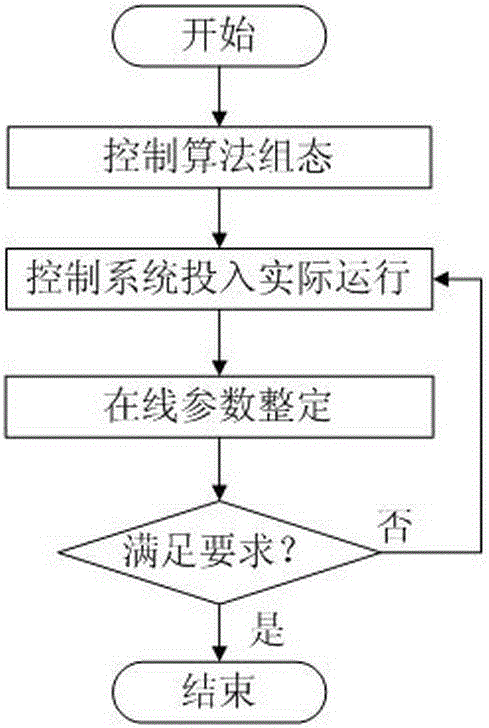

[0024]The invention is a method for optimizing the outlet temperature control of a medium-speed coal mill of a thermal power unit. The regulating door control logic and the primary air pressure setting value correction control logic control the cold primary air regulating door, the hot primary air regulating door, and the primary fan outlet pressure control actuator to coordinate actions to ensure that the outlet temperature of the medium-speed coal mill meets the requirements, such as image 3 As shown, it specifically includes the following steps:

[0025] Step 1: Add the following PID regulators in the control logic configuration of the DCS of the thermal power unit distributed control system: the PID regulator for the cold primary air adjustment door for the outlet temperature of the medium-speed coal mill, the heat primary air regulator for the outlet temperature of the medium-speed coal mill Wind adjustment door PID regulator.

[0026] Among them: DCS is the English abb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com