Mixed atomizer cooling protection system for entrained-flow reactor

A technology of mixed atomization and cooling protection, applied in the direction of granular/powder fuel gasification, inorganic chemistry, manufacture of combustible gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

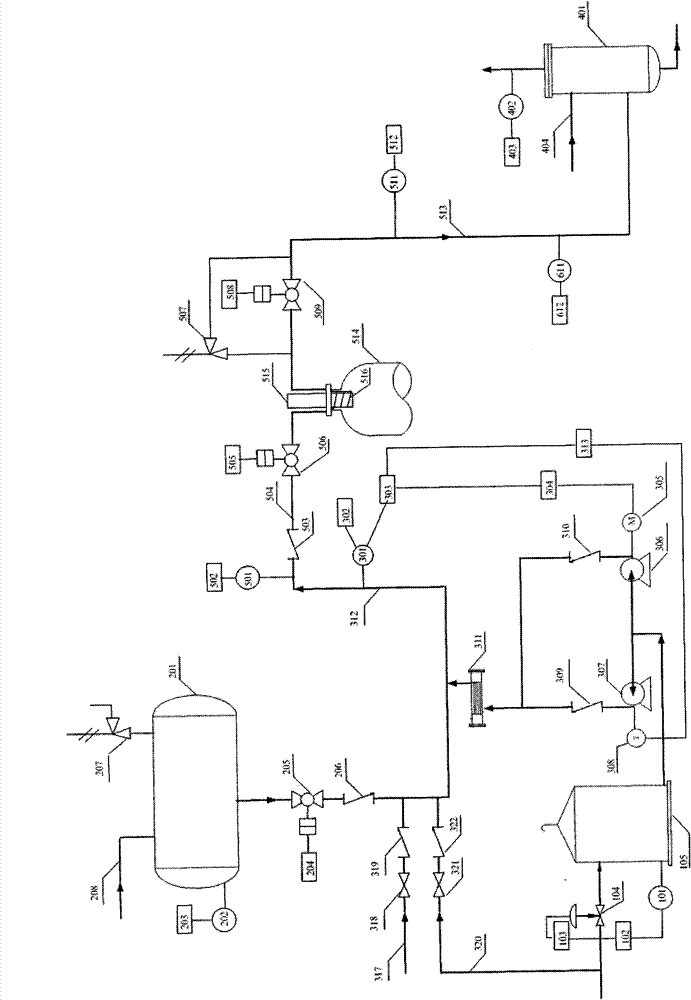

Embodiment 1

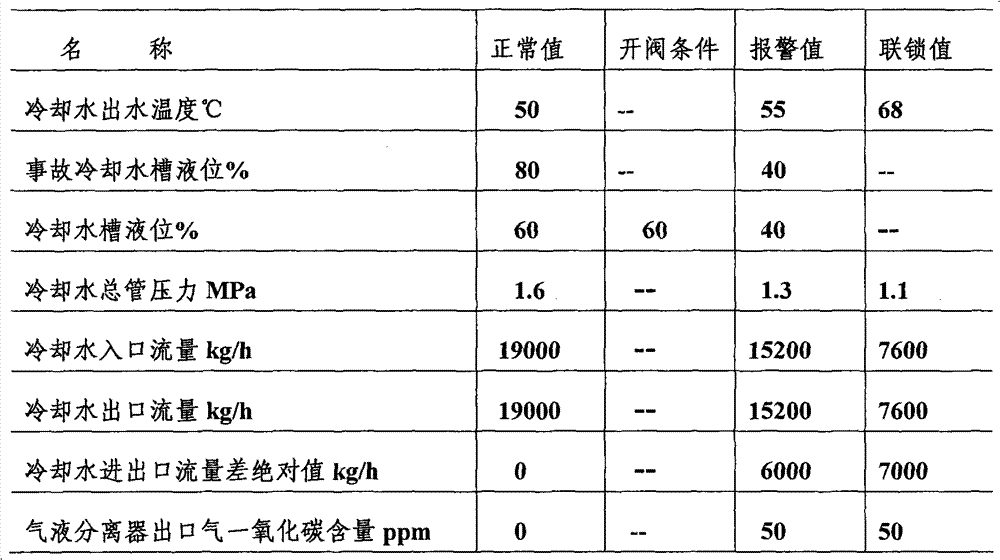

[0179] Using Henan Yima coal as raw material, the single-mixing atomizer coal-water slurry entrained bed reactor with a single reactor daily processing capacity of 1065 tons has a furnace shell diameter of 2.8 meters, and the operating pressure of the entrained bed reactor is 6.5 MPa , The operating temperature of the furnace is 1350°C. The cooling protection system of the mixed atomizer of the entrained bed reactor adopts figure 1 protection system shown. exist figure 1 In the middle, the pressure is normal pressure, and the cooling water in the cooling water tank 105 with a temperature of about 50°C is pressurized to 1.6MPa by the cooling water pump 306 or 307, and then enters the cooling water heat exchanger 311, where it is heated with circulating water. After heat exchange, it cools down to about 40°C and enters the cooling water coil 516 of the mixing atomizer. The cooling water with a pressure of 0.2 MPa and a temperature of about 50° C. coming out of the cooling wat...

Embodiment 2

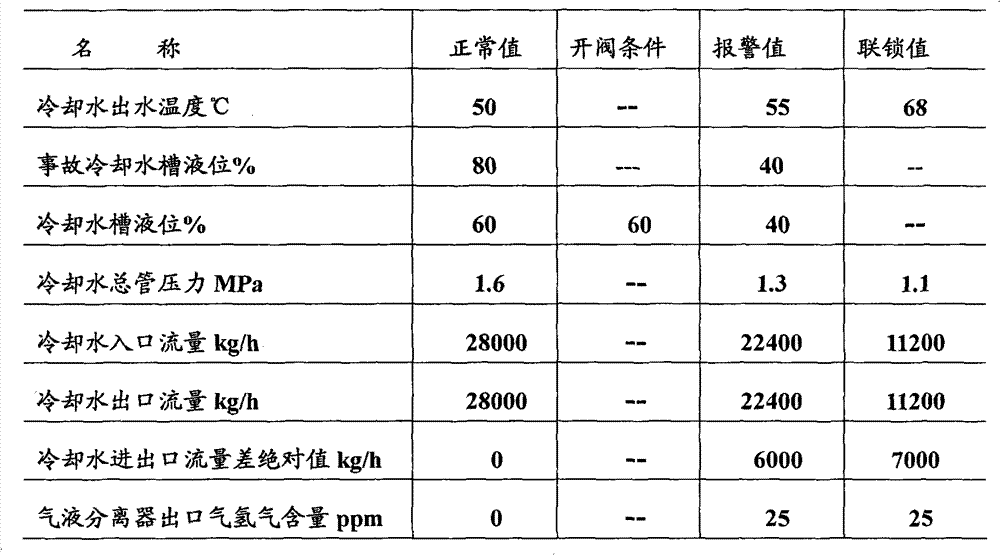

[0210] In a domestic production plant with an annual output of 300,000 tons of synthetic ammonia and 200,000 tons of methanol, the diameter of the furnace shell of a single mixing atomizer coal-water slurry entrained bed reactor with a daily processing capacity of 78,701 tons of coal is 3.2 m, the operating pressure of the entrained bed reactor is 6.5MPa, the operating temperature of the furnace is 1320°C, and the cooling protection system of the entrained bed reactor mixing atomizer adopts figure 1 protection system shown.

[0211] In this embodiment, the cooling protection system of the mixed atomizer of the entrained bed reactor adopts the cooling protection system of the mixed atomizer of the present invention, and the hydrogen content in the outlet gas of the cooling water gas-liquid separator is measured by a hydrogen analyzer. When the hydrogen content in the outlet gas of the cooling water gas-liquid separator 401 exceeds 25ppm, the hydrogen indicating alarm device sen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com