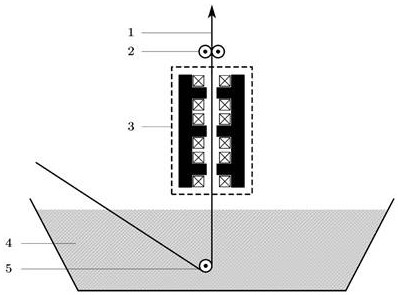

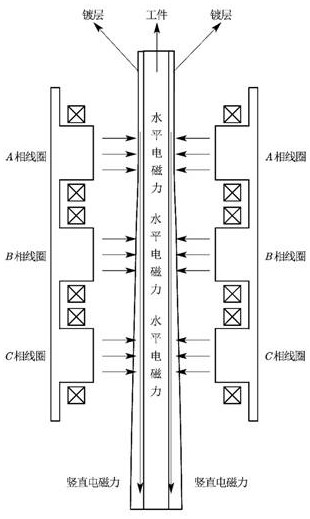

A three-phase electromagnetic wiping device and hot-dip coating system for strip-shaped workpieces

An electromagnetic and ribbon technology, applied in hot dip plating process, metal material coating process, coating and other directions, can solve the problems of large magnetic field gradient change, high tangential electromagnetic force, low axial electromagnetic force, etc. The effect of high directional electromagnetic force, enhanced tangential electromagnetic force, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

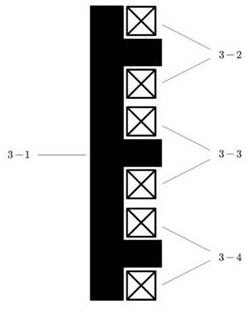

[0030] The invention provides a three-phase electromagnetic wiping device for a strip-shaped workpiece, which can generate electromagnetic wiping force based on a traveling wave magnetic field, and the electromagnetic force is evenly distributed along the sideline of the normal section of the strip-shaped workpiece, thereby achieving the effect of uniform wiping .

[0031]For rod-shaped workpieces such as round rods and hexagonal rods, and wire-shaped workpieces such as steel wires, their relative cross-sectional dimensions are small. When performing electromagnetic wiping and designing electromagn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com