Bracket-free construction method for double-limb thin-wall high-pier tie beam

A construction method and beam-tying technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as large support height-to-width ratio, large number of support materials, and long construction period, and achieve the effect of improving safety and security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

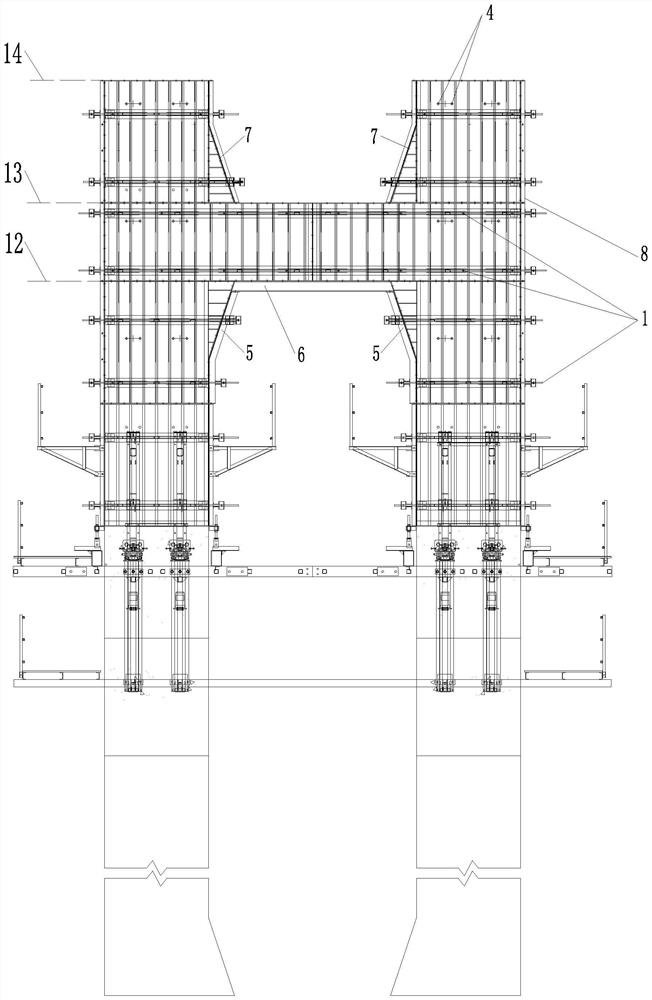

[0045] The present invention will be further described below in conjunction with accompanying drawing:

[0046] A construction method without support for the tie-beam of the thin-walled high pier with two limbs, comprising the following steps:

[0047] S1. The elevation of the top of the climbing formwork after climbing is located at the bottom elevation of the tie beam minus the height of the lower chamfer of the tie beam, and the pier body concrete of this section is poured;

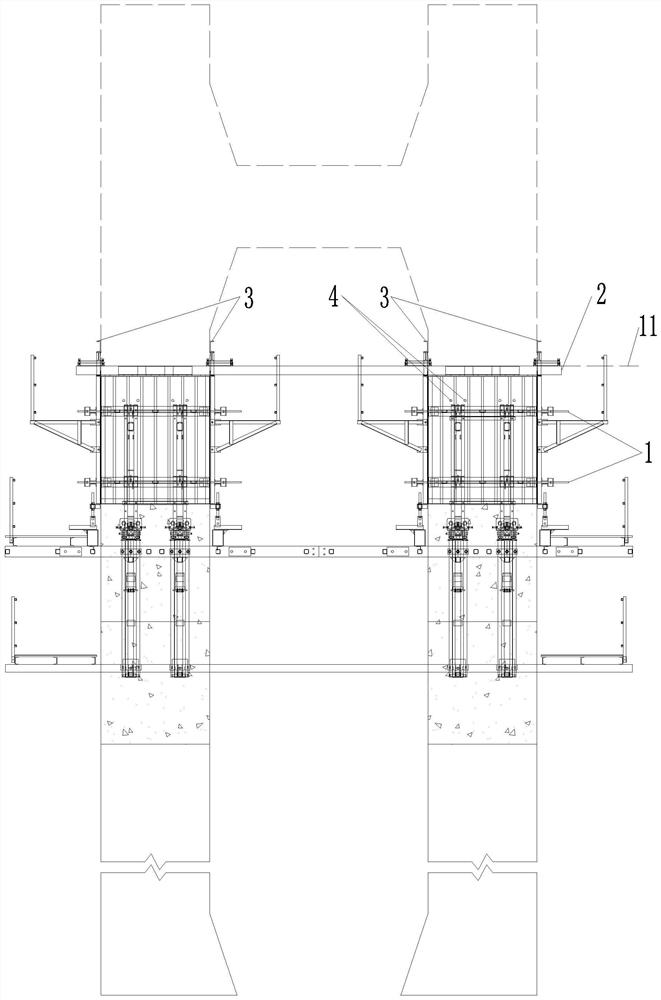

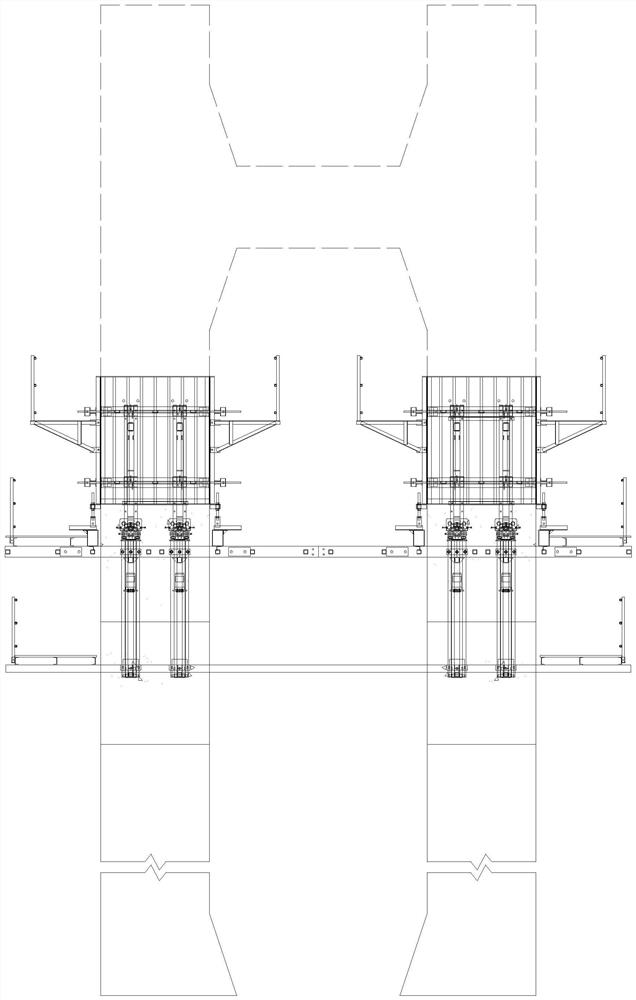

[0048] S2. When the concrete reaches a certain strength, remove the suspension beam on the top of the climbing formwork (the suspension beam includes such as figure 1 The first suspension beam 2 shown and the second suspension beam 3) respectively install the formwork of the lower chamfering section of the tie beam, the formwork of the middle section of the tie beam, and the formwork of the upper chamfering section of the tie beam, and pour the lower chamfering section of the tie beam and the middle se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com