Rubber concrete hollow pier with internal and external constraint

A rubberized concrete and concrete technology, applied in bridges, bridge parts, bridge materials, etc., can solve the problems of unconstrained concrete, prone to earthquake damage, etc., to avoid sudden changes in section stiffness, good stability, and improved bearing capacity and ductility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

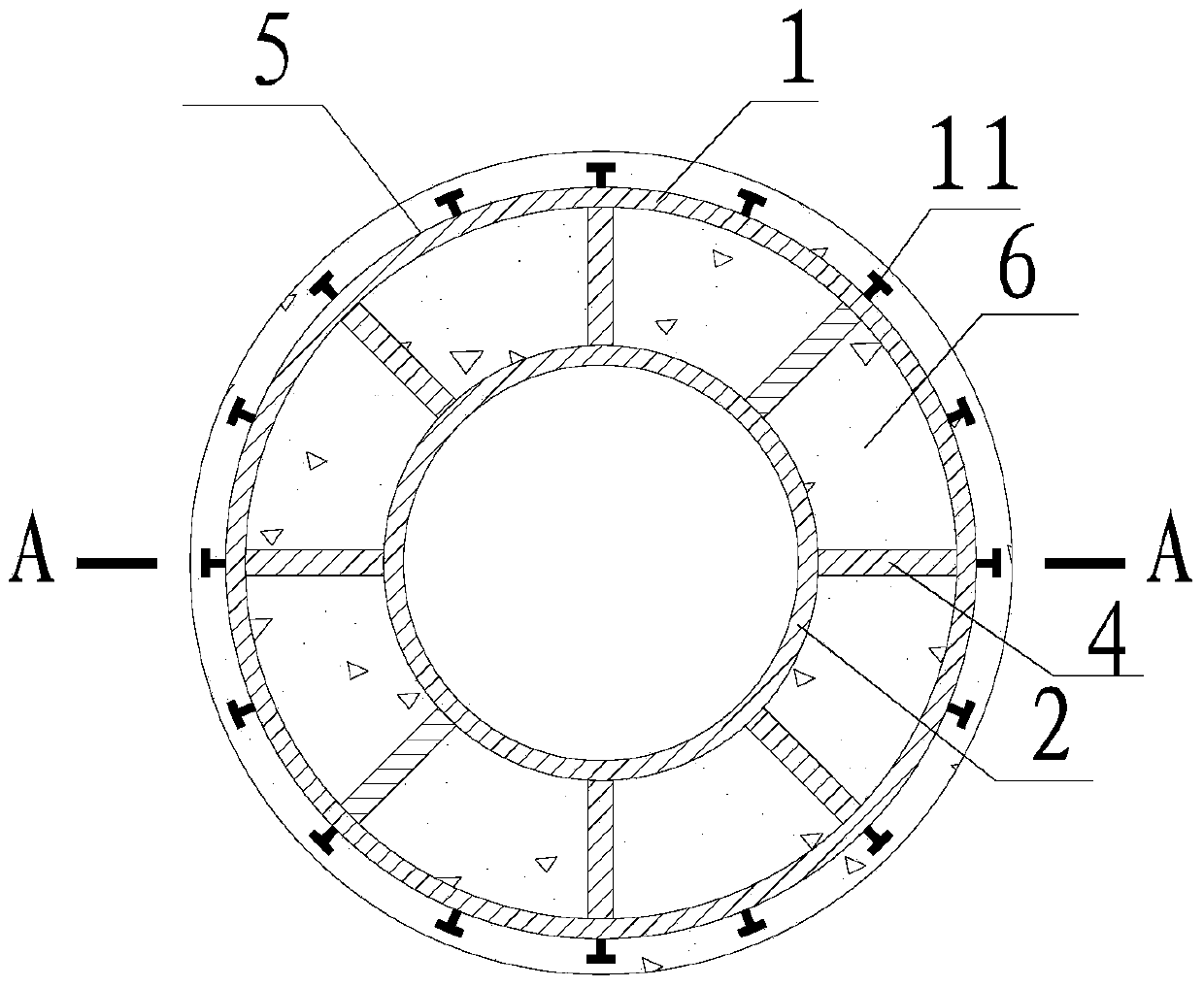

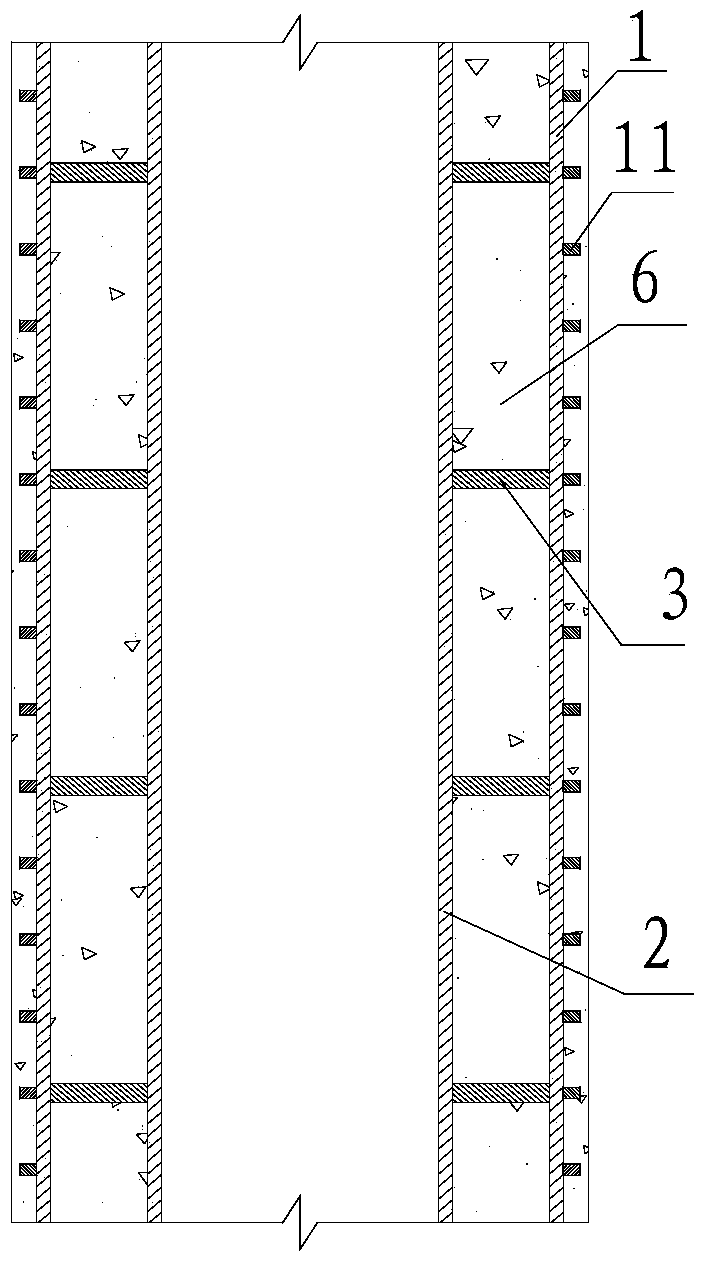

[0031] Embodiment 1 The rubber concrete hollow pier with internal and external constraints described in the present invention includes an outer tube 1, an inner tube 2, a stiffening plate 3, a vertical partition 4, and a concrete protective layer 5. The outer surface of the outer tube 1 is distributed The shear nail 11 used to increase the adhesion between the concrete protective layer 5, the concrete protective layer 5 is coated on the outer wall of the outer tube 1; the inner tube 2 is coaxially arranged on the The inside of the outer tube 1; between the outer tube 1 and the inner tube 2, a plurality of stiffening plates 3 with central holes are arranged along the axial direction, and the inner edge of the stiffening plate 3 is fixed to the outer wall of the inner tube 2, and the outer The edge is connected with the inner wall of the outer tube 1 to form a cavity for accommodating the rubber concrete 6; multiple vertical partitions 4 are arranged in the cavity, and the two si...

Embodiment 2

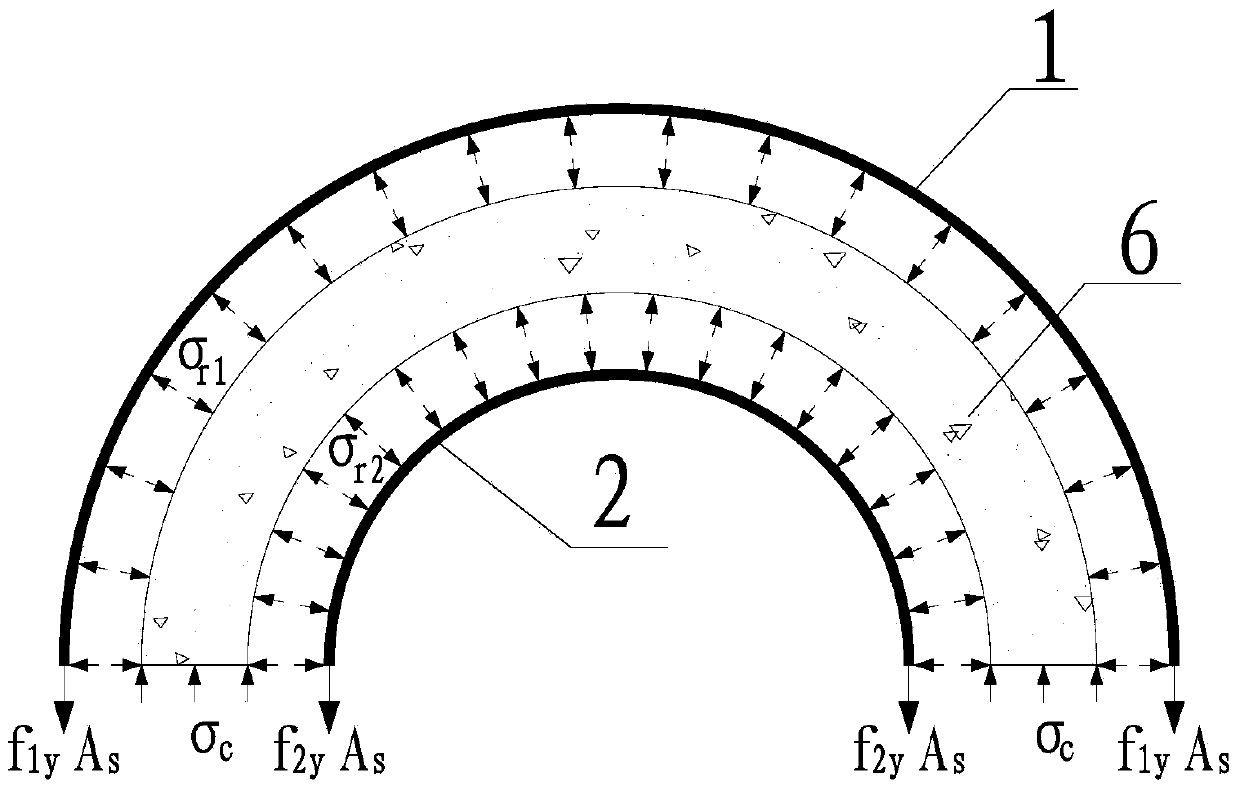

[0042] Example 2 as figure 2 As shown, the outer side of the concrete in the middle of the rubber concrete shock-absorbing hollow pier is subject to the constraint force σ from the outside to the inside of the outer tube 1 r1 , the inside is subject to the constraint force σ of the inner tube 2 from the inside to the outside r2, in the state of three-way stress, the mechanical properties of the side wall rubber concrete have undergone essential changes, and the strength and ductility have been greatly improved. The outer tube 1 and inner tube 2 are strengthened by the vertical partition 4, which is the side wall of the hollow pier Provide strong and effective internal and external support, and at the same time use the energy absorption effect of rubber concrete, which can effectively reduce the damage of the pier under the earthquake load.

Embodiment 3

[0043] Embodiment 3 The installation steps of the pier described in Embodiment 1 are as follows: first process the inner pipe 2 and the outer pipe 1, and then install the stiffening plate 3 and the vertical partition 4, and the two ends of the vertical partition 4 are closely attached to the inner wall of the outer pipe 1 and the outer wall of the inner pipe 2, the thickness of the steel plate of the vertical partition 4 is the same as that of the inner and outer steel pipes, and its width should not be less than 50mm. The minimum size of the cross-section shape is the diameter of a circular cross-section or the short side of a rectangular cross-section or the minor axis length of an elliptical cross-section or the diameter of the round end of a round-end cross-section or the diameter of the inscribed circle of a hexagonal cross-section. After the pipe 1, the stiffener 3 and the vertical partition 4 are welded and connected, they are hoisted to the construction site for install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com