Machine vision defect detection method and system

A machine vision, defect detection technology, applied in the field of defect detection, can solve problems such as difficulty in obtaining detection results, accurate detection of parts, and changes in the shape of dimensional defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

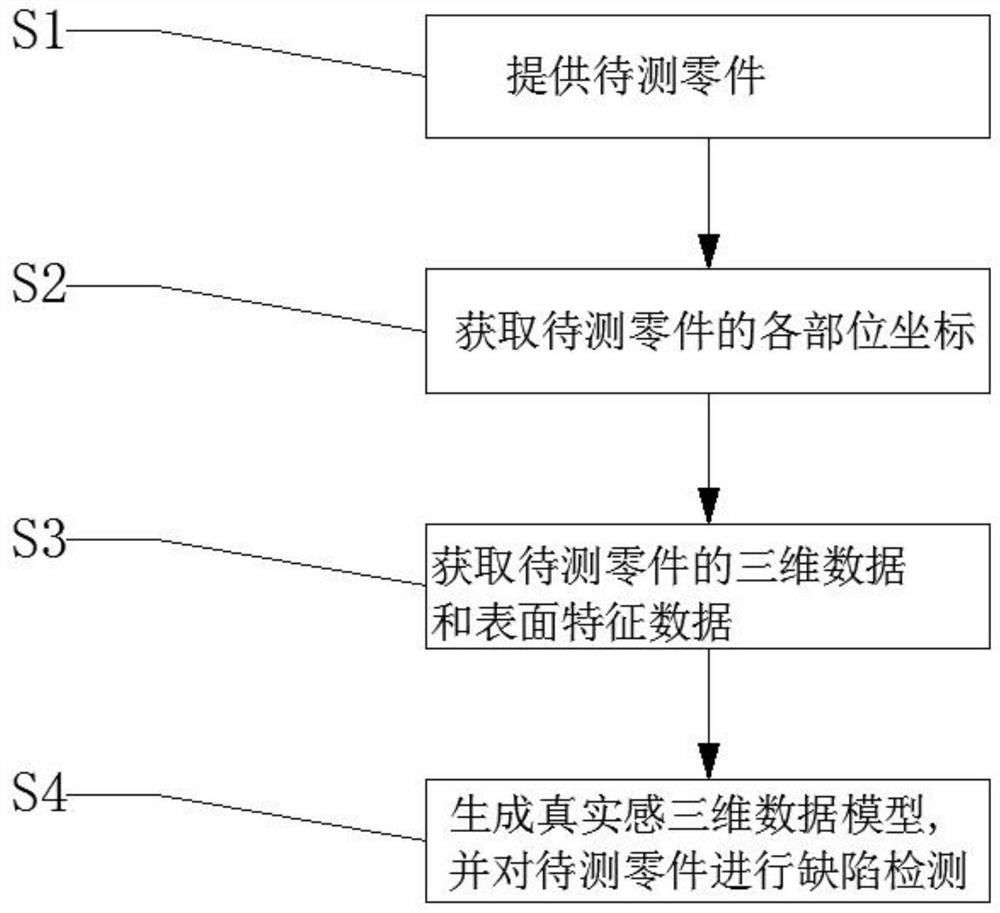

[0027] see figure 1 , the present invention provides a kind of machine vision defect detection method, comprises the following steps,

[0028] Step S1: providing the parts to be tested;

[0029] Step S2: Obtain the coordinates of each part of the part to be measured;

[0030] Step S3: Obtain the three-dimensional data and surface feature data of the part according to the coordinates of each part of the part to be measured;

[0031] Step S4: Generate a realistic three-dimensional data model based on the three-dimensional data and surface feature data of the part to be tested, and perform high-dimensional data expression and defect detection on the part to be tested.

[0032] In this embodiment, by obtaining the coordinates of each part of the part, analyzing the coordinates of each part of the part, and obtaining the three-dimensional data and surface feature data of the part according to the coordinates of each part of the part, by analyzing the three-dimensional data and su...

Embodiment 2

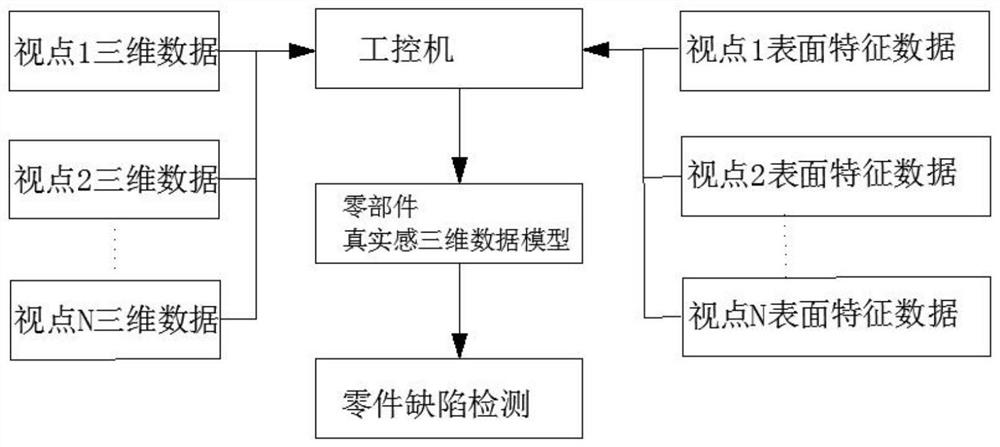

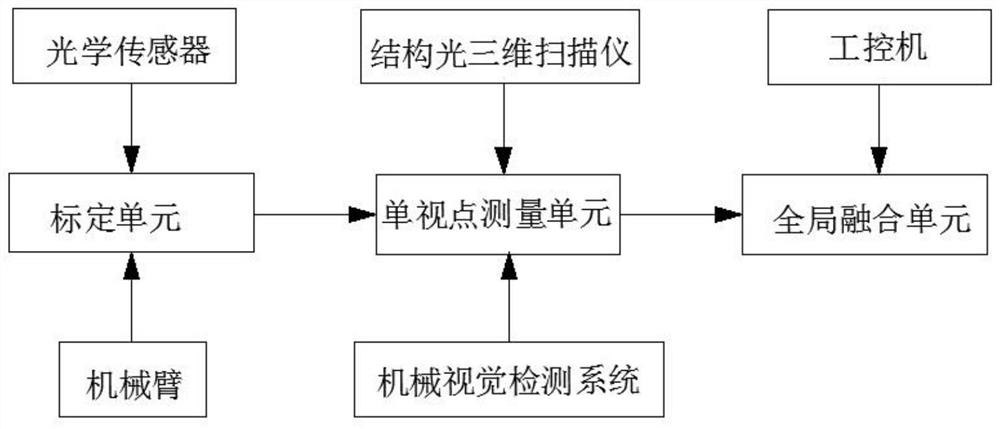

[0034] see Figure 2-3 , the present invention provides a machine vision defect detection system, including a calibration unit, a single-view measurement unit and a global data fusion unit,

[0035] The calibration unit is used to obtain the coordinates of each part of the part to be tested;

[0036] The single-view point measurement unit is used to analyze the coordinates of each part of the part and generate three-dimensional data and surface feature data;

[0037] The global data fusion unit generates a realistic three-dimensional data model through a data fusion formula according to the three-dimensional data and surface feature data of the part, and detects defects on the part.

[0038] In this embodiment, the coordinates of each part of the part to be measured are obtained by setting the calibration unit, and the coordinate data of each part of the part to be measured is transmitted to the single-viewpoint measurement unit, and the single-viewpoint measurement unit perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com