A Stress Uniform Optical Fiber Microbending Additional Loss Testing Device, System and Method

A technology of additional loss and testing equipment, which is applied in the direction of measuring equipment, optical instrument testing, and testing optical performance, etc., and can solve problems such as difficulty in accurate realization, poor operability, and greater influence on the control accuracy of rewinding equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

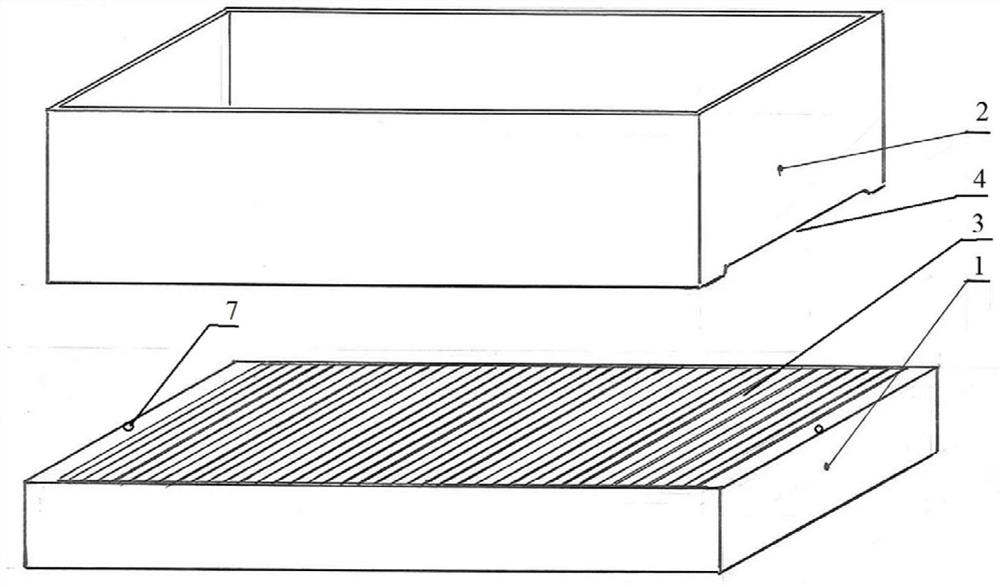

[0043] like figure 1 As shown, a stress-distributed optical fiber microbending additional loss testing device provided in this embodiment includes:

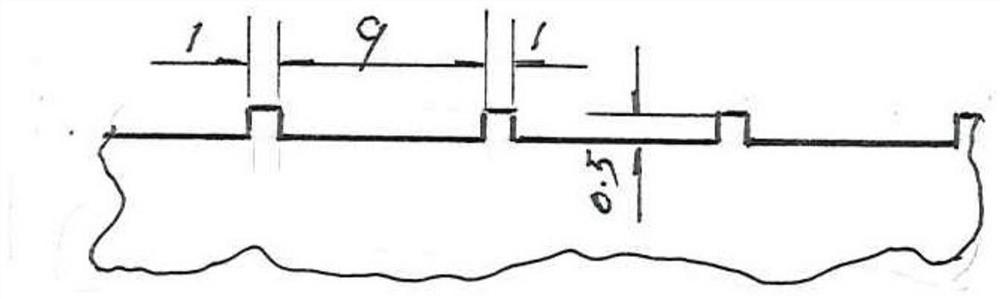

[0044] A grooved bottom plate and a water bag limiting frame 2, the upper surface of the grooved bottom plate is provided with a tooth groove 3 along the width direction;

[0045] When using the test device to test the tested optical fiber 6, the tested optical fiber 6 is placed on the bottom plate with a groove and the water bag limiting frame 2 is placed above the edge of the grooved bottom plate, and then placed on the water bag limiting frame 2. Entering the water bag 5, the measured optical fiber 6 is deformed along the shape of the alveolar 3 under the gravity of the water bag 5, thereby generating a slight bend.

[0046]In the testing device of the present embodiment, in order to make the tested optical fiber 6 produce the pressure of slight bending to be produced by the water bag 5 on the bottom plate with the groove, th...

Embodiment 2

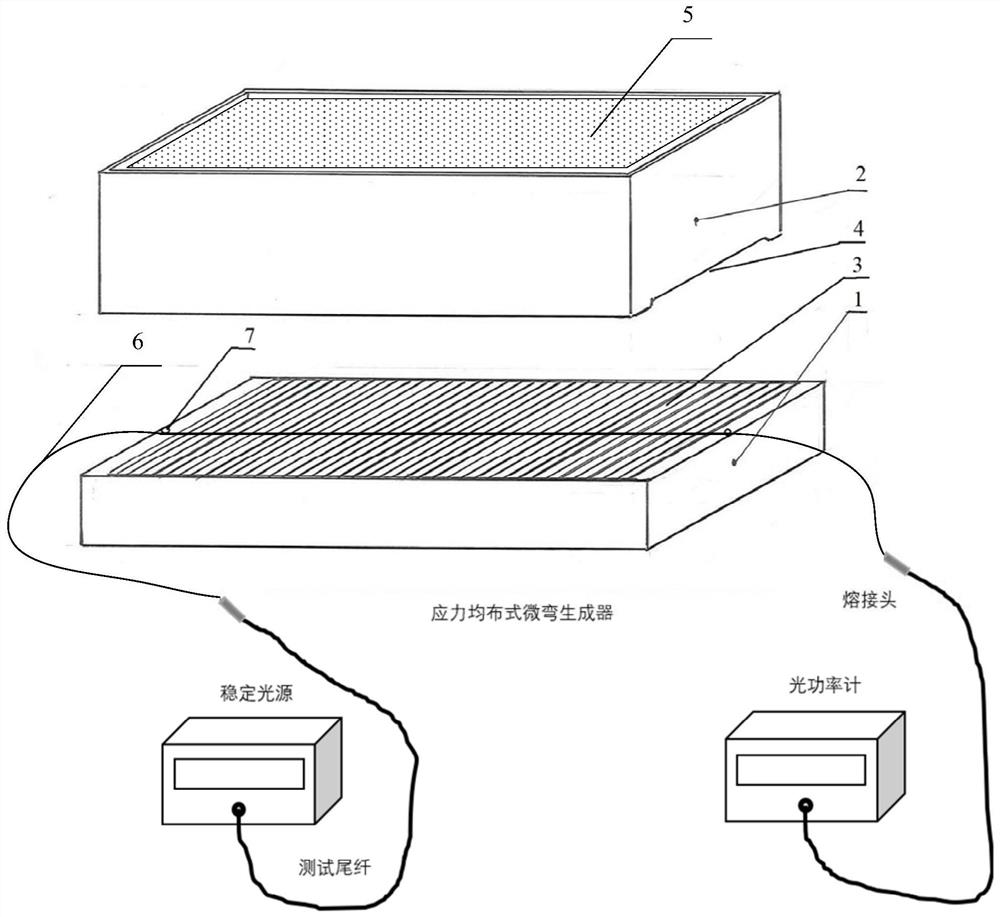

[0052] like image 3 As shown, this embodiment provides a stress-distributed optical fiber micro-bending additional loss testing system, including a stable light source, an optical power meter, and the stress-distributed optical fiber micro-bending additional loss testing device described in the embodiment.

[0053] The stress-distributed optical fiber micro-bending additional loss test method realized based on the test system can be divided into two types: one is to fill the water bag 5 with an appropriate amount of water, and then pack the water bag limit frame 2; the other The first is to arrange the water bag 5 in the water bag limiting frame 2, and then fill in an appropriate amount of water. They are as follows:

[0054] like Figure 4 As shown, the first stress-distributed optical fiber microbending additional loss testing method includes the following steps:

[0055] S11, placing the tested optical fiber 6 flatly on the grooved base plate, keeping the tested optical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com