A kind of inflation and deflation device and method

A technology of inflating, deflating and air intake valves, applied in measuring devices, gas/liquid distribution and storage, instruments, etc., can solve problems such as high pressure of filling gas, deformation of containers, shortening of storage for placing products, etc., to achieve accurate gas concentration Control, simple structure, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

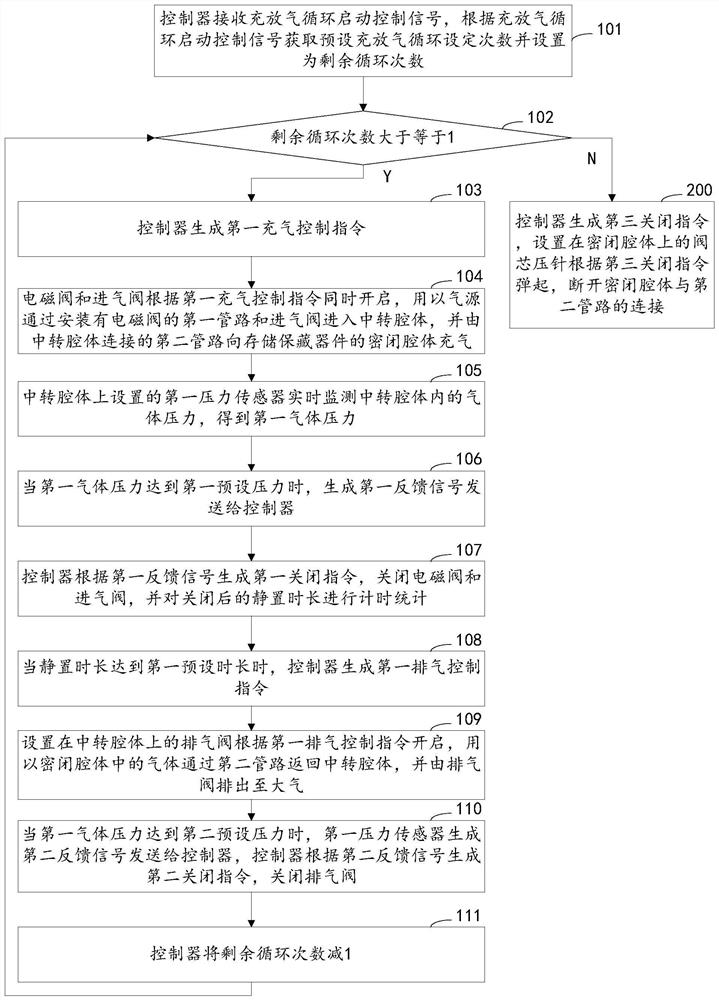

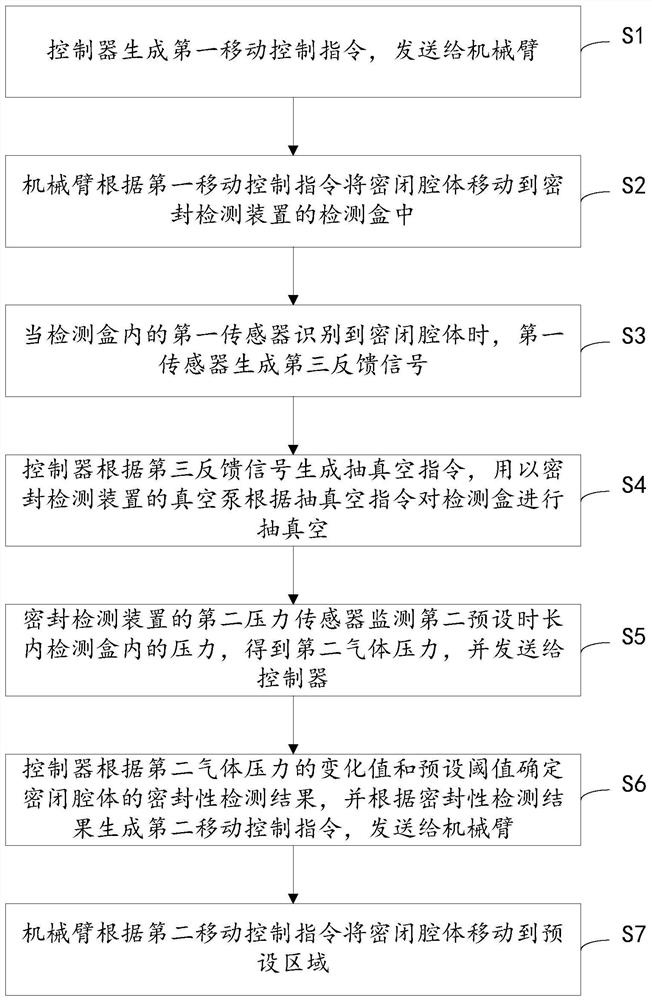

[0040] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0041] The gas filling and deflation device and method provided by the present invention have a simple structure and are easy to operate. Gas replacement is performed through a single hole in a closed cavity to realize precise control of the gas concentration in the closed cavity.

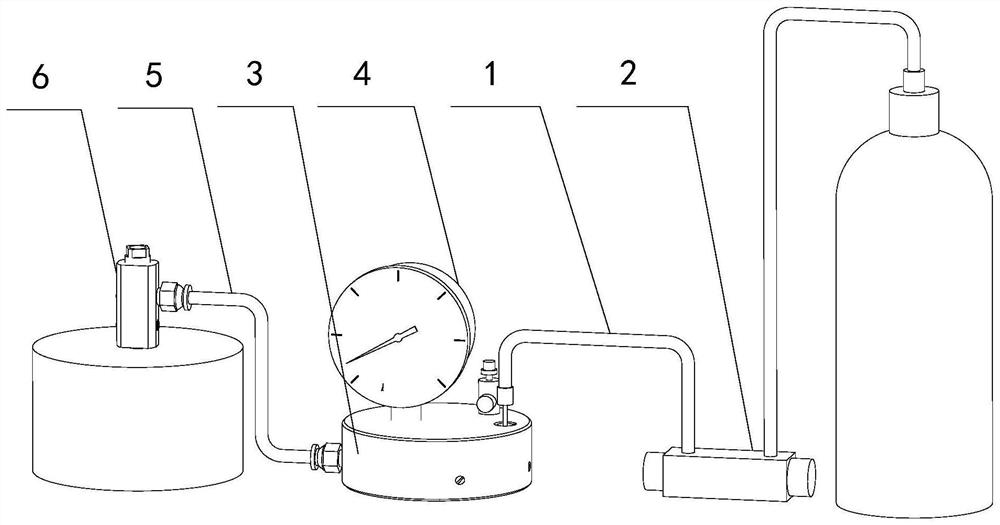

[0042] figure 1 The schematic structural diagram of the inflation and deflation device provided by the embodiment of the present invention, such as figure 1 As shown, the inflation and deflation device provided by the present invention includes: a first pipeline 1, a solenoid valve 2, a transfer cavity 3, a first pressure sensor 4, a second pipeline 5, a valve core needle 6, and an intake valve 7 (not shown in the figure), exhaust valve 8 (not shown in the figure) and controller 9 (not shown in the figure).

[0043] The first pipeline 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com