CCD visual positioning feeder for 3C stamped sheets

A technology of visual positioning and feeder, which is applied in the direction of object supply, thin material handling, pile separation, etc., and can solve problems such as potential safety hazards, a large amount of manpower, and difficulty in determining the position after unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

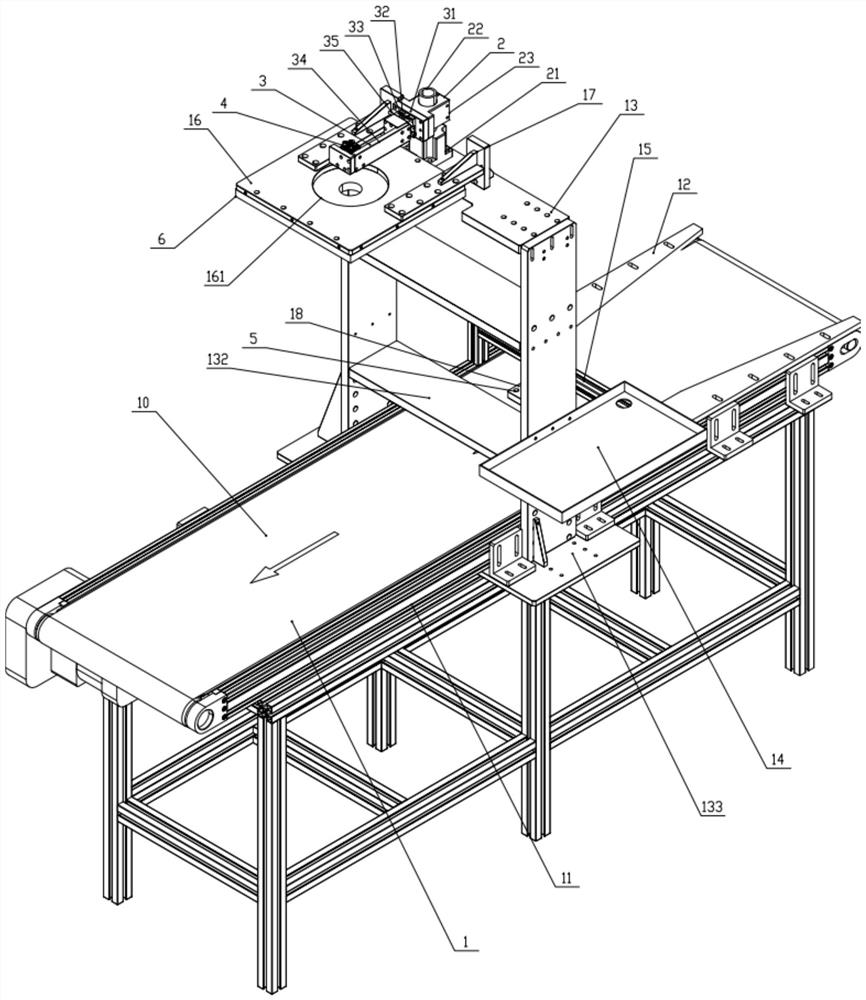

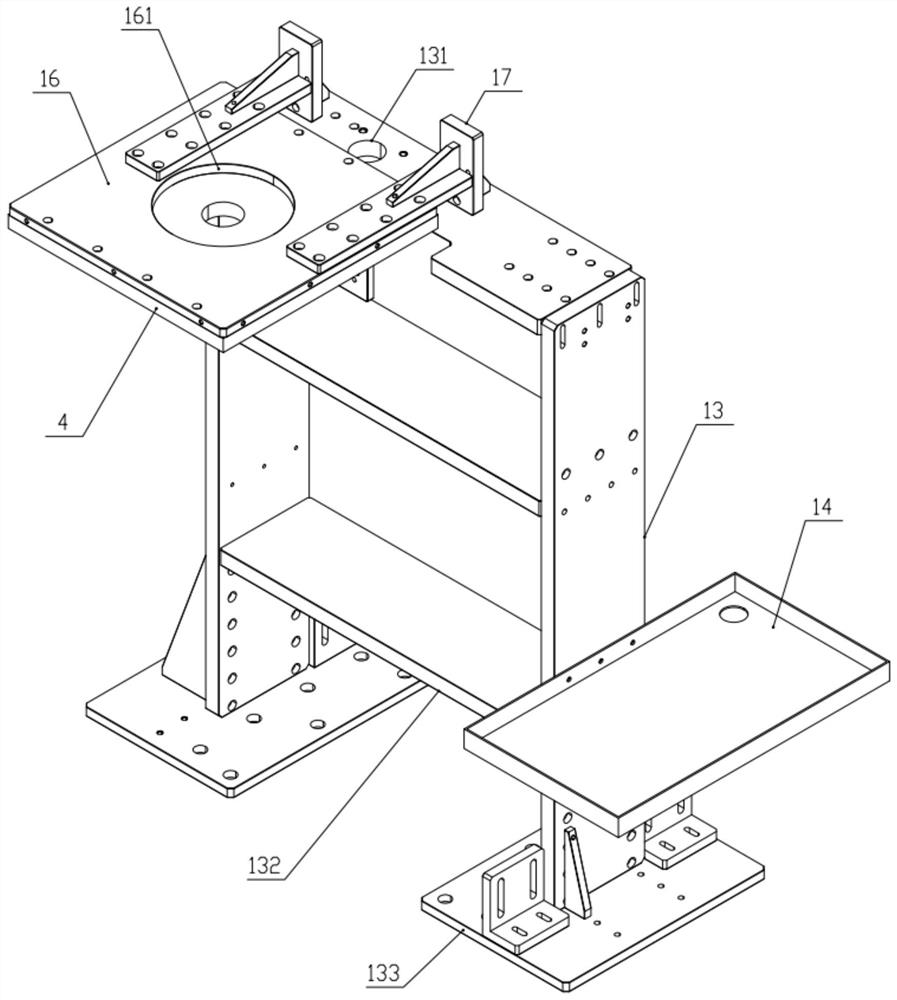

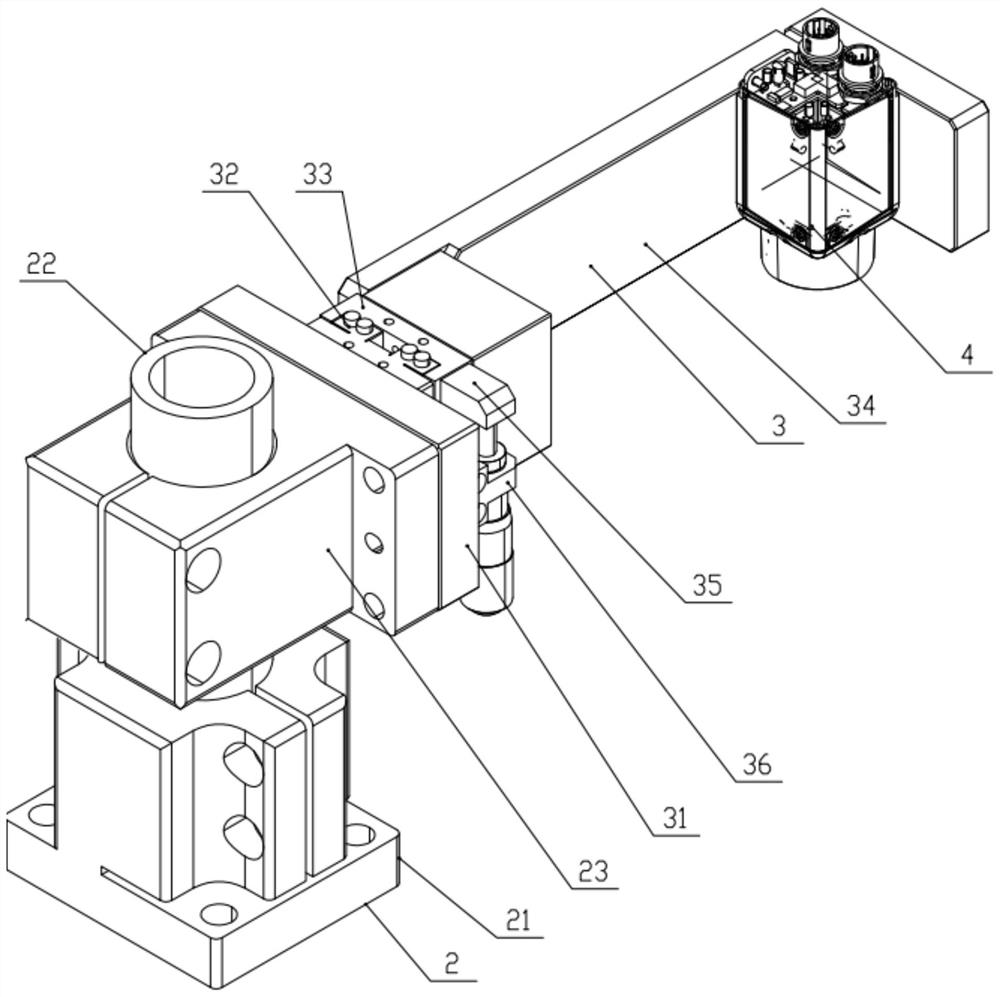

[0031] Figure 1 to Figure 4 Schematically shows a CCD visual positioning feeder for 3C stamping sheets according to an embodiment of the present invention. As shown in the figure, the device includes a belt conveyor 1, a circumferential adjustment part 2, a vertical adjustment part 3 and a CCD visual camera 4;

[0032] The frame 11 of the belt conveyor 1 is provided with a wide belt 10 capable of circular motion, and the feed guide plate 12 is symmetrically fixed on both sides of the right end of the frame 11; the main door frame 13 is installed in the middle of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com