Concrete automatic steam curing system

A technology of steam curing and concrete, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of lack of cohesion, insufficient hydration of cement particles, and inability to transform crystallization, etc., to achieve the effect of improving the quality of molding and curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

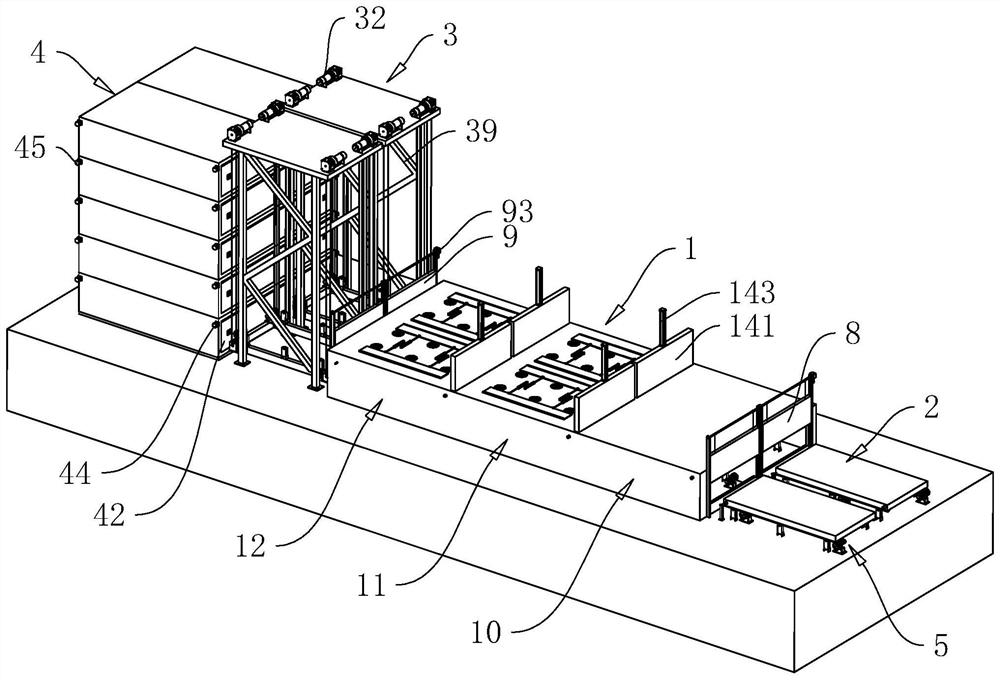

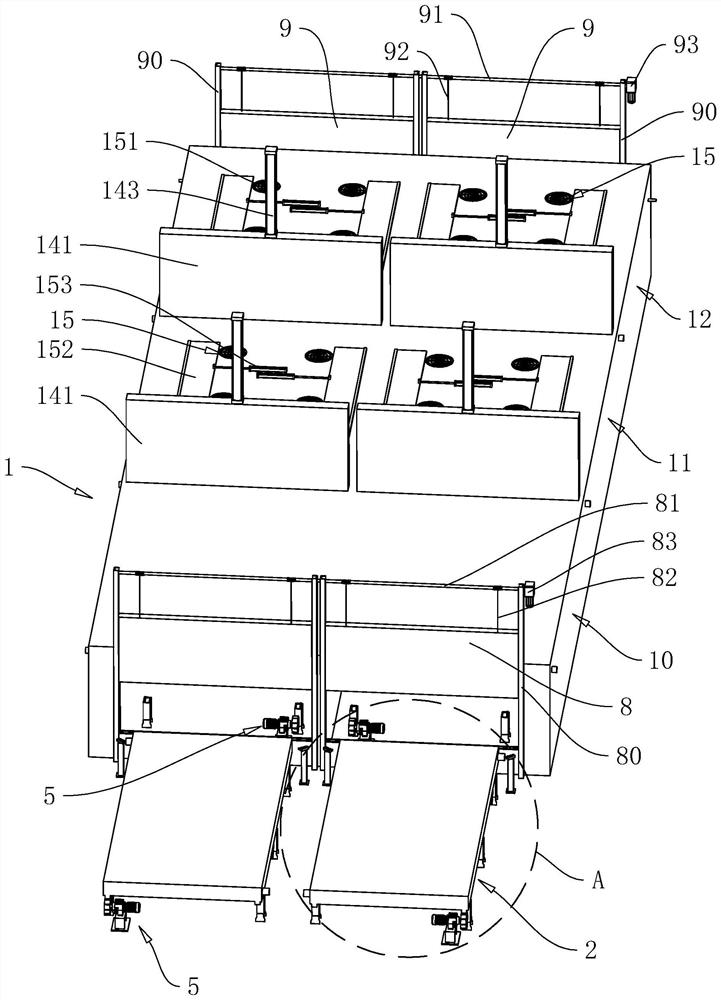

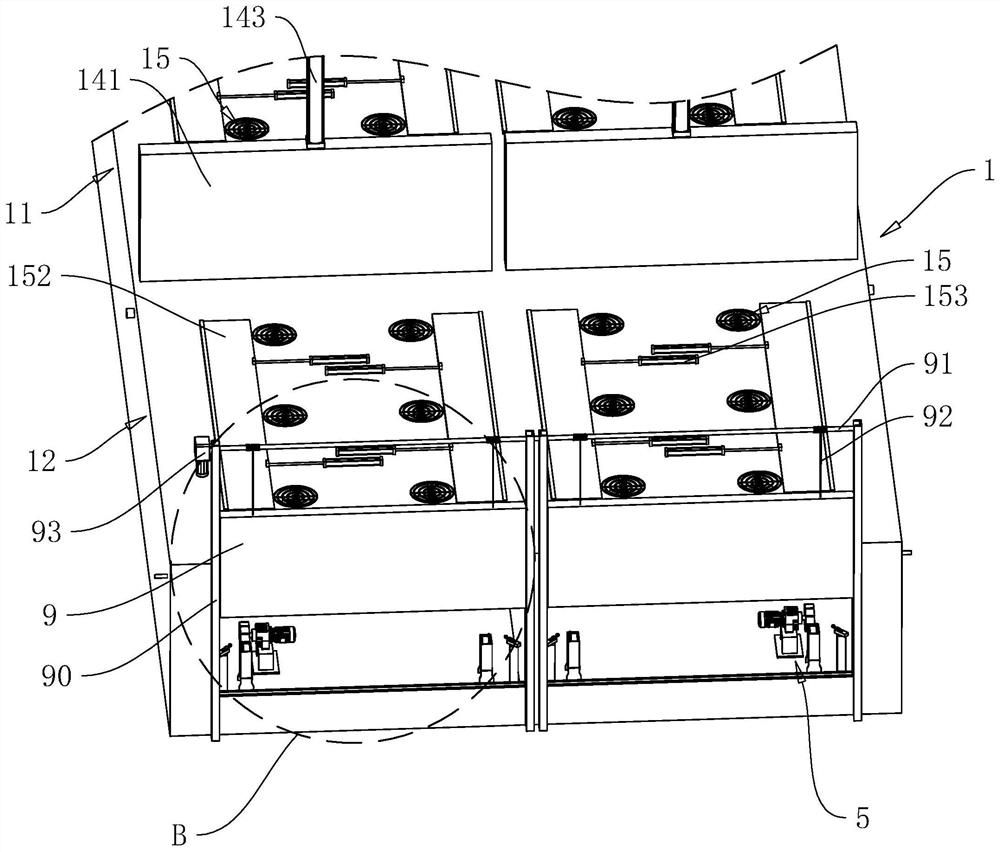

[0052] The following is attached Figure 1-12 The application is described in further detail.

[0053] The embodiment of the present application discloses a fully automatic steam curing system for concrete. refer to figure 1 , a fully automatic concrete steam curing system, which sequentially includes a steam curing channel 1, a lifting conveying device 3 connected to the outlet end of the steam curing channel 1, and a steam curing room 4 arranged on the side of the lifting conveying device 3 away from the steam curing channel 1, and the steam curing channel 1 The number of settings can be adjusted arbitrarily. In the embodiment of the present application, two steam curing passages 1 arranged side by side are taken as an example. At this time, the corresponding number of lifting conveying devices 3 and steam curing chambers 4 are set to two correspondingly. Moving along the steam curing channel 1, the lifting conveying device 3 and the steam curing room 4 in sequence, the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com