Lead-contaminated soil stabilizing agent and lead-contaminated soil stabilizing remediation method

A technology of lead-contaminated soil and remediation method, which is applied in the field of contaminated soil treatment and remediation, and can solve the problems of high remediation cost and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0039] As an embodiment of the present invention, the particle size of the waste red brick powder may be 2-110 μm, and the specific surface area of the waste red brick powder may be 350-400 m 2 / kg.

[0040] The smaller the particle size of waste red brick powder, the larger its specific surface area, and the better the adsorption and ion exchange effect of lead in lead-contaminated soil.

[0041] As an embodiment of the present invention, in the waste red brick powder, Fe 2 o 3 The mass fraction of Al can be 3-7%, Al 2 o 3 The mass fraction of SiO can be 10-16%. 2 The mass fraction can be 50-60%. Iron oxides, aluminum oxides and silicates in waste red brick powder are beneficial to improve the ability of stabilizing agents to adsorb and exchange lead, so that Pb in the soil exists in a state of low solubility and low mobility.

[0042] As an embodiment of the present invention, in the ferric chloride, the mass fraction of impurities is <5%.

[0043] As an embodiment ...

Embodiment 1

[0057] Embodiment 1 provides a lead-contaminated soil stabilization agent and a lead-contaminated soil stabilization repair method using waste red brick powder as a raw material. The contaminated soil is taken from a certain iron and steel metallurgical industry site, and the lead ion concentration in the treated leachate is 0.347 mg / L.

[0058] Stabilizer preparation:

[0059] Take 10.0g of red brick powder, 0.5g of ferric chloride, and 1.5g of calcium dihydrogen phosphate, spread red brick powder and calcium dihydrogen phosphate evenly on the surface of 300g of contaminated soil to be treated, stir and mix thoroughly, and obtain the first mixed pollute the soil.

[0060] Dissolving ferric chloride in an appropriate amount of water, fully mixing and stirring with the first mixed polluted soil, wherein the mass of the water is 18% of the mass of the polluted soil to be treated. Cover with plastic wrap and preserve for 7 days. Afterwards, samples were taken for leaching, and...

Embodiment 2

[0063] The contaminated soil was taken from a coking site. After leaching, the leachate was collected. The lead ion concentration in the leachate was 0.068mg / L.

[0064] Stabilizer preparation:

[0065] Take 2.73g of red brick powder, 0.13g of ferric chloride, and 0.14g of calcium dihydrogen phosphate, spread red brick powder and calcium dihydrogen phosphate evenly on the surface of 300g of contaminated soil to be treated, stir and mix thoroughly, and obtain the first mixed To pollute the soil, dissolve ferric chloride in an appropriate amount of water, fully mix and stir with the first mixed polluted soil, wherein the mass of the water is 15% of the mass of the polluted soil to be treated. Cover with plastic wrap and preserve for 5 days. Afterwards, samples were taken for leaching, and the leachate was collected to detect the concentration of Pb.

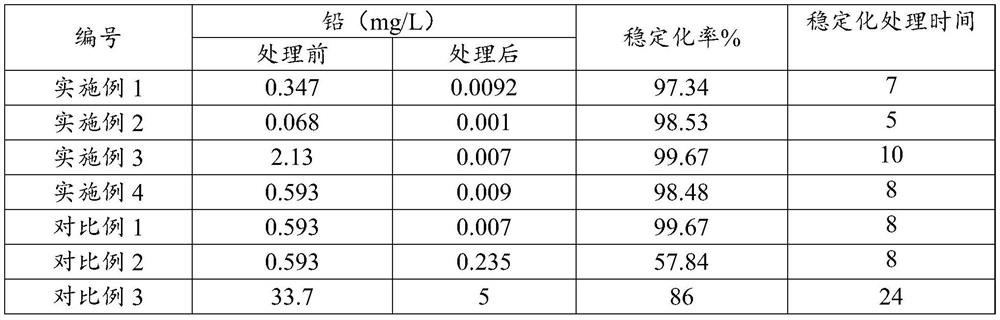

[0066] The leaching toxicity test results of lead in the soil before and after treatment are shown in Table 1, and the treated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com