Light emitting diode lamp

A technology of light-emitting diodes and lamps, which is applied to illuminated signs, instruments, display devices, etc., and can solve problems such as heavy oily smoke and light-emitting areas of lamp beads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

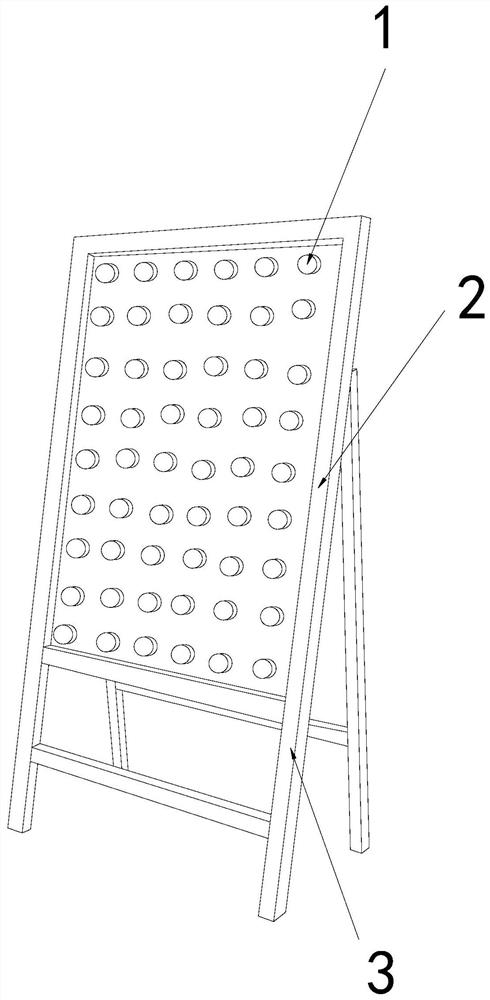

[0026] For example figure 1 -example Figure 5 Shown:

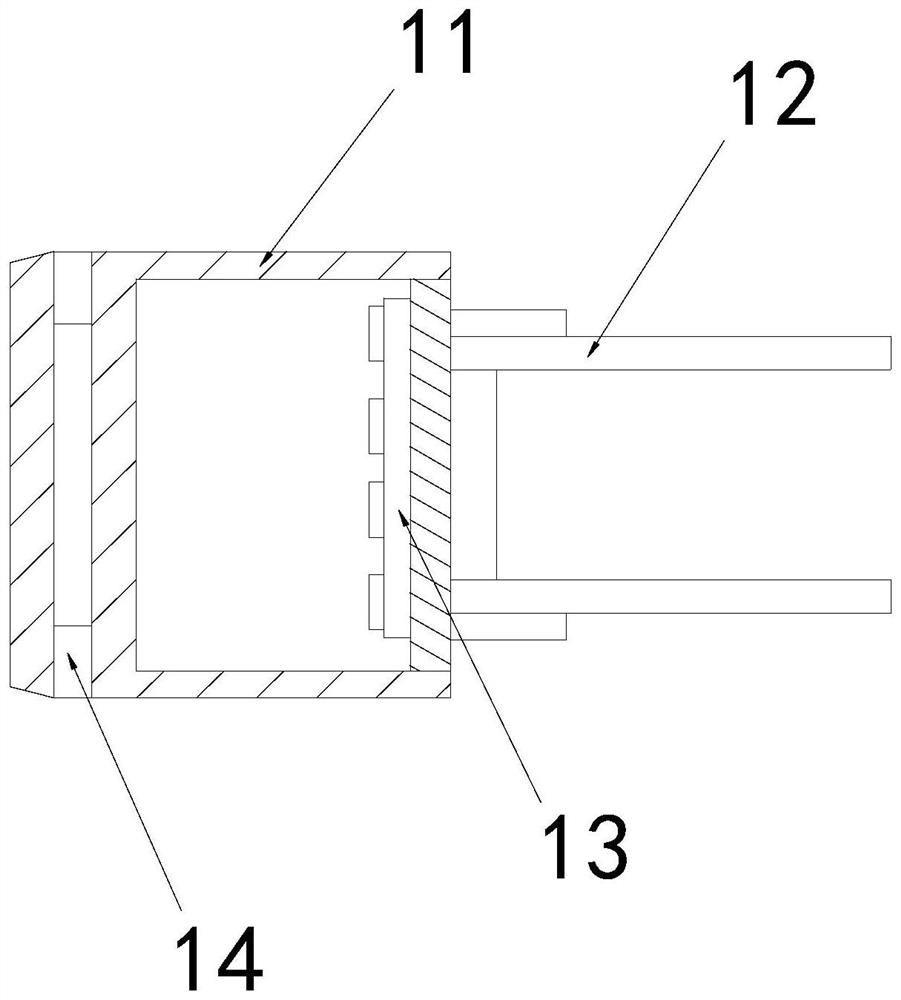

[0027] The invention provides a light-emitting diode lamp, the structure of which includes a lamp bead 1, a lamp board 2, and a support frame 3, the lamp board 2 and the support frame 3 are an integrated structure, and the lamp bead 1 and the lamp board 2 are embedded and connected The lamp bead 1 includes a shell 11, a pole 12, a wick 13, and an oil cleaning mechanism 14, the pole 12 is embedded in the right side of the wick 13, and the wick 13 is installed at the right end of the shell 11, The oil cleaning mechanism 14 is integrated with the housing 11 .

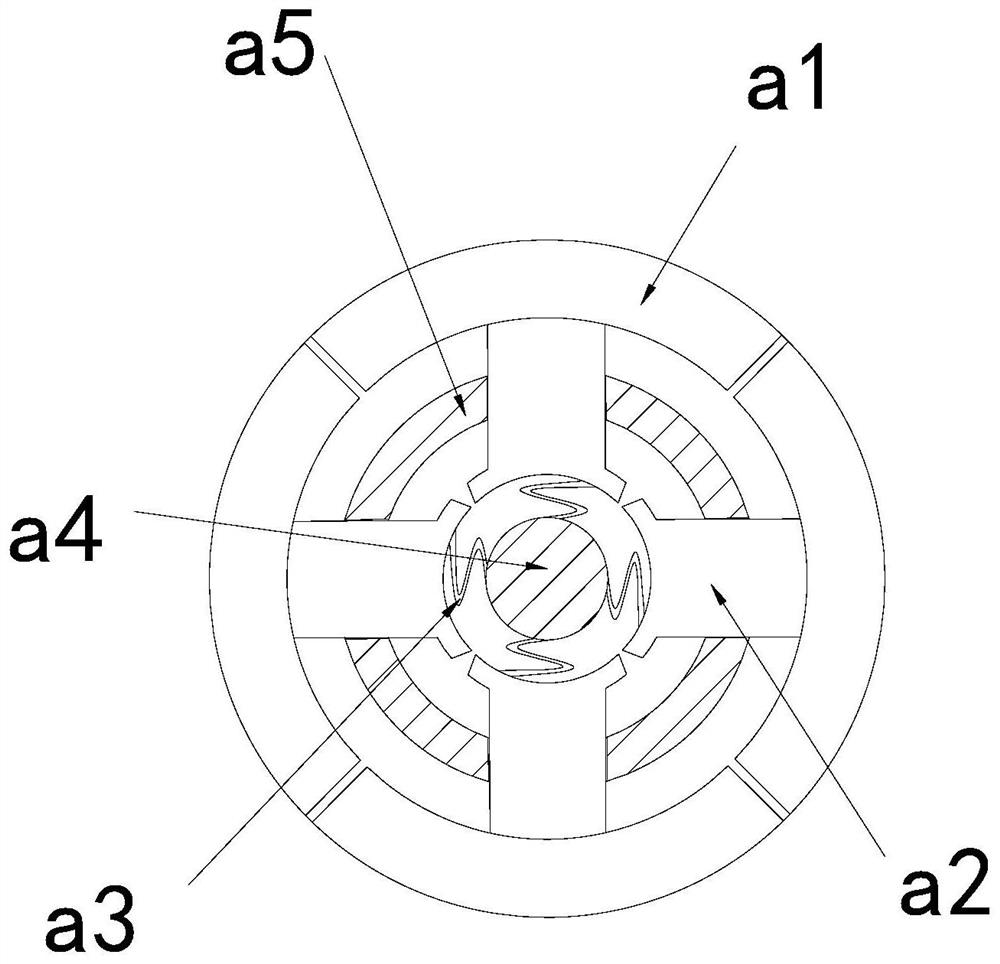

[0028] Wherein, the oil cleaning mechanism 14 includes an outer expansion ring a1, a booster rod a2, an elastic strip a3, a middle solid block a4, and an inner connection ring a5, and the outer side of the booster rod a2 is connected with the inner side of the outer expansion ring a1, And the booster rod a2 is in clearance fit with the inner ring a5, the elastic ba...

Embodiment 2

[0034] For example Figure 6 -example Figure 8 Shown:

[0035] Wherein, the lower slider b3 includes a flow-increasing groove b31, a baffle b32, and a bottom plate b33. connected, the flow-increasing groove b31 is in the form of a triangular groove structure, through which the flow-increasing groove b31 can enhance the downflow speed of the melted grease.

[0036] Wherein, the flow increasing tank b31 includes an external plate c1, a bottom plate c2, a sleeve frame c3, and a joint block c4, the external plate c1 is hinged to the right end of the joint block c4, and the sleeve frame c3 is connected to the bottom The middle part of the inner side of the plate c2 is embedded and connected, and the joint block c4 is movably engaged with the sleeve frame c3. Mercury liquid is installed between the rear end of the joint block c4 and the sleeve frame c3, and the temperature of the object is continuously increased, which can The mercury liquid between the combination block c4 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com