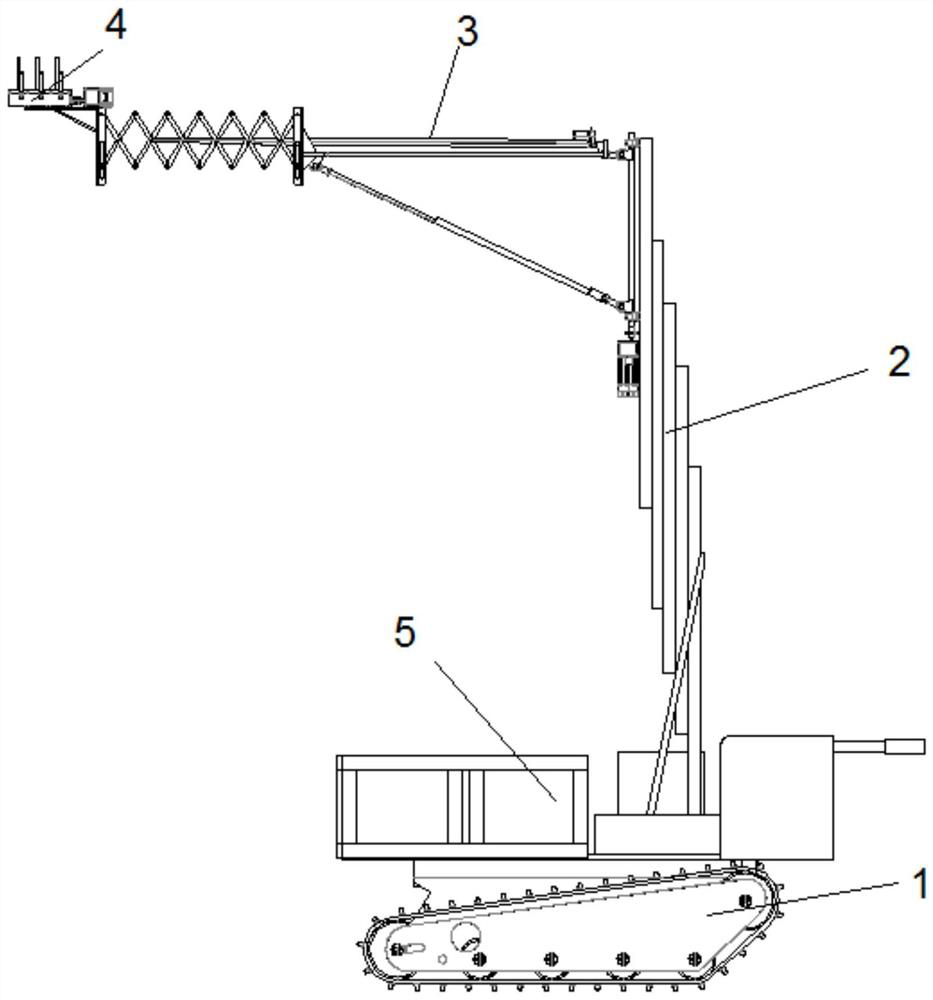

Automatic nut harvester

A harvester and nut technology, applied in the field of fruit harvesting equipment, can solve the problems of inability to reduce the degree of labor in manual harvesting, high labor consumption, small working area, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

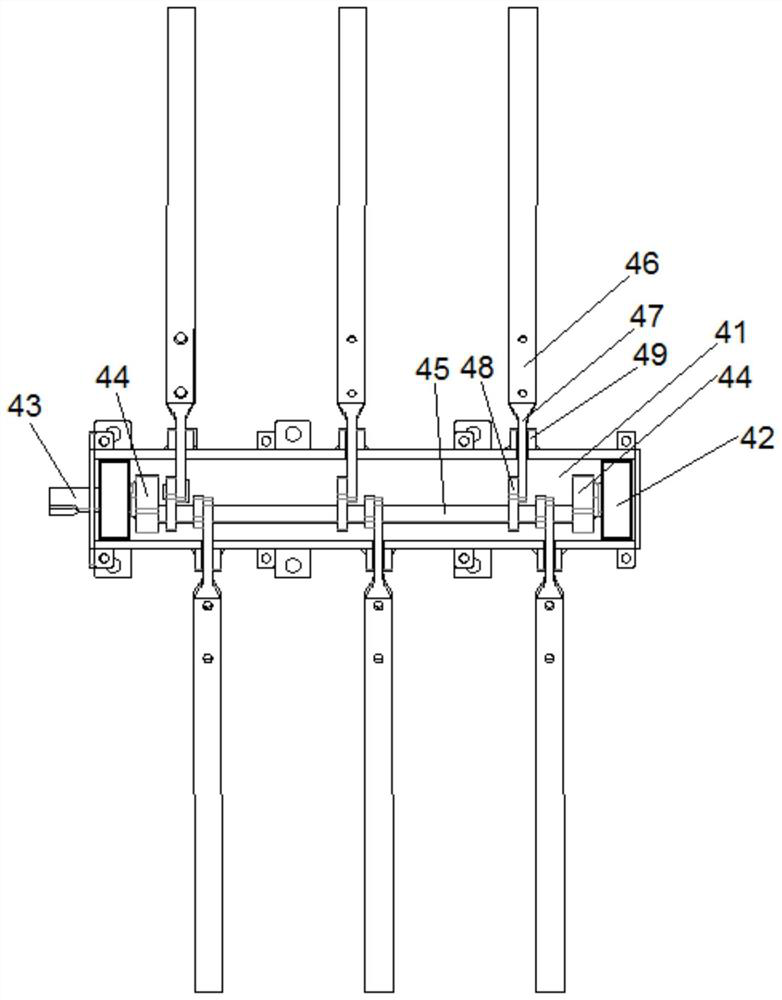

[0020] As an embodiment, the crank rocker mechanism includes a mounting plate 41, a base 42, a drive motor 43, an eccentric block 44, and a long shaft 45. The two ends are hinged, and the second turning point on the other side of one eccentric block 44 is hinged to the base 42 through the rotating shaft, the base 42 is fixed on the mounting plate 41, and the second turning point on the other side of the other eccentric block 44 is fixed on the drive motor 43 output end, the drive motor 43 is fixed on the mounting plate 41, and the line connecting the second rotation points of the two eccentric blocks 44 is parallel to the long axis 45 and does not overlap.

[0021] As an embodiment, the slapping unit includes a slap bar 46, a swing rod 47 and a connecting rod 48, one end of the slapping bar 46 is fixed to the swing rod 47, the other end of the swing rod 47 is hinged to the connecting rod 48 through a rotating shaft, and the connecting rod 48 other ends are fixed on the major a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com