Blackboard gluing device with anti-overflow mechanism

A glue coating device and anti-overflow technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of uneven glue coating and waste, and achieve the effect of preventing glue overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

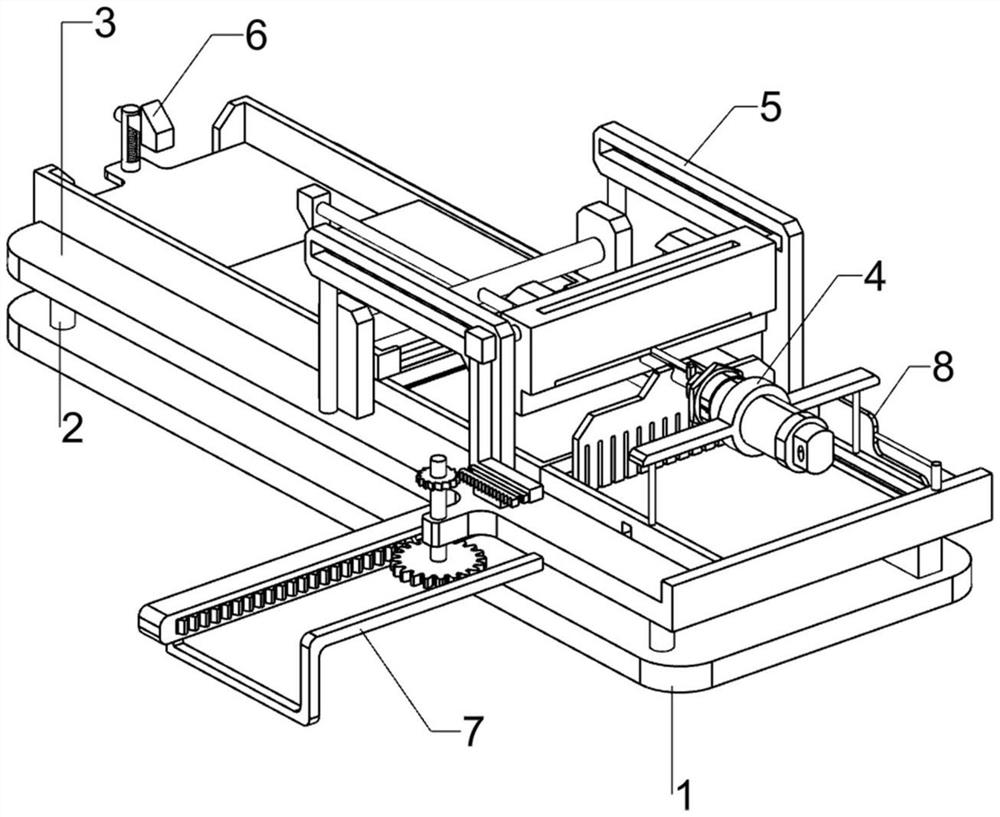

[0066] A blackboard gluing device with an overflow prevention mechanism, such as figure 1 As shown, it includes a base 1, a pillar 2, a placement anti-leakage mechanism 3 and a glue brushing mechanism 4. Two pillars 2 are connected to the front and rear sides of the upper part of the base 1, and a placement leak-proof mechanism 3 is connected between the tops of the pillars 2. The upper side of the right part of the anti-leakage mechanism 3 is connected with a glue brushing mechanism 4 .

[0067] When the device needs to be used, the user can place the raw material board in the anti-leakage mechanism 3, pour the glue onto the glue brushing mechanism 4, start the glue brushing mechanism 4, and the glue brushing mechanism 4 is placed on the anti-leakage mechanism 3. The raw material board is glued to achieve the purpose of automatic glue brushing. The leak-proof mechanism 3 is placed to prevent the glue from overflowing, resulting in waste of glue. After the operation is complet...

Embodiment 2

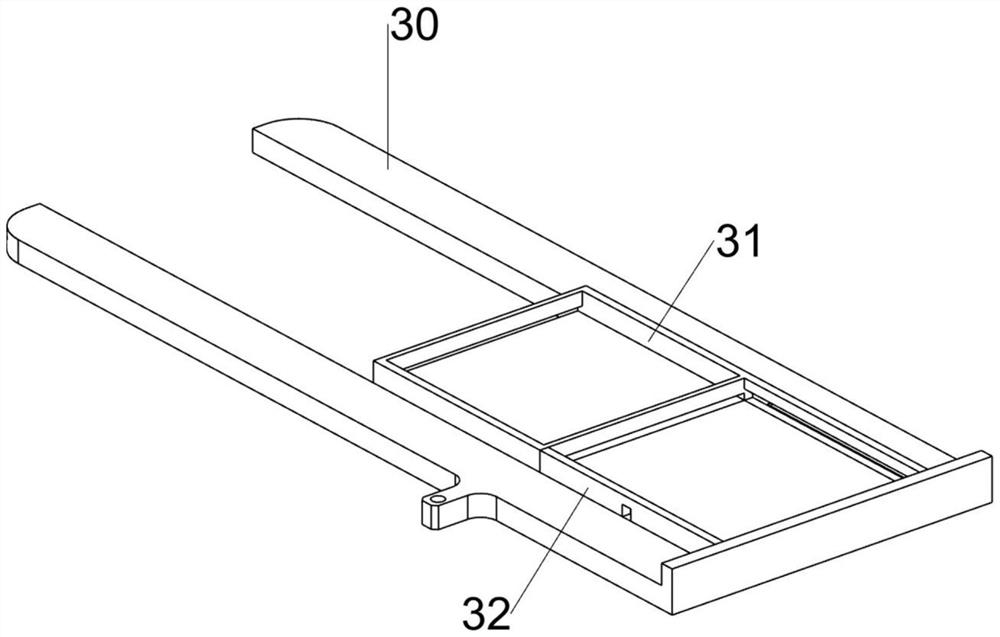

[0069] On the basis of Example 1, such as figure 2 As shown, the placement of the leak-proof mechanism 3 includes a connecting plate 30, a glue brushing box 31 and an installation box 32. The connecting plate 30 is connected between the tops of the four pillars 2, and the installation box 32 is connected between the inner sides of the right part of the connecting plate 30. The left side of the installation box 32 is connected with a glue brushing box 31 , and the glue brushing box 31 is connected with the connecting plate 30 .

[0070] When the device needs to be used, the user can place the raw material plate in the glue brushing box 31, pour the glue onto the glue brushing mechanism 4, start the glue brushing mechanism 4, and the glue brushing mechanism 4 will match the raw material plate in the glue brushing box 31 Glue brushing is carried out to achieve the purpose of automatic glue brushing. The glue brushing box 31 can prevent the glue from overflowing and cause the waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com