Preparation method of aluminum alloy sheet

A technology of aluminum alloy plates and plates, applied in metal rolling, metal rolling, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1. After obtaining the low residual stress ingot, carry out homogenization heating to reach the rolling conditions, and the temperature of the ingot is not allowed to have an obvious temperature gradient (the temperature error is less than 5 °C).

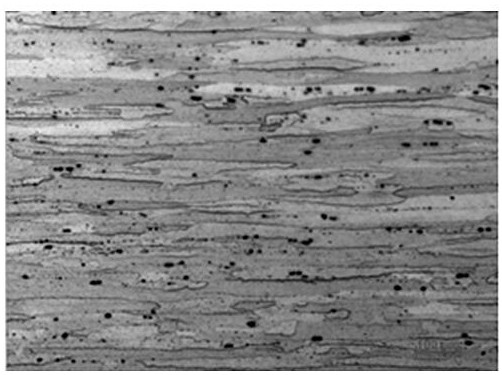

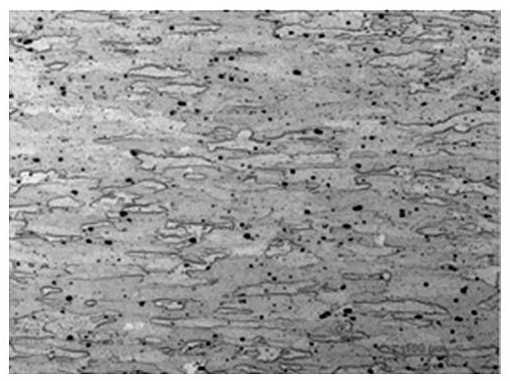

[0049] 2. Using a special rolling process, equal reduction, equal rolling force, and horizontal roll shape disturbance, during the rolling process, the ingots extend uniformly in the longitudinal direction, and at the same time, they extend uniformly in the longitudinal direction at different points in the transverse direction. The amount of compression deformation is consistent, which reduces the inconsistency of compressive stress caused by unevenness in the rolling process. The subsequent process cannot be eliminated or the inconsistency after elimination, resulting in inconsistency of sheet stress inside the sheet. In a reasonable rolling process, the roll disturbance is well controlled, so that the ingot structure flows u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com