Wrapper making module of dumpling machine

A mechanism and technology for dumplings, which are applied in dough forming machinery or equipment, dough sheeter/roller/rolling pin, baking, etc., can solve problems such as hidden dangers of blocking sight, and make it easy to observe and reach out. operation, improve the safety factor, reduce the effect of the dough belt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

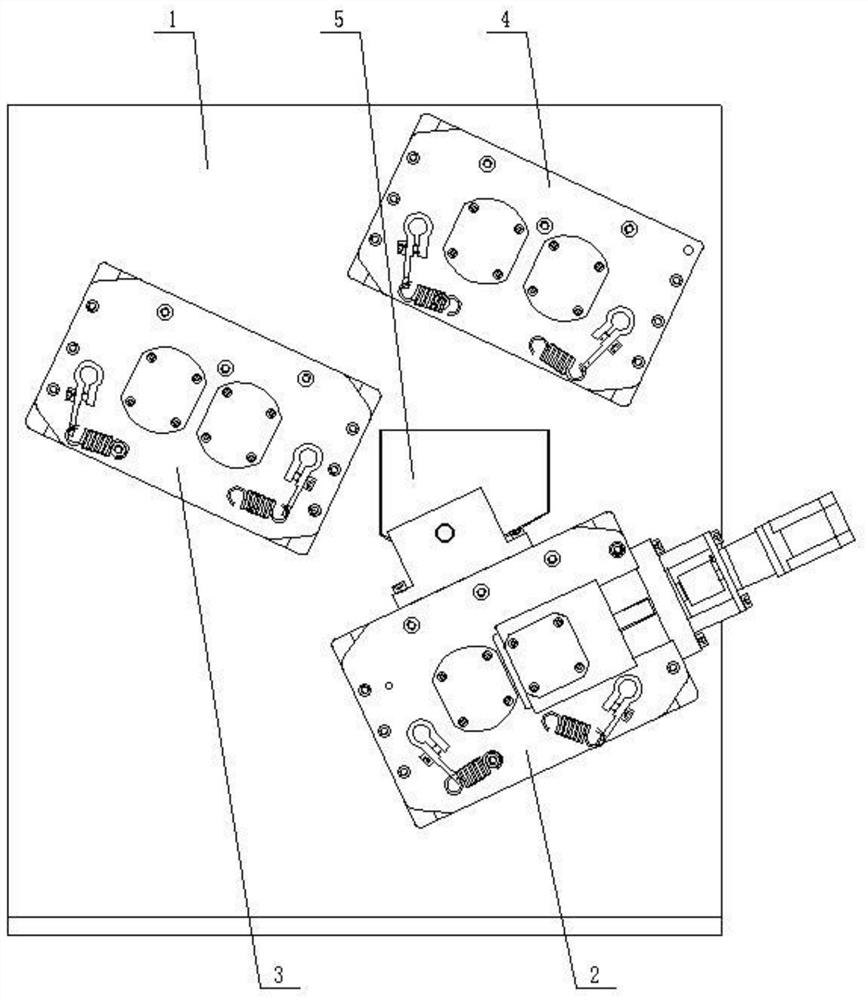

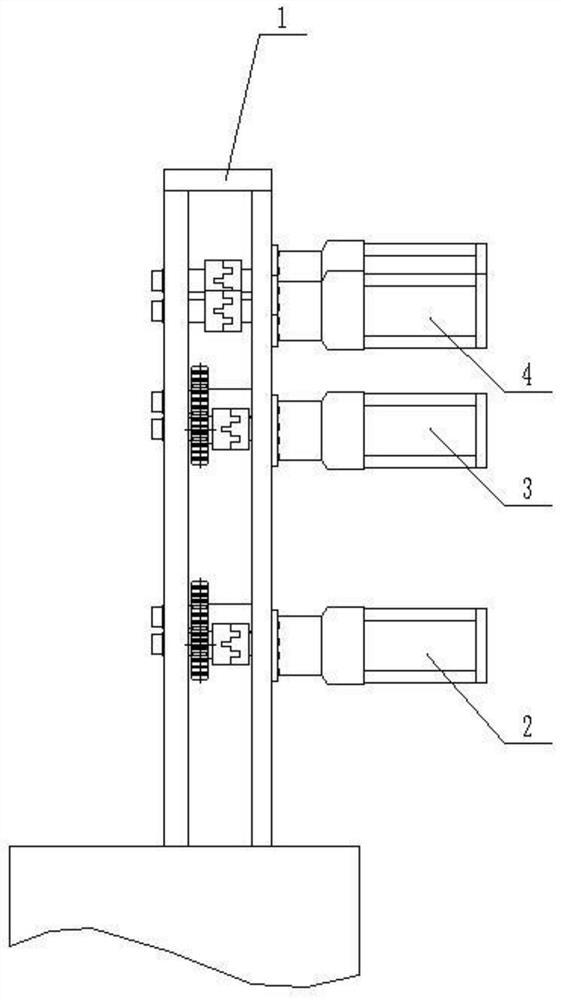

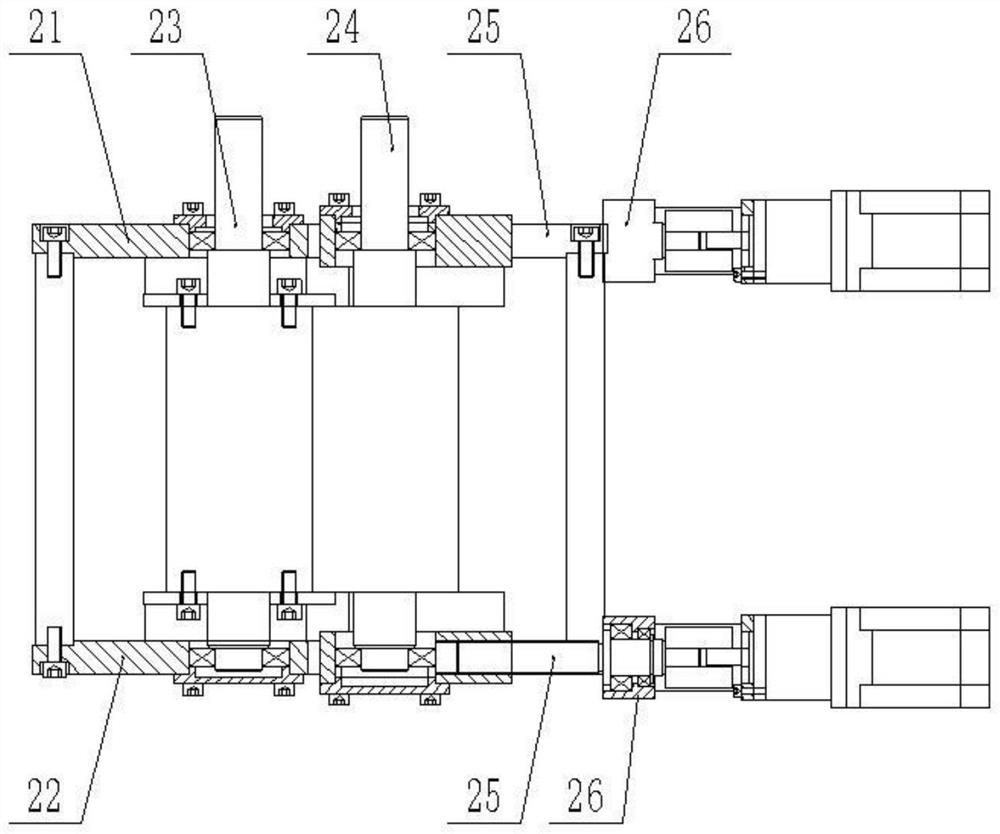

[0031] Such as Figure 1 to Figure 6 Shown: the dumpling machine skin module of the present invention includes: a support 1, a first roller group 2, a second roller group 3 and a third roller group 4; the support 1 is fixed on the dumpling machine base, and the support 1 One side is a vertical surface, the first roller group 2, the second roller group 3 and the third roller group 4 are arranged sequentially from bottom to top, and the end face of the first roller group 2, the second roller group 3 The side end face and the end face on one side of the third roller group 4 are all fixedly connected to the vertical surface, the other side face opposite to the end face of the first roller group 2, the other side face opposite to the end face of the second roller group 3 and the first roller group 3 The other side opposite to the end face of the three roller groups 4 is not connected to any component, the other side of the first roller group 2, the other side of the second roller g...

Embodiment 2

[0049] Such as Figure 1 to Figure 6 Shown: the dumpling machine skin module of the present invention includes: a support 1, a first roller group 2, a second roller group 3 and a third roller group 4; the support 1 is fixed on the dumpling machine base, and the support 1 One side is a vertical surface, the first roller group 2, the second roller group 3 and the third roller group 4 are arranged sequentially from bottom to top, and the end face of the first roller group 2, the second roller group 3 The side end face and the end face on one side of the third roller group 4 are all fixedly connected to the vertical surface, the other side face opposite to the end face of the first roller group 2, the other side face opposite to the end face of the second roller group 3 and the first roller group 3 The other side opposite to the end face of the three roller groups 4 is not connected to any component, the other side of the first roller group 2, the other side of the second roller g...

Embodiment 3

[0067] Such as Figure 1 to Figure 6 Shown: the dumpling machine skin module of the present invention includes: a support 1, a first roller group 2, a second roller group 3 and a third roller group 4; the support 1 is fixed on the dumpling machine base, and the support 1 One side is a vertical surface, the first roller group 2, the second roller group 3 and the third roller group 4 are arranged sequentially from bottom to top, and the end face of the first roller group 2, the second roller group 3 The side end face and the end face on one side of the third roller group 4 are all fixedly connected to the vertical surface, the other side face opposite to the end face of the first roller group 2, the other side face opposite to the end face of the second roller group 3 and the first roller group 3 The other side opposite to the end face of the three roller groups 4 is not connected to any component, the other side of the first roller group 2, the other side of the second roller g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com