Pressure vessel spherical head inner wall polishing device

A technology for spherical heads and pressure vessels, which is applied to grinding drive devices, grinding/polishing equipment, and machine tools for surface polishing, etc. It can solve the problems of unfavorable inner walls of spherical heads, low polishing adequacy, and rotary polishing treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

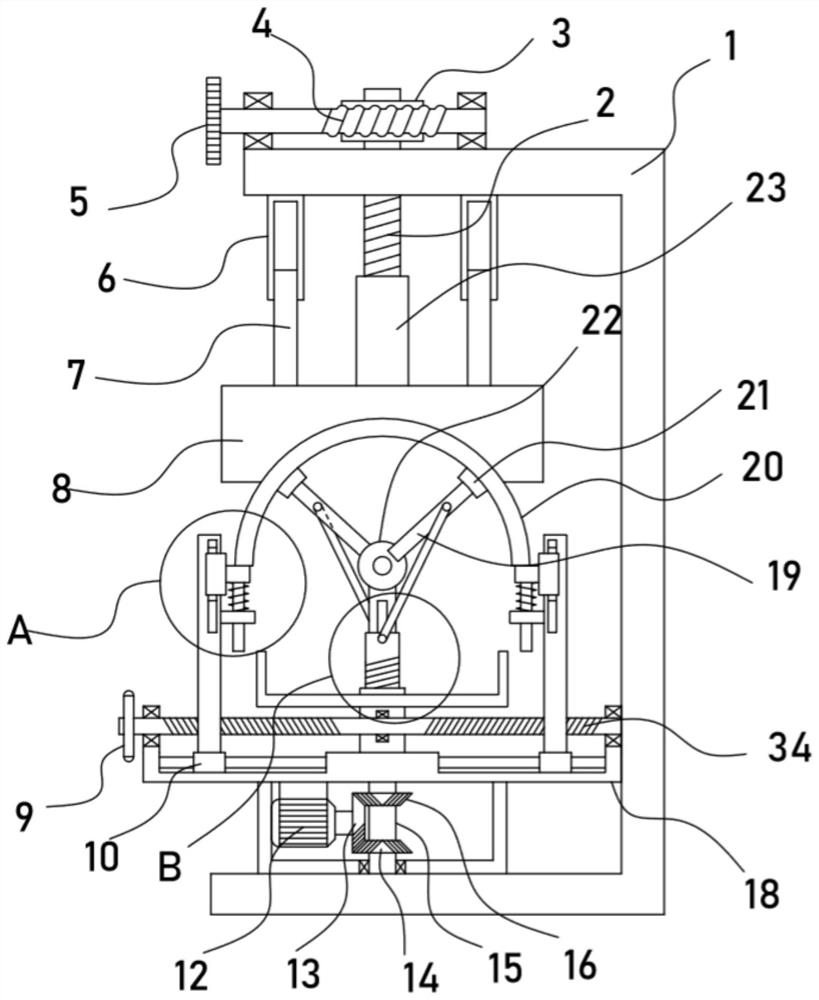

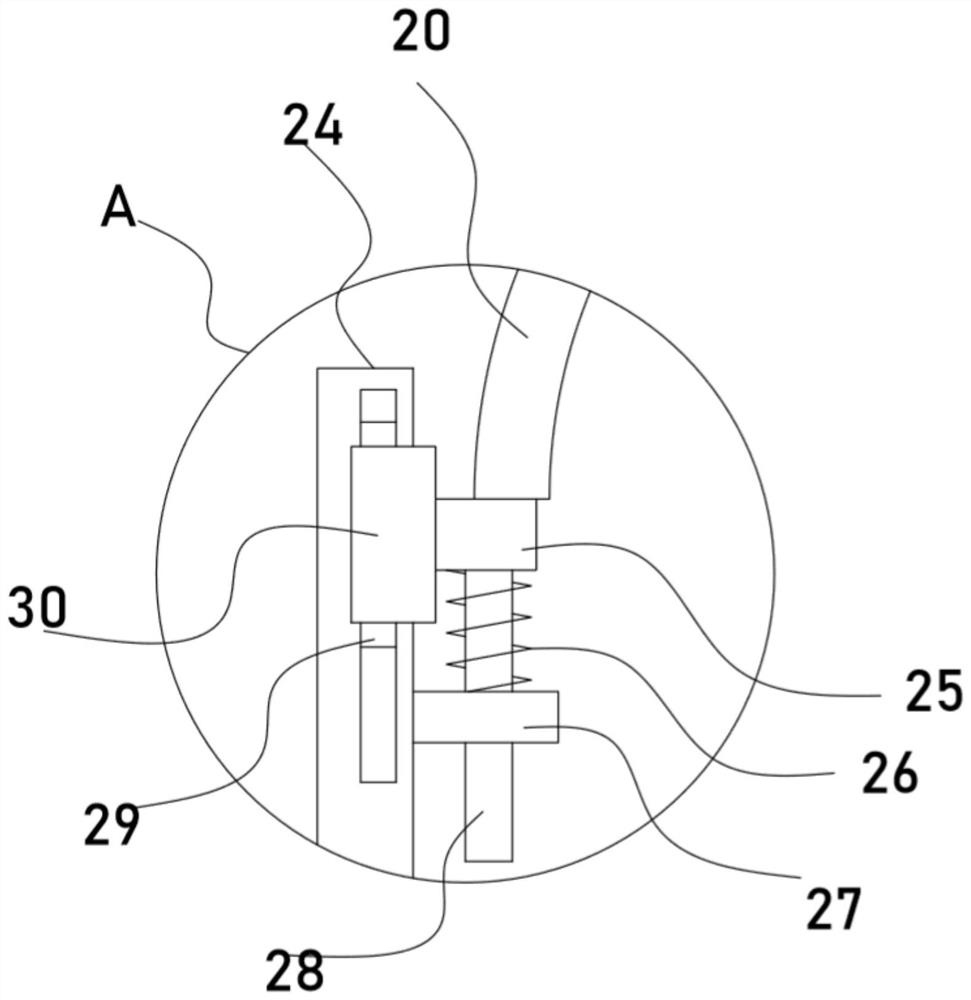

[0023] see Figure 1-3 , a pressure vessel spherical head inner wall polishing device, comprising a fixed frame 1, a support frame 18 is fixed on the fixed frame 1, a pressure plate 8 is suspended from the fixed frame 1, and the bottom of the pressure plate 8 is connected to the spherical head 20 The outer wall is suitable for fitting, and the fixed frame 1 is provided with a lifting mechanism for driving the pressure plate 8 to rise and fall, and a hand wheel II9 is installed on the support frame 18, and a horizontal adjustment mechanism is connected to the hand wheel II9. The horizontal adjustment mechanism is provided with a support mechanism for supporting the spherical head 20. The drive motor 12 is fixed on the bottom of the support frame 18, and the forward and reverse mechanism is driven on the drive motor 12. The positive and negative mechanism is driven and connected. There is a steering shaft 15 on which a polishing mechanism for polishing the inner wall of the sp...

Embodiment 2

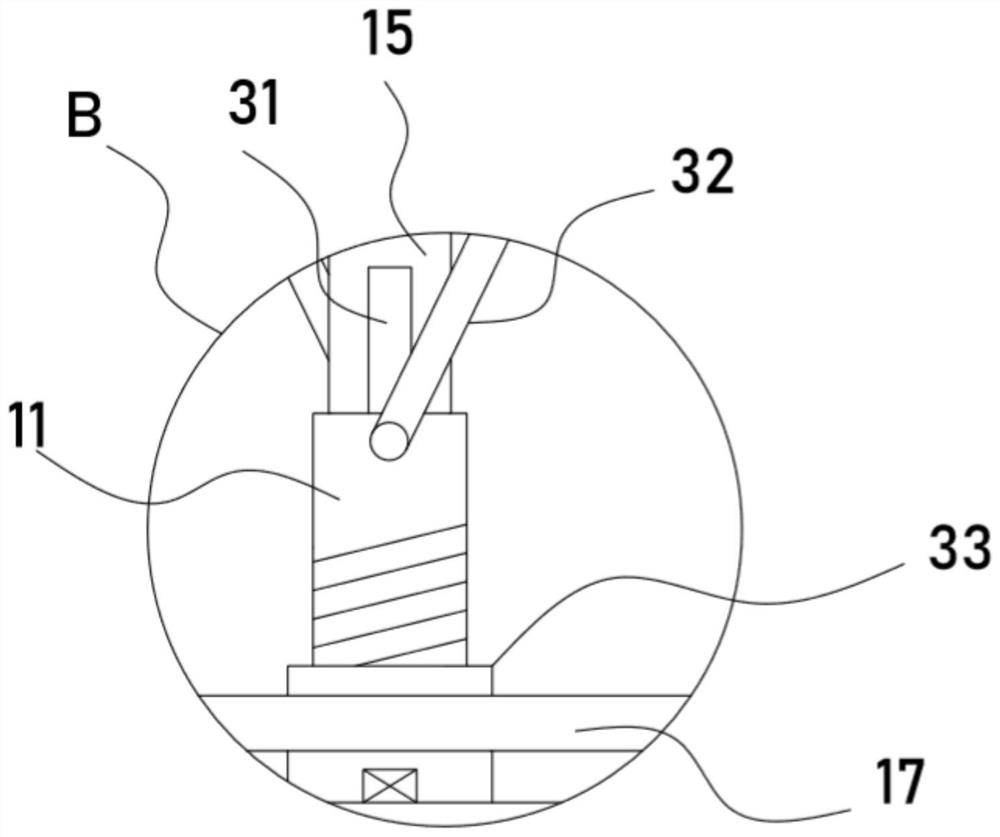

[0031] On the basis of Embodiment 1, in addition, the polishing mechanism of this device includes a transmission sleeve 11 sleeved on the steering shaft 15, and the inner wall of the transmission sleeve 11 is slidably embedded with a clip 31 fixed on the side wall of the steering shaft 15, A rotating disc 22 is mounted on the steering shaft 15, a rotating rod 19 is fixed on the rotating disc 22, and a grinding arc 21 is fixed on the end of the rotating rod 19 to fit the inner wall of the spherical head 20. The polishing mechanism also includes an internally threaded pipe 33 threaded on the transmission sleeve 11, the lower end of the internally threaded pipe 33 is fixed on the support frame 18, and a pull rod 32 is hinged between the transmission sleeve 11 and the rotating rod 19. The rotating disk 22 is rotatably mounted on the upper end of the steering shaft 15 , and the collection groove 17 is sheathed and fixed on the internally threaded pipe 33 . The reversing mechanism i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com