Three-layer screen cloth with color changing function and manufacturing method and application of three-layer screen cloth

A technology of three-layer mesh cloth and production method, which is applied in the field of mesh cloth, can solve the problems of poor air permeability of mesh cloth, low structural stability, and high weight of mesh cloth, and achieve novel appearance, strong three-dimensional effect, and improved air permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

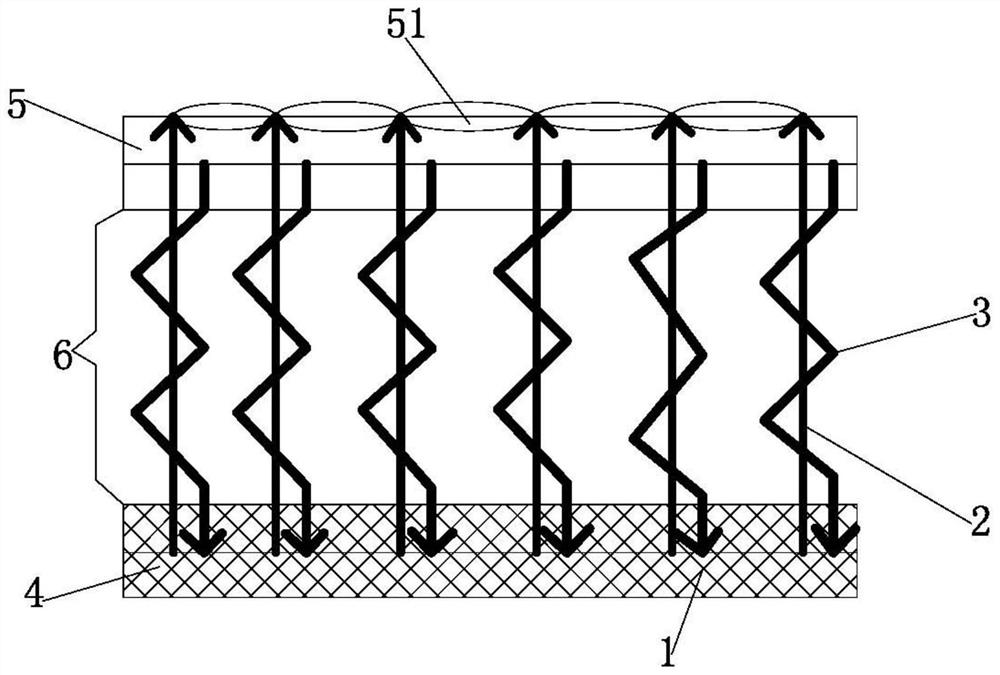

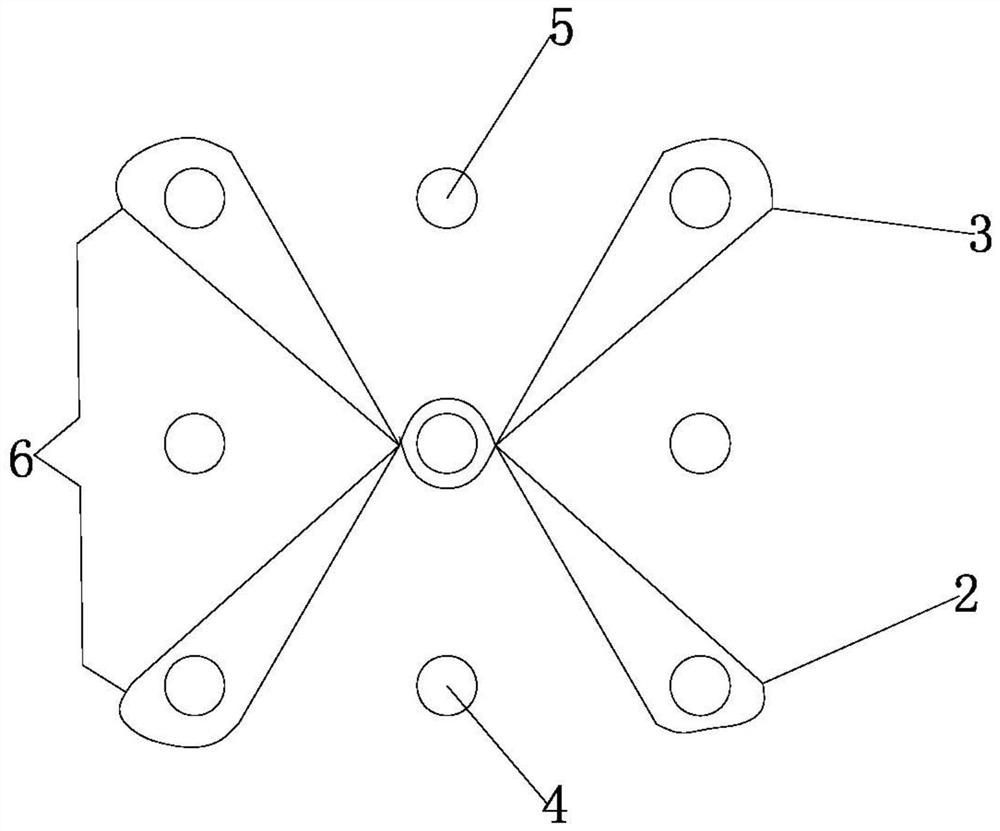

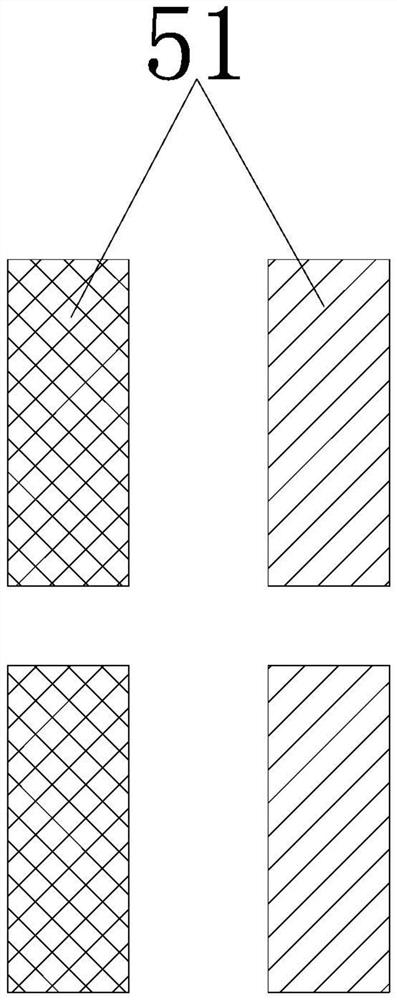

[0038] refer to Figure 1-2 as well as Figure 6-7, a three-layer mesh cloth with a color-changing function, including a plurality of first yarns 1, a plurality of second yarns 2, and a plurality of third yarns 3, and a plurality of first yarns 1 are cross-woven to form a bottom layer 4, A plurality of second yarns 2 are woven upward from the bottom of the bottom layer 4 to form a surface layer 5, and several meshes 51 are formed at the top of the surface layer 4, and a plurality of third yarns 3 are formed from the top of the surface layer 5. The bottom end is cross-woven downward to the top of the bottom layer 4, and the second yarn 2 is cross-woven between the surface layer 5 and the bottom layer 4 to form the middle layer 6, and the third yarn 3 has two or more yarn colors.

[0039] Several mesh holes 51 form several grooves 52 at the top of the surface layer 4 .

[0040] The yarn color of the second yarn 2 is different from the yarn color of the third yarn 3 .

[0041]...

Embodiment 2

[0055] refer to Figure 1-2 as well as Figure 6-7 , a three-layer mesh cloth with a color-changing function, including a plurality of first yarns 1, a plurality of second yarns 2, and a plurality of third yarns 3, and a plurality of first yarns 1 are cross-woven to form a bottom layer 4, A plurality of second yarns 2 are woven upward from the bottom of the bottom layer 4 to form a surface layer 5, and several meshes 51 are formed at the top of the surface layer 5, and a plurality of third yarns 3 are formed from the bottom end of the surface layer 5. Cross weave down to the top of the bottom layer 4, and cross weave with the second yarn 2 between the surface layer 5 and the bottom layer 4 to form the middle layer 6, and the third yarn 3 has two or more yarn colors.

[0056] Several mesh holes 51 form several grooves 52 at the top of the surface layer 5 .

[0057] The yarn color of the second yarn 2 is different from the yarn color of the third yarn 3 .

[0058] The mesh 51...

Embodiment 3

[0072] refer to Figure 1-2 as well as Figure 6-7, a three-layer mesh cloth with a color-changing function, including a plurality of first yarns 1, a plurality of second yarns 2, and a plurality of third yarns 3, and a plurality of first yarns 1 are cross-woven to form a bottom layer 4, A plurality of second yarns 2 are woven upward from the bottom of the bottom layer 4 to form a surface layer 5, and several meshes 51 are formed at the top of the surface layer 5, and a plurality of third yarns 3 are formed from the bottom end of the surface layer 5. Cross weave down to the top of the bottom layer 4, and cross weave with the second yarn 2 between the surface layer 5 and the bottom layer 4 to form the middle layer 6, and the third yarn 3 has two or more yarn colors.

[0073] Several mesh holes 51 form several grooves 52 at the top of the surface layer 5 .

[0074] The yarn color of the second yarn 2 is different from the yarn color of the third yarn 3 .

[0075] The mesh 51 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com