A large area spreader load balancing system

A load balancing and balancing system technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of difficult balance of the system, difficulty of synchronizing the hoisting system, and reducing the operating efficiency of the spreader, so as to eliminate the effect of load difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, the substantial features and advantages of the present invention will be further described with reference to examples, but the present invention is not limited to the listed embodiments.

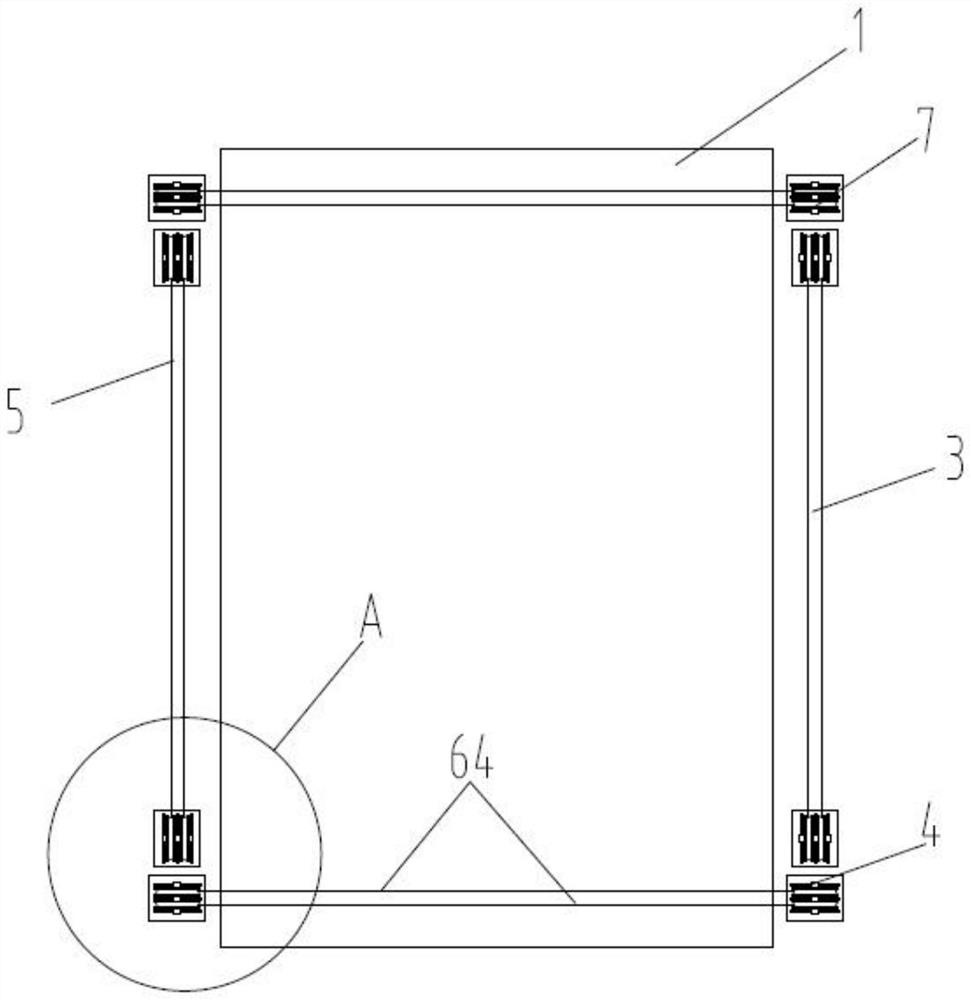

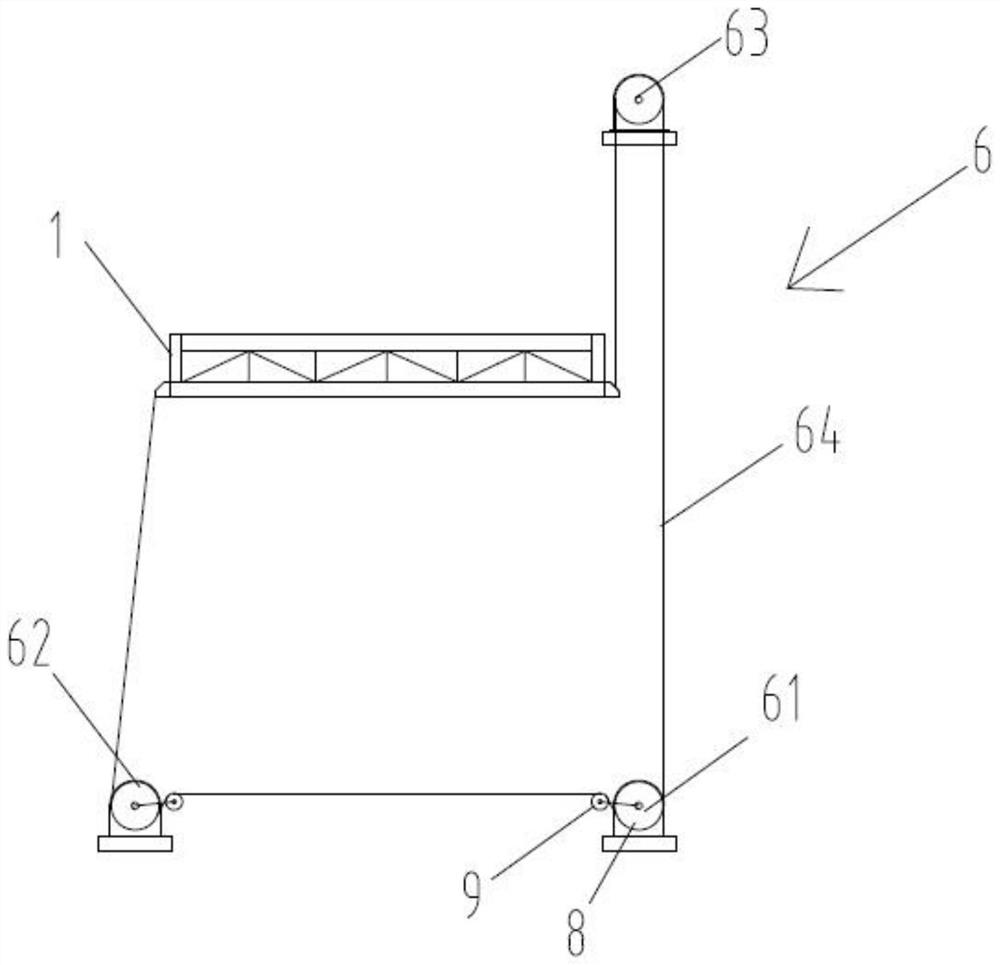

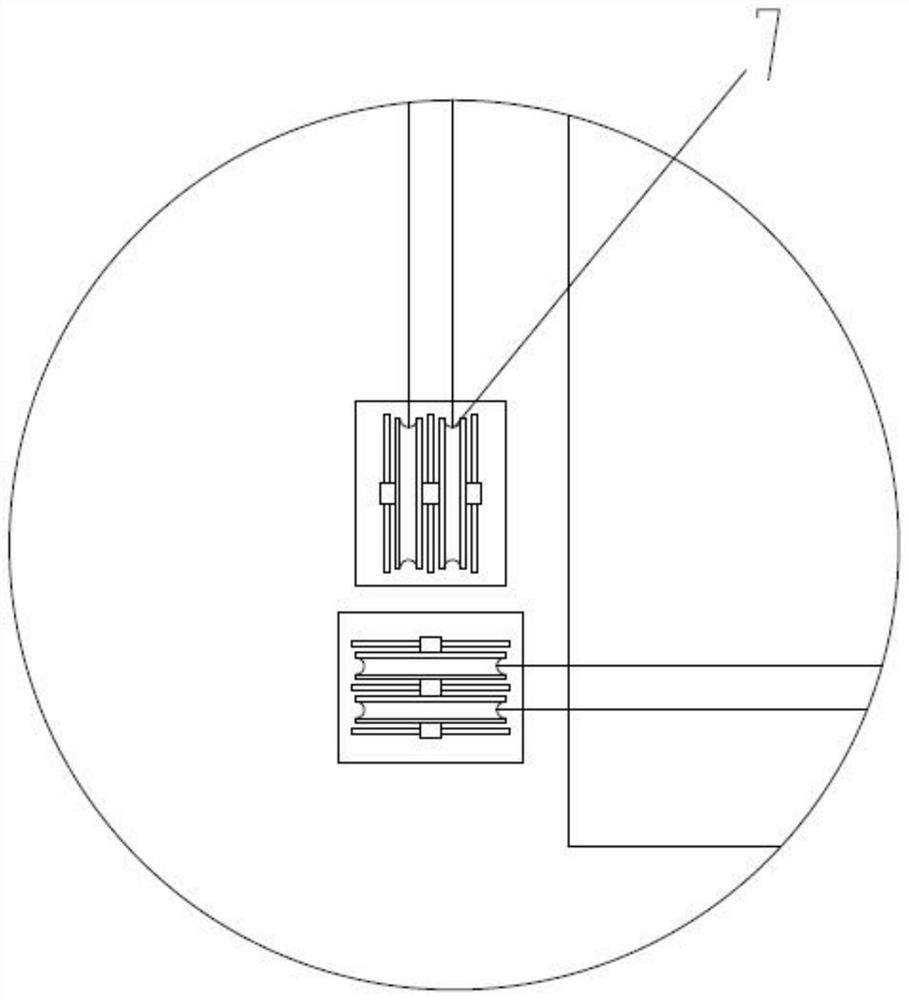

[0020] like Figure 1 to Figure 3 As shown, a large-area spreader load balancing system in this embodiment includes a spreader 1, and around the spreader 1 are respectively provided with a front balance wheel set 2, a right balance wheel set 3, a rear balance wheel set 4 and a left balance wheel set 5. The front and rear balance wheel sets are arranged on the outside of the left and right balance wheel sets, so as to avoid the interference of the balance guide rope. The front, rear, left and right balance wheel sets respectively include two groups of balance system element structures 6, and the two groups of balance system element structures 6 are symmetrically arranged. The balance system element structure 6 includes a first tension pulley 61 , a second tension pulley 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com