Medium and low yield field soil condition improvement equipment and improvement method thereof

A medium and low-yield, soil technology, applied in the direction of soil lifting machinery, shovel, plow, etc., can solve the problems of feeding pipe jam, the effect of feeding speed of feeding pipe, and insufficient soil fertilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

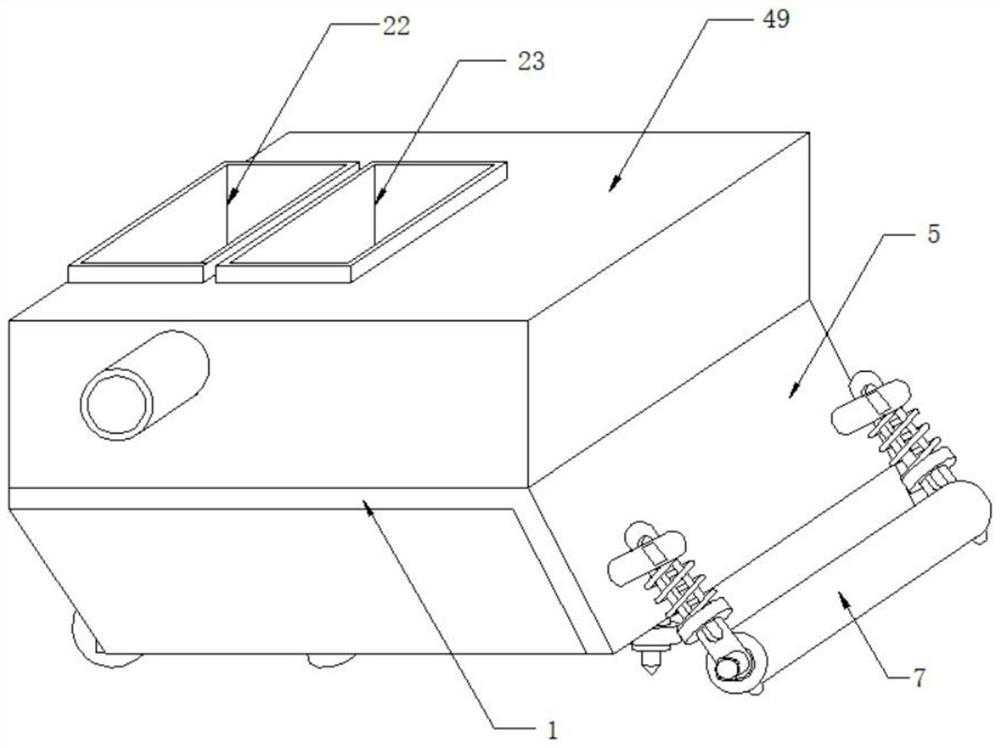

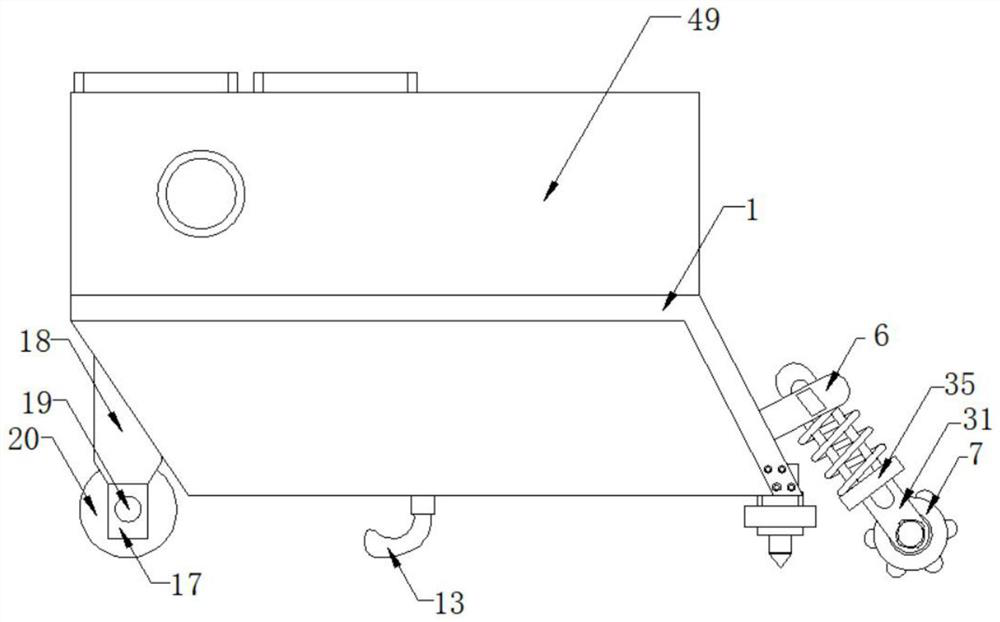

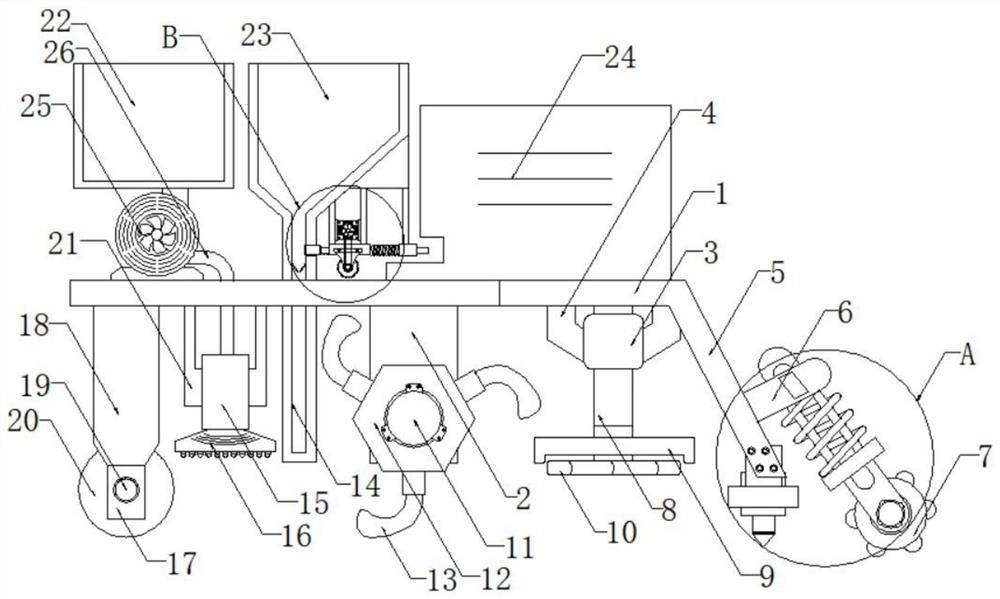

[0035] Embodiment one, by Figure 1-8 Given, the present invention includes a drag support plate 1, the bottom of the drag support plate 1 is fixedly installed with a first rotating bracket 18, the bottom of the first rotating bracket 18 is fixedly equipped with a concave bracket 17, and the inside of the concave bracket 17 is provided with a spiral cutter head 20. Two rotating bearings 19 are fixedly installed inside the concave bracket 17, both ends of the spiral cutter head 20 are rotatably socketed with the concave bracket 17 through the rotating bearings 19, and two second rotating bearings are fixedly installed on the bottom of the drag support plate 1. Bracket 2, the two second rotating brackets 2 are distributed symmetrically around the axis of the drag support plate 1, the inner rotation of the two second rotating brackets 2 is sleeved with a transmission link 11, and the outer fixed sleeve of the transmission link 11 is There are several hexagonal cutterheads 12, and...

Embodiment 2

[0036] Embodiment 2. On the basis of Embodiment 1, a switch panel is fixedly installed on one side of the protective shell 49, and a water pump switch, a transmission switch and an atomization switch are arranged on one side of the switch panel. The transmission motor 39 is electrically connected to the power supply through the transmission switch, and the liquefaction sprayer 15 is electrically connected to the power supply through the atomization switch.

Embodiment 3

[0037] Embodiment 3, on the basis of Embodiment 1, the outer parts of the three transfer rods 8 are fixedly sleeved with soil-shielding circular plates 9, and the three crushing cutter heads 10 are respectively set with the corresponding soil-shielding circular plates 9 Next, the depth value of each pulverizing cutter head 10 is greater than the depth value of the soil shielding circular plate 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com