A movable hard connection sealing device for zinc powder contacting powder

A sealing device and hard connection technology, applied in the field of zinc powder processing and conveying equipment, can solve problems such as insufficient stability, easy residual zinc powder, poor durability, etc., and achieve the effect of a convenient detachable hard connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

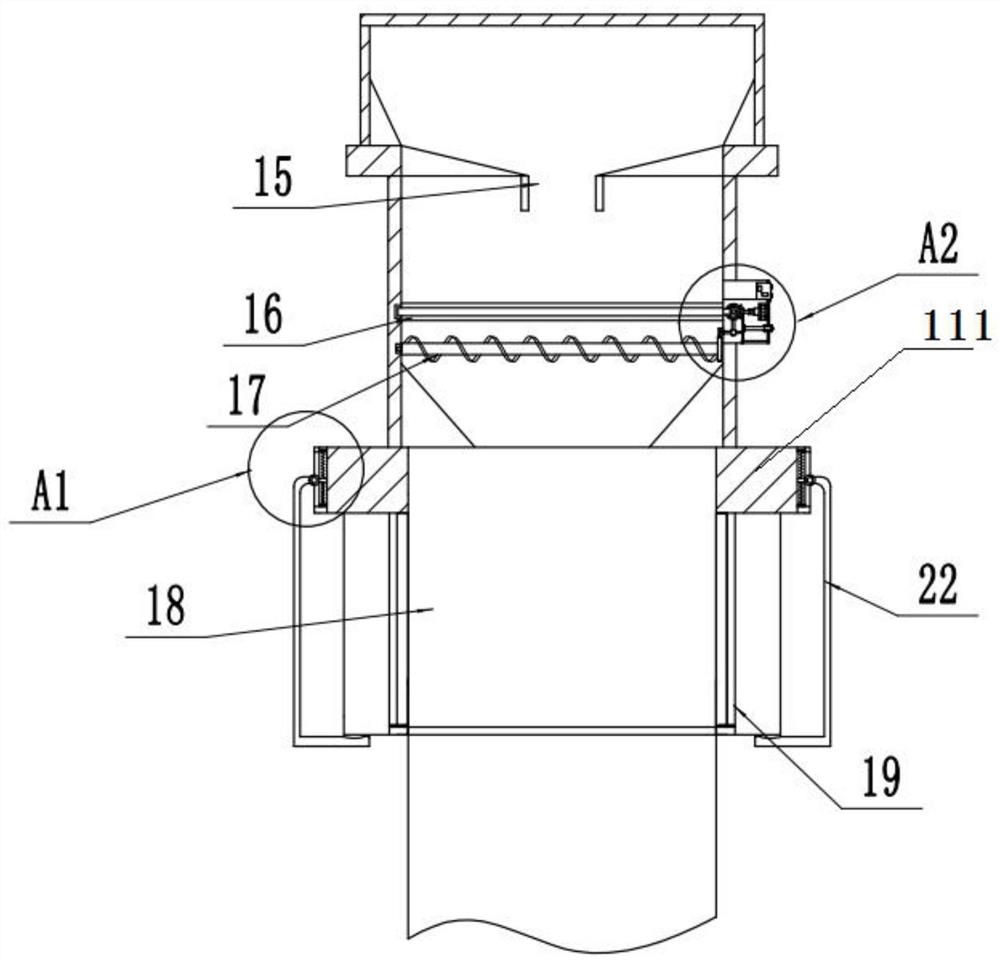

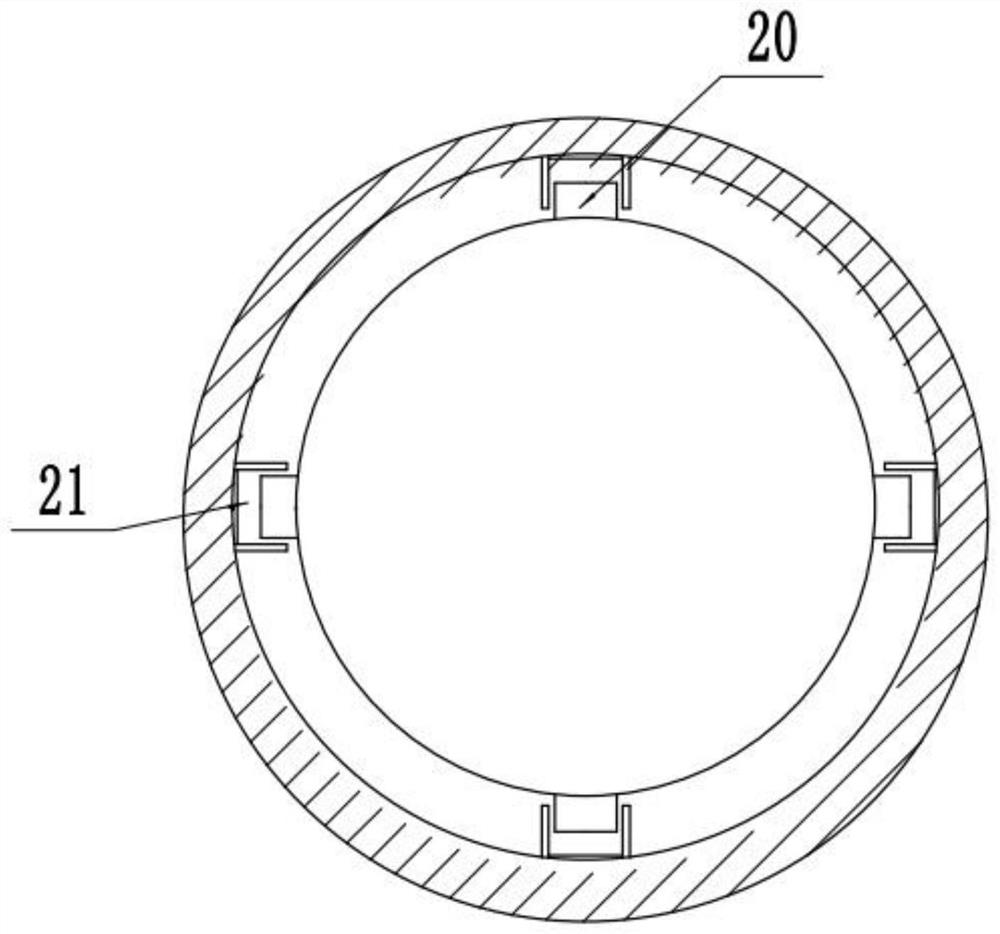

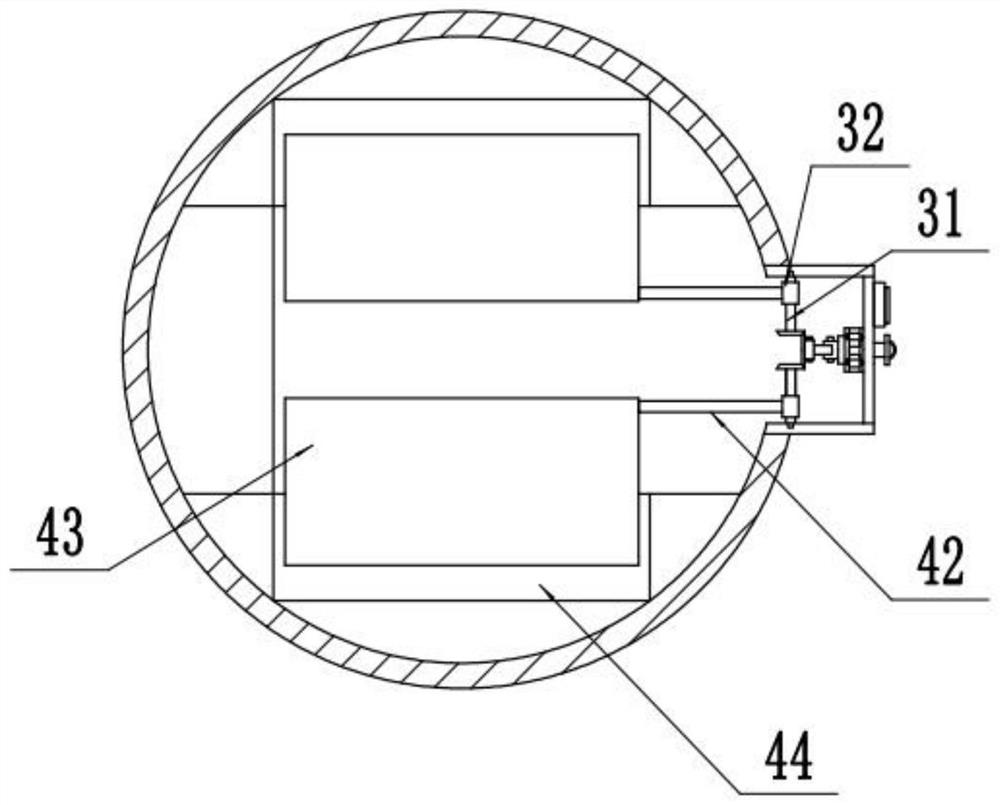

[0026] see Figure 1-5, a kind of active hard connection sealing device for zinc powder contacting powder, comprising a lower pipe body 10, an upper pipe body 11, and a material storage chamber 12; The bottom is provided with a feed opening 15 for conveying the zinc powder inside the storage chamber 12 downward. The bottom of the upper tube body 11 is fixedly connected with a communication convex cylinder 18 with a smaller aperture than the upper tube body 11, and the top of the lower tube body 10 is fixedly connected with a communication groove 19 that is engaged with the communication convex tube 18. 18 and the communication groove 19 are snapped in communication, so that the lower tube body 10 and the upper tube body 11 are hard connected. Four sets of rectangular sliders 20 are fixedly installed on the outer surface of the communication protrusion 18 at equal intervals, and the inner side of the communication groove 19 corresponding to the slider 20 is provided with a chu...

Embodiment 2

[0030] refer to Image 6 , on the basis of Embodiment 1, a ring of protective steel body 13 is detachably installed on the outer side of the communication protrusion 18 and the communication groove 19 through the fastening bolt 14, and the protective steel body 13 can well prevent external Collision damage to the junction of the lower pipe body 10 and the upper pipe body 11 ensures that the connection of the entire zinc powder pipe body is in a high-safety protection state.

[0031] The working principle of the present invention is: firstly, when using, put the zinc powder to be transported in the storage chamber 12 for storage, and then snap the connecting convex cylinder 18 at the bottom of the upper pipe body 11 into the top of the lower pipe body 10 Connect the interior of the groove 19, and then swing and pull the fastening rod 22 downward by rotating the fastening rod 22, and the bottom straight section of the fastening rod 22 is clamped on the bottom of the connecting g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com