Fire extinguisher shaking-up device for fire protection

A fire extinguisher and fire-fighting technology, which is applied in fire rescue and other fields, can solve the problems of low efficiency, unsatisfactory effect, and easy consumption of firefighters' physical strength, etc., and achieve the effects of increasing the force, improving the wind-shielding effect, and improving the shock effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

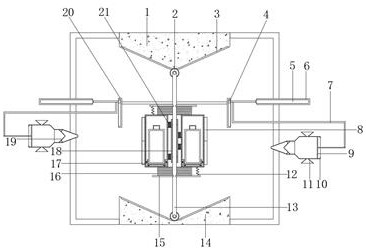

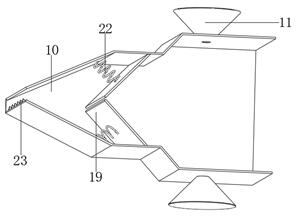

[0029] refer to Figure 1-4 , a fire extinguisher shaking equipment for fire fighting, comprising a lower concave block 14, the two sides of the lower concave block 14 are welded with a support frame, the top of the support frame is welded with the same upper triangular end block 1, and the upper triangular end block 1 and The opposite side of the lower concave block 14 is provided with parallel slide rails 3, and the opposite side of the lower concave block 14 and the upper triangular end block 1 is provided with a mounting column 13, and the two ends of the mounting column 13 are rotatably connected by bearings. There is a pulley 2 slidingly connected with the slide rail 3, the two ends of the mounting column 13 close to the central axis are connected to the turntable 15 through bearing rotation, and the opposite side of the turntable 15 is welded with a vibrating spring 16, and the opposite side of the vibrating spring 16 The same placement cylinder 17 is welded, and the ci...

Embodiment 2

[0039] refer to figure 1 and Figure 5 , a fire extinguisher shaking equipment for fire fighting. Compared with Embodiment 1, this embodiment also includes two side springs 12 that are welded with staggered distribution on the opposite side of the two turntables 15 and the placement cylinder 17; The side springs 12 staggered between the tubes 17 can aggravate the imbalance in the horizontal direction of the tubes 17 during the up and down vibration of the tubes 17 and improve the vibration effect.

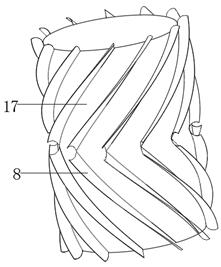

[0040] In the present invention, the inner arc side of the baffle 8 is welded with multiple ribs 26 equidistantly distributed, and the radians of the multiple ribs 26 and the baffle 8 are the same; the multiple ribs 26 arranged on the baffle 8 can improve its surface area, thereby effectively improving the windshielding effect of the baffle 8.

[0041] When the present invention is in use: the side springs 12 arranged in a staggered manner between the turntable 15 and the placeme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com