A long-distance optical fiber inspection system based on optical fiber random laser

A long-distance optical fiber and random laser technology, which is used in the testing of machine/structural components, testing optical fiber/optical waveguide equipment, optical instrument testing, etc. Achieve a wide range of applications, enhanced visibility, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

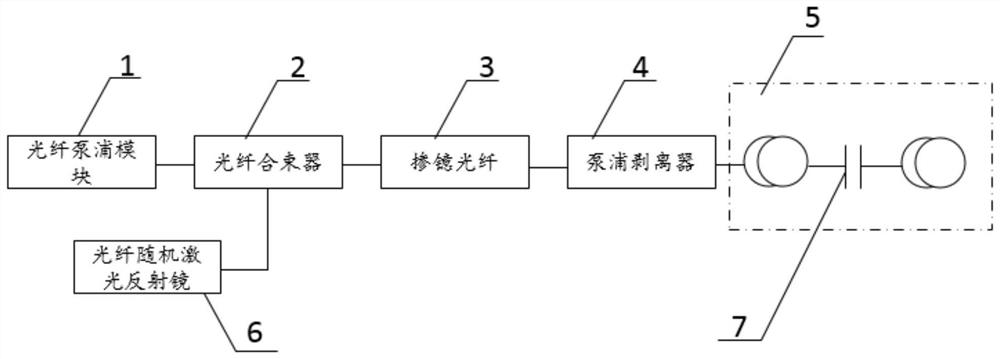

[0019] see figure 1 , a long-distance fiber detection system based on fiber random laser, its structure includes fiber pump module 1, fiber combiner 2, ytterbium-doped fiber 3, pump stripper 4, fiber to be tested 5 and fiber random laser reflector 6. The output end of the fiber pump module 1 is connected to the pump port of the fiber combiner 2, the signal end of the fiber combiner 2 is connected to the random fiber laser mirror 6, and the output end of the fiber combiner 2 is connected to the The input end of the ytterbium fiber 3 is connected, the output end of the ytterbium fiber 3 is connected with the input end of the pump stripper 4 for removing excess pump light, and the output end of the pump stripper 4 is connected with the fiber to be tested 5 . Possible breakpoints in the fiber to be tested7 such as figure 1 shown.

[0020] The pum...

Embodiment 2

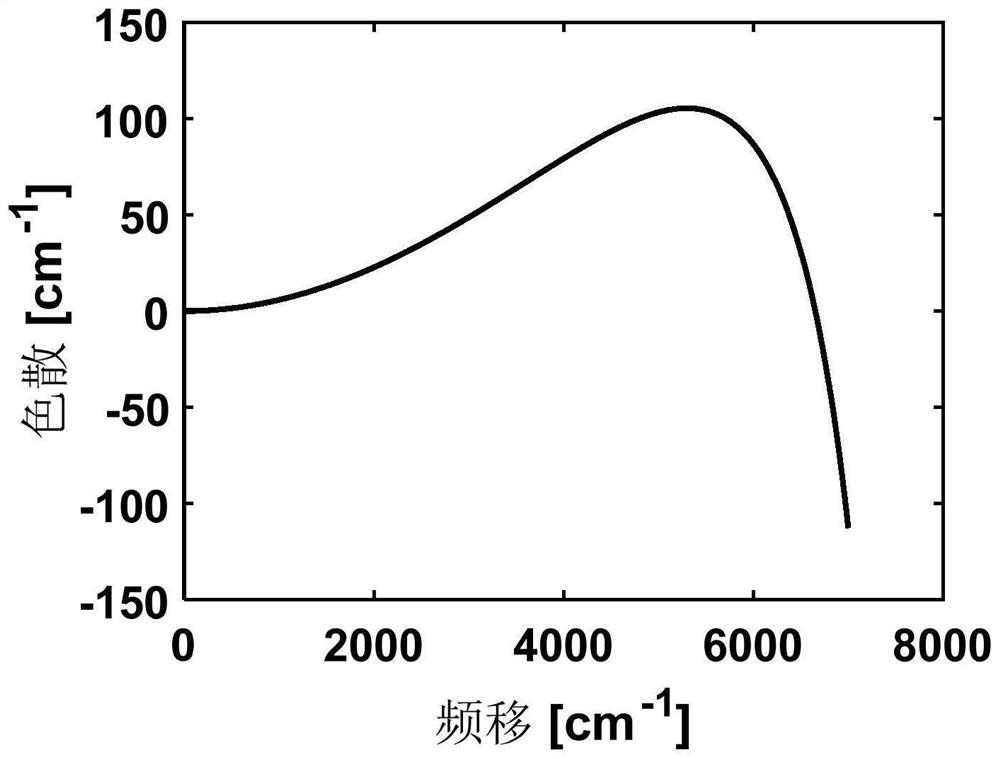

[0028] refer to figure 2 , figure 2 It shows the process of the present invention to produce visible light color selection in a demonstration fiber, wherein the two pump photons are both 1064 nm, the abscissa corresponds to the frequency shift of the new photons, and the ordinate is the comprehensive dispersion evaluation result. Under certain conditions, the two pump photons will excite the two new photons. When the sum of the material dispersion and the waveguide dispersion of the two newborn photons in the fiber under test is 0, stable excitation will be achieved and stable visible light will be generated. For G.652.D fiber, its zero dispersion frequency shift is 6650cm -1 , corresponding to the nascent visible light wavelength of 621 nm.

[0029] The specific four-wave mixing process is: 1064nm+1064nm=621nm+3700nm.

[0030] The 621nm light is orange light.

[0031] Therefore, if the system designed in the present invention detects that the optical fiber emits orange...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap