Inductive angle sensor

An angle sensor and inductive technology, applied in the field of non-directional devices, can solve the problems of being susceptible to external magnetic field interference, uncertainty of angular displacement, unclear relationship between the phase and amplitude of induced current, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In the following description, equal or equivalent elements or elements having equal or equivalent functions are denoted by equal or equivalent reference numerals.

[0021] Method steps described by and with reference to block diagrams may also be performed in a different order than depicted and / or described. Furthermore, method steps relating to specific features of a device may be replaced by said features of said device, and vice versa.

[0022] As an introduction to the principles presented in this paper, a brief definition of the term "k-fold symmetry" should be given: If a shape can be rotated 360° × x / k (x is any integer) about an axis to make it appear the same, then the The shape may have k-fold symmetry.

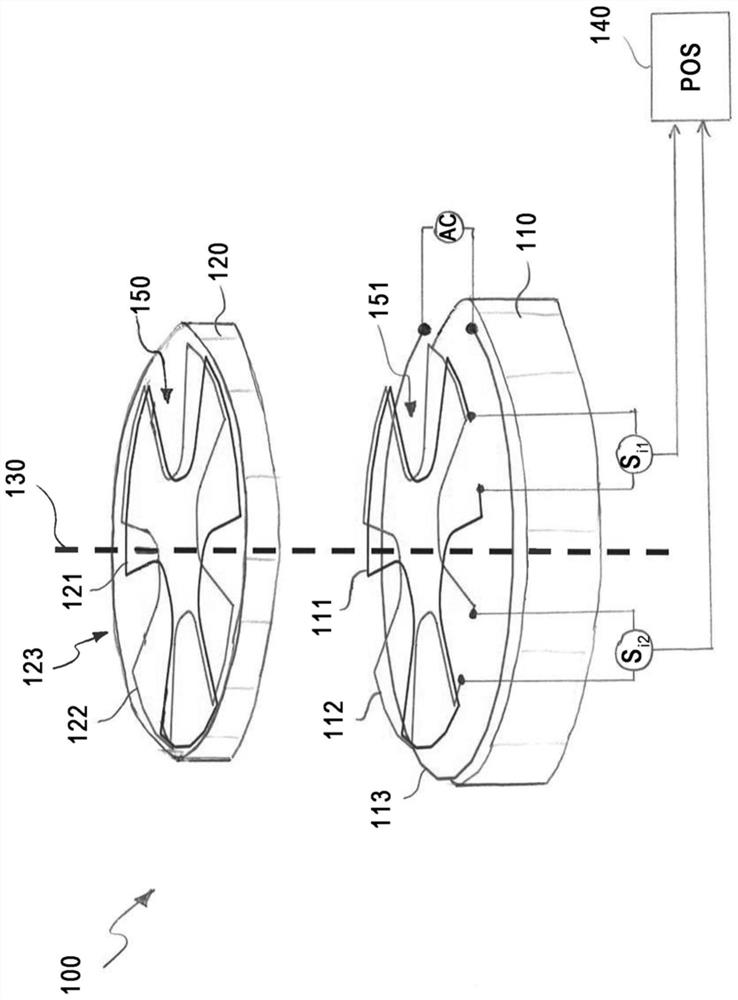

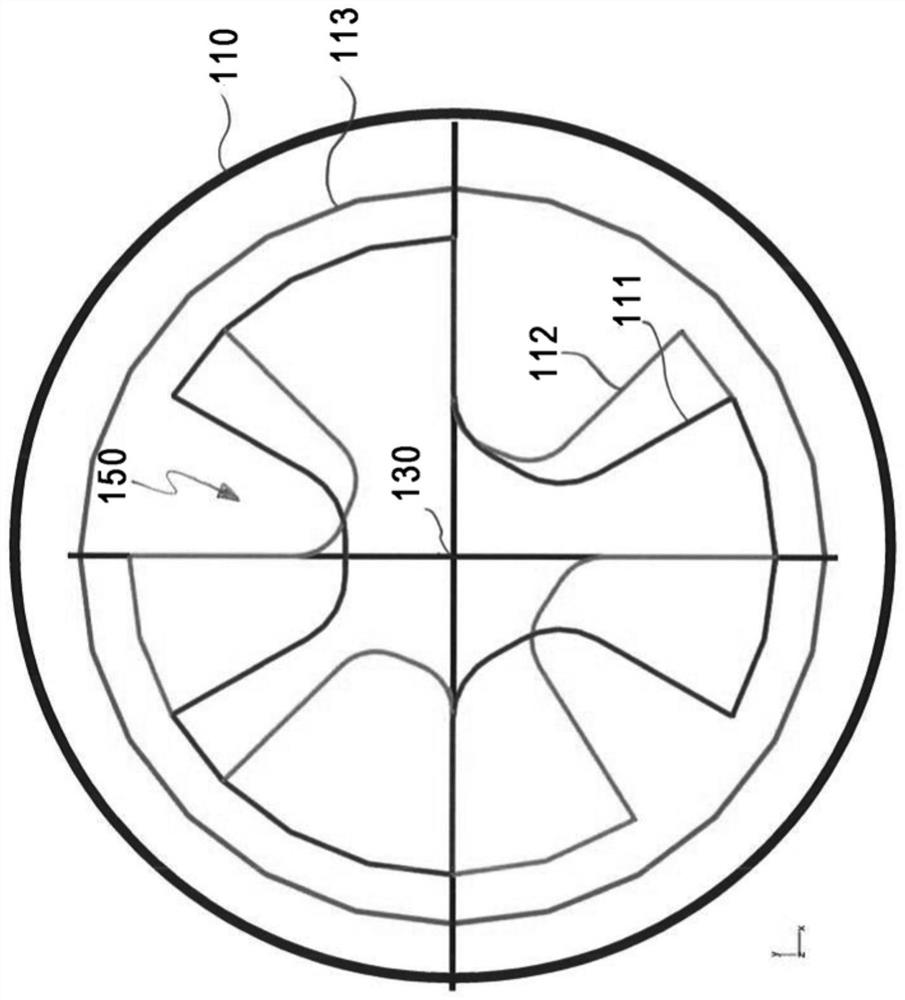

[0023] figure 1 An exemplary embodiment of an inductive angle sensor 100 according to the first aspect is shown. The inductive angle sensor 100 may include a stator 110 and a rotor 120 , and the stator 110 and the rotor 120 may rotate relative to each othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com