Apparatus and method for measuring cracks in wall surface

A technology of crack and angle measurement, applied in measuring instruments, measuring devices, surveying and navigation, etc., can solve problems that require a lot of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]A preferred embodiment of the present invention will be described with reference to the accompanying drawings.

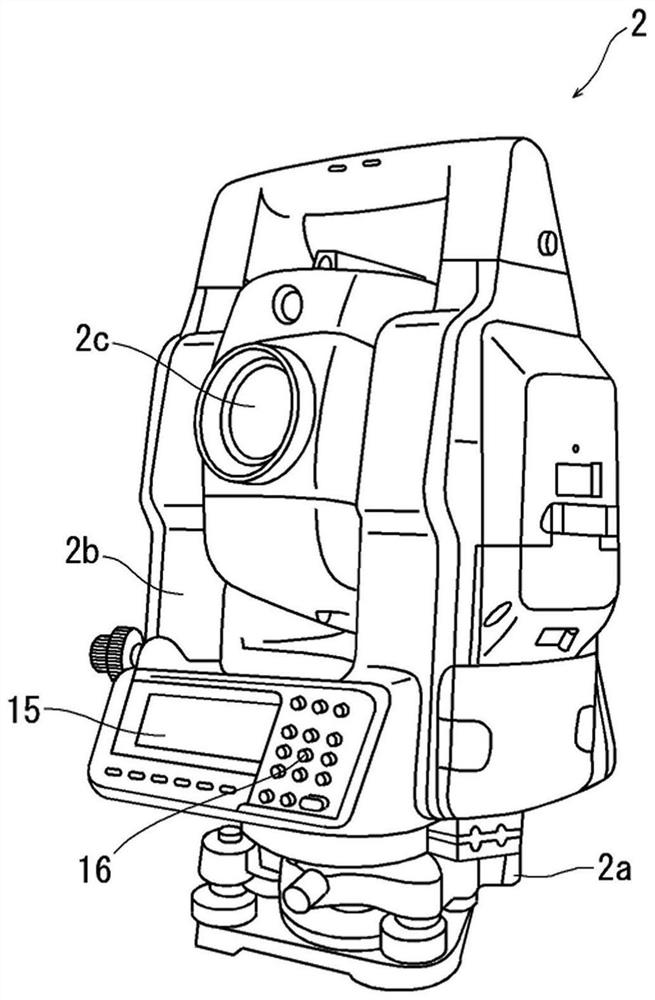

[0026]figure 1 It is an appearance perspective view of the measuring machine of the embodiment. Crack meter 2 (hereinafter referred to as meter 2) is a full station. The measuring machine 2 has a base portion 2a disposed over the calibrator, a tray portion 2b that is horizontally rotated on the base disk portion 2a, and a telescope 2c of the center lead rotation of the carrier portion 2b, and is provided in the bracket The front display unit 15 and the operation portion 16 of the portion 2b are.

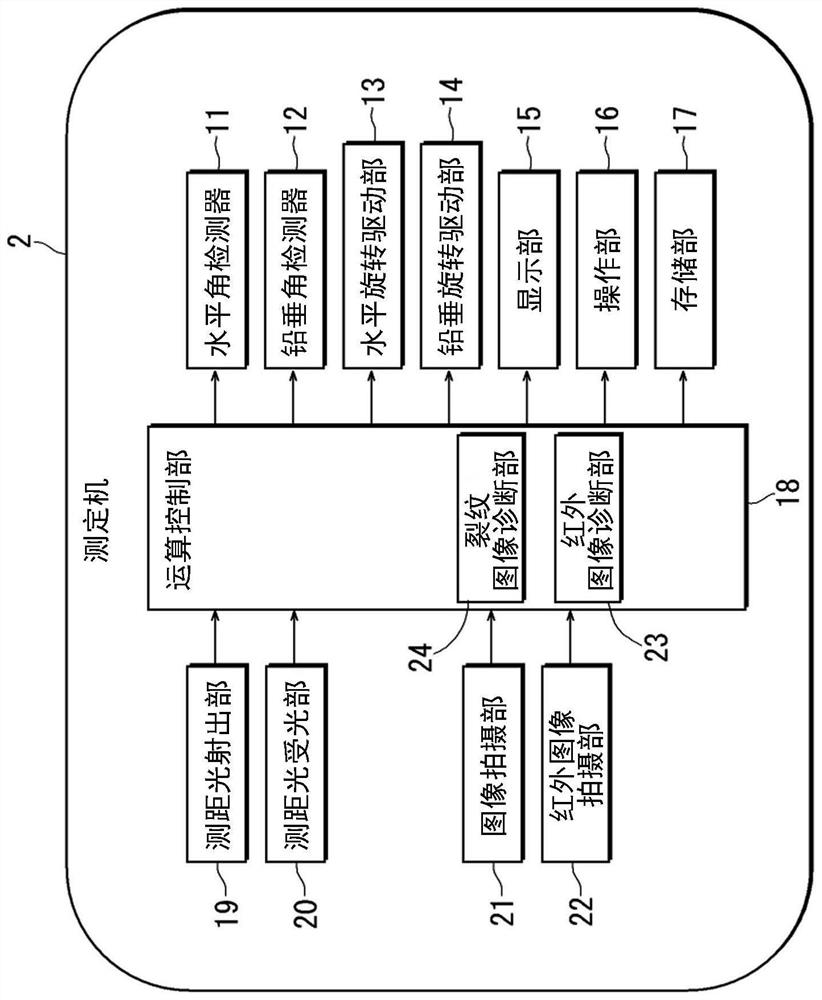

[0027]figure 2 It is a block diagram of the measuring machine 2. The measuring machine 2 includes a horizontal angle detector 11, a lead profit angle detector 12, a horizontal rotary drive unit 13, a lead rotation drive portion 14, a display portion 15, an operation unit 16, a storage unit 17, an arithmetic control unit 18, a ranging The light shift portion 19, the ranging light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com