Lifting and leveling mechanism of piggyback roller way self-balancing AGV

A leveling mechanism and self-balancing technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of easy jamming and inconsistent height direction of trays, and achieve the effect of meeting the needs of docking and conveying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

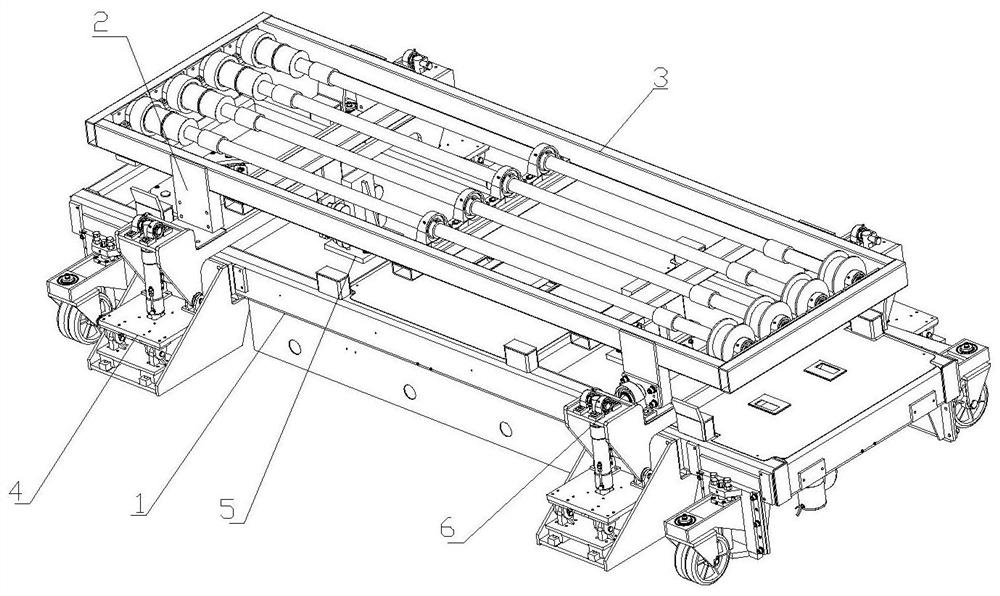

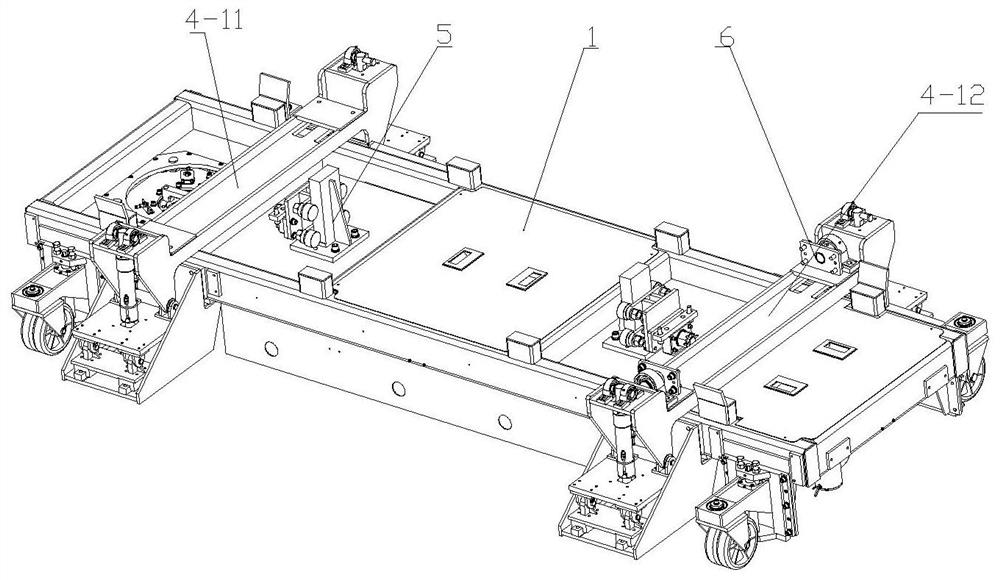

[0039] like figure 1 As shown, the AGV car body 1, the AGV roller table 3 placed above the AGV car body 1, the AGV car body 1 below the AGV roller table 3 is provided with a device for adjusting the AGV roller table 3 to be parallel to the horizontal plane under different road conditions. The lifting and leveling mechanism 4 and the centering assembly 5 that limits the centerline of the lifting and leveling mechanism 4 .

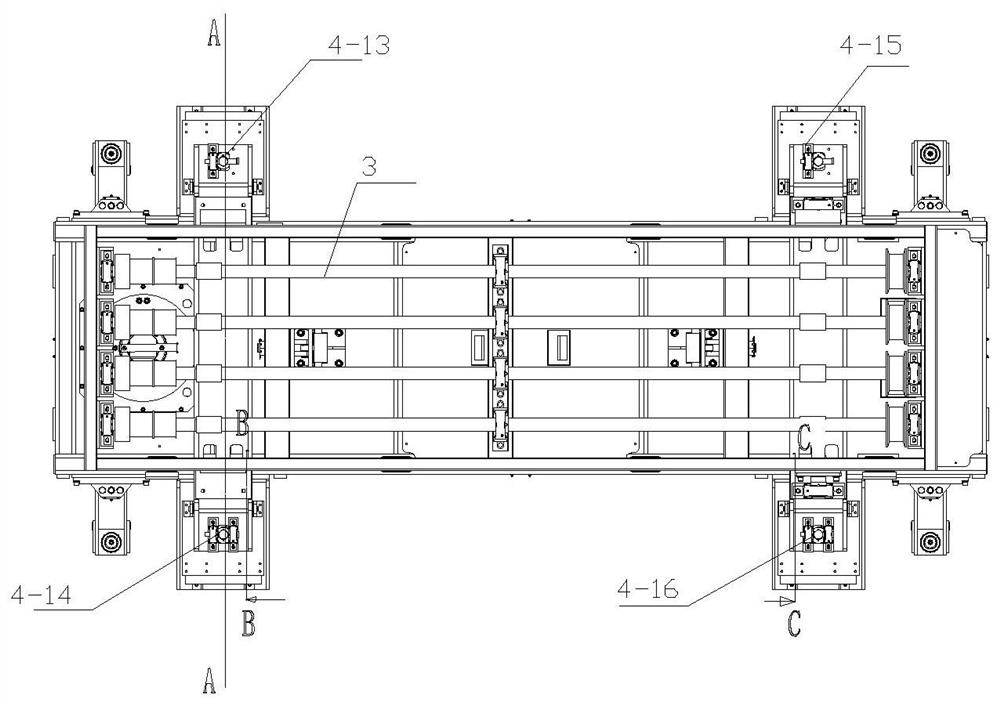

[0040] like figure 2 , image 3 As shown, the lifting and leveling mechanism 4 of the present invention includes a first lifting and leveling support 4-13 positioned at the front end of the AGV body 1, a second lifting and leveling support 4-14, and a 1. The third lifting and leveling support 4-15 and the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com