Shock absorber piston valve seat

A piston valve and shock absorber technology, which is applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems of easy deformation of the valve plate, fatigue, affecting the use effect and service life of the shock absorber, etc. To achieve the effect of ensuring normal use, improving life and reducing failure risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following embodiments are combined with the accompanying drawings to elaborate on the present invention.

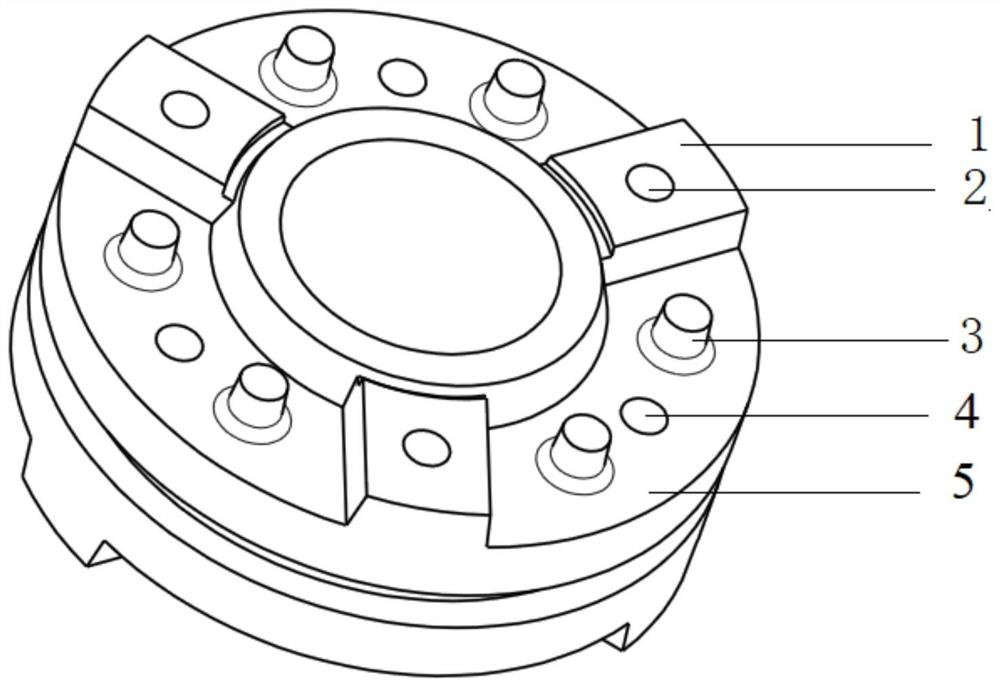

[0019] figure 1 For the structure schematic diagram of the present invention, refer to figure 1 As shown, a shock absorber piston valve seat, the shock absorber piston valve seat is provided with the same number of multiple bosses and a plurality of fan-shaped low platforms between the bosses, the height of the boss table is Consistent with the height of the end face of the valve seat, the forward normal through hole runs through one end face (that is, figure 1 The boss of the lower end face of the valve seat shown) and the other end face (that is, figure 1 The shown fan-shaped low platform on the upper end surface of the valve seat), the reverse normal through hole penetrates through the fan-shaped low platform on one end surface a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com