Shock absorber piston

A shock absorber and piston technology, which is applied in the field of shock absorber pistons, can solve the problems of affecting the use effect of shock absorbers, increasing the damping force of shock absorbers, and reducing the performance of shock absorbers, etc. The effect of bending deformation and damping force value stabilization

Inactive Publication Date: 2012-10-17

LIUZHOU CARRERA SHOCK ABSORBER CO LTD

View PDF4 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Since the height of the fan-shaped low platform is lower than the end surface of the boss, the space of the fan-shaped low platform does not support the valve plate. After repeated use, the valve plate will be fatigued or deformed quickly, and the deformation of the valve plate may block the outlet of the normal through hole. If the damping force of the shock absorber is increased, the performance of the shock absorber will be reduced, which will affect the use effect of the shock absorber and fail to meet the design requirements.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

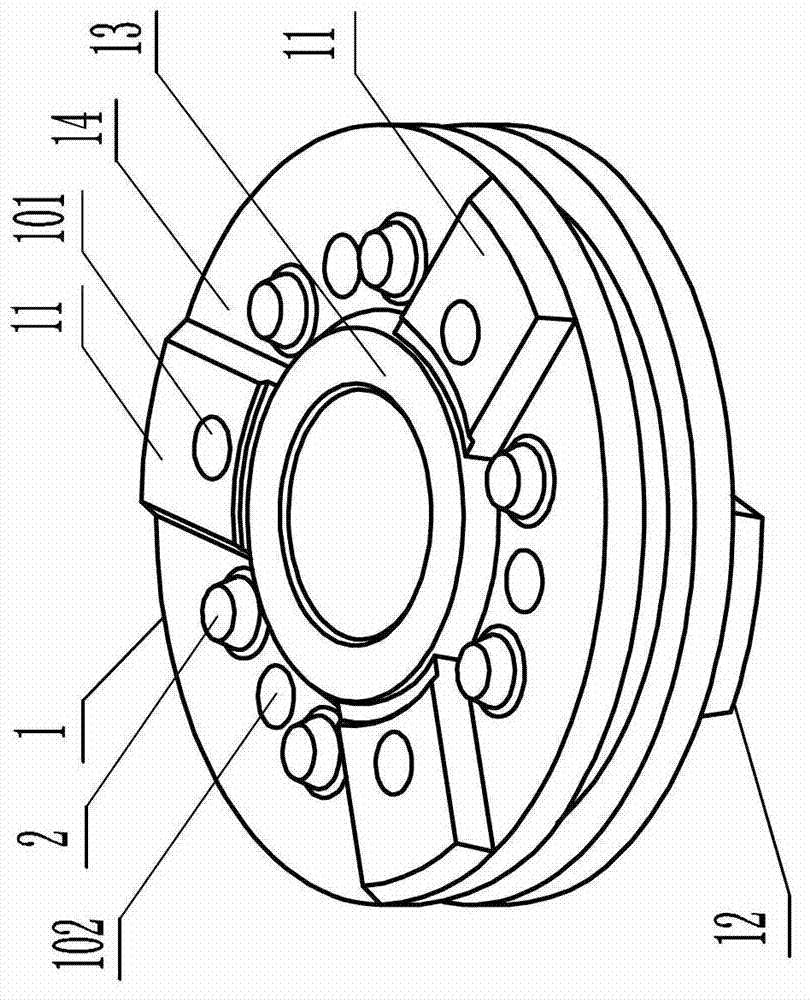

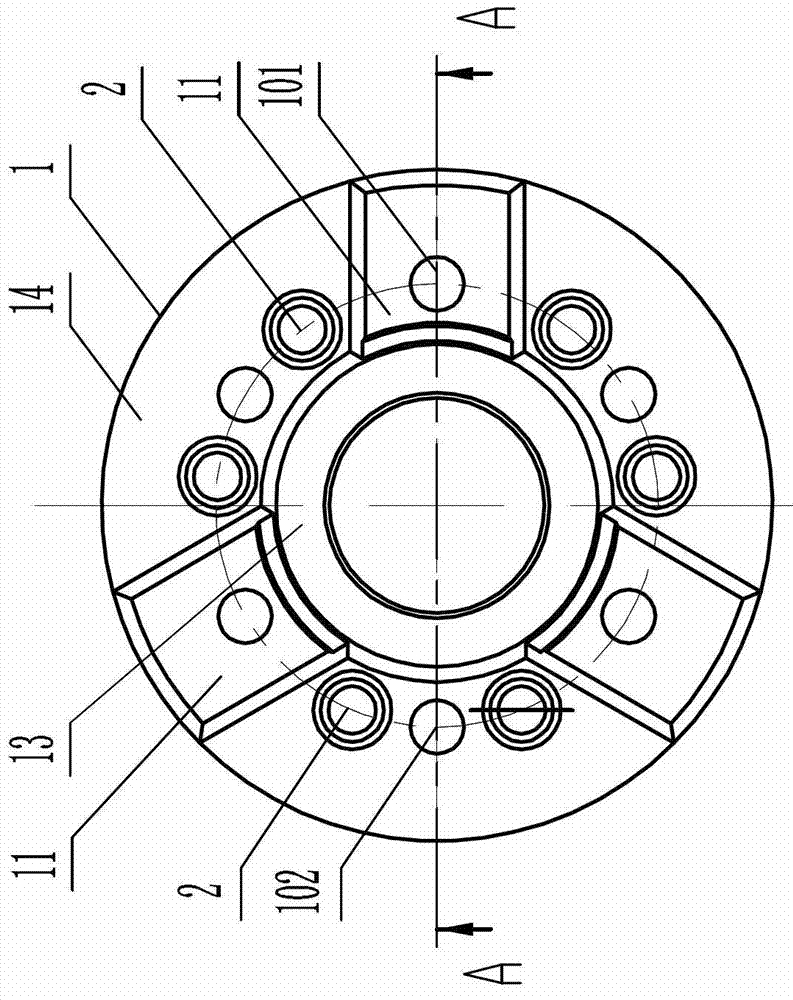

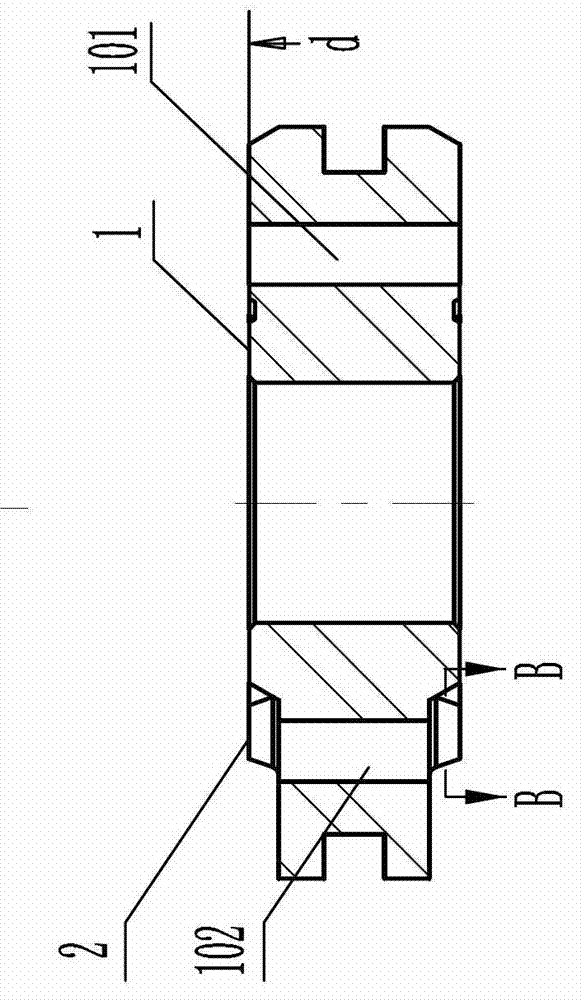

The invention discloses a shock absorber piston. N salient points are distributed on each sector low station of two end surfaces of the piston, the height of the salient points is consistent with the height of the end surface of a salient station of the piston, and n is an arbitrary integer ranging from 1 to 30. If the salient point is a cylinder or a circular frustum body, the cross section of the salient point is circular; and if the salient point is a square cylinder or a square frustum body, then the cross section of the salient point is square. According to the shock absorber piston disclosed by the invention, the original structure functions of the piston are not affected, but the service life of valve plates is prolonged, the force value performance of a shock absorber is improved, and the shock absorber piston has a simple structure and is economic and practical; and in the working process of the shock absorber, when the valve plates arranged on the two end surfaces of the piston are pressed, the salient points of the two end surfaces and the salient station can simultaneously support the valve plates, so that bending deformation of the valve plates is reduced, and the valve plates are difficult to generate fatigue, so that the service lives of the valve plates are prolonged, the normal use of the shock absorber is guaranteed, a constant through hole of the piston can be prevented from being blocked by fatigue deformation of the valve plates, and a damping force value of the shock absorber is more stable.

Description

technical field [0001] The invention relates to a component of a cylinder type shock absorber, in particular to a shock absorber piston with convex points. Background technique The piston used in the cylinder type shock absorber is generally equipped with a normal through hole for the forward and reverse flow of the compressed oil. The through hole is covered, and the reverse normal through hole is unblocked. When the piston moves up in the cylinder, the valve plate close to the upper surface of the piston will cover the reverse normal through hole, and the forward normal through hole is unblocked, thus regulating The effect of damping force. In order to achieve the above purpose, the two end faces of the currently used piston are provided with bosses with the same height as the end faces, and a fan-shaped low platform with a height lower than the end face of the bosses is formed between the bosses. , from the fan-shaped low platform at the other end. When the shock ab...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16F9/32F16J1/00

Inventor 廖嵘马晨赵俊发

Owner LIUZHOU CARRERA SHOCK ABSORBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com