Single-circulation-structure oil damper piston assembly for rail car

A technology for hydraulic shock absorbers and rail vehicles, which is applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., and can solve the problems of easy leakage of the valve plate, so that it is not easy to leak, low in processing accuracy requirements, The effect of damping force value stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

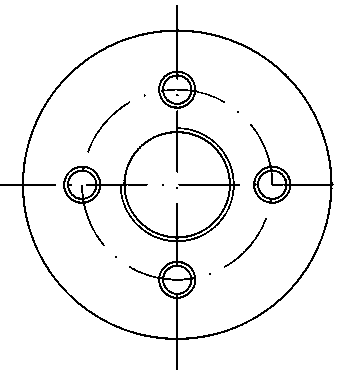

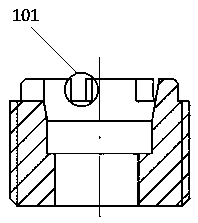

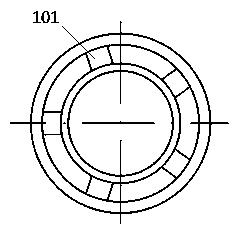

[0020] Embodiment 1: as Figure 1-5 As shown, a piston assembly of a single-circulation structure hydraulic shock absorber for rail vehicles in the present invention mainly includes: a piston body and four sets of valve trains distributed symmetrically along the center of the piston body, wherein the valve trains are arranged on In the through hole opened on the piston body, the valve system includes: an adjusting screw, a spring and a core valve. The two ends of the spring are respectively connected with the adjustment screw and the core valve, the middle part of the core valve is provided with an oil passage, and the side wall of the core valve is provided with a discharge valve connected with the oil passage. Loading hole, when the piston is in a stretched state, the unloading hole is closed by the inner wall of the through hole, and the oil passage is also in a closed state at this time, when the piston is in a compressed state, the unloading hole and the The inner wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com