Novel mechanical automatic lock body structure

An automatic lock and mechanical technology, applied in building locks, building structures, buildings, etc., can solve the problems of large capital occupation and incompatibility, achieve the effect of convenient production and stocking, and reduce the backlog of funds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

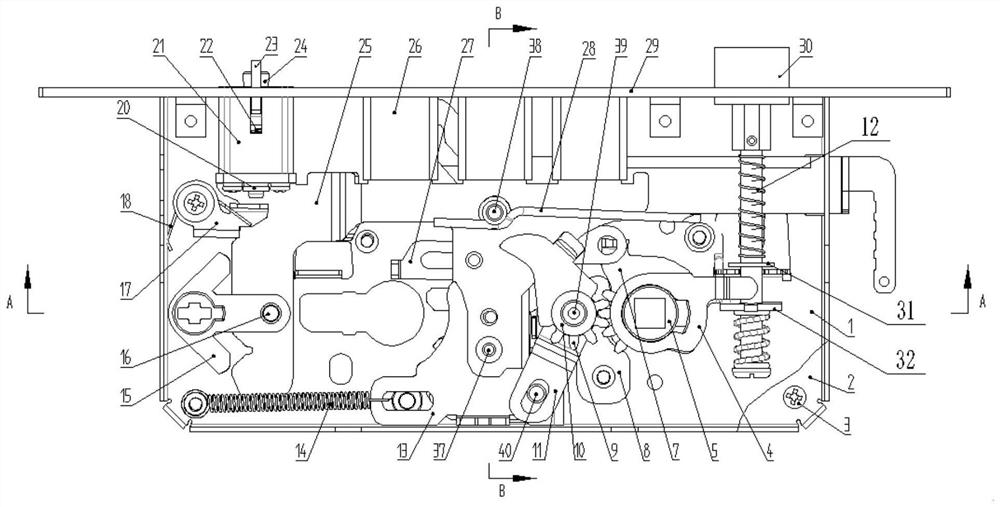

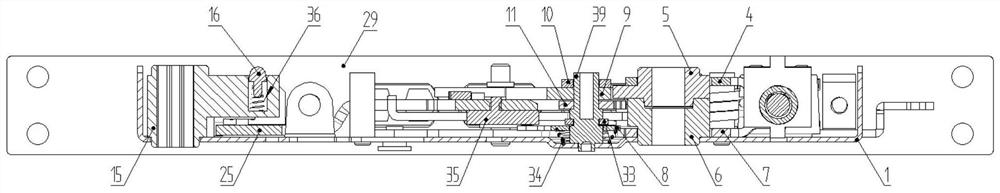

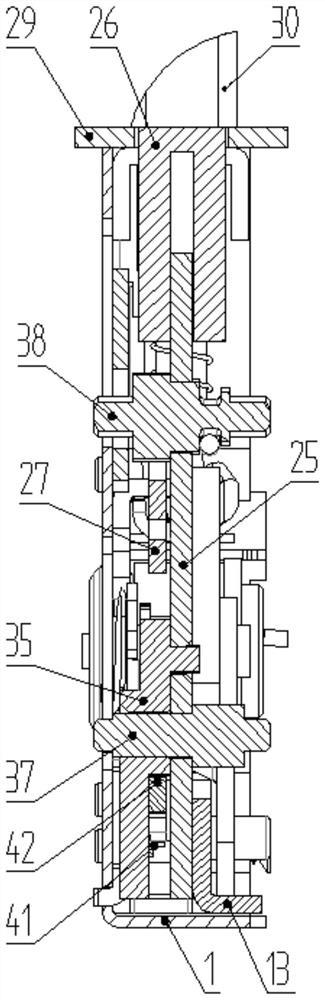

[0034] Such as Figure 1-16 As shown, a novel mechanical automatic lock body structure includes a lock body shell composed of a lower cover plate 1, an upper cover plate 2, an upper cover plate screw 3 and a lock body panel 29, and a main lock is installed in the lock body shell The tongue 26 assembly and the oblique bolt 30 assembly, the main bolt 26 assembly includes the bolt fixing plate 25 and the main bolt 26 anchored on the bolt fixing plate 25 and can be ejected along the lock body panel 29, the bolt fixing plate 25 Such as Figure 5 As shown; the main bolt 26 assembly also includes a deadbolt fixing plate 25 rivets and a main tongue thrust torsion spring 28, and the dead bolt fixing plate 25 rivets are riveted on the dead bolt fixing plate 25, and the main tongue thrust torsion spring 28 is fixed On a stud on the lower cover 1. The deadbolt fixing plate 25 is riveted on the deadbolt fixing plate 25 with a rivet. An annular groove is arranged on the rivet. One arm foo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com