A kind of earphone cover fabric making process

A production process and technology of earphone cover, which is applied in printing process, earpiece/earphone accessories, typewriter, etc., can solve the problems of changing printing effect and single appearance of earphone cover fabric, so as to achieve the stability of printing effect and reduce the overall The effect of high weight and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

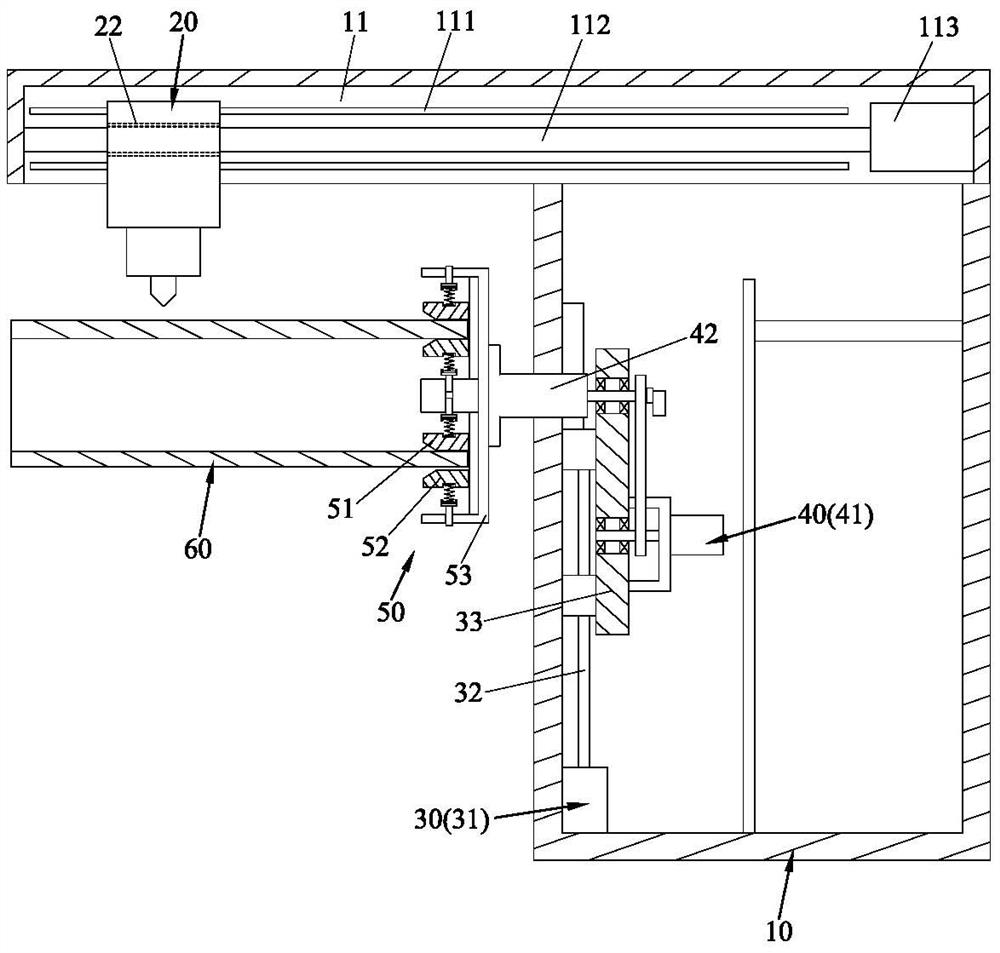

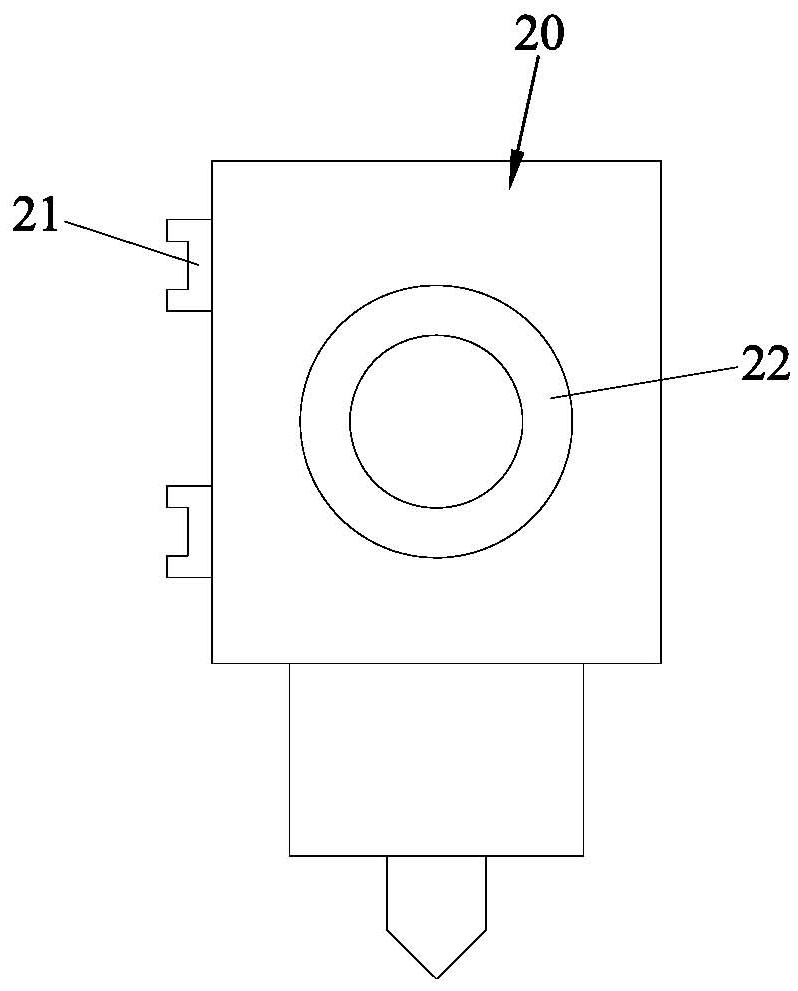

[0060] Please refer to Figure 1 to Figure 5 As shown, it shows the specific structure of the preferred embodiment of the present invention, which is a manufacturing process of earphone cover fabric.

[0061] The fabric making process of the earphone cover includes the following steps:

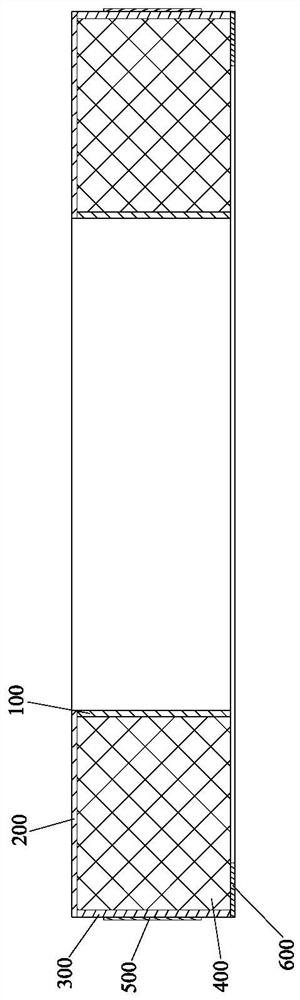

[0062] Step 1, cutting to obtain an annular piece of cloth, a first strip of cloth, and a second strip of cloth; the first strip of cloth is longer than the second strip of cloth;

[0063] Step 2: Sewing the head and tail ends of the first long strip of cloth into a ring shape, and then sew an annular end of the first long strip of cloth on the outer edge of the circular cloth; The head and tail ends of the sheet are sewn together into a ring shape, and then a ring end of the second long strip-shaped cloth sheet is sewn on the inner ring edge of the ring cloth sheet; in this way, a cloth cover with a U-shaped cross-section is obtained;

[0064] Step 3, covering the cloth cover on the outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com