A kind of spreading type iron-carbon composite filler powder for concrete and preparation method thereof

A technology of composite filler and concrete, which is applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of large manpower, material and financial resources, complex and harsh preparation process, and cost of filler laying, etc., and achieve the best results Strong, high processing efficiency, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

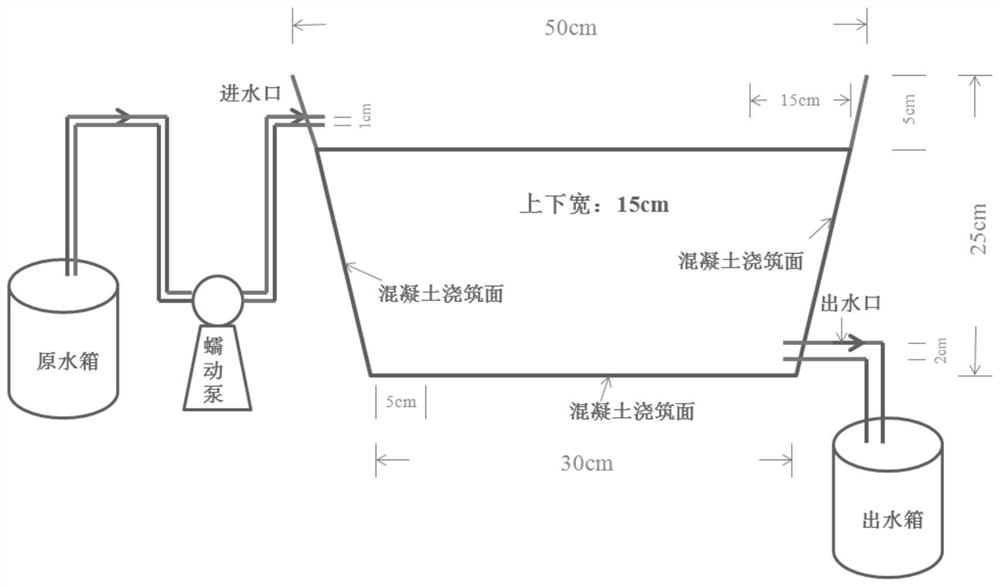

Image

Examples

Embodiment 1

[0022] A spread-type iron-carbon composite filler powder for concrete is composed of the following raw materials by weight: 30 parts of iron carbon, 30 parts of zeolite, 20 parts of ceramsite, 10 parts of anthracite, and 10 parts of volcanic rock. Put each component into the crusher for crushing, then enter the pulverizer, pass through a 1mm sieve, and finally add each component into the compounding tank, stir evenly to obtain the filler powder. After the concrete has just been poured into the mold, the prepared iron-carbon composite filler powder is evenly sprinkled on the water-facing surface of the concrete with a thickness of 5mm, and the powder can be firmly bonded to the concrete surface after waiting for the concrete to harden.

Embodiment 2

[0024] A sprinkling type iron-carbon composite filler powder for concrete is composed of the following raw materials by weight: 30 parts of iron carbon, 40 parts of zeolite, 10 parts of ceramsite, 10 parts of anthracite, and 10 parts of volcanic rock. Put each component into the crusher for crushing, then enter the pulverizer, pass through a 1mm sieve, and finally add each component into the compounding tank, stir evenly to obtain the filler powder. After the concrete has just been poured into the mold, the prepared iron-carbon composite filler powder is evenly sprinkled on the water-facing surface of the concrete with a thickness of 5mm, and the powder can be firmly bonded to the concrete surface after waiting for the concrete to harden.

Embodiment 3

[0026] A spread-type iron-carbon composite filler powder for concrete is composed of the following raw materials by weight: 32 parts of iron carbon, 30 parts of zeolite, 12 parts of ceramsite, 10 parts of anthracite, and 16 parts of volcanic rock. Put each component into the crusher for crushing, then enter the pulverizer, pass through a 1mm sieve, and finally add each component into the compounding tank, stir evenly to obtain the filler powder. After the concrete has just been poured into the mold, the prepared iron-carbon composite filler powder is evenly sprinkled on the water-facing surface of the concrete with a thickness of 5mm, and the powder can be firmly bonded to the concrete surface after waiting for the concrete to harden.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com