Clay plate forming rolling method mold assembly in ceramic art

A kind of clay plate and mold technology, which is applied in the direction of ceramic molding machine, mold auxiliary parts, molds, etc., can solve the problems of obvious traces, etc., and achieve the effect of simple operation, guarantee of surface flatness, and improvement of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

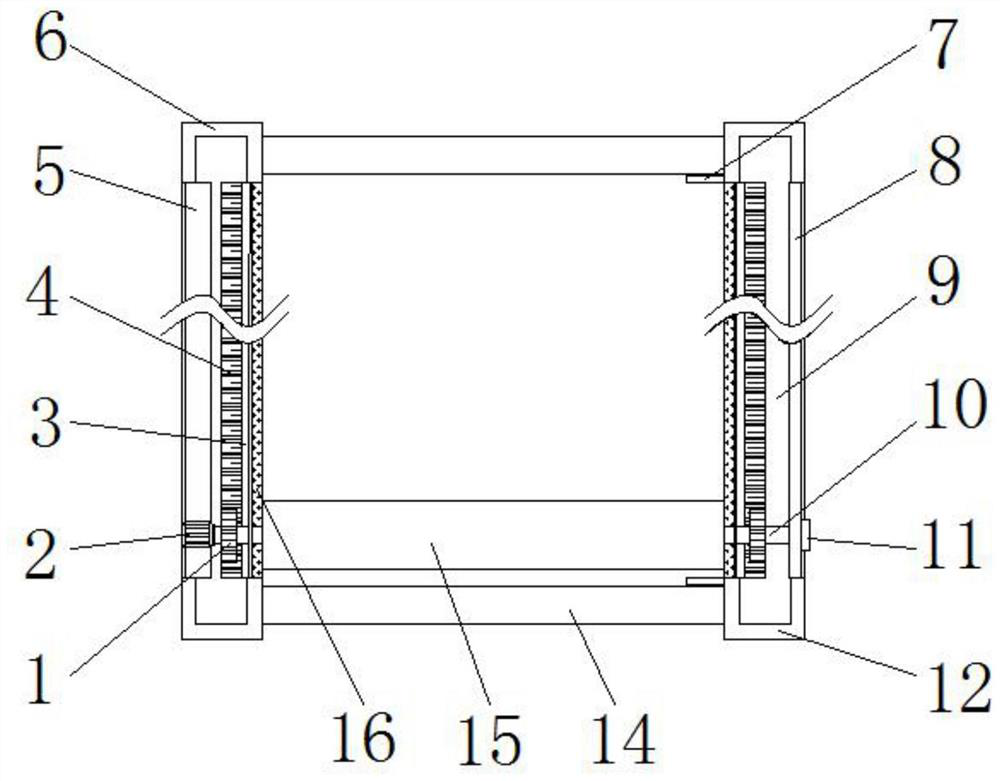

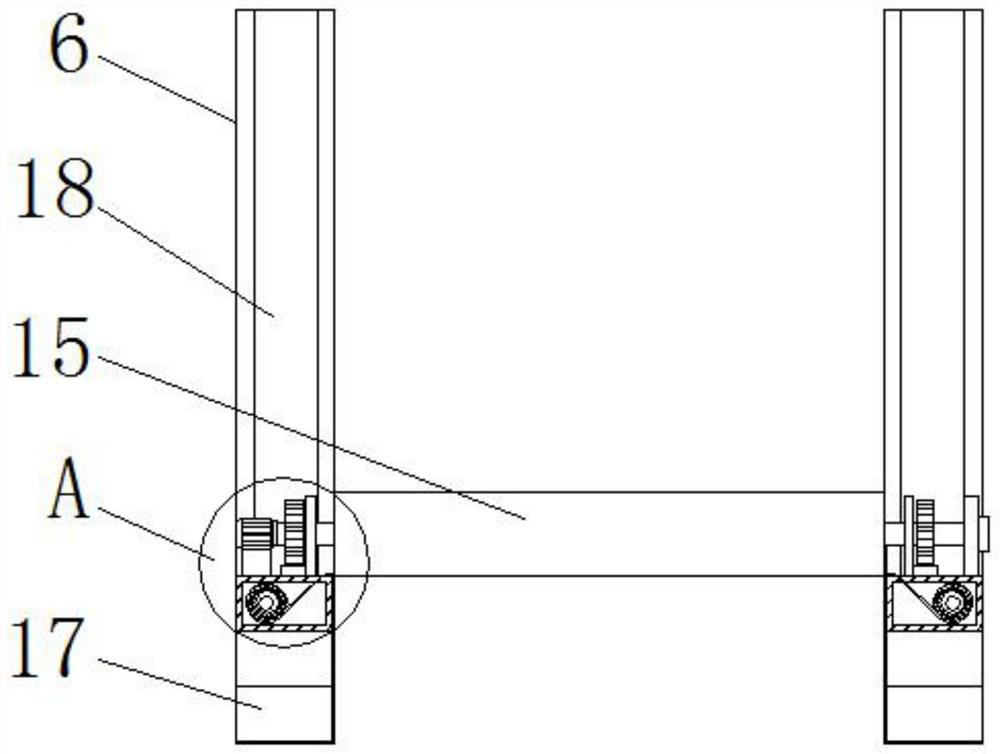

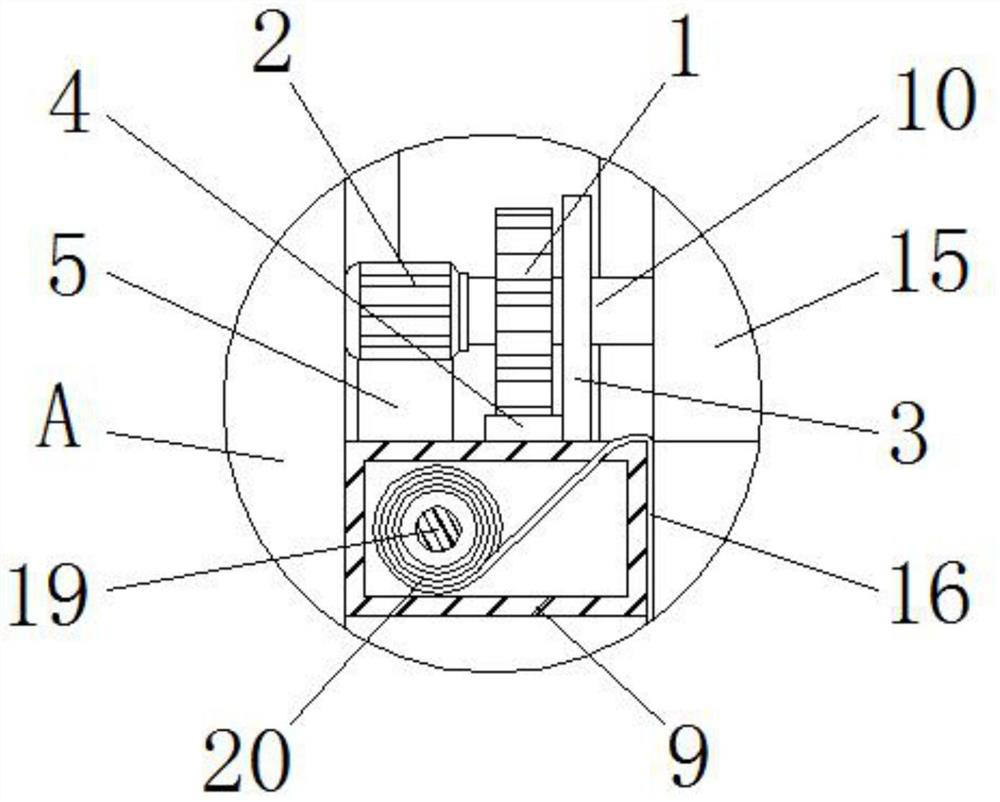

[0031] Such as figure 1 The shown mold assembly of clay plate forming rolling method in pottery art includes two sets of limit frames respectively located on both sides, and each set of limit frames includes a front stand 12 and a rear stand 6 oppositely arranged, and the front stand The end faces of the frame 12 and the rear stand 6 are all U-shaped, and a bottom plate 17 is fixedly connected between the front stand 12 and the corresponding rear stand 6; All are fixedly connected with fixed connecting plate 14 between back stand 6, as figure 1 , figure 2 and image 3 As shown, the top of each bottom plate 17 is overlapped with a top plate 9, and the top plate 9 is hollow inside and is provided with a central shaft 19 parallel to its length direction, as image 3 and Figure 4 As shown, the central rotating shaft 19 is wound with a covering cloth roll 20, and the beginning of the covering cloth roll 20 extends from the top surface of the top plate 9 to the outside and is ...

Embodiment 2

[0037] The difference between this embodiment and embodiment 1 is:

[0038] In this example, if Image 6 As shown, the upper and lower end surfaces of the thickened plate 21 are open, and the lower end surface of the thickened plate 21 is formed with a protruding edge 25 that is retracted and extends downward. The edge 25 is matched with the socket 26 , the upper end of the bottom plate 17 is provided with the socket 26 , and the lower end of the top plate 9 is formed with a protruding edge 25 . The bottom board 17, the thickened board 21, and the top board 9 are connected between every adjacent two boards through the plug-in fitting of the protruding edge 25 and the socket 26, which can prevent relative movement in the horizontal plane, thereby having It is beneficial to ensure the stability of the bar plate that is formed by the bottom plate 17, the thickened plate 21 and the top plate 9 to limit the mud plate, thereby ensuring the position-limiting effect on the mud plate....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com