Novel mixing kettle

A mixing kettle, a new type of technology, applied in mixers, shaking/oscillating/vibrating mixers, dissolving and other directions, can solve the problems of general mixing efficiency and difficulty in adapting to high-speed production needs, achieve no mixing dead ends, improve mixing efficiency, and structure. unique effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

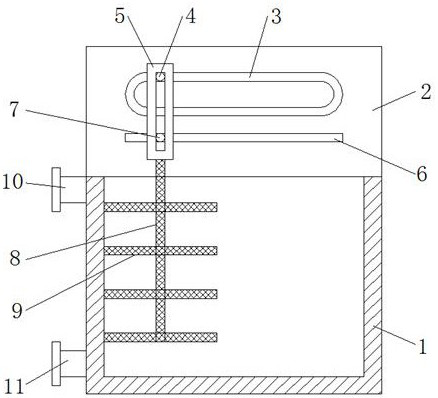

[0017] As shown in the figure, a new type of mixing kettle includes a mixing kettle body 1. The mixing kettle body 1 is a hollow cuboid structure with an open upper end. The front and rear sides of the top of the mixing kettle body 1 are symmetrically provided with a vertical support plate 2. The support plate 2 It is a rectangular plate structure, and the opposite sides of the two support plates 2 are symmetrically provided with a rotary slide rail 3, and the rotary slide rail 3 includes two first slide rails arranged up and down, and the first slide rail is a strip slide rail arranged horizontally. The left and right sides of the first slide rail are symmetrically pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com