Lampshade, processing method thereof and ceiling lamp

A technology for lampshades and face shields, applied in lampshades, lighting and heating equipment, fixed lighting devices, etc., can solve the problems of metal frame errors, disadvantages, and affecting product appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

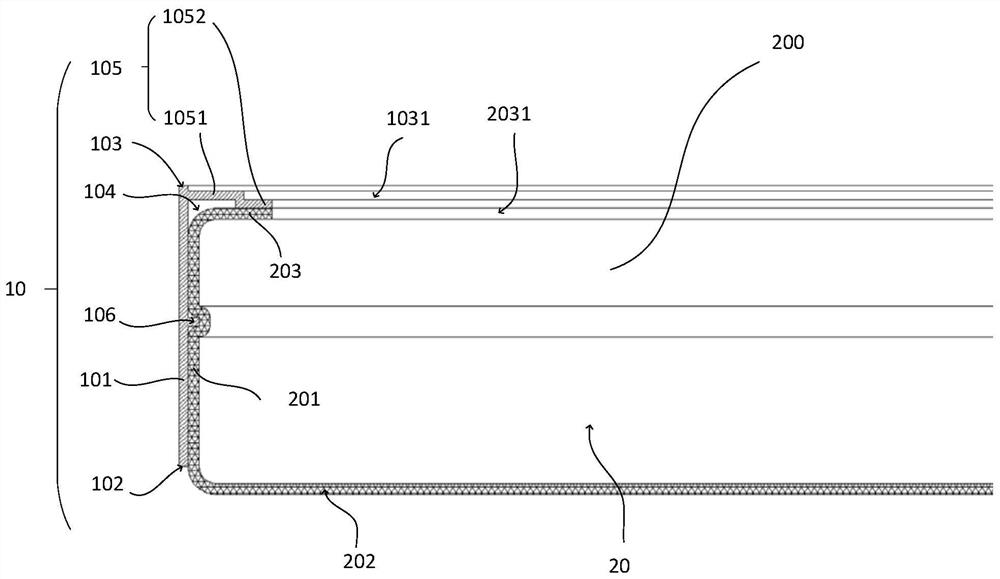

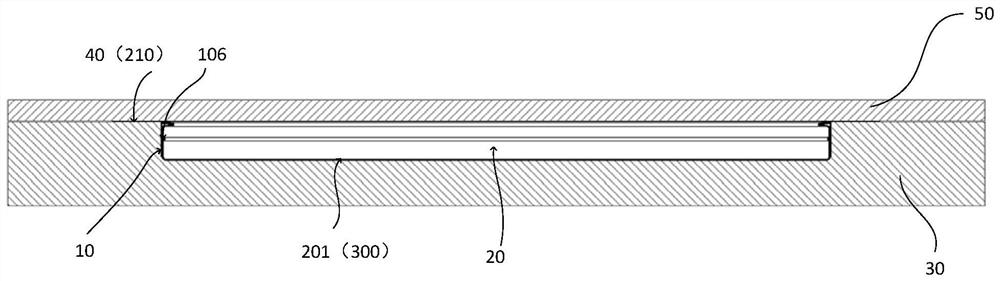

[0042] In the present invention, throughout the specification, when terms such as 'first' and 'second' may be used to describe various components, these components are not necessarily limited to the above terms. The above terms are only used to distinguish one component from another. Unless otherwise clearly specified and limited, terms such as "installation", "connected", "connected" and "fixed" should be understood in a broad sense. In the present invention, unless otherwise clearly specified and limited, the first feature is "On" or "under" a second feature may include that the first and second features are in direct contact, and may also include that the first and second features are not in direct contact but through another feature therebetween. Moreover, "above", "above" and "above" the first feature on the second feature include that the first feature is directly above and obliquely above the second feature, or simply means that the first feature is horizontally higher ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com