Positioning assembly suitable for electromechanical equipment mounting

A technology for positioning components and electromechanical equipment, applied in the direction of adopting mechanical devices, mechanical measuring devices, measuring devices, etc., can solve problems such as out-of-synchronization of adjustment methods, offset of electromechanical equipment, and inability to detect the balance of electromechanical equipment, etc., to achieve the convenience of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

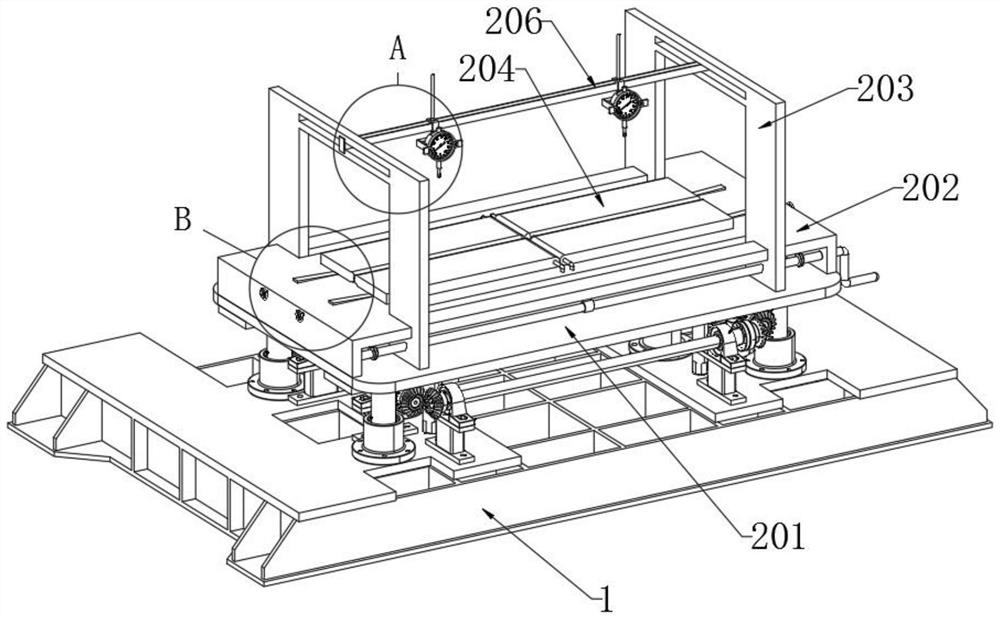

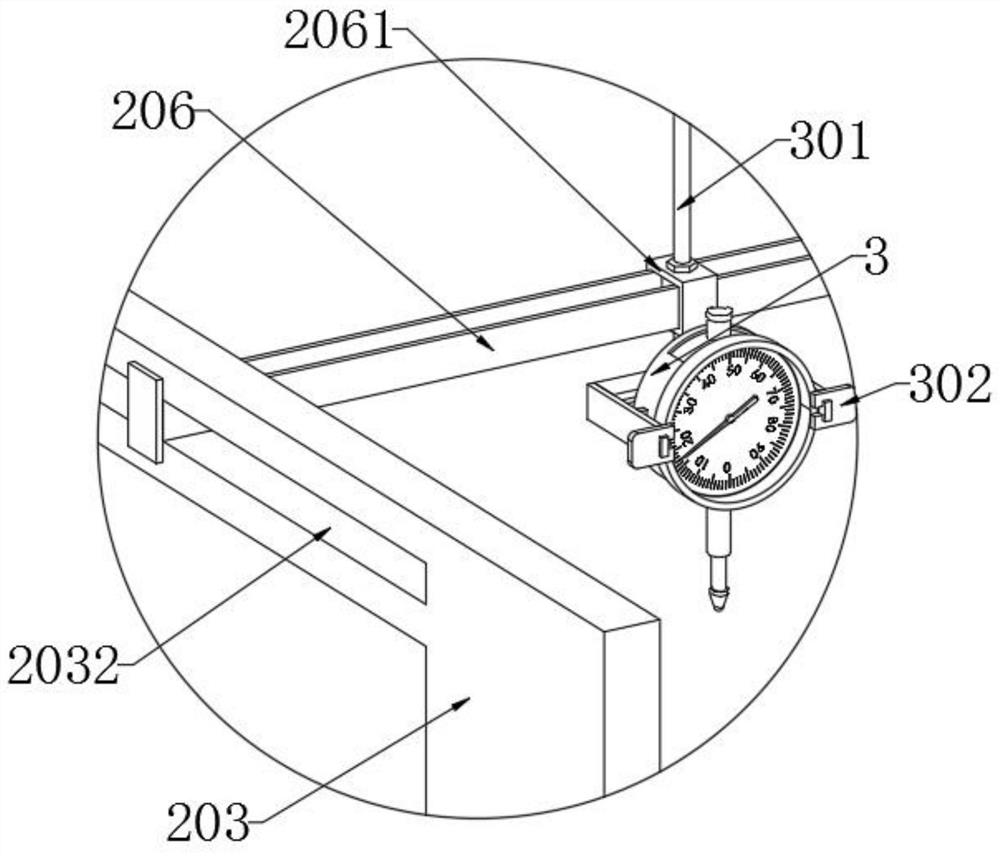

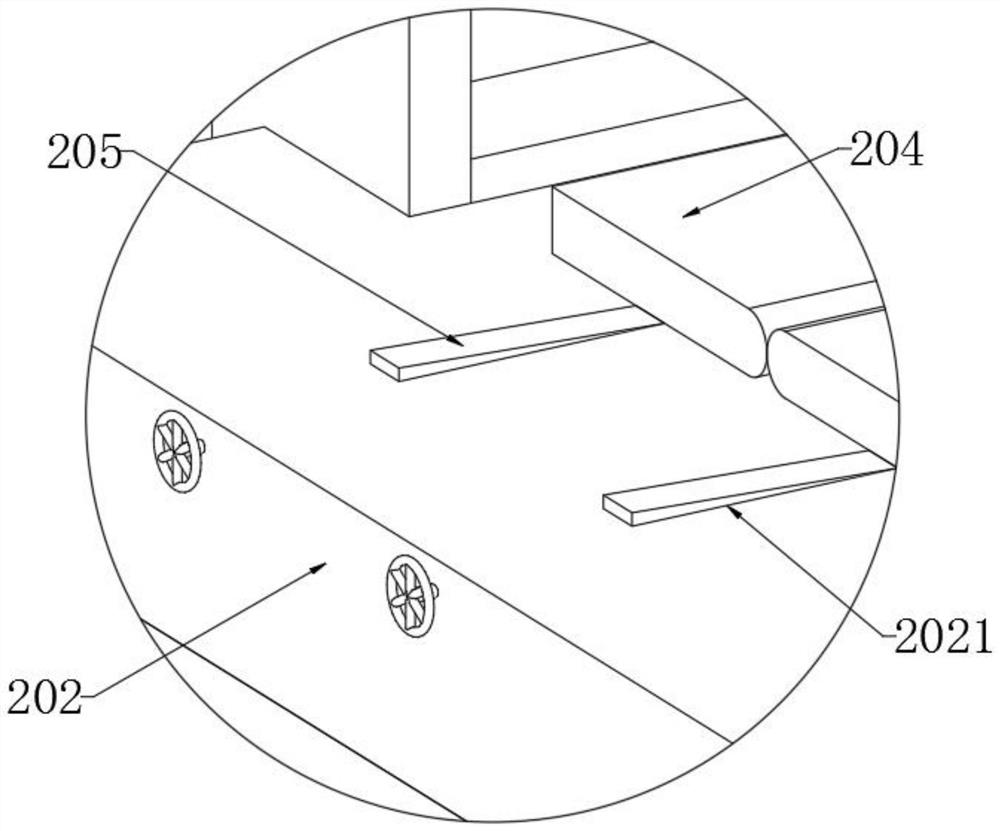

[0034] as attached figure 1 to attach Figure 9 Shown:

[0035] The present invention provides a positioning assembly suitable for installation of electromechanical equipment, including a base 1 and a positioning plate frame 2; two sets of support cylinders 101 and four sets of support rods 102 are installed on the base 1, and the four sets of support rods 102 are respectively slidably inserted into the The shaft sleeve 105 is located at the four corners of the base 1, and the top ends of the support cylinder 101 and the support rod 102 are respectively fixedly connected to the lower connecting plate 201 by screws, and four sets of limit stop rods 106 are fixedly inserted on the base 1. , and the limit bar 106 is set on the inner side of the strut 102 respectively, the positioning plate frame 2 includes a lower connecting plate 201, a U-shaped frame 202, a clamping frame 203 and a positioning strut 204, and the U-shaped frame 202 is connected to the lower On the top side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com